MXene's Role in Advanced Battery Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene in BMS: Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for advanced battery management systems (BMS). The development of MXene technology can be traced back to 2011 when it was first synthesized at Drexel University. Since then, MXene has garnered significant attention in the scientific community due to its unique properties, including high electrical conductivity, large surface area, and excellent mechanical strength.

The evolution of MXene in BMS applications has been driven by the increasing demand for more efficient and reliable energy storage systems. As the automotive industry shifts towards electrification and renewable energy sources become more prevalent, the need for advanced BMS has grown exponentially. MXene's potential in this field stems from its ability to enhance various aspects of battery performance, including energy density, charging speed, and overall lifespan.

One of the primary objectives in incorporating MXene into BMS is to improve the accuracy and responsiveness of battery monitoring systems. Traditional BMS often struggle with precise state-of-charge (SOC) and state-of-health (SOH) estimations, which are crucial for optimizing battery performance and longevity. MXene-based sensors and electrodes have shown promise in providing more accurate real-time data on battery conditions, enabling better decision-making in power management and predictive maintenance.

Another key goal is to enhance the thermal management capabilities of BMS. MXene's excellent thermal conductivity properties make it an ideal candidate for developing more efficient heat dissipation systems. This is particularly important in high-performance applications, such as electric vehicles, where thermal runaway can pose significant safety risks. By integrating MXene-based materials into cooling systems, researchers aim to improve overall battery safety and performance under various operating conditions.

Furthermore, the development of MXene in BMS seeks to address the growing concern of battery degradation and capacity fade. The material's unique structure and properties offer potential solutions for mitigating common issues such as dendrite formation and electrode degradation. By incorporating MXene into electrode designs or as protective coatings, researchers aim to extend battery life and maintain consistent performance over time.

As the technology continues to evolve, the ultimate objective is to create a new generation of BMS that can revolutionize energy storage systems across various applications. This includes not only improving the performance and reliability of existing battery technologies but also paving the way for the development of next-generation battery chemistries. The integration of MXene in BMS represents a significant step towards achieving more sustainable, efficient, and intelligent energy storage solutions for the future.

The evolution of MXene in BMS applications has been driven by the increasing demand for more efficient and reliable energy storage systems. As the automotive industry shifts towards electrification and renewable energy sources become more prevalent, the need for advanced BMS has grown exponentially. MXene's potential in this field stems from its ability to enhance various aspects of battery performance, including energy density, charging speed, and overall lifespan.

One of the primary objectives in incorporating MXene into BMS is to improve the accuracy and responsiveness of battery monitoring systems. Traditional BMS often struggle with precise state-of-charge (SOC) and state-of-health (SOH) estimations, which are crucial for optimizing battery performance and longevity. MXene-based sensors and electrodes have shown promise in providing more accurate real-time data on battery conditions, enabling better decision-making in power management and predictive maintenance.

Another key goal is to enhance the thermal management capabilities of BMS. MXene's excellent thermal conductivity properties make it an ideal candidate for developing more efficient heat dissipation systems. This is particularly important in high-performance applications, such as electric vehicles, where thermal runaway can pose significant safety risks. By integrating MXene-based materials into cooling systems, researchers aim to improve overall battery safety and performance under various operating conditions.

Furthermore, the development of MXene in BMS seeks to address the growing concern of battery degradation and capacity fade. The material's unique structure and properties offer potential solutions for mitigating common issues such as dendrite formation and electrode degradation. By incorporating MXene into electrode designs or as protective coatings, researchers aim to extend battery life and maintain consistent performance over time.

As the technology continues to evolve, the ultimate objective is to create a new generation of BMS that can revolutionize energy storage systems across various applications. This includes not only improving the performance and reliability of existing battery technologies but also paving the way for the development of next-generation battery chemistries. The integration of MXene in BMS represents a significant step towards achieving more sustainable, efficient, and intelligent energy storage solutions for the future.

Market Analysis for MXene-Enhanced BMS

The market for MXene-enhanced Battery Management Systems (BMS) is experiencing significant growth, driven by the increasing demand for high-performance energy storage solutions across various industries. MXene, a two-dimensional material with exceptional electrical conductivity and mechanical properties, has emerged as a promising candidate for improving BMS efficiency and capabilities.

