MXene Integration in Water-Splitting Photoelectrochemical Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene in PEC Systems: Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for various applications, including water-splitting photoelectrochemical (PEC) systems. The integration of MXene in PEC systems represents a significant advancement in the field of renewable energy and sustainable hydrogen production.

The development of MXene can be traced back to 2011 when it was first synthesized by researchers at Drexel University. Since then, MXene has garnered substantial attention due to its unique properties, such as high electrical conductivity, large surface area, and excellent mechanical strength. These characteristics make MXene an ideal candidate for enhancing the performance of PEC systems.

Water-splitting PEC systems have been a focus of research for decades, aiming to harness solar energy to produce hydrogen fuel efficiently. The integration of MXene in these systems addresses several key challenges that have hindered the widespread adoption of PEC technology, including low efficiency, poor stability, and high costs.

The primary objective of incorporating MXene into PEC systems is to improve their overall performance and efficiency. Specifically, researchers aim to enhance charge separation and transfer, increase the active surface area for catalytic reactions, and improve the stability of photoelectrodes. By leveraging the unique properties of MXene, scientists seek to overcome the limitations of traditional materials used in PEC systems.

The evolution of MXene integration in PEC systems has seen rapid progress in recent years. Initial studies focused on using MXene as a co-catalyst or protective layer for existing photoelectrode materials. As research advanced, more sophisticated approaches emerged, such as developing MXene-based composite photoelectrodes and utilizing MXene as a charge transport layer.

Current technological trends in this field include the exploration of various MXene compositions and structures to optimize their performance in PEC systems. Researchers are investigating the synergistic effects of combining MXene with other nanomaterials, such as graphene and metal oxides, to create hybrid structures with enhanced properties.

The integration of MXene in PEC systems aligns with broader goals in renewable energy research, including the development of sustainable hydrogen production methods and the reduction of carbon emissions. As global efforts to combat climate change intensify, the potential of MXene to revolutionize PEC technology becomes increasingly significant.

Looking ahead, the field of MXene integration in PEC systems is poised for further advancements. Researchers are working towards scaling up production methods, improving the long-term stability of MXene-based photoelectrodes, and exploring new applications beyond water splitting, such as CO2 reduction and nitrogen fixation.

The development of MXene can be traced back to 2011 when it was first synthesized by researchers at Drexel University. Since then, MXene has garnered substantial attention due to its unique properties, such as high electrical conductivity, large surface area, and excellent mechanical strength. These characteristics make MXene an ideal candidate for enhancing the performance of PEC systems.

Water-splitting PEC systems have been a focus of research for decades, aiming to harness solar energy to produce hydrogen fuel efficiently. The integration of MXene in these systems addresses several key challenges that have hindered the widespread adoption of PEC technology, including low efficiency, poor stability, and high costs.

The primary objective of incorporating MXene into PEC systems is to improve their overall performance and efficiency. Specifically, researchers aim to enhance charge separation and transfer, increase the active surface area for catalytic reactions, and improve the stability of photoelectrodes. By leveraging the unique properties of MXene, scientists seek to overcome the limitations of traditional materials used in PEC systems.

The evolution of MXene integration in PEC systems has seen rapid progress in recent years. Initial studies focused on using MXene as a co-catalyst or protective layer for existing photoelectrode materials. As research advanced, more sophisticated approaches emerged, such as developing MXene-based composite photoelectrodes and utilizing MXene as a charge transport layer.

Current technological trends in this field include the exploration of various MXene compositions and structures to optimize their performance in PEC systems. Researchers are investigating the synergistic effects of combining MXene with other nanomaterials, such as graphene and metal oxides, to create hybrid structures with enhanced properties.

The integration of MXene in PEC systems aligns with broader goals in renewable energy research, including the development of sustainable hydrogen production methods and the reduction of carbon emissions. As global efforts to combat climate change intensify, the potential of MXene to revolutionize PEC technology becomes increasingly significant.

