Structural Design of MXene for Thermal Management Systems

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Thermal Management Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for thermal management systems due to its unique structural and thermal properties. The development of MXene-based thermal management solutions has gained significant attention in recent years, driven by the increasing demand for efficient heat dissipation in various applications, including electronics, aerospace, and energy storage.

The evolution of MXene technology can be traced back to its discovery in 2011 by researchers at Drexel University. Since then, the field has witnessed rapid growth, with researchers exploring various synthesis methods, structural modifications, and applications. The primary objective of MXene thermal management research is to harness the material's exceptional thermal conductivity, which can exceed that of many traditional heat-dissipating materials, while maintaining its flexibility and scalability.

As electronic devices continue to shrink in size and increase in power density, the need for innovative thermal management solutions becomes more critical. MXene's potential to address these challenges lies in its unique layered structure, which allows for efficient heat transfer along its two-dimensional planes. This characteristic, combined with its high electrical conductivity and mechanical strength, makes MXene an ideal candidate for next-generation thermal management systems.

The current technological landscape for MXene thermal management focuses on several key areas. These include the development of MXene-based thermal interface materials, heat spreaders, and composites for enhanced thermal conductivity. Researchers are also exploring the integration of MXene into existing thermal management systems to improve their overall performance and efficiency.

One of the primary goals in MXene thermal management research is to optimize the material's structure for maximum heat dissipation. This involves tailoring the composition, thickness, and surface functionalization of MXene sheets to enhance their thermal properties. Additionally, efforts are being made to develop scalable production methods that can maintain the material's superior thermal characteristics while enabling large-scale manufacturing for commercial applications.

The objectives of MXene thermal management research extend beyond material optimization. There is a growing focus on understanding the fundamental heat transfer mechanisms in MXene-based systems, which is crucial for designing more effective thermal management solutions. Furthermore, researchers aim to develop multifunctional MXene materials that can simultaneously address thermal management and other performance requirements, such as electromagnetic shielding or energy storage.

As the field progresses, there is an increasing emphasis on the environmental sustainability and cost-effectiveness of MXene-based thermal management systems. This includes exploring eco-friendly synthesis methods and investigating the potential for recycling and reusing MXene materials at the end of their lifecycle. These considerations are essential for ensuring the long-term viability and widespread adoption of MXene technology in thermal management applications.

The evolution of MXene technology can be traced back to its discovery in 2011 by researchers at Drexel University. Since then, the field has witnessed rapid growth, with researchers exploring various synthesis methods, structural modifications, and applications. The primary objective of MXene thermal management research is to harness the material's exceptional thermal conductivity, which can exceed that of many traditional heat-dissipating materials, while maintaining its flexibility and scalability.

As electronic devices continue to shrink in size and increase in power density, the need for innovative thermal management solutions becomes more critical. MXene's potential to address these challenges lies in its unique layered structure, which allows for efficient heat transfer along its two-dimensional planes. This characteristic, combined with its high electrical conductivity and mechanical strength, makes MXene an ideal candidate for next-generation thermal management systems.

The current technological landscape for MXene thermal management focuses on several key areas. These include the development of MXene-based thermal interface materials, heat spreaders, and composites for enhanced thermal conductivity. Researchers are also exploring the integration of MXene into existing thermal management systems to improve their overall performance and efficiency.

One of the primary goals in MXene thermal management research is to optimize the material's structure for maximum heat dissipation. This involves tailoring the composition, thickness, and surface functionalization of MXene sheets to enhance their thermal properties. Additionally, efforts are being made to develop scalable production methods that can maintain the material's superior thermal characteristics while enabling large-scale manufacturing for commercial applications.

The objectives of MXene thermal management research extend beyond material optimization. There is a growing focus on understanding the fundamental heat transfer mechanisms in MXene-based systems, which is crucial for designing more effective thermal management solutions. Furthermore, researchers aim to develop multifunctional MXene materials that can simultaneously address thermal management and other performance requirements, such as electromagnetic shielding or energy storage.

As the field progresses, there is an increasing emphasis on the environmental sustainability and cost-effectiveness of MXene-based thermal management systems. This includes exploring eco-friendly synthesis methods and investigating the potential for recycling and reusing MXene materials at the end of their lifecycle. These considerations are essential for ensuring the long-term viability and widespread adoption of MXene technology in thermal management applications.

Market Analysis for MXene-based Thermal Solutions

The market for MXene-based thermal management solutions is experiencing rapid growth, driven by the increasing demand for efficient heat dissipation in various industries. As electronic devices become more compact and powerful, the need for advanced thermal management systems has become critical. MXene, a two-dimensional material with exceptional thermal properties, has emerged as a promising candidate for addressing these challenges.