The automotive sector represents a primary market for MXene-enhanced BMS, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs). As the global EV market continues to expand, the need for advanced BMS solutions that can optimize battery performance, extend range, and improve safety becomes paramount. MXene's ability to enhance thermal management and increase charge/discharge rates aligns well with these requirements, positioning it as a valuable component in next-generation BMS designs.

Beyond automotive applications, the renewable energy sector presents another substantial market opportunity for MXene-enhanced BMS. As solar and wind power installations grow, the demand for efficient energy storage systems increases. MXene's potential to improve the performance of grid-scale batteries and enhance their longevity makes it an attractive option for integrating renewable energy sources into existing power grids.

The consumer electronics industry also stands to benefit from MXene-enhanced BMS. With the ever-increasing power demands of smartphones, laptops, and wearable devices, manufacturers are seeking ways to improve battery life and charging speeds. MXene's properties could lead to more efficient power management systems, potentially extending device usage times and reducing charging intervals.

In the industrial sector, MXene-enhanced BMS could find applications in uninterruptible power supplies (UPS) and backup power systems. The material's ability to improve energy density and power output could result in more compact and efficient systems, crucial for data centers, hospitals, and other facilities requiring reliable power sources.

The aerospace and defense industries represent niche markets with high potential for MXene-enhanced BMS. These sectors demand high-performance, lightweight energy storage solutions for applications ranging from satellites to military equipment. MXene's unique properties could contribute to the development of advanced BMS tailored to these specialized needs.

While the market potential for MXene-enhanced BMS is substantial, it is important to note that the technology is still in its early stages of commercialization. Factors such as production scalability, cost-effectiveness, and long-term stability will play crucial roles in determining the extent of market penetration. As research and development efforts continue, and as more real-world applications demonstrate the benefits of MXene in BMS, the market is expected to expand further, potentially disrupting traditional BMS technologies and creating new opportunities across multiple industries.

The automotive sector represents a primary market for MXene-enhanced BMS, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs). As the global EV market continues to expand, the need for advanced BMS solutions that can optimize battery performance, extend range, and improve safety becomes paramount. MXene's ability to enhance thermal management and increase charge/discharge rates aligns well with these requirements, positioning it as a valuable component in next-generation BMS designs.

Beyond automotive applications, the renewable energy sector presents another substantial market opportunity for MXene-enhanced BMS. As solar and wind power installations grow, the demand for efficient energy storage systems increases. MXene's potential to improve the performance of grid-scale batteries and enhance their longevity makes it an attractive option for integrating renewable energy sources into existing power grids.

The consumer electronics industry also stands to benefit from MXene-enhanced BMS. With the ever-increasing power demands of smartphones, laptops, and wearable devices, manufacturers are seeking ways to improve battery life and charging speeds. MXene's properties could lead to more efficient power management systems, potentially extending device usage times and reducing charging intervals.

In the industrial sector, MXene-enhanced BMS could find applications in uninterruptible power supplies (UPS) and backup power systems. The material's ability to improve energy density and power output could result in more compact and efficient systems, crucial for data centers, hospitals, and other facilities requiring reliable power sources.

The aerospace and defense industries represent niche markets with high potential for MXene-enhanced BMS. These sectors demand high-performance, lightweight energy storage solutions for applications ranging from satellites to military equipment. MXene's unique properties could contribute to the development of advanced BMS tailored to these specialized needs.

While the market potential for MXene-enhanced BMS is substantial, it is important to note that the technology is still in its early stages of commercialization. Factors such as production scalability, cost-effectiveness, and long-term stability will play crucial roles in determining the extent of market penetration. As research and development efforts continue, and as more real-world applications demonstrate the benefits of MXene in BMS, the market is expected to expand further, potentially disrupting traditional BMS technologies and creating new opportunities across multiple industries.

Current Challenges in MXene BMS Integration

The integration of MXene into Battery Management Systems (BMS) presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the optimization of MXene's electrical conductivity within the BMS environment. While MXene exhibits excellent conductivity in isolation, maintaining this property when incorporated into complex battery systems requires careful engineering and material science considerations.