Looking ahead, the field of MXene integration in PEC systems is poised for further advancements. Researchers are working towards scaling up production methods, improving the long-term stability of MXene-based photoelectrodes, and exploring new applications beyond water splitting, such as CO2 reduction and nitrogen fixation.

Market Analysis for MXene-Enhanced Water Splitting

The market for MXene-enhanced water splitting technologies is experiencing significant growth, driven by the increasing global demand for clean and sustainable energy solutions. As the world shifts towards renewable energy sources, hydrogen production through water splitting has emerged as a promising avenue for energy storage and utilization. MXenes, a class of two-dimensional transition metal carbides and nitrides, have shown exceptional potential in enhancing the efficiency and performance of water-splitting photoelectrochemical systems.

The global hydrogen market is projected to reach substantial volumes in the coming years, with water electrolysis playing a crucial role in green hydrogen production. MXene integration in water-splitting systems is positioned to capture a significant portion of this market due to its unique properties and advantages over traditional catalysts. The automotive industry, in particular, is showing keen interest in hydrogen fuel cell technologies, which could drive further demand for efficient water-splitting solutions.

In the industrial sector, MXene-enhanced water splitting technologies are gaining traction for on-site hydrogen production, offering cost-effective and environmentally friendly alternatives to traditional hydrogen sourcing methods. The chemical industry is another key market segment, where hydrogen is essential for various processes, including ammonia production and hydrogenation reactions.

The Asia-Pacific region is expected to lead the market growth for MXene-enhanced water splitting technologies, with China and Japan at the forefront of research and development efforts. Europe follows closely, driven by ambitious renewable energy targets and substantial investments in hydrogen infrastructure. North America is also showing increased interest, particularly in applications related to energy storage and grid stabilization.

Market analysts predict a compound annual growth rate (CAGR) for the MXene-enhanced water splitting market that outpaces the overall hydrogen production market. This growth is attributed to the superior performance characteristics of MXenes, including high electrical conductivity, large surface area, and excellent stability in harsh electrochemical environments.

However, the market faces challenges, including the need for scalable production methods for MXenes and the current high costs associated with their synthesis. Additionally, competition from other emerging materials and technologies in the water-splitting domain could impact market penetration rates for MXene-based solutions.

Despite these challenges, the long-term outlook for MXene-enhanced water splitting remains positive. As research progresses and manufacturing processes improve, the cost-effectiveness of these materials is expected to increase, making them more attractive for commercial applications. The growing emphasis on decarbonization and the transition to a hydrogen-based economy are likely to provide sustained market opportunities for MXene integration in water-splitting photoelectrochemical systems.

The global hydrogen market is projected to reach substantial volumes in the coming years, with water electrolysis playing a crucial role in green hydrogen production. MXene integration in water-splitting systems is positioned to capture a significant portion of this market due to its unique properties and advantages over traditional catalysts. The automotive industry, in particular, is showing keen interest in hydrogen fuel cell technologies, which could drive further demand for efficient water-splitting solutions.

In the industrial sector, MXene-enhanced water splitting technologies are gaining traction for on-site hydrogen production, offering cost-effective and environmentally friendly alternatives to traditional hydrogen sourcing methods. The chemical industry is another key market segment, where hydrogen is essential for various processes, including ammonia production and hydrogenation reactions.

The Asia-Pacific region is expected to lead the market growth for MXene-enhanced water splitting technologies, with China and Japan at the forefront of research and development efforts. Europe follows closely, driven by ambitious renewable energy targets and substantial investments in hydrogen infrastructure. North America is also showing increased interest, particularly in applications related to energy storage and grid stabilization.

Market analysts predict a compound annual growth rate (CAGR) for the MXene-enhanced water splitting market that outpaces the overall hydrogen production market. This growth is attributed to the superior performance characteristics of MXenes, including high electrical conductivity, large surface area, and excellent stability in harsh electrochemical environments.

