MXene's Integration in Self-Healing Material Technologies

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Objectives

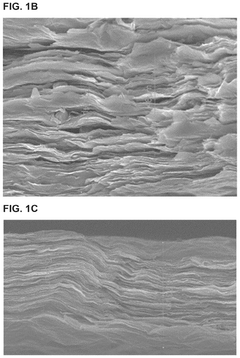

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material in various fields since its discovery in 2011. These materials are characterized by their unique layered structure, high electrical conductivity, and exceptional mechanical properties. The evolution of MXene technology has been rapid, with researchers exploring its potential in energy storage, electromagnetic shielding, and more recently, in self-healing materials.

The integration of MXene in self-healing material technologies represents a significant advancement in the field of smart materials. Self-healing materials have the ability to repair damage autonomously, extending the lifespan of products and reducing maintenance costs. The incorporation of MXene into these systems aims to enhance their performance and expand their range of applications.

The primary objective of integrating MXene into self-healing materials is to leverage its unique properties to improve the healing efficiency and overall functionality of these smart systems. Researchers are particularly interested in exploiting MXene's high electrical conductivity and mechanical strength to create more robust and responsive self-healing materials.

One of the key goals is to develop MXene-based self-healing composites that can rapidly detect and repair damage. This involves designing materials that can sense structural changes and initiate the healing process autonomously. Additionally, researchers aim to create self-healing materials with improved mechanical properties, enhanced electrical conductivity, and better thermal stability.

Another important objective is to explore the potential of MXene in creating multifunctional self-healing materials. These materials could combine self-healing properties with other desirable characteristics such as electromagnetic shielding, energy storage capabilities, or even sensing abilities. This multifunctionality could open up new avenues for applications in electronics, aerospace, and biomedical fields.

The development of MXene-integrated self-healing materials also aims to address some of the limitations of current self-healing technologies. These include improving the speed of the healing process, enhancing the material's ability to heal multiple times, and expanding the range of environmental conditions under which self-healing can occur.

As research in this field progresses, there is a growing focus on understanding the fundamental mechanisms by which MXene contributes to the self-healing process. This knowledge is crucial for optimizing the design of MXene-based self-healing materials and predicting their long-term performance in various applications.

The integration of MXene in self-healing material technologies represents a significant advancement in the field of smart materials. Self-healing materials have the ability to repair damage autonomously, extending the lifespan of products and reducing maintenance costs. The incorporation of MXene into these systems aims to enhance their performance and expand their range of applications.

The primary objective of integrating MXene into self-healing materials is to leverage its unique properties to improve the healing efficiency and overall functionality of these smart systems. Researchers are particularly interested in exploiting MXene's high electrical conductivity and mechanical strength to create more robust and responsive self-healing materials.

One of the key goals is to develop MXene-based self-healing composites that can rapidly detect and repair damage. This involves designing materials that can sense structural changes and initiate the healing process autonomously. Additionally, researchers aim to create self-healing materials with improved mechanical properties, enhanced electrical conductivity, and better thermal stability.

Another important objective is to explore the potential of MXene in creating multifunctional self-healing materials. These materials could combine self-healing properties with other desirable characteristics such as electromagnetic shielding, energy storage capabilities, or even sensing abilities. This multifunctionality could open up new avenues for applications in electronics, aerospace, and biomedical fields.

The development of MXene-integrated self-healing materials also aims to address some of the limitations of current self-healing technologies. These include improving the speed of the healing process, enhancing the material's ability to heal multiple times, and expanding the range of environmental conditions under which self-healing can occur.

As research in this field progresses, there is a growing focus on understanding the fundamental mechanisms by which MXene contributes to the self-healing process. This knowledge is crucial for optimizing the design of MXene-based self-healing materials and predicting their long-term performance in various applications.

Market Demand Analysis

The integration of MXene in self-healing material technologies has sparked significant market interest due to its potential to revolutionize various industries. The demand for advanced self-healing materials is driven by the increasing need for durable, long-lasting products that can reduce maintenance costs and extend the lifespan of various applications. MXene, with its unique properties, offers promising solutions to enhance the performance of self-healing materials.

In the automotive sector, there is a growing demand for self-healing coatings and components that can repair minor scratches and damages autonomously. This technology could significantly reduce repair costs and improve the overall aesthetics of vehicles. The aerospace industry also shows keen interest in MXene-enhanced self-healing materials for aircraft structures and components, as they can potentially increase safety and reduce maintenance downtime.