The global thermal management market is projected to reach significant value in the coming years, with MXene-based solutions poised to capture a substantial share. The automotive sector, particularly electric vehicles, represents a key market for MXene thermal management systems. As the automotive industry shifts towards electrification, the demand for efficient battery thermal management solutions is expected to surge, creating opportunities for MXene-based products.

In the consumer electronics sector, MXene thermal management solutions are gaining traction due to their ability to enhance device performance and longevity. Smartphones, laptops, and wearable devices are prime targets for MXene integration, as manufacturers seek to improve heat dissipation in increasingly powerful and compact designs. The growing adoption of 5G technology and the Internet of Things (IoT) is further fueling the demand for advanced thermal management solutions.

The aerospace and defense industries are also showing interest in MXene-based thermal management systems. The material's lightweight nature and superior thermal conductivity make it an attractive option for applications in aircraft, satellites, and military equipment. As these sectors continue to prioritize performance and efficiency, the market for MXene solutions is expected to expand.

Data centers and high-performance computing facilities represent another significant market opportunity for MXene thermal management systems. With the exponential growth of data processing and storage requirements, efficient cooling solutions are crucial for maintaining optimal performance and reducing energy consumption. MXene's ability to provide effective heat dissipation in compact spaces aligns well with the needs of this sector.

The industrial sector, including manufacturing and energy production, is also exploring MXene-based thermal management solutions. Applications in power electronics, industrial machinery, and renewable energy systems are driving demand for advanced heat dissipation technologies. MXene's versatility and adaptability make it suitable for a wide range of industrial applications, contributing to market growth.

As research and development in MXene technology continue to advance, new applications and market opportunities are likely to emerge. The material's potential for integration with existing thermal management systems and its ability to be tailored for specific applications are expected to drive further market expansion. However, challenges such as scalability of production and cost-effectiveness need to be addressed to fully realize the market potential of MXene-based thermal management solutions.

The global thermal management market is projected to reach significant value in the coming years, with MXene-based solutions poised to capture a substantial share. The automotive sector, particularly electric vehicles, represents a key market for MXene thermal management systems. As the automotive industry shifts towards electrification, the demand for efficient battery thermal management solutions is expected to surge, creating opportunities for MXene-based products.

In the consumer electronics sector, MXene thermal management solutions are gaining traction due to their ability to enhance device performance and longevity. Smartphones, laptops, and wearable devices are prime targets for MXene integration, as manufacturers seek to improve heat dissipation in increasingly powerful and compact designs. The growing adoption of 5G technology and the Internet of Things (IoT) is further fueling the demand for advanced thermal management solutions.

The aerospace and defense industries are also showing interest in MXene-based thermal management systems. The material's lightweight nature and superior thermal conductivity make it an attractive option for applications in aircraft, satellites, and military equipment. As these sectors continue to prioritize performance and efficiency, the market for MXene solutions is expected to expand.

Data centers and high-performance computing facilities represent another significant market opportunity for MXene thermal management systems. With the exponential growth of data processing and storage requirements, efficient cooling solutions are crucial for maintaining optimal performance and reducing energy consumption. MXene's ability to provide effective heat dissipation in compact spaces aligns well with the needs of this sector.

The industrial sector, including manufacturing and energy production, is also exploring MXene-based thermal management solutions. Applications in power electronics, industrial machinery, and renewable energy systems are driving demand for advanced heat dissipation technologies. MXene's versatility and adaptability make it suitable for a wide range of industrial applications, contributing to market growth.

As research and development in MXene technology continue to advance, new applications and market opportunities are likely to emerge. The material's potential for integration with existing thermal management systems and its ability to be tailored for specific applications are expected to drive further market expansion. However, challenges such as scalability of production and cost-effectiveness need to be addressed to fully realize the market potential of MXene-based thermal management solutions.