However, the market faces challenges, including the need for scalable production methods for MXenes and the current high costs associated with their synthesis. Additionally, competition from other emerging materials and technologies in the water-splitting domain could impact market penetration rates for MXene-based solutions.

Despite these challenges, the long-term outlook for MXene-enhanced water splitting remains positive. As research progresses and manufacturing processes improve, the cost-effectiveness of these materials is expected to increase, making them more attractive for commercial applications. The growing emphasis on decarbonization and the transition to a hydrogen-based economy are likely to provide sustained market opportunities for MXene integration in water-splitting photoelectrochemical systems.

MXene Integration Challenges in PEC Systems

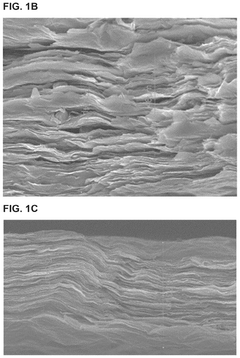

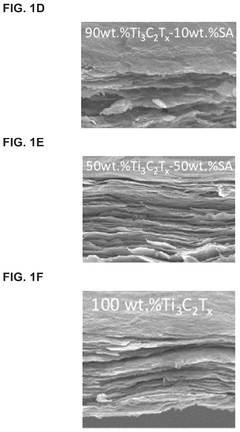

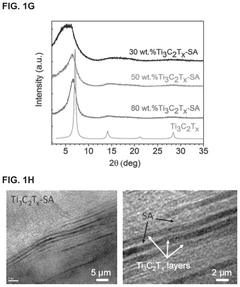

The integration of MXenes into water-splitting photoelectrochemical (PEC) systems presents several significant challenges that researchers and engineers must address. One of the primary obstacles is achieving stable and efficient incorporation of MXene materials into the PEC device architecture. MXenes, being two-dimensional materials, tend to restack and aggregate, which can reduce their active surface area and diminish their performance in PEC systems.

Another critical challenge lies in optimizing the electronic properties of MXenes for PEC applications. While MXenes exhibit excellent conductivity, their band structure and energy levels need to be carefully tuned to align with the requirements of water-splitting reactions. This involves modifying the MXene composition, surface termination, and interlayer spacing to achieve the desired electronic characteristics.

The long-term stability of MXenes in aqueous environments poses a significant hurdle. Many MXenes are prone to oxidation and degradation when exposed to water and light over extended periods. This instability can lead to a decrease in performance and lifetime of the PEC devices, necessitating the development of effective protection strategies or the synthesis of more stable MXene variants.

Interfacial engineering between MXenes and other components of the PEC system is another area of concern. Achieving seamless integration and efficient charge transfer between MXenes and semiconductors, electrocatalysts, or other functional materials is crucial for maximizing the overall system efficiency. This requires careful consideration of surface chemistry and the development of novel fabrication techniques.

Scale-up and manufacturability of MXene-based PEC systems present additional challenges. Current synthesis methods for high-quality MXenes are often limited to small-scale production, making it difficult to produce large-area PEC devices. Developing scalable and cost-effective manufacturing processes for MXene integration is essential for the commercial viability of these systems.

Furthermore, the environmental impact and toxicity of MXenes need to be thoroughly assessed. As relatively new materials, the long-term effects of MXenes on ecosystems and human health are not yet fully understood. Ensuring the safety and sustainability of MXene-based PEC systems is crucial for their widespread adoption and acceptance.

Lastly, the optimization of MXene properties for specific PEC applications remains a complex task. Different water-splitting reactions and device architectures may require MXenes with tailored properties, necessitating a deep understanding of structure-property relationships and the ability to fine-tune MXene characteristics for optimal performance in diverse PEC systems.

Another critical challenge lies in optimizing the electronic properties of MXenes for PEC applications. While MXenes exhibit excellent conductivity, their band structure and energy levels need to be carefully tuned to align with the requirements of water-splitting reactions. This involves modifying the MXene composition, surface termination, and interlayer spacing to achieve the desired electronic characteristics.