Another challenge lies in the long-term stability of MXene-enhanced BMS components. The harsh electrochemical environment inside batteries can potentially degrade MXene materials over time, affecting their performance and reliability. Researchers are working on developing protective coatings and stabilization techniques to mitigate this issue, but finding a balance between protection and maintaining MXene's beneficial properties remains a complex task.

The scalability of MXene production for large-scale BMS applications is also a significant hurdle. Current synthesis methods for high-quality MXene are often laboratory-scale processes, and scaling these up to meet industrial demands while maintaining material quality and cost-effectiveness is an ongoing challenge. This scalability issue directly impacts the feasibility of widespread MXene adoption in commercial BMS solutions.

Thermal management is another critical area where MXene integration faces challenges. While MXene shows promise in heat dissipation, effectively incorporating it into BMS designs to optimize thermal regulation without compromising other system components or adding excessive weight or complexity is a delicate balancing act.

Furthermore, the integration of MXene with existing BMS sensor technologies presents its own set of challenges. Ensuring compatibility and synergy between MXene-enhanced components and traditional BMS sensors, while leveraging MXene's unique properties to improve overall system performance, requires extensive research and development efforts.

Lastly, the environmental impact and recyclability of MXene-enhanced BMS components are areas of growing concern. As the battery industry moves towards more sustainable practices, developing eco-friendly production methods for MXene and designing BMS components that can be easily recycled or repurposed at the end of their lifecycle is becoming increasingly important. Addressing these environmental challenges is crucial for the long-term viability of MXene in BMS applications.

Another challenge lies in the long-term stability of MXene-enhanced BMS components. The harsh electrochemical environment inside batteries can potentially degrade MXene materials over time, affecting their performance and reliability. Researchers are working on developing protective coatings and stabilization techniques to mitigate this issue, but finding a balance between protection and maintaining MXene's beneficial properties remains a complex task.

The scalability of MXene production for large-scale BMS applications is also a significant hurdle. Current synthesis methods for high-quality MXene are often laboratory-scale processes, and scaling these up to meet industrial demands while maintaining material quality and cost-effectiveness is an ongoing challenge. This scalability issue directly impacts the feasibility of widespread MXene adoption in commercial BMS solutions.

Thermal management is another critical area where MXene integration faces challenges. While MXene shows promise in heat dissipation, effectively incorporating it into BMS designs to optimize thermal regulation without compromising other system components or adding excessive weight or complexity is a delicate balancing act.

Furthermore, the integration of MXene with existing BMS sensor technologies presents its own set of challenges. Ensuring compatibility and synergy between MXene-enhanced components and traditional BMS sensors, while leveraging MXene's unique properties to improve overall system performance, requires extensive research and development efforts.

Lastly, the environmental impact and recyclability of MXene-enhanced BMS components are areas of growing concern. As the battery industry moves towards more sustainable practices, developing eco-friendly production methods for MXene and designing BMS components that can be easily recycled or repurposed at the end of their lifecycle is becoming increasingly important. Addressing these environmental challenges is crucial for the long-term viability of MXene in BMS applications.

Existing MXene-Based BMS Solutions

01 MXene synthesis and composition

MXenes are two-dimensional transition metal carbides, nitrides, or carbonitrides with unique properties. They are typically synthesized by selective etching of MAX phases. The composition and structure of MXenes can be tailored for specific applications, offering a wide range of possibilities in material science and engineering.- MXene synthesis and composition: MXenes are a class of two-dimensional transition metal carbides, nitrides, or carbonitrides. They are synthesized by selective etching of MAX phases, resulting in layered structures with unique properties. The composition and synthesis methods can be tailored to achieve specific characteristics for various applications.

- Energy storage applications: MXenes show promising potential in energy storage devices such as supercapacitors and batteries. Their high electrical conductivity, large surface area, and ability to intercalate ions make them suitable for improving the performance of electrodes in these devices. Research focuses on optimizing MXene-based materials for enhanced energy density and cycling stability.

- Electromagnetic interference shielding: MXenes exhibit excellent electromagnetic interference (EMI) shielding properties due to their high electrical conductivity and ability to absorb electromagnetic waves. They can be incorporated into composites or coatings to provide effective EMI shielding in electronic devices and other applications where protection from electromagnetic radiation is crucial.