The construction industry presents another substantial market for MXene-integrated self-healing materials. Self-healing concrete and protective coatings for buildings and infrastructure could dramatically reduce maintenance costs and extend the lifespan of structures. This is particularly relevant in regions prone to harsh weather conditions or seismic activities.

In the electronics sector, the demand for self-healing materials is driven by the need for more durable and flexible devices. MXene's integration in self-healing polymers and composites could lead to the development of scratch-resistant screens, self-repairing wearable devices, and more resilient electronic components.

The healthcare industry also shows significant potential for MXene-based self-healing materials. There is a growing interest in smart bandages and wound dressings that can adapt to the healing process and promote faster recovery. Additionally, self-healing implants and prosthetics could greatly improve patient comfort and reduce the need for replacements.

The energy sector, particularly in the field of renewable energy, presents another promising market for MXene-integrated self-healing materials. Solar panels and wind turbine components that can self-repair could significantly increase efficiency and reduce maintenance costs in harsh environmental conditions.

Market analysts project substantial growth in the self-healing materials market over the coming years, with MXene playing a crucial role in driving innovation. The global self-healing materials market is expected to expand at a compound annual growth rate (CAGR) of over 25% from 2021 to 2028. This growth is attributed to increasing investments in research and development, rising demand for durable and sustainable materials, and advancements in nanotechnology.

As industries continue to seek more efficient, cost-effective, and sustainable solutions, the demand for MXene-integrated self-healing materials is likely to surge. However, challenges such as scalability, cost-effectiveness, and regulatory approvals need to be addressed to fully realize the market potential of these advanced materials.

In the automotive sector, there is a growing demand for self-healing coatings and components that can repair minor scratches and damages autonomously. This technology could significantly reduce repair costs and improve the overall aesthetics of vehicles. The aerospace industry also shows keen interest in MXene-enhanced self-healing materials for aircraft structures and components, as they can potentially increase safety and reduce maintenance downtime.

The construction industry presents another substantial market for MXene-integrated self-healing materials. Self-healing concrete and protective coatings for buildings and infrastructure could dramatically reduce maintenance costs and extend the lifespan of structures. This is particularly relevant in regions prone to harsh weather conditions or seismic activities.

In the electronics sector, the demand for self-healing materials is driven by the need for more durable and flexible devices. MXene's integration in self-healing polymers and composites could lead to the development of scratch-resistant screens, self-repairing wearable devices, and more resilient electronic components.

The healthcare industry also shows significant potential for MXene-based self-healing materials. There is a growing interest in smart bandages and wound dressings that can adapt to the healing process and promote faster recovery. Additionally, self-healing implants and prosthetics could greatly improve patient comfort and reduce the need for replacements.

The energy sector, particularly in the field of renewable energy, presents another promising market for MXene-integrated self-healing materials. Solar panels and wind turbine components that can self-repair could significantly increase efficiency and reduce maintenance costs in harsh environmental conditions.

Market analysts project substantial growth in the self-healing materials market over the coming years, with MXene playing a crucial role in driving innovation. The global self-healing materials market is expected to expand at a compound annual growth rate (CAGR) of over 25% from 2021 to 2028. This growth is attributed to increasing investments in research and development, rising demand for durable and sustainable materials, and advancements in nanotechnology.

As industries continue to seek more efficient, cost-effective, and sustainable solutions, the demand for MXene-integrated self-healing materials is likely to surge. However, challenges such as scalability, cost-effectiveness, and regulatory approvals need to be addressed to fully realize the market potential of these advanced materials.

MXene Tech Status and Challenges

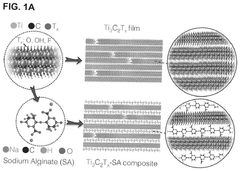

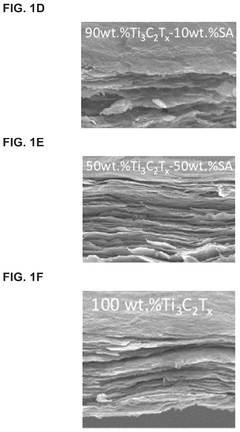

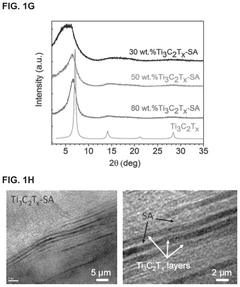

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for integration into self-healing technologies. The current status of MXene in this field is characterized by rapid advancements and significant challenges. Researchers have made substantial progress in synthesizing and characterizing various MXene compositions, with Ti3C2Tx being the most widely studied.