The long-term stability of MXenes in aqueous environments poses a significant hurdle. Many MXenes are prone to oxidation and degradation when exposed to water and light over extended periods. This instability can lead to a decrease in performance and lifetime of the PEC devices, necessitating the development of effective protection strategies or the synthesis of more stable MXene variants.

Interfacial engineering between MXenes and other components of the PEC system is another area of concern. Achieving seamless integration and efficient charge transfer between MXenes and semiconductors, electrocatalysts, or other functional materials is crucial for maximizing the overall system efficiency. This requires careful consideration of surface chemistry and the development of novel fabrication techniques.

Scale-up and manufacturability of MXene-based PEC systems present additional challenges. Current synthesis methods for high-quality MXenes are often limited to small-scale production, making it difficult to produce large-area PEC devices. Developing scalable and cost-effective manufacturing processes for MXene integration is essential for the commercial viability of these systems.

Furthermore, the environmental impact and toxicity of MXenes need to be thoroughly assessed. As relatively new materials, the long-term effects of MXenes on ecosystems and human health are not yet fully understood. Ensuring the safety and sustainability of MXene-based PEC systems is crucial for their widespread adoption and acceptance.

Lastly, the optimization of MXene properties for specific PEC applications remains a complex task. Different water-splitting reactions and device architectures may require MXenes with tailored properties, necessitating a deep understanding of structure-property relationships and the ability to fine-tune MXene characteristics for optimal performance in diverse PEC systems.

Current MXene Integration Strategies for PEC

01 MXene-based catalysts for water splitting

MXene materials are being used as catalysts for water splitting reactions. These two-dimensional materials offer high surface area and excellent electrical conductivity, making them promising candidates for enhancing water-splitting efficiency. The unique structure of MXenes allows for efficient charge transfer and improved catalytic activity.- MXene-based catalysts for water splitting: MXene materials are being explored as efficient catalysts for water splitting reactions. Their unique 2D structure and tunable electronic properties make them promising candidates for enhancing the efficiency of hydrogen and oxygen evolution reactions in electrolysis processes.

- Surface modification of MXenes for improved catalytic activity: Researchers are focusing on modifying the surface of MXene materials to enhance their catalytic activity in water splitting. This includes doping with other elements, creating defects, or functionalizing the surface to optimize the adsorption and desorption of reactants and products.

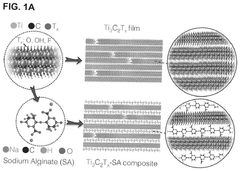

- MXene-based composite materials for water splitting: Composite materials incorporating MXenes with other nanomaterials or catalysts are being developed to synergistically improve water splitting efficiency. These composites aim to combine the advantages of different materials to overcome limitations and enhance overall performance.

- Optimization of MXene structure for water splitting: Studies are focused on optimizing the structure of MXene materials, including controlling the number of layers, interlayer spacing, and pore size distribution. These structural modifications aim to maximize the active surface area and facilitate mass transport during water splitting reactions.

- Integration of MXenes in photoelectrochemical water splitting systems: MXene materials are being investigated for their potential in photoelectrochemical water splitting systems. Their unique optical and electronic properties make them suitable for light harvesting and charge separation, potentially improving the overall efficiency of solar-driven water splitting processes.

02 Doping and functionalization of MXenes

Researchers are exploring various methods to modify MXenes through doping and functionalization. These techniques aim to enhance the catalytic properties of MXenes for water splitting. By introducing specific elements or functional groups, the electronic structure and surface properties of MXenes can be tailored to improve their performance in hydrogen and oxygen evolution reactions.Expand Specific Solutions03 MXene-based composite materials

Composite materials incorporating MXenes are being developed to enhance water-splitting efficiency. These composites often combine MXenes with other nanomaterials or conductive supports to create synergistic effects. The resulting hybrid structures can exhibit improved stability, conductivity, and catalytic activity compared to individual components.Expand Specific Solutions04 Optimization of MXene synthesis and processing