- Water purification and environmental applications: MXenes show potential in water purification and environmental remediation applications. Their high surface area and tunable surface chemistry allow for efficient adsorption of contaminants, including heavy metals and organic pollutants. Research explores the development of MXene-based membranes and adsorbents for water treatment and environmental cleanup.

- Biomedical applications: MXenes are being investigated for various biomedical applications, including drug delivery, biosensing, and tissue engineering. Their biocompatibility, photothermal properties, and ability to be functionalized make them promising candidates for developing advanced medical technologies. Research focuses on optimizing MXene-based materials for specific biomedical applications and addressing potential safety concerns.

02 Energy storage applications

MXenes show great potential in energy storage applications, particularly in supercapacitors and batteries. Their high electrical conductivity, large surface area, and ability to intercalate ions make them promising materials for improving energy density and charge-discharge rates in various energy storage devices.Expand Specific Solutions03 Electromagnetic interference shielding

MXenes exhibit excellent electromagnetic interference (EMI) shielding properties due to their high electrical conductivity and ability to absorb electromagnetic waves. This makes them suitable for use in electronic devices, aerospace applications, and other fields where EMI protection is crucial.Expand Specific Solutions04 Water purification and environmental applications

MXenes show promise in water purification and environmental remediation applications. Their large surface area and tunable surface chemistry allow for efficient adsorption of various contaminants, including heavy metals and organic pollutants, from water and other environmental matrices.Expand Specific Solutions05 Biomedical applications

MXenes are being explored for various biomedical applications, including drug delivery, biosensing, and tissue engineering. Their biocompatibility, photothermal properties, and ability to be functionalized with biomolecules make them attractive candidates for developing advanced medical technologies and treatments.Expand Specific Solutions

Key Players in MXene and BMS Industries

The MXene-based advanced battery management systems market is in its early growth stage, characterized by rapid technological advancements and increasing research interest. The market size is expanding, driven by the growing demand for high-performance energy storage solutions in various sectors. While the technology is still evolving, its potential for revolutionizing battery management has attracted significant attention from both academic institutions and industry players. Key research contributors include Shandong University, Jilin University, and Auburn University, who are actively exploring MXene's applications in battery systems. Companies like Chaowei Power Group and Hankook & Company are also investing in MXene-based technologies, indicating a growing industrial interest in commercializing these advanced battery management solutions.

Shandong University

Technical Solution: Shandong University has made significant strides in incorporating MXene into advanced battery management systems. Their research focuses on developing MXene-based composite materials for lithium-sulfur batteries, which are known for their high theoretical energy density. The university's team has created a novel MXene/sulfur composite cathode that addresses the common issues of sulfur shuttling and capacity fading in lithium-sulfur batteries[4]. By leveraging the high conductivity and large surface area of MXene, they have achieved improved sulfur utilization and enhanced cycling stability. Furthermore, Shandong University has explored the use of MXene as a protective layer for lithium metal anodes, which could potentially enable the development of high-energy-density lithium metal batteries with improved safety characteristics[5].

Strengths: Innovative approach to lithium-sulfur batteries, potential for high-energy-density systems, addressing key challenges in battery technology. Weaknesses: Lithium-sulfur technology still faces commercialization hurdles, long-term stability needs further improvement.

Auburn University

Technical Solution: Auburn University has been at the forefront of integrating MXene into advanced battery management systems, particularly focusing on its application in sodium-ion batteries. Their research team has developed a novel MXene-based electrode material that significantly enhances the performance of sodium-ion batteries, which are considered a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium[6]. The university's approach involves using MXene as a host material for sodium ions, taking advantage of its large interlayer spacing and high electrical conductivity. This has resulted in batteries with improved capacity retention and faster charging capabilities. Additionally, Auburn researchers have explored the use of MXene in battery thermal management systems, leveraging its excellent thermal conductivity to enhance heat dissipation and improve overall battery safety[7].

Strengths: Focus on cost-effective sodium-ion technology, improvements in capacity retention and charging speed, potential for enhanced battery safety. Weaknesses: Sodium-ion technology still lags behind lithium-ion in terms of energy density, commercialization challenges remain.