MXene Structural Design Challenges

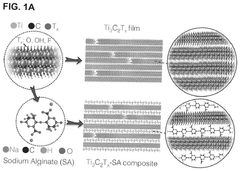

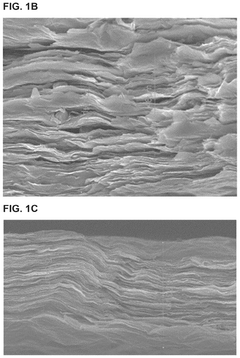

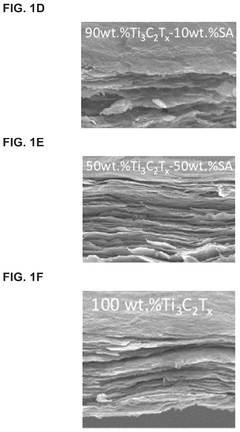

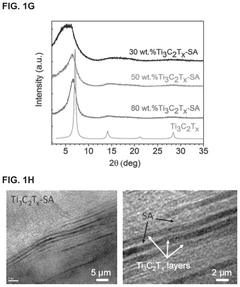

The structural design of MXene for thermal management systems presents several significant challenges that researchers and engineers must address to fully harness the potential of these two-dimensional materials. One of the primary obstacles is controlling the interlayer spacing and alignment of MXene sheets. The thermal conductivity and heat dissipation properties of MXene-based systems are highly dependent on the arrangement of individual layers, and achieving precise control over this aspect remains difficult.

Another challenge lies in the development of scalable and cost-effective production methods for MXene structures with specific thermal management properties. While laboratory-scale synthesis techniques have shown promising results, translating these processes to industrial-scale production while maintaining consistent quality and performance is a complex task. This includes optimizing the exfoliation and delamination processes to produce MXene sheets with uniform thickness and lateral dimensions.

The stability of MXene structures in various environmental conditions poses another significant hurdle. MXene materials can be sensitive to oxidation and degradation when exposed to air or moisture, which can compromise their thermal management capabilities over time. Developing effective encapsulation or surface modification techniques to enhance the long-term stability of MXene-based thermal management systems is crucial for practical applications.

Interface engineering between MXene and other materials in composite structures is another critical challenge. Maximizing thermal transport across material interfaces while minimizing thermal boundary resistance requires careful consideration of surface chemistry and bonding mechanisms. This is particularly important when integrating MXene into existing thermal management solutions or developing hybrid systems.

The anisotropic nature of MXene's thermal properties also presents design challenges. While in-plane thermal conductivity is typically high, out-of-plane thermal transport can be significantly lower. Developing strategies to optimize heat flow in three dimensions, such as creating aligned structures or introducing thermal bridges, is essential for maximizing the overall thermal management performance of MXene-based systems.

Lastly, the mechanical properties of MXene structures must be carefully balanced with their thermal performance. Ensuring that MXene-based thermal management systems maintain their structural integrity and flexibility under various operating conditions, including thermal cycling and mechanical stress, is crucial for their practical implementation in real-world applications.

Another challenge lies in the development of scalable and cost-effective production methods for MXene structures with specific thermal management properties. While laboratory-scale synthesis techniques have shown promising results, translating these processes to industrial-scale production while maintaining consistent quality and performance is a complex task. This includes optimizing the exfoliation and delamination processes to produce MXene sheets with uniform thickness and lateral dimensions.

The stability of MXene structures in various environmental conditions poses another significant hurdle. MXene materials can be sensitive to oxidation and degradation when exposed to air or moisture, which can compromise their thermal management capabilities over time. Developing effective encapsulation or surface modification techniques to enhance the long-term stability of MXene-based thermal management systems is crucial for practical applications.

Interface engineering between MXene and other materials in composite structures is another critical challenge. Maximizing thermal transport across material interfaces while minimizing thermal boundary resistance requires careful consideration of surface chemistry and bonding mechanisms. This is particularly important when integrating MXene into existing thermal management solutions or developing hybrid systems.

The anisotropic nature of MXene's thermal properties also presents design challenges. While in-plane thermal conductivity is typically high, out-of-plane thermal transport can be significantly lower. Developing strategies to optimize heat flow in three dimensions, such as creating aligned structures or introducing thermal bridges, is essential for maximizing the overall thermal management performance of MXene-based systems.

Lastly, the mechanical properties of MXene structures must be carefully balanced with their thermal performance. Ensuring that MXene-based thermal management systems maintain their structural integrity and flexibility under various operating conditions, including thermal cycling and mechanical stress, is crucial for their practical implementation in real-world applications.

Current MXene Structural Design Approaches

01 MXene-based thermal management materials

MXene materials are being developed for thermal management applications due to their excellent thermal conductivity and unique 2D structure. These materials can be incorporated into various composites or coatings to enhance heat dissipation in electronic devices, batteries, and other thermal management systems.- MXene-based thermal management materials: MXene materials are being developed for thermal management applications due to their excellent thermal conductivity and unique 2D structure. These materials can be incorporated into various composites or coatings to enhance heat dissipation in electronic devices, batteries, and other high-temperature environments.

