Incorporating MXene into Flexible Antenna Designs

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Antenna Background

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for flexible antenna designs. Discovered in 2011 by researchers at Drexel University, MXenes have garnered significant attention due to their unique combination of properties, including high electrical conductivity, mechanical flexibility, and tunable surface chemistry.

The integration of MXene into flexible antenna designs represents a convergence of two rapidly evolving fields: nanomaterials and flexible electronics. This intersection has the potential to revolutionize wireless communication technologies, particularly in applications requiring conformal, lightweight, and high-performance antennas.

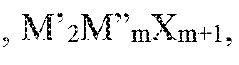

MXenes are derived from MAX phases, which are ternary carbides or nitrides with the general formula Mn+1AXn, where M is an early transition metal, A is an A-group element (usually from groups 13 or 14), and X is carbon or nitrogen. The synthesis of MXenes involves the selective etching of the A-layer from MAX phases, resulting in a layered structure with exceptional electronic and mechanical properties.

The interest in MXene-based antennas stems from several key advantages offered by this material. Firstly, MXenes exhibit metallic conductivity comparable to that of graphene, making them excellent candidates for electromagnetic wave manipulation. Secondly, their two-dimensional nature allows for the fabrication of ultra-thin, flexible structures that can conform to various surfaces without compromising performance.

Furthermore, MXenes possess a hydrophilic surface, which facilitates their processing and integration into various composite materials. This characteristic is particularly advantageous for creating flexible substrates and enabling solution-based fabrication methods, which are crucial for large-scale production of flexible antennas.

The development of MXene-based flexible antennas aligns with the growing demand for wearable electronics, Internet of Things (IoT) devices, and next-generation wireless communication systems. These applications require antennas that can maintain high performance while being subjected to bending, stretching, and other mechanical deformations.

As research in this field progresses, scientists and engineers are exploring various MXene compositions and fabrication techniques to optimize antenna performance. The ability to tune the electronic properties of MXenes through surface functionalization and compositional variations offers a wide design space for tailoring antenna characteristics to specific applications.

While the incorporation of MXene into flexible antenna designs is still in its early stages, preliminary results have shown great promise. Researchers have demonstrated MXene-based antennas with excellent flexibility, high radiation efficiency, and broad bandwidth capabilities. These initial successes have spurred further investigations into the scalability and long-term reliability of MXene antennas, paving the way for their potential commercialization in the near future.

The integration of MXene into flexible antenna designs represents a convergence of two rapidly evolving fields: nanomaterials and flexible electronics. This intersection has the potential to revolutionize wireless communication technologies, particularly in applications requiring conformal, lightweight, and high-performance antennas.

MXenes are derived from MAX phases, which are ternary carbides or nitrides with the general formula Mn+1AXn, where M is an early transition metal, A is an A-group element (usually from groups 13 or 14), and X is carbon or nitrogen. The synthesis of MXenes involves the selective etching of the A-layer from MAX phases, resulting in a layered structure with exceptional electronic and mechanical properties.

The interest in MXene-based antennas stems from several key advantages offered by this material. Firstly, MXenes exhibit metallic conductivity comparable to that of graphene, making them excellent candidates for electromagnetic wave manipulation. Secondly, their two-dimensional nature allows for the fabrication of ultra-thin, flexible structures that can conform to various surfaces without compromising performance.

Furthermore, MXenes possess a hydrophilic surface, which facilitates their processing and integration into various composite materials. This characteristic is particularly advantageous for creating flexible substrates and enabling solution-based fabrication methods, which are crucial for large-scale production of flexible antennas.

The development of MXene-based flexible antennas aligns with the growing demand for wearable electronics, Internet of Things (IoT) devices, and next-generation wireless communication systems. These applications require antennas that can maintain high performance while being subjected to bending, stretching, and other mechanical deformations.

As research in this field progresses, scientists and engineers are exploring various MXene compositions and fabrication techniques to optimize antenna performance. The ability to tune the electronic properties of MXenes through surface functionalization and compositional variations offers a wide design space for tailoring antenna characteristics to specific applications.