Core MXene Innovations for BMS

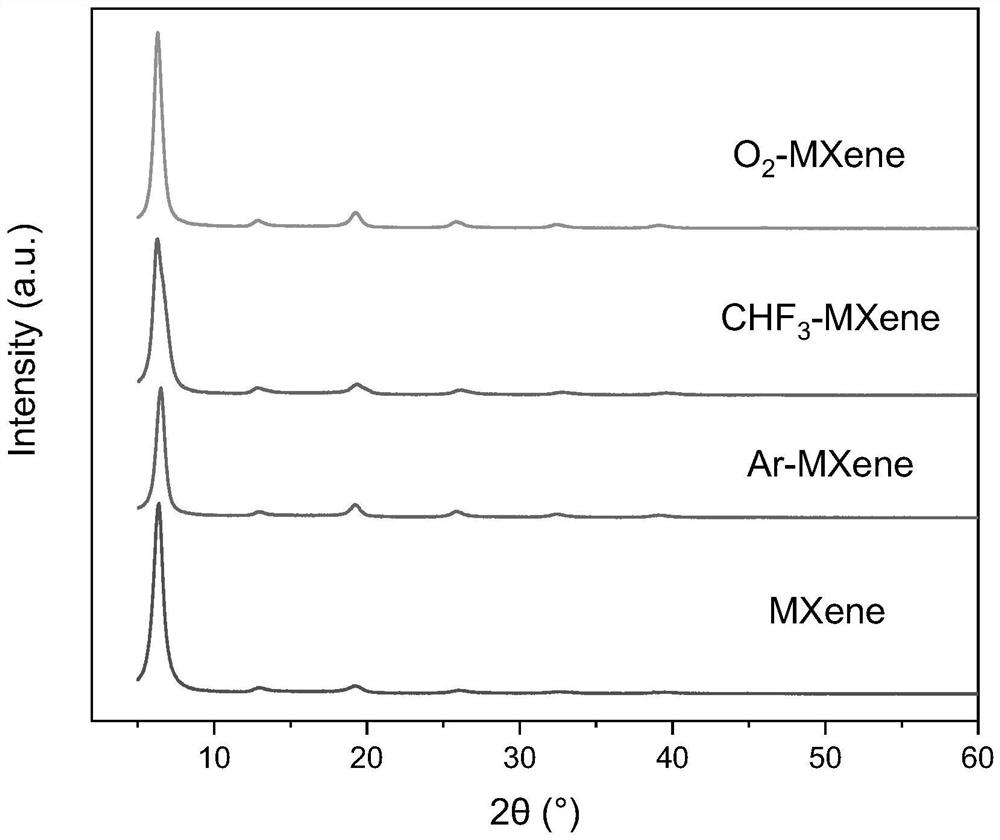

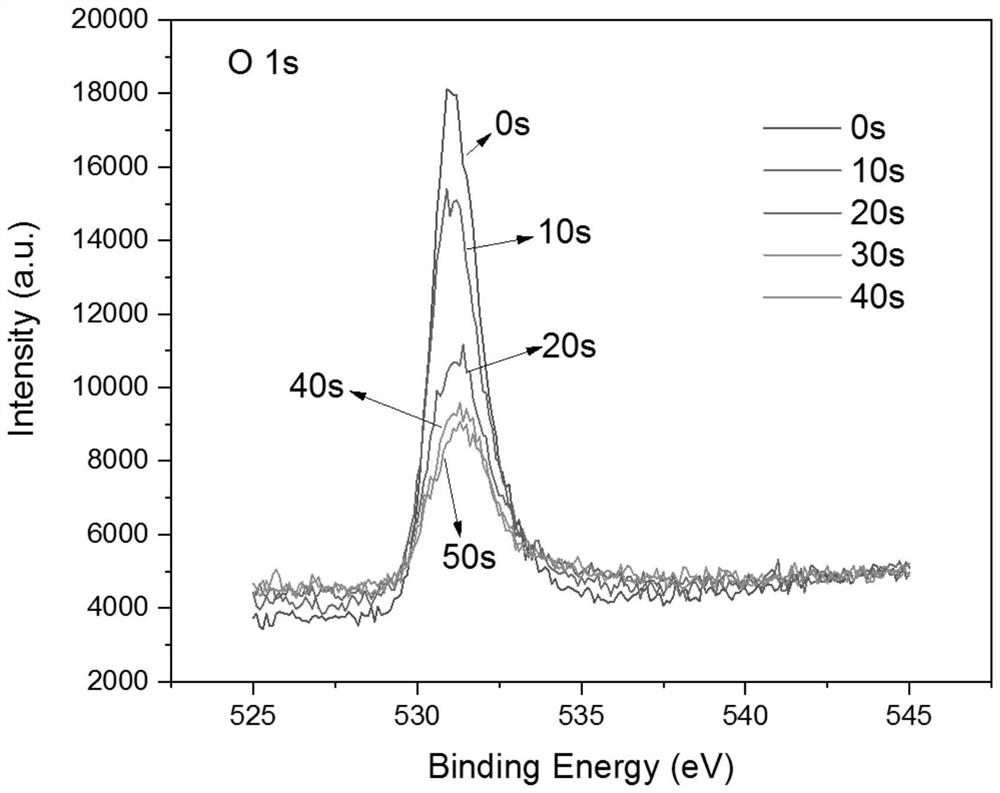

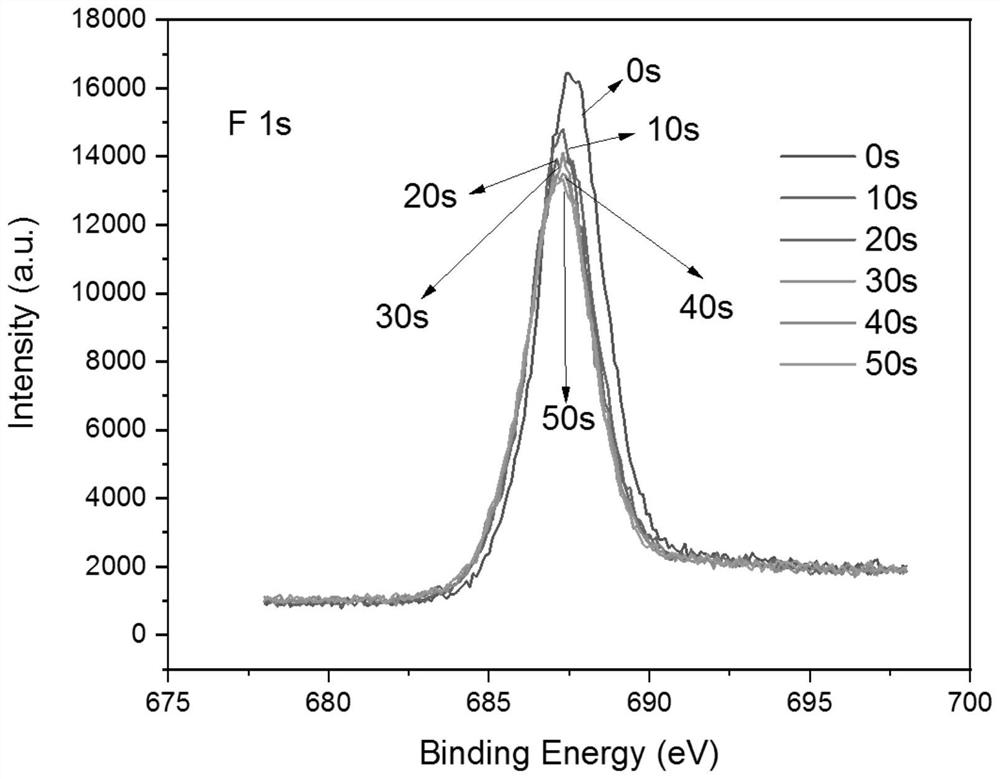

Highly ordered terminated MXene as well as preparation method and application thereof

PatentActiveCN114843700A

Innovation

- By preparing MXene powder and performing ultrasonic and centrifugal treatment, a self-supporting film is formed, and then high-energy plasma is used to react on the MXene surface during the plasma etching process to achieve highly ordered F, O, and N terminalization, replacing Disordered end groups form high-performance, highly ordered end-grouped MXenes.