The integration of MXene into self-healing materials has shown great potential due to its unique properties, including high electrical conductivity, mechanical strength, and surface functionality. These characteristics make MXene an excellent candidate for enhancing the self-healing capabilities of polymers, composites, and coatings. However, several challenges persist in fully realizing MXene's potential in self-healing applications.

One of the primary challenges is the scalability of MXene production. While lab-scale synthesis has been well-established, large-scale manufacturing processes that maintain the material's quality and properties are still under development. This limitation hinders the widespread adoption of MXene in commercial self-healing products.

Another significant challenge lies in controlling the oxidation stability of MXene. The material's tendency to oxidize in ambient conditions can affect its long-term performance in self-healing applications. Researchers are actively working on developing strategies to improve MXene's oxidation resistance without compromising its desirable properties.

The integration of MXene into various polymer matrices for self-healing applications presents another hurdle. Achieving uniform dispersion and strong interfacial interactions between MXene and the host material is crucial for optimal performance. Current research focuses on developing effective functionalization methods and compatibilization techniques to address this challenge.

Furthermore, the mechanisms by which MXene contributes to self-healing processes are not yet fully understood. While some studies have demonstrated enhanced healing efficiency in MXene-based composites, a comprehensive understanding of the underlying principles is still lacking. This knowledge gap hampers the rational design of MXene-integrated self-healing systems.

The environmental impact and long-term stability of MXene in self-healing materials also require further investigation. As these materials are intended for prolonged use, ensuring their safety and durability under various environmental conditions is paramount. Researchers are conducting studies to assess the potential release of MXene particles and their ecological effects.

In terms of geographical distribution, MXene research in self-healing technologies is primarily concentrated in North America, Europe, and East Asia. Collaborative efforts between academic institutions and industrial partners are driving innovation in this field. However, the technology readiness level varies across different applications, with some nearing commercialization while others remain in early experimental stages.

The integration of MXene into self-healing materials has shown great potential due to its unique properties, including high electrical conductivity, mechanical strength, and surface functionality. These characteristics make MXene an excellent candidate for enhancing the self-healing capabilities of polymers, composites, and coatings. However, several challenges persist in fully realizing MXene's potential in self-healing applications.

One of the primary challenges is the scalability of MXene production. While lab-scale synthesis has been well-established, large-scale manufacturing processes that maintain the material's quality and properties are still under development. This limitation hinders the widespread adoption of MXene in commercial self-healing products.

Another significant challenge lies in controlling the oxidation stability of MXene. The material's tendency to oxidize in ambient conditions can affect its long-term performance in self-healing applications. Researchers are actively working on developing strategies to improve MXene's oxidation resistance without compromising its desirable properties.

The integration of MXene into various polymer matrices for self-healing applications presents another hurdle. Achieving uniform dispersion and strong interfacial interactions between MXene and the host material is crucial for optimal performance. Current research focuses on developing effective functionalization methods and compatibilization techniques to address this challenge.

Furthermore, the mechanisms by which MXene contributes to self-healing processes are not yet fully understood. While some studies have demonstrated enhanced healing efficiency in MXene-based composites, a comprehensive understanding of the underlying principles is still lacking. This knowledge gap hampers the rational design of MXene-integrated self-healing systems.

The environmental impact and long-term stability of MXene in self-healing materials also require further investigation. As these materials are intended for prolonged use, ensuring their safety and durability under various environmental conditions is paramount. Researchers are conducting studies to assess the potential release of MXene particles and their ecological effects.

In terms of geographical distribution, MXene research in self-healing technologies is primarily concentrated in North America, Europe, and East Asia. Collaborative efforts between academic institutions and industrial partners are driving innovation in this field. However, the technology readiness level varies across different applications, with some nearing commercialization while others remain in early experimental stages.