While the incorporation of MXene into flexible antenna designs is still in its early stages, preliminary results have shown great promise. Researchers have demonstrated MXene-based antennas with excellent flexibility, high radiation efficiency, and broad bandwidth capabilities. These initial successes have spurred further investigations into the scalability and long-term reliability of MXene antennas, paving the way for their potential commercialization in the near future.

Flexible Antenna Market

The flexible antenna market has been experiencing significant growth in recent years, driven by the increasing demand for compact, lightweight, and adaptable communication devices across various industries. This market segment is particularly influenced by the rapid advancements in wearable technology, Internet of Things (IoT) devices, and the automotive sector.

The global flexible antenna market is projected to expand at a robust rate, with key factors such as the proliferation of smart devices, the emergence of 5G technology, and the growing adoption of connected vehicles contributing to its growth. The versatility of flexible antennas makes them ideal for applications where traditional rigid antennas are impractical or inefficient.

In the consumer electronics sector, flexible antennas are becoming increasingly popular in smartphones, tablets, and wearable devices. These antennas offer improved signal reception and transmission while allowing for sleeker device designs. The wearable technology market, in particular, is driving demand for flexible antennas that can conform to the human body or be integrated into clothing.

The automotive industry is another significant driver of the flexible antenna market. As vehicles become more connected and autonomous, the need for multiple antennas to support various communication systems increases. Flexible antennas provide a solution for integrating these systems without compromising vehicle aesthetics or aerodynamics.

In the aerospace and defense sectors, flexible antennas are gaining traction due to their ability to be mounted on curved surfaces and their resistance to vibration and shock. These characteristics make them suitable for use in aircraft, drones, and military equipment.

The healthcare industry is also emerging as a potential growth area for flexible antennas. Wearable medical devices and remote patient monitoring systems are increasingly utilizing these antennas to ensure reliable communication and data transmission.

Geographically, North America and Europe are currently leading the flexible antenna market, owing to their advanced technological infrastructure and high adoption rates of IoT and smart devices. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid expansion of the consumer electronics industry and increasing investments in 5G technology.

As the market continues to evolve, manufacturers are focusing on developing innovative materials and designs to enhance the performance and durability of flexible antennas. The incorporation of advanced materials like MXenes into flexible antenna designs represents a promising avenue for further market expansion and technological advancement.

The global flexible antenna market is projected to expand at a robust rate, with key factors such as the proliferation of smart devices, the emergence of 5G technology, and the growing adoption of connected vehicles contributing to its growth. The versatility of flexible antennas makes them ideal for applications where traditional rigid antennas are impractical or inefficient.

In the consumer electronics sector, flexible antennas are becoming increasingly popular in smartphones, tablets, and wearable devices. These antennas offer improved signal reception and transmission while allowing for sleeker device designs. The wearable technology market, in particular, is driving demand for flexible antennas that can conform to the human body or be integrated into clothing.

The automotive industry is another significant driver of the flexible antenna market. As vehicles become more connected and autonomous, the need for multiple antennas to support various communication systems increases. Flexible antennas provide a solution for integrating these systems without compromising vehicle aesthetics or aerodynamics.

In the aerospace and defense sectors, flexible antennas are gaining traction due to their ability to be mounted on curved surfaces and their resistance to vibration and shock. These characteristics make them suitable for use in aircraft, drones, and military equipment.

The healthcare industry is also emerging as a potential growth area for flexible antennas. Wearable medical devices and remote patient monitoring systems are increasingly utilizing these antennas to ensure reliable communication and data transmission.

Geographically, North America and Europe are currently leading the flexible antenna market, owing to their advanced technological infrastructure and high adoption rates of IoT and smart devices. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid expansion of the consumer electronics industry and increasing investments in 5G technology.

As the market continues to evolve, manufacturers are focusing on developing innovative materials and designs to enhance the performance and durability of flexible antennas. The incorporation of advanced materials like MXenes into flexible antenna designs represents a promising avenue for further market expansion and technological advancement.