- MXene-polymer composites for heat dissipation: Researchers are developing MXene-polymer composites that combine the thermal properties of MXenes with the processability of polymers. These composites can be used in flexible thermal interface materials, heat spreaders, and thermally conductive coatings for improved thermal management in electronic devices and energy storage systems.

- MXene-based phase change materials: MXenes are being incorporated into phase change materials to enhance their thermal energy storage and heat transfer capabilities. These advanced materials can be used in thermal management systems for buildings, solar energy storage, and temperature regulation in electronic devices.

- MXene coatings for thermal management: Thin MXene coatings are being developed for thermal management applications. These coatings can be applied to various surfaces to improve heat dissipation, protect against thermal damage, and enhance the overall thermal performance of devices and structures in aerospace, automotive, and electronics industries.

- MXene-based thermal interface materials: MXenes are being utilized in the development of advanced thermal interface materials. These materials aim to improve thermal conductivity between heat-generating components and heat sinks in electronic devices, leading to more efficient heat dissipation and better overall thermal management in compact electronic systems.

02 MXene-polymer composites for heat dissipation

Researchers are developing MXene-polymer composites that combine the thermal properties of MXenes with the processability of polymers. These composites can be used in flexible thermal interface materials, heat spreaders, and thermal management coatings for various applications in electronics and energy storage devices.Expand Specific Solutions03 MXene-based phase change materials

MXenes are being incorporated into phase change materials to enhance their thermal energy storage and management capabilities. These advanced materials can be used in smart building materials, thermal energy storage systems, and temperature regulation devices for improved energy efficiency and thermal comfort.Expand Specific Solutions04 MXene-enhanced thermal interface materials

MXenes are being used to improve the performance of thermal interface materials, which are crucial for efficient heat transfer between electronic components and heat sinks. These enhanced thermal interface materials can significantly reduce thermal resistance and improve overall thermal management in electronic devices and power systems.Expand Specific Solutions05 MXene-based coatings for thermal management

Researchers are developing MXene-based coatings that can be applied to various surfaces to enhance their thermal management properties. These coatings can provide improved heat dissipation, thermal insulation, or thermal energy harvesting capabilities, depending on the specific application requirements.Expand Specific Solutions

Key Players in MXene Research and Industry

The structural design of MXene for thermal management systems is an emerging field in advanced materials research, currently in its early development stage. The market for MXene-based thermal management solutions is growing, driven by increasing demand for efficient heat dissipation in electronics and energy systems. While the technology is still maturing, several key players are making significant strides. Universities like Huazhong University of Science & Technology and Korea Advanced Institute of Science & Technology are leading academic research, while companies such as Murata Manufacturing Co. Ltd. and First Line Technology LLC are exploring commercial applications. The involvement of diverse institutions, from academic to industrial, indicates a competitive landscape with potential for rapid advancements in MXene-based thermal management technologies.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed innovative MXene-based thermal management systems. Their approach involves engineering the structural design of MXene to enhance its thermal properties. They have created MXene/polymer composites with aligned MXene flakes, achieving a thermal conductivity of up to 12.5 W/m·K[1]. This represents a significant improvement over traditional polymer materials. The university has also explored the use of MXene in phase change materials (PCMs) for thermal energy storage, demonstrating a 45% increase in thermal conductivity compared to pure PCMs[2]. Additionally, they have investigated the potential of MXene-based coatings for electronic devices, showing a 20% reduction in device operating temperatures[3].

Strengths: High thermal conductivity, versatile applications in composites and coatings, improved energy storage capabilities. Weaknesses: Potential high production costs, scalability challenges for large-scale manufacturing.

Shandong University

Technical Solution: Shandong University has made significant strides in the structural design of MXene for thermal management systems. Their research focuses on creating hierarchical MXene structures to maximize thermal performance. They have developed a novel freeze-drying method to produce 3D MXene aerogels with a thermal conductivity of 35.5 W/m·K, which is among the highest reported for MXene-based materials[4]. The university has also explored the integration of MXene into flexible thermal interface materials, achieving a 200% improvement in through-plane thermal conductivity compared to conventional materials[5]. Furthermore, they have investigated the use of MXene in heat spreaders for electronic devices, demonstrating a 30% reduction in hotspot temperatures[6].

Strengths: Exceptional thermal conductivity in 3D structures, adaptability for flexible electronics, significant improvements in heat dissipation. Weaknesses: Potential issues with long-term stability, need for further optimization of production processes.