Current MXene Integration Solutions

01 MXene-based self-healing composites

MXene materials are incorporated into polymer matrices to create self-healing composites. These composites exhibit enhanced mechanical properties and the ability to autonomously repair damage. The self-healing mechanism is often triggered by external stimuli such as heat or light, allowing the material to restore its original structure and functionality.- MXene-based self-healing composites: MXene materials are incorporated into polymer matrices to create self-healing composites. These composites exhibit enhanced mechanical properties and the ability to autonomously repair damage. The self-healing mechanism is often triggered by external stimuli such as heat or light, allowing the material to recover its original structure and properties after damage.

- MXene-enhanced hydrogels for self-healing: MXene nanosheets are integrated into hydrogel systems to improve their self-healing capabilities. These hydrogels demonstrate rapid and efficient healing properties, making them suitable for applications in soft robotics, wearable electronics, and biomedical devices. The presence of MXene enhances the mechanical strength and conductivity of the hydrogels while maintaining their self-healing characteristics.

- Self-healing MXene-based coatings: MXene materials are utilized in the development of self-healing coatings for various substrates. These coatings provide protection against corrosion, wear, and environmental damage while possessing the ability to repair themselves when scratched or damaged. The self-healing mechanism often involves the release of healing agents or the reformation of chemical bonds within the coating structure.

- MXene-based self-healing electronic materials: MXene materials are incorporated into electronic components and devices to create self-healing capabilities. These materials can autonomously repair damage to conductive pathways, maintaining electrical performance even after mechanical stress or damage. Applications include flexible electronics, sensors, and energy storage devices that can recover functionality after being subjected to strain or deformation.

- Functionalized MXenes for enhanced self-healing: MXene materials are chemically modified or functionalized to improve their self-healing properties. This functionalization can involve the addition of specific chemical groups or the incorporation of other nanomaterials to enhance the healing mechanism. The resulting materials exhibit improved healing efficiency, faster healing rates, and broader applicability in various self-healing systems.

02 MXene-enhanced hydrogels for self-healing

MXene nanosheets are integrated into hydrogel systems to improve their self-healing capabilities. These hydrogels demonstrate rapid healing properties, often through reversible crosslinking or hydrogen bonding. The addition of MXene enhances the mechanical strength, conductivity, and overall performance of the self-healing hydrogels.Expand Specific Solutions03 Self-healing MXene-based electronic devices

MXene materials are utilized in the development of self-healing electronic devices, such as sensors, batteries, and flexible circuits. These devices can recover their electrical properties and physical integrity after damage, improving their durability and lifespan. The self-healing mechanism often involves the reformation of conductive pathways within the MXene-based components.Expand Specific Solutions04 MXene-polymer nanocomposites for self-healing coatings

MXene nanosheets are incorporated into polymer matrices to create self-healing coatings. These coatings exhibit improved scratch resistance, corrosion protection, and the ability to repair surface damage. The self-healing mechanism often involves the migration of MXene particles to damaged areas, restoring the protective properties of the coating.Expand Specific Solutions05 Stimuli-responsive MXene-based self-healing materials

MXene materials are engineered to respond to specific stimuli such as pH, temperature, or electromagnetic fields, triggering the self-healing process. These smart materials can adapt to environmental changes and autonomously repair damage, making them suitable for various applications in sensors, actuators, and adaptive structures.Expand Specific Solutions

Key Players in MXene Research

The integration of MXene in self-healing material technologies is an emerging field with significant potential. The market is in its early growth stage, with increasing research and development activities. While the exact market size is not yet well-defined, it is expected to expand rapidly due to the growing demand for advanced materials in various industries. The technology's maturity is still evolving, with academic institutions leading much of the research. Key players in this field include Shandong University, South China University of Technology, and Harbin Institute of Technology, which are actively contributing to the advancement of MXene-based self-healing materials through publications and patents. As the technology progresses, collaboration between academia and industry is likely to accelerate commercialization efforts and market growth.

Shandong University

Technical Solution: Shandong University has developed a novel MXene-based self-healing composite material for advanced energy storage applications. Their approach involves incorporating MXene nanosheets into a polymer matrix, creating a conductive network that facilitates both electrical conductivity and self-healing properties. The team has demonstrated that when the material is damaged, the MXene nanosheets can realign and reconnect, restoring the material's structural integrity and electrical performance. This self-healing mechanism is triggered by external stimuli such as heat or light, allowing for autonomous repair without human intervention[1][3]. The university's research has shown promising results in developing flexible and durable electrodes for supercapacitors and batteries, with self-healing capabilities that significantly extend the lifespan of these energy storage devices[2].