MXene Integration Challenges

The integration of MXene into flexible antenna designs presents several significant challenges that researchers and engineers must address. One of the primary obstacles is achieving uniform dispersion of MXene nanosheets within the flexible substrate material. The tendency of MXene to agglomerate due to strong van der Waals forces between layers can lead to inconsistent electrical properties and reduced performance of the antenna.

Another critical challenge lies in maintaining the electrical conductivity of MXene throughout the fabrication process. Exposure to oxygen and moisture during manufacturing can cause oxidation of MXene, potentially degrading its conductive properties. This necessitates the development of advanced encapsulation techniques or protective coatings to preserve MXene's electrical characteristics.

The adhesion between MXene and the flexible substrate is also a crucial concern. Poor interfacial bonding can result in delamination or cracking of the MXene layer during bending or stretching, compromising the antenna's flexibility and durability. Researchers must explore various surface modification techniques or coupling agents to enhance the adhesion and ensure long-term stability of the MXene-substrate interface.

Furthermore, the thickness control of MXene layers in flexible antenna designs poses a significant challenge. Achieving precise and uniform thickness is essential for optimizing the antenna's performance, as variations can lead to inconsistent electromagnetic properties. Developing reliable deposition methods that allow for accurate thickness control on flexible substrates is crucial for successful MXene integration.

The scalability of MXene production and integration processes also presents a considerable hurdle. While laboratory-scale synthesis and fabrication techniques have shown promising results, scaling up these processes for commercial production while maintaining consistent quality and performance remains a challenge. This includes developing cost-effective methods for large-scale MXene synthesis and establishing reliable manufacturing processes for flexible MXene-based antennas.

Additionally, the long-term stability and reliability of MXene in flexible antenna applications require further investigation. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can potentially affect the performance and lifespan of MXene-integrated antennas. Comprehensive studies on the aging behavior and degradation mechanisms of MXene in flexible antenna designs are necessary to ensure their viability in real-world applications.

Lastly, the optimization of antenna designs to fully leverage MXene's unique properties while accommodating its integration challenges is a complex task. This involves balancing factors such as MXene concentration, substrate material selection, and antenna geometry to achieve the desired performance characteristics while addressing the aforementioned integration challenges.

Another critical challenge lies in maintaining the electrical conductivity of MXene throughout the fabrication process. Exposure to oxygen and moisture during manufacturing can cause oxidation of MXene, potentially degrading its conductive properties. This necessitates the development of advanced encapsulation techniques or protective coatings to preserve MXene's electrical characteristics.

The adhesion between MXene and the flexible substrate is also a crucial concern. Poor interfacial bonding can result in delamination or cracking of the MXene layer during bending or stretching, compromising the antenna's flexibility and durability. Researchers must explore various surface modification techniques or coupling agents to enhance the adhesion and ensure long-term stability of the MXene-substrate interface.

Furthermore, the thickness control of MXene layers in flexible antenna designs poses a significant challenge. Achieving precise and uniform thickness is essential for optimizing the antenna's performance, as variations can lead to inconsistent electromagnetic properties. Developing reliable deposition methods that allow for accurate thickness control on flexible substrates is crucial for successful MXene integration.

The scalability of MXene production and integration processes also presents a considerable hurdle. While laboratory-scale synthesis and fabrication techniques have shown promising results, scaling up these processes for commercial production while maintaining consistent quality and performance remains a challenge. This includes developing cost-effective methods for large-scale MXene synthesis and establishing reliable manufacturing processes for flexible MXene-based antennas.

Additionally, the long-term stability and reliability of MXene in flexible antenna applications require further investigation. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can potentially affect the performance and lifespan of MXene-integrated antennas. Comprehensive studies on the aging behavior and degradation mechanisms of MXene in flexible antenna designs are necessary to ensure their viability in real-world applications.

Lastly, the optimization of antenna designs to fully leverage MXene's unique properties while accommodating its integration challenges is a complex task. This involves balancing factors such as MXene concentration, substrate material selection, and antenna geometry to achieve the desired performance characteristics while addressing the aforementioned integration challenges.