Efforts are being made to optimize the synthesis and processing methods for MXenes to improve their water-splitting performance. This includes developing new exfoliation techniques, controlling the thickness and size of MXene nanosheets, and exploring various post-processing treatments. These optimizations aim to enhance the intrinsic properties of MXenes for more efficient water splitting.Expand Specific Solutions05 Integration of MXenes in electrochemical systems

Researchers are investigating the integration of MXenes into various electrochemical systems for water splitting. This includes the development of MXene-based electrodes, membranes, and electrocatalysts. The focus is on optimizing the interface between MXenes and other components of the electrochemical cell to maximize charge transfer and catalytic efficiency in water-splitting reactions.Expand Specific Solutions

Key Players in MXene and PEC Research

The integration of MXene in water-splitting photoelectrochemical systems is an emerging field at the intersection of materials science and renewable energy. The competitive landscape is characterized by early-stage research and development, with academic institutions leading the charge. The market size is still relatively small but growing, driven by the increasing focus on clean energy solutions. Technologically, MXene integration is in its nascent stages, with research teams from institutions like Tianjin University, Drexel University, and King Fahd University of Petroleum & Minerals exploring its potential. While promising, the technology's maturity level indicates a need for further development before widespread commercial adoption.

Tianjin University

Technical Solution: Tianjin University has made significant strides in integrating MXenes into water-splitting photoelectrochemical systems. Their approach focuses on creating hybrid structures combining MXenes with other nanomaterials to enhance overall performance. One notable development is the synthesis of MXene/metal oxide composites, where Ti3C2Tx MXene is combined with TiO2 nanotubes to form a hierarchical structure[4]. This hybrid material exhibits improved light absorption, charge separation, and catalytic activity. The university has also explored the use of MXene as a protective layer for unstable photoelectrodes, significantly enhancing their stability in aqueous environments[5]. Additionally, Tianjin University researchers have developed novel methods for controlling the interlayer spacing of MXene sheets, allowing for optimized ion transport and increased active surface area[6].

Strengths: Innovative hybrid material design, focus on stability enhancement, and expertise in nanostructure engineering. Weaknesses: Potential challenges in maintaining consistent performance across large-scale production.

KIST Corp. (South Korea)

Technical Solution: KIST Corp. has made significant advancements in the integration of MXenes into water-splitting photoelectrochemical systems. Their approach focuses on developing MXene-based electrocatalysts for both the hydrogen evolution reaction (HER) and oxygen evolution reaction (OER). One of their key innovations is the synthesis of MXene/transition metal dichalcogenide (TMD) hybrid materials, which exhibit synergistic effects in catalyzing water-splitting reactions[10]. KIST researchers have also developed methods for creating vertically aligned MXene arrays on conductive substrates, significantly increasing the active surface area and improving charge transfer kinetics[11]. Additionally, they have explored the use of MXenes as protective coatings for silicon-based photoelectrodes, enhancing their stability and performance in alkaline electrolytes[12].

Strengths: Strong focus on practical applications, expertise in hybrid material design, and advanced fabrication techniques. Weaknesses: Potential challenges in scaling up production of complex nanostructured materials.

Breakthrough MXene Innovations for Water Splitting

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact of MXene-Based PEC Systems

The integration of MXene in water-splitting photoelectrochemical (PEC) systems presents both opportunities and challenges from an environmental perspective. MXene-based PEC systems offer promising advancements in clean energy production, potentially reducing reliance on fossil fuels and mitigating greenhouse gas emissions. These systems harness solar energy to split water into hydrogen and oxygen, providing a sustainable pathway for hydrogen production.

However, the environmental impact of MXene-based PEC systems extends beyond their operational benefits. The production process of MXenes involves chemical etching and exfoliation, which may generate hazardous waste and consume significant energy. Proper waste management and recycling protocols are essential to minimize the environmental footprint of MXene synthesis.