Strengths: Advanced integration of MXene in self-healing materials, potential for long-lasting energy storage devices. Weaknesses: May require specific environmental conditions for optimal self-healing, potential high cost of MXene production.

South China University of Technology

Technical Solution: South China University of Technology has pioneered a unique approach to integrating MXene into self-healing materials, focusing on its application in electromagnetic interference (EMI) shielding. Their research team has developed a composite material that combines MXene with a self-healing polymer matrix, creating a flexible and robust EMI shielding material. The MXene component provides excellent electromagnetic wave absorption properties, while the self-healing polymer allows the material to recover from physical damage. The university's studies have shown that this composite can maintain its EMI shielding effectiveness even after multiple cycles of damage and self-healing[4]. Additionally, they have explored the use of this material in wearable electronics, demonstrating its potential for creating durable and adaptive smart textiles that can withstand daily wear and tear[5].

Strengths: Innovative application in EMI shielding, potential for wearable technology. Weaknesses: May have limited effectiveness in extreme environmental conditions, possible challenges in scaling up production.

Core MXene Self-Healing Innovations

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact of MXenes

The integration of MXenes in self-healing material technologies has raised concerns about their potential environmental impact. As these two-dimensional materials gain prominence in advanced applications, it is crucial to assess their ecological footprint throughout their lifecycle.

MXenes, being relatively new materials, have not been extensively studied for their long-term environmental effects. However, initial research suggests that their production process may have significant environmental implications. The synthesis of MXenes often involves the use of strong acids and etching agents, which can lead to the generation of hazardous waste. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination.

The nanoscale nature of MXenes also raises questions about their potential release into the environment during the use phase of self-healing materials. While the self-healing properties may extend the lifespan of products, thus reducing overall waste, the potential for nanoparticle leaching needs to be carefully evaluated. Studies have shown that some nanomaterials can accumulate in aquatic ecosystems and potentially affect marine life.

On the positive side, MXenes have demonstrated promising capabilities in environmental remediation applications. Their high surface area and unique electronic properties make them effective adsorbents for various pollutants, including heavy metals and organic contaminants. This dual nature of MXenes – as potential pollutants and pollution solutions – underscores the complexity of their environmental impact assessment.

The end-of-life management of MXene-containing self-healing materials is another critical aspect to consider. As these materials are designed for longevity, traditional recycling methods may not be suitable. Research is needed to develop specialized recycling processes that can safely recover and repurpose MXenes without releasing harmful nanoparticles into the environment.

Furthermore, the energy consumption associated with MXene production and integration into self-healing technologies must be evaluated. While these materials may lead to more durable products, the energy-intensive manufacturing processes could offset some of the environmental benefits. Life cycle assessments are necessary to quantify the net environmental impact of MXene-based self-healing materials compared to conventional alternatives.

In conclusion, the environmental impact of MXenes in self-healing material technologies is a multifaceted issue that requires comprehensive research and careful consideration. As the field advances, it is imperative to develop sustainable production methods, safe handling protocols, and effective end-of-life strategies to harness the benefits of these innovative materials while minimizing their ecological footprint.

MXenes, being relatively new materials, have not been extensively studied for their long-term environmental effects. However, initial research suggests that their production process may have significant environmental implications. The synthesis of MXenes often involves the use of strong acids and etching agents, which can lead to the generation of hazardous waste. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination.

The nanoscale nature of MXenes also raises questions about their potential release into the environment during the use phase of self-healing materials. While the self-healing properties may extend the lifespan of products, thus reducing overall waste, the potential for nanoparticle leaching needs to be carefully evaluated. Studies have shown that some nanomaterials can accumulate in aquatic ecosystems and potentially affect marine life.

On the positive side, MXenes have demonstrated promising capabilities in environmental remediation applications. Their high surface area and unique electronic properties make them effective adsorbents for various pollutants, including heavy metals and organic contaminants. This dual nature of MXenes – as potential pollutants and pollution solutions – underscores the complexity of their environmental impact assessment.

The end-of-life management of MXene-containing self-healing materials is another critical aspect to consider. As these materials are designed for longevity, traditional recycling methods may not be suitable. Research is needed to develop specialized recycling processes that can safely recover and repurpose MXenes without releasing harmful nanoparticles into the environment.