Current MXene Solutions

01 MXene-based flexible electrodes

MXene materials are used to create flexible electrodes for various applications. These electrodes combine high electrical conductivity with mechanical flexibility, making them suitable for wearable electronics and flexible energy storage devices. The unique 2D structure of MXenes allows for excellent bending and stretching capabilities while maintaining their electrical properties.- MXene-based flexible electrodes: MXene materials are used to create flexible electrodes for various applications. These electrodes exhibit high conductivity and mechanical flexibility, making them suitable for wearable electronics and flexible energy storage devices. The unique 2D structure of MXenes allows for excellent bending and stretching capabilities while maintaining electrical performance.

- MXene-polymer composites for enhanced flexibility: Combining MXenes with polymers results in composite materials with improved flexibility and mechanical properties. These composites can be used in flexible sensors, actuators, and energy storage devices. The polymer matrix provides additional flexibility and durability to the MXene-based materials, enabling their use in applications requiring high bendability and stretchability.

- Flexible MXene-based energy storage devices: MXenes are utilized in the development of flexible energy storage devices such as supercapacitors and batteries. Their high surface area, excellent conductivity, and mechanical flexibility make them ideal for creating bendable and foldable power sources. These flexible energy storage devices can be integrated into wearable electronics and other applications requiring conformable power solutions.

- MXene-based flexible sensors and actuators: The flexibility of MXene materials is exploited in the creation of highly sensitive and flexible sensors and actuators. These devices can detect various stimuli such as pressure, strain, and chemical compounds while maintaining their performance under bending and stretching conditions. The high electrical conductivity and mechanical properties of MXenes enable the development of responsive and adaptable sensing systems.

- Processing techniques for enhancing MXene flexibility: Various processing techniques are employed to enhance the flexibility of MXene materials. These include exfoliation methods, surface modifications, and assembly strategies that improve the mechanical properties and flexibility of MXene-based structures. Advanced fabrication processes enable the creation of ultrathin MXene films and fibers with exceptional flexibility and durability for use in flexible electronics and smart textiles.

02 MXene composites for enhanced flexibility

Composites incorporating MXenes with other materials are developed to improve flexibility and mechanical properties. These composites often combine MXenes with polymers or other 2D materials to create hybrid structures with enhanced flexibility, strength, and functionality. Such composites find applications in flexible sensors, actuators, and energy storage devices.Expand Specific Solutions03 Flexible MXene-based energy storage devices

MXenes are utilized in the development of flexible energy storage devices, such as supercapacitors and batteries. The high surface area and conductivity of MXenes, combined with their flexibility, allow for the creation of thin, bendable, and high-performance energy storage solutions. These devices can be integrated into wearable electronics and flexible electronic systems.Expand Specific Solutions04 MXene films and membranes with tunable flexibility

Thin films and membranes made from MXenes exhibit tunable flexibility and mechanical properties. These films can be fabricated through various methods, including vacuum filtration, spin coating, or layer-by-layer assembly. The thickness, composition, and processing conditions of MXene films can be adjusted to achieve desired flexibility and performance for specific applications.Expand Specific Solutions05 Flexible MXene-based sensors and actuators

MXenes are employed in the development of flexible sensors and actuators due to their unique combination of electrical, mechanical, and chemical properties. These devices can detect various stimuli such as strain, pressure, or chemical species while maintaining flexibility. MXene-based actuators can convert electrical or chemical energy into mechanical motion, enabling applications in soft robotics and adaptive structures.Expand Specific Solutions

MXene Antenna Players

The incorporation of MXene into flexible antenna designs represents an emerging field in advanced materials and electronics. This technology is in its early development stage, with significant potential for growth in the coming years. The market size is expected to expand rapidly as flexible electronics gain traction across various industries. While the technology is still maturing, several key players are driving innovation in this space. Universities such as Drexel University, Harbin Institute of Technology, and Southeast University are at the forefront of MXene research, collaborating with industry partners to develop practical applications. Companies like Zhejiang Lab and Nanning Guidian Electronic Technology Research Institute are also actively exploring MXene-based flexible antennas, indicating growing commercial interest in this technology.