A kind of lithium-sulfur battery cathode material

PatentActiveCN115000410B

Innovation

- Carbon nanotube-titanium carbide composite porous microspheres are used as sulfur carriers. The carbon nanotubes prevent the lamellar structure of the MXene material from collapsing and stacking, enhance the conductivity and physical barrier capabilities of the composite material, and reduce the dissolution and migration of polysulfides.

Environmental Impact of MXene in BMS

The integration of MXene in Battery Management Systems (BMS) presents both opportunities and challenges from an environmental perspective. MXene, a class of two-dimensional transition metal carbides and nitrides, offers promising advancements in energy storage and management. However, its environmental impact throughout the lifecycle of BMS applications requires careful consideration.

MXene's unique properties, such as high electrical conductivity and large surface area, contribute to improved battery performance and longevity. This enhancement in battery efficiency can lead to reduced energy consumption and fewer battery replacements, potentially decreasing the overall environmental footprint of electronic devices and electric vehicles.

The production process of MXene, however, raises some environmental concerns. The synthesis of MXene typically involves the use of hydrofluoric acid, a highly corrosive and toxic substance. Proper handling and disposal of this acid are crucial to prevent environmental contamination and ensure worker safety. Research into alternative, more environmentally friendly synthesis methods is ongoing, with some promising results using less hazardous etchants.

In BMS applications, MXene's ability to improve thermal management can indirectly benefit the environment. Better heat dissipation in batteries leads to increased efficiency and reduced risk of thermal runaway, potentially preventing catastrophic failures that could result in environmental hazards.

The end-of-life management of MXene-enhanced BMS components presents another environmental consideration. While MXene itself is not inherently toxic, the composite materials it forms with other battery components may complicate recycling processes. Developing effective recycling methods for MXene-containing materials is essential to minimize waste and recover valuable resources.

MXene's potential to enable faster charging and higher energy density in batteries could contribute to the wider adoption of electric vehicles and renewable energy storage systems. This shift towards cleaner energy technologies could have significant positive environmental impacts, reducing greenhouse gas emissions and dependence on fossil fuels.

However, the increased mining activities required to source raw materials for MXene production, particularly titanium, could lead to localized environmental degradation. Sustainable mining practices and efficient material utilization are crucial to mitigate these impacts.

In conclusion, while MXene shows promise in advancing BMS technology with potential environmental benefits, a holistic approach considering its entire lifecycle is necessary to ensure its sustainable integration. Ongoing research and development should focus not only on performance enhancements but also on minimizing environmental impacts throughout production, use, and disposal phases.

MXene's unique properties, such as high electrical conductivity and large surface area, contribute to improved battery performance and longevity. This enhancement in battery efficiency can lead to reduced energy consumption and fewer battery replacements, potentially decreasing the overall environmental footprint of electronic devices and electric vehicles.

The production process of MXene, however, raises some environmental concerns. The synthesis of MXene typically involves the use of hydrofluoric acid, a highly corrosive and toxic substance. Proper handling and disposal of this acid are crucial to prevent environmental contamination and ensure worker safety. Research into alternative, more environmentally friendly synthesis methods is ongoing, with some promising results using less hazardous etchants.

In BMS applications, MXene's ability to improve thermal management can indirectly benefit the environment. Better heat dissipation in batteries leads to increased efficiency and reduced risk of thermal runaway, potentially preventing catastrophic failures that could result in environmental hazards.

The end-of-life management of MXene-enhanced BMS components presents another environmental consideration. While MXene itself is not inherently toxic, the composite materials it forms with other battery components may complicate recycling processes. Developing effective recycling methods for MXene-containing materials is essential to minimize waste and recover valuable resources.

MXene's potential to enable faster charging and higher energy density in batteries could contribute to the wider adoption of electric vehicles and renewable energy storage systems. This shift towards cleaner energy technologies could have significant positive environmental impacts, reducing greenhouse gas emissions and dependence on fossil fuels.

However, the increased mining activities required to source raw materials for MXene production, particularly titanium, could lead to localized environmental degradation. Sustainable mining practices and efficient material utilization are crucial to mitigate these impacts.