Furthermore, the energy consumption associated with MXene production and integration into self-healing technologies must be evaluated. While these materials may lead to more durable products, the energy-intensive manufacturing processes could offset some of the environmental benefits. Life cycle assessments are necessary to quantify the net environmental impact of MXene-based self-healing materials compared to conventional alternatives.

In conclusion, the environmental impact of MXenes in self-healing material technologies is a multifaceted issue that requires comprehensive research and careful consideration. As the field advances, it is imperative to develop sustainable production methods, safe handling protocols, and effective end-of-life strategies to harness the benefits of these innovative materials while minimizing their ecological footprint.

MXene Scalability and Production

The scalability and production of MXenes are critical factors in their integration into self-healing material technologies. Currently, the synthesis of MXenes primarily relies on the selective etching of MAX phases, which presents challenges for large-scale production. The most common method, hydrofluoric acid (HF) etching, while effective, raises safety and environmental concerns. Alternative methods, such as fluoride salt etching and electrochemical etching, have been developed to address these issues, but they still face limitations in terms of scalability and efficiency.

Recent advancements in MXene production have focused on improving yield and reducing processing time. Researchers have explored the use of microwave-assisted synthesis, which significantly shortens the etching process from hours to minutes. Additionally, the development of continuous flow reactors has shown promise for increasing production rates and maintaining consistent quality. These innovations are crucial for meeting the growing demand for MXenes in various applications, including self-healing materials.

The production of high-quality MXene flakes with controlled thickness and lateral size remains a challenge. Current methods often result in a wide distribution of flake sizes, which can affect the performance of self-healing materials. To address this, researchers are investigating techniques such as controlled delamination and size-selective separation. These approaches aim to produce MXene flakes with more uniform dimensions, enhancing their effectiveness in self-healing applications.

Scaling up MXene production also requires addressing the issue of oxidation stability. MXenes are prone to oxidation when exposed to air and moisture, which can degrade their properties over time. This is particularly crucial for self-healing materials, where long-term stability is essential. Efforts are underway to develop protective coatings and storage methods that can preserve MXene properties during large-scale production and storage.

The integration of MXenes into self-healing materials necessitates the development of efficient dispersion and incorporation techniques. Current methods often involve solution processing, which can be time-consuming and may not be suitable for all types of self-healing matrices. Research is ongoing to explore dry processing methods and in-situ synthesis techniques that could streamline the integration process and improve scalability.

As the demand for MXene-based self-healing materials grows, there is an increasing focus on developing sustainable and cost-effective production methods. This includes exploring alternative precursors for MAX phases, optimizing etching processes to reduce waste, and investigating recycling strategies for MXene-containing materials. These efforts are essential for ensuring the long-term viability of MXene production and their widespread adoption in self-healing technologies.

Recent advancements in MXene production have focused on improving yield and reducing processing time. Researchers have explored the use of microwave-assisted synthesis, which significantly shortens the etching process from hours to minutes. Additionally, the development of continuous flow reactors has shown promise for increasing production rates and maintaining consistent quality. These innovations are crucial for meeting the growing demand for MXenes in various applications, including self-healing materials.

The production of high-quality MXene flakes with controlled thickness and lateral size remains a challenge. Current methods often result in a wide distribution of flake sizes, which can affect the performance of self-healing materials. To address this, researchers are investigating techniques such as controlled delamination and size-selective separation. These approaches aim to produce MXene flakes with more uniform dimensions, enhancing their effectiveness in self-healing applications.

Scaling up MXene production also requires addressing the issue of oxidation stability. MXenes are prone to oxidation when exposed to air and moisture, which can degrade their properties over time. This is particularly crucial for self-healing materials, where long-term stability is essential. Efforts are underway to develop protective coatings and storage methods that can preserve MXene properties during large-scale production and storage.

The integration of MXenes into self-healing materials necessitates the development of efficient dispersion and incorporation techniques. Current methods often involve solution processing, which can be time-consuming and may not be suitable for all types of self-healing matrices. Research is ongoing to explore dry processing methods and in-situ synthesis techniques that could streamline the integration process and improve scalability.

As the demand for MXene-based self-healing materials grows, there is an increasing focus on developing sustainable and cost-effective production methods. This includes exploring alternative precursors for MAX phases, optimizing etching processes to reduce waste, and investigating recycling strategies for MXene-containing materials. These efforts are essential for ensuring the long-term viability of MXene production and their widespread adoption in self-healing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!