Drexel University

Technical Solution: Drexel University has pioneered the development of MXene-based flexible antennas. Their approach involves creating ultrathin MXene films that can be easily integrated into flexible substrates. The team has developed a spray coating method to deposit MXene onto various flexible materials, resulting in antennas with exceptional conductivity and flexibility[1]. These antennas exhibit high electromagnetic interference (EMI) shielding effectiveness, typically above 45 dB in the X-band frequency range[2]. The university has also explored the use of MXene-based ink for printing antennas directly onto flexible substrates, achieving a balance between electrical performance and mechanical flexibility[3].

Strengths: Cutting-edge research in MXene synthesis and application; expertise in flexible electronics. Weaknesses: Potential scalability issues for mass production; need for further optimization of long-term stability.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed a novel approach to incorporating MXene into flexible antenna designs by creating MXene-based aerogels. These ultralight, highly conductive aerogels are fabricated through a freeze-drying process, resulting in a 3D porous structure that maintains excellent flexibility and stretchability[4]. The team has demonstrated antennas with a high specific surface area of over 200 m²/g and electrical conductivity exceeding 1000 S/m[5]. These MXene aerogel antennas show promising performance in wearable and conformal applications, maintaining stable signal transmission even under significant bending and stretching conditions.

Strengths: Innovative 3D MXene structures for enhanced flexibility and performance; expertise in material science. Weaknesses: Complexity of aerogel fabrication process may impact large-scale production; potential moisture sensitivity of aerogel structures.

Key MXene Antenna Patents

Antennas comprising MX-ENE films and composites

PatentWO2018039298A1

Innovation

- The use of MXene compositions, specifically titanium and carbon-based MXene films and composites, as a conductive material for antennas, which can be produced as freestanding films and applied to various substrates, enabling thinner, more flexible antennas with improved conductivity and ease of processing.

Antennas Comprising MX-ENE Films And Composites

PatentActiveUS20240088550A1

Innovation

- MXene films and composites are used to create thin, flexible antennas that can be applied as coatings or molded bodies on various substrates, including organic polymers and fabrics, offering high conductivity and ease of dispersion in solvents.

MXene Material Properties

MXene materials, a class of two-dimensional transition metal carbides and nitrides, exhibit exceptional properties that make them highly suitable for incorporation into flexible antenna designs. These materials possess a unique combination of high electrical conductivity, mechanical flexibility, and tunable surface chemistry, which are crucial for developing advanced antenna systems.

The electrical conductivity of MXenes is comparable to that of metals, with some compositions reaching conductivities as high as 10,000 S/cm. This high conductivity enables efficient signal transmission and reception in antenna applications. Moreover, the conductivity of MXenes can be tuned by controlling their composition and surface termination, allowing for customization of antenna performance.

Mechanical flexibility is another key property of MXenes that makes them ideal for flexible antenna designs. These materials can withstand significant bending and stretching without compromising their electrical properties. MXene films have demonstrated excellent flexibility, with the ability to maintain conductivity even after thousands of bending cycles. This characteristic is essential for developing antennas that can conform to curved surfaces or be integrated into wearable devices.

The surface chemistry of MXenes can be tailored through various functionalization methods, enabling the optimization of their properties for specific antenna applications. By modifying the surface terminations, researchers can adjust the work function, hydrophilicity, and chemical reactivity of MXenes. This versatility allows for the fine-tuning of antenna performance and the development of multifunctional devices.

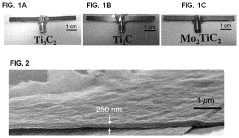

MXenes also exhibit excellent electromagnetic interference (EMI) shielding properties, with some compositions achieving shielding effectiveness of over 90 dB. This property is particularly valuable for antenna designs in environments with high electromagnetic noise or for developing antennas with reduced interference.