In conclusion, while MXene shows promise in advancing BMS technology with potential environmental benefits, a holistic approach considering its entire lifecycle is necessary to ensure its sustainable integration. Ongoing research and development should focus not only on performance enhancements but also on minimizing environmental impacts throughout production, use, and disposal phases.

Scalability of MXene BMS Technologies

The scalability of MXene-based Battery Management System (BMS) technologies is a critical factor in determining their potential for widespread adoption in advanced energy storage applications. As MXene materials continue to demonstrate promising properties for enhancing battery performance, the ability to scale up production and integration processes becomes increasingly important.

One of the primary challenges in scaling MXene BMS technologies lies in the synthesis of high-quality MXene materials in large quantities. Current lab-scale production methods, such as selective etching of MAX phases, may not be directly transferable to industrial-scale manufacturing. Researchers are exploring alternative synthesis routes, including chemical vapor deposition and electrochemical exfoliation, to overcome these limitations and achieve consistent, large-scale MXene production.

Integration of MXene materials into existing BMS architectures presents another scalability hurdle. While MXene-enhanced sensors and electrodes have shown excellent performance in laboratory settings, translating these improvements to commercial BMS products requires careful consideration of manufacturing processes, cost-effectiveness, and compatibility with current battery technologies.

The scalability of MXene-based BMS also depends on the availability and cost of raw materials. As demand for MXene materials increases, securing a stable supply chain for precursor materials, such as titanium and aluminum, becomes crucial. Additionally, the environmental impact and sustainability of large-scale MXene production must be addressed to ensure long-term viability.

Advancements in MXene processing techniques are contributing to improved scalability. Researchers are developing methods for creating MXene inks and films that can be easily incorporated into existing manufacturing processes. These developments are paving the way for roll-to-roll production of MXene-based components, which could significantly enhance the scalability of MXene BMS technologies.

The scalability of MXene BMS technologies is also influenced by the adaptability of the material to different battery chemistries and form factors. As the energy storage landscape evolves, MXene-based BMS solutions must be versatile enough to accommodate various battery types, from traditional lithium-ion to emerging solid-state and flexible batteries.

Collaboration between academic institutions, material suppliers, and battery manufacturers is crucial for addressing scalability challenges. Joint research efforts and industry partnerships are accelerating the development of scalable production methods and integration techniques for MXene-based BMS technologies. These collaborations are essential for bridging the gap between laboratory discoveries and commercial applications.

One of the primary challenges in scaling MXene BMS technologies lies in the synthesis of high-quality MXene materials in large quantities. Current lab-scale production methods, such as selective etching of MAX phases, may not be directly transferable to industrial-scale manufacturing. Researchers are exploring alternative synthesis routes, including chemical vapor deposition and electrochemical exfoliation, to overcome these limitations and achieve consistent, large-scale MXene production.

Integration of MXene materials into existing BMS architectures presents another scalability hurdle. While MXene-enhanced sensors and electrodes have shown excellent performance in laboratory settings, translating these improvements to commercial BMS products requires careful consideration of manufacturing processes, cost-effectiveness, and compatibility with current battery technologies.

The scalability of MXene-based BMS also depends on the availability and cost of raw materials. As demand for MXene materials increases, securing a stable supply chain for precursor materials, such as titanium and aluminum, becomes crucial. Additionally, the environmental impact and sustainability of large-scale MXene production must be addressed to ensure long-term viability.

Advancements in MXene processing techniques are contributing to improved scalability. Researchers are developing methods for creating MXene inks and films that can be easily incorporated into existing manufacturing processes. These developments are paving the way for roll-to-roll production of MXene-based components, which could significantly enhance the scalability of MXene BMS technologies.

The scalability of MXene BMS technologies is also influenced by the adaptability of the material to different battery chemistries and form factors. As the energy storage landscape evolves, MXene-based BMS solutions must be versatile enough to accommodate various battery types, from traditional lithium-ion to emerging solid-state and flexible batteries.

Collaboration between academic institutions, material suppliers, and battery manufacturers is crucial for addressing scalability challenges. Joint research efforts and industry partnerships are accelerating the development of scalable production methods and integration techniques for MXene-based BMS technologies. These collaborations are essential for bridging the gap between laboratory discoveries and commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!