The long-term stability and degradation of MXenes in aqueous environments also warrant consideration. As these materials interact with water and electrolytes during the PEC process, there is potential for nanomaterial release into the environment. While MXenes have shown low toxicity in initial studies, their long-term ecological impact requires further investigation to ensure environmental safety.

Energy efficiency is a crucial factor in assessing the environmental impact of MXene-based PEC systems. These systems must demonstrate superior efficiency compared to conventional hydrogen production methods to justify their adoption. Lifecycle assessments are necessary to quantify the overall environmental benefits, considering factors such as raw material extraction, manufacturing, operation, and end-of-life disposal.

The scalability of MXene-based PEC systems also influences their environmental impact. Large-scale production and deployment may lead to increased resource consumption and potential environmental disruptions. Sustainable sourcing of raw materials, particularly titanium and other transition metals used in MXene synthesis, is crucial to prevent ecological damage and resource depletion.

Water consumption is another critical aspect to consider. While PEC systems utilize water as a feedstock, the overall water footprint, including water used in MXene production and system maintenance, must be evaluated. In water-scarce regions, the implementation of MXene-based PEC systems should be carefully assessed to ensure responsible water management.

In conclusion, the environmental impact of MXene-based PEC systems is multifaceted. While they offer significant potential for clean energy production, careful consideration of their entire lifecycle is necessary to maximize environmental benefits and minimize potential risks. Ongoing research and development should focus on optimizing production processes, enhancing material stability, and implementing robust recycling strategies to ensure the sustainable integration of MXenes in water-splitting PEC systems.

However, the environmental impact of MXene-based PEC systems extends beyond their operational benefits. The production process of MXenes involves chemical etching and exfoliation, which may generate hazardous waste and consume significant energy. Proper waste management and recycling protocols are essential to minimize the environmental footprint of MXene synthesis.

The long-term stability and degradation of MXenes in aqueous environments also warrant consideration. As these materials interact with water and electrolytes during the PEC process, there is potential for nanomaterial release into the environment. While MXenes have shown low toxicity in initial studies, their long-term ecological impact requires further investigation to ensure environmental safety.

Energy efficiency is a crucial factor in assessing the environmental impact of MXene-based PEC systems. These systems must demonstrate superior efficiency compared to conventional hydrogen production methods to justify their adoption. Lifecycle assessments are necessary to quantify the overall environmental benefits, considering factors such as raw material extraction, manufacturing, operation, and end-of-life disposal.

The scalability of MXene-based PEC systems also influences their environmental impact. Large-scale production and deployment may lead to increased resource consumption and potential environmental disruptions. Sustainable sourcing of raw materials, particularly titanium and other transition metals used in MXene synthesis, is crucial to prevent ecological damage and resource depletion.

Water consumption is another critical aspect to consider. While PEC systems utilize water as a feedstock, the overall water footprint, including water used in MXene production and system maintenance, must be evaluated. In water-scarce regions, the implementation of MXene-based PEC systems should be carefully assessed to ensure responsible water management.

In conclusion, the environmental impact of MXene-based PEC systems is multifaceted. While they offer significant potential for clean energy production, careful consideration of their entire lifecycle is necessary to maximize environmental benefits and minimize potential risks. Ongoing research and development should focus on optimizing production processes, enhancing material stability, and implementing robust recycling strategies to ensure the sustainable integration of MXenes in water-splitting PEC systems.

Scalability and Cost Analysis of MXene-PEC Technology

The scalability and cost analysis of MXene-PEC technology is crucial for assessing its potential for large-scale implementation in water-splitting photoelectrochemical systems. MXenes, as two-dimensional transition metal carbides and nitrides, offer unique properties that make them promising candidates for enhancing PEC performance. However, their integration into practical, commercially viable systems requires careful consideration of production scalability and overall cost-effectiveness.