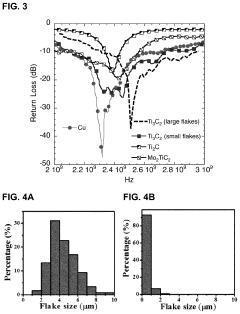

The thickness of MXene films can be precisely controlled, ranging from a few nanometers to several micrometers. This ability to create ultrathin films is advantageous for developing compact and lightweight antenna designs. Additionally, the high aspect ratio of MXene flakes contributes to their excellent mechanical properties and allows for the creation of highly oriented films with anisotropic electrical properties.

MXenes have demonstrated compatibility with various substrate materials, including polymers, textiles, and paper. This versatility enables the integration of MXene-based antennas into a wide range of flexible and wearable devices. Furthermore, MXenes can be processed using solution-based methods, making them amenable to large-scale, cost-effective manufacturing processes such as spray coating, inkjet printing, and roll-to-roll production.

In summary, the unique combination of high electrical conductivity, mechanical flexibility, tunable surface chemistry, and EMI shielding properties makes MXenes highly promising materials for incorporation into flexible antenna designs. Their versatility in processing and compatibility with various substrates further enhance their potential for developing next-generation antenna systems.

The electrical conductivity of MXenes is comparable to that of metals, with some compositions reaching conductivities as high as 10,000 S/cm. This high conductivity enables efficient signal transmission and reception in antenna applications. Moreover, the conductivity of MXenes can be tuned by controlling their composition and surface termination, allowing for customization of antenna performance.

Mechanical flexibility is another key property of MXenes that makes them ideal for flexible antenna designs. These materials can withstand significant bending and stretching without compromising their electrical properties. MXene films have demonstrated excellent flexibility, with the ability to maintain conductivity even after thousands of bending cycles. This characteristic is essential for developing antennas that can conform to curved surfaces or be integrated into wearable devices.

The surface chemistry of MXenes can be tailored through various functionalization methods, enabling the optimization of their properties for specific antenna applications. By modifying the surface terminations, researchers can adjust the work function, hydrophilicity, and chemical reactivity of MXenes. This versatility allows for the fine-tuning of antenna performance and the development of multifunctional devices.

MXenes also exhibit excellent electromagnetic interference (EMI) shielding properties, with some compositions achieving shielding effectiveness of over 90 dB. This property is particularly valuable for antenna designs in environments with high electromagnetic noise or for developing antennas with reduced interference.

The thickness of MXene films can be precisely controlled, ranging from a few nanometers to several micrometers. This ability to create ultrathin films is advantageous for developing compact and lightweight antenna designs. Additionally, the high aspect ratio of MXene flakes contributes to their excellent mechanical properties and allows for the creation of highly oriented films with anisotropic electrical properties.

MXenes have demonstrated compatibility with various substrate materials, including polymers, textiles, and paper. This versatility enables the integration of MXene-based antennas into a wide range of flexible and wearable devices. Furthermore, MXenes can be processed using solution-based methods, making them amenable to large-scale, cost-effective manufacturing processes such as spray coating, inkjet printing, and roll-to-roll production.

In summary, the unique combination of high electrical conductivity, mechanical flexibility, tunable surface chemistry, and EMI shielding properties makes MXenes highly promising materials for incorporation into flexible antenna designs. Their versatility in processing and compatibility with various substrates further enhance their potential for developing next-generation antenna systems.

Antenna Performance Metrics

Antenna performance metrics are crucial for evaluating the effectiveness and efficiency of flexible antennas incorporating MXene materials. These metrics provide quantitative measures to assess the antenna's capabilities and compare different designs. One of the primary metrics is radiation efficiency, which indicates the antenna's ability to convert input power into radiated electromagnetic waves. MXene-based flexible antennas have shown promising results in this aspect, with some designs achieving radiation efficiencies comparable to traditional rigid antennas.

Gain is another essential metric, representing the antenna's ability to concentrate radiated power in a specific direction. Flexible antennas with MXene have demonstrated improved gain characteristics, particularly when compared to other flexible antenna materials. This enhancement is attributed to MXene's unique electrical properties and its ability to maintain performance under bending conditions.