From a scalability perspective, the synthesis of MXenes has shown significant progress in recent years. The most common method, selective etching of MAX phases, has been successfully scaled up from laboratory to pilot-scale production. Several companies have demonstrated the ability to produce MXenes in kilogram quantities, indicating the potential for industrial-scale manufacturing. However, challenges remain in maintaining consistent quality and properties across large-scale production batches.

The integration of MXenes into PEC systems presents additional scalability considerations. Current laboratory-scale fabrication methods, such as drop-casting or spin-coating, may not be directly transferable to large-area electrodes required for commercial applications. Development of scalable deposition techniques, such as spray coating or roll-to-roll processing, is essential for the widespread adoption of MXene-PEC technology.

Cost analysis of MXene-PEC systems must consider several factors. The raw materials for MXene synthesis, particularly the transition metals used, can be a significant cost driver. While some MXenes use relatively abundant elements like titanium, others incorporate more expensive metals like molybdenum or tantalum. The etching process, typically using hydrofluoric acid or its derivatives, also contributes to the overall cost and requires careful handling and waste management.

When comparing MXene-PEC technology to existing water-splitting methods, such as traditional electrolysis or other PEC systems, the cost-benefit analysis becomes more complex. The potential improvements in efficiency and durability offered by MXenes must be weighed against the increased material and processing costs. Long-term stability and performance under real-world conditions are critical factors that can significantly impact the overall cost-effectiveness of the technology.

Environmental and safety considerations also play a role in the scalability and cost analysis. The use of hazardous chemicals in MXene synthesis and the potential for nanomaterial release during operation or disposal must be addressed. Developing greener synthesis routes and ensuring proper containment and recycling strategies are essential for sustainable large-scale implementation.

In conclusion, while MXene-PEC technology shows promise for enhancing water-splitting efficiency, its scalability and cost-effectiveness remain areas requiring further research and development. Advances in large-scale MXene production, integration techniques, and life-cycle analysis will be crucial in determining the viability of this technology for commercial water-splitting applications.

From a scalability perspective, the synthesis of MXenes has shown significant progress in recent years. The most common method, selective etching of MAX phases, has been successfully scaled up from laboratory to pilot-scale production. Several companies have demonstrated the ability to produce MXenes in kilogram quantities, indicating the potential for industrial-scale manufacturing. However, challenges remain in maintaining consistent quality and properties across large-scale production batches.

The integration of MXenes into PEC systems presents additional scalability considerations. Current laboratory-scale fabrication methods, such as drop-casting or spin-coating, may not be directly transferable to large-area electrodes required for commercial applications. Development of scalable deposition techniques, such as spray coating or roll-to-roll processing, is essential for the widespread adoption of MXene-PEC technology.

Cost analysis of MXene-PEC systems must consider several factors. The raw materials for MXene synthesis, particularly the transition metals used, can be a significant cost driver. While some MXenes use relatively abundant elements like titanium, others incorporate more expensive metals like molybdenum or tantalum. The etching process, typically using hydrofluoric acid or its derivatives, also contributes to the overall cost and requires careful handling and waste management.

When comparing MXene-PEC technology to existing water-splitting methods, such as traditional electrolysis or other PEC systems, the cost-benefit analysis becomes more complex. The potential improvements in efficiency and durability offered by MXenes must be weighed against the increased material and processing costs. Long-term stability and performance under real-world conditions are critical factors that can significantly impact the overall cost-effectiveness of the technology.

Environmental and safety considerations also play a role in the scalability and cost analysis. The use of hazardous chemicals in MXene synthesis and the potential for nanomaterial release during operation or disposal must be addressed. Developing greener synthesis routes and ensuring proper containment and recycling strategies are essential for sustainable large-scale implementation.

In conclusion, while MXene-PEC technology shows promise for enhancing water-splitting efficiency, its scalability and cost-effectiveness remain areas requiring further research and development. Advances in large-scale MXene production, integration techniques, and life-cycle analysis will be crucial in determining the viability of this technology for commercial water-splitting applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!