Bandwidth is a critical parameter that determines the range of frequencies over which the antenna can operate effectively. MXene-incorporated flexible antennas have exhibited broadband performance, with some designs achieving impressive bandwidth improvements over conventional flexible antennas. This broadband capability is particularly valuable for applications requiring multi-frequency operation or high data transmission rates.

Return loss, or S11 parameter, is a measure of how well the antenna is matched to its feed line and how efficiently it accepts power. Flexible antennas with MXene have shown good impedance matching characteristics, resulting in lower return losses across their operating frequency ranges. This translates to better power transfer and overall antenna efficiency.

Polarization is another important metric, especially for applications requiring specific signal orientations. MXene-based flexible antennas have demonstrated the ability to maintain consistent polarization characteristics even when subjected to bending or flexing, which is a significant advantage over some traditional flexible antenna materials.

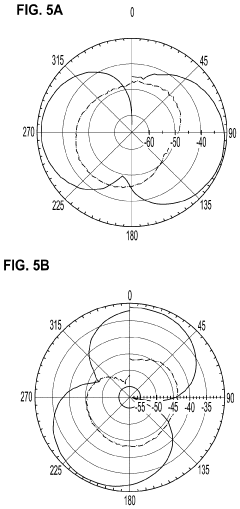

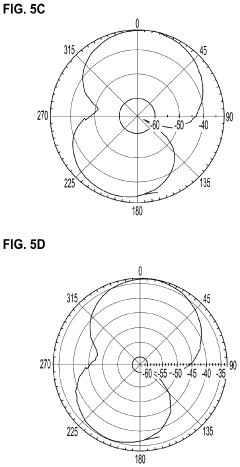

Radiation pattern, which describes the directional dependence of the antenna's radiation, is also a key consideration. Flexible antennas incorporating MXene have shown the ability to maintain stable radiation patterns under various bending conditions, ensuring consistent performance in dynamic environments.

Lastly, the flexibility and mechanical durability of the antenna are crucial metrics for wearable and conformal applications. MXene-based antennas have exhibited excellent flexibility and resilience, maintaining their electrical performance even after repeated bending cycles. This durability is a significant advantage for applications in smart textiles, wearable devices, and other scenarios where the antenna may be subjected to frequent mechanical stress.

Gain is another essential metric, representing the antenna's ability to concentrate radiated power in a specific direction. Flexible antennas with MXene have demonstrated improved gain characteristics, particularly when compared to other flexible antenna materials. This enhancement is attributed to MXene's unique electrical properties and its ability to maintain performance under bending conditions.

Bandwidth is a critical parameter that determines the range of frequencies over which the antenna can operate effectively. MXene-incorporated flexible antennas have exhibited broadband performance, with some designs achieving impressive bandwidth improvements over conventional flexible antennas. This broadband capability is particularly valuable for applications requiring multi-frequency operation or high data transmission rates.

Return loss, or S11 parameter, is a measure of how well the antenna is matched to its feed line and how efficiently it accepts power. Flexible antennas with MXene have shown good impedance matching characteristics, resulting in lower return losses across their operating frequency ranges. This translates to better power transfer and overall antenna efficiency.

Polarization is another important metric, especially for applications requiring specific signal orientations. MXene-based flexible antennas have demonstrated the ability to maintain consistent polarization characteristics even when subjected to bending or flexing, which is a significant advantage over some traditional flexible antenna materials.

Radiation pattern, which describes the directional dependence of the antenna's radiation, is also a key consideration. Flexible antennas incorporating MXene have shown the ability to maintain stable radiation patterns under various bending conditions, ensuring consistent performance in dynamic environments.

Lastly, the flexibility and mechanical durability of the antenna are crucial metrics for wearable and conformal applications. MXene-based antennas have exhibited excellent flexibility and resilience, maintaining their electrical performance even after repeated bending cycles. This durability is a significant advantage for applications in smart textiles, wearable devices, and other scenarios where the antenna may be subjected to frequent mechanical stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!