Innovative MXene Architectures for Heat Dissipation

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact of MXene-based Cooling Systems

The environmental impact of MXene-based cooling systems is a critical consideration in the development and implementation of these advanced thermal management solutions. MXene, a class of two-dimensional transition metal carbides and nitrides, has shown promising potential in enhancing the efficiency of cooling systems. However, the widespread adoption of MXene-based cooling technologies necessitates a comprehensive assessment of their environmental implications.

One of the primary environmental benefits of MXene-based cooling systems is their potential to significantly reduce energy consumption. The high thermal conductivity and unique properties of MXene materials enable more efficient heat dissipation, potentially leading to reduced power requirements for cooling applications. This energy efficiency can translate into lower greenhouse gas emissions associated with electricity generation, contributing to climate change mitigation efforts.

The production process of MXene materials, however, raises some environmental concerns. The synthesis of MXene typically involves the use of strong acids and etching agents, which can generate hazardous waste if not properly managed. Additionally, the production of precursor materials, such as MAX phases, may have its own environmental footprint. It is crucial to develop and implement sustainable manufacturing processes that minimize waste generation and optimize resource utilization throughout the MXene production chain.

The durability and lifecycle of MXene-based cooling systems also play a role in their overall environmental impact. If these systems demonstrate enhanced longevity compared to conventional cooling technologies, they could reduce the frequency of replacements and associated waste generation. However, the end-of-life management of MXene-containing products requires careful consideration. Developing effective recycling and disposal methods for MXene materials is essential to prevent potential environmental contamination and recover valuable resources.

Water consumption is another aspect to consider in the environmental assessment of MXene-based cooling systems. While these systems may offer improved thermal management efficiency, their impact on water resources, particularly in water-intensive applications, needs to be evaluated. Optimizing water usage and exploring closed-loop cooling designs could help mitigate potential strain on local water supplies.

The potential for MXene materials to leach into the environment during the operation or disposal of cooling systems is an area that requires thorough investigation. Understanding the environmental fate and potential ecological impacts of MXene particles is crucial for ensuring the long-term sustainability of these technologies. Research into the bioaccumulation and toxicity of MXene in various ecosystems is necessary to inform risk assessment and management strategies.

In conclusion, while MXene-based cooling systems offer promising environmental benefits through enhanced energy efficiency, a holistic approach to their environmental impact is essential. This includes addressing challenges in sustainable production, responsible use of resources, and effective end-of-life management. Continued research and development efforts should focus on optimizing the environmental performance of MXene-based cooling technologies throughout their lifecycle, ensuring that their adoption aligns with broader sustainability goals.

One of the primary environmental benefits of MXene-based cooling systems is their potential to significantly reduce energy consumption. The high thermal conductivity and unique properties of MXene materials enable more efficient heat dissipation, potentially leading to reduced power requirements for cooling applications. This energy efficiency can translate into lower greenhouse gas emissions associated with electricity generation, contributing to climate change mitigation efforts.

The production process of MXene materials, however, raises some environmental concerns. The synthesis of MXene typically involves the use of strong acids and etching agents, which can generate hazardous waste if not properly managed. Additionally, the production of precursor materials, such as MAX phases, may have its own environmental footprint. It is crucial to develop and implement sustainable manufacturing processes that minimize waste generation and optimize resource utilization throughout the MXene production chain.

The durability and lifecycle of MXene-based cooling systems also play a role in their overall environmental impact. If these systems demonstrate enhanced longevity compared to conventional cooling technologies, they could reduce the frequency of replacements and associated waste generation. However, the end-of-life management of MXene-containing products requires careful consideration. Developing effective recycling and disposal methods for MXene materials is essential to prevent potential environmental contamination and recover valuable resources.

Water consumption is another aspect to consider in the environmental assessment of MXene-based cooling systems. While these systems may offer improved thermal management efficiency, their impact on water resources, particularly in water-intensive applications, needs to be evaluated. Optimizing water usage and exploring closed-loop cooling designs could help mitigate potential strain on local water supplies.

The potential for MXene materials to leach into the environment during the operation or disposal of cooling systems is an area that requires thorough investigation. Understanding the environmental fate and potential ecological impacts of MXene particles is crucial for ensuring the long-term sustainability of these technologies. Research into the bioaccumulation and toxicity of MXene in various ecosystems is necessary to inform risk assessment and management strategies.

In conclusion, while MXene-based cooling systems offer promising environmental benefits through enhanced energy efficiency, a holistic approach to their environmental impact is essential. This includes addressing challenges in sustainable production, responsible use of resources, and effective end-of-life management. Continued research and development efforts should focus on optimizing the environmental performance of MXene-based cooling technologies throughout their lifecycle, ensuring that their adoption aligns with broader sustainability goals.

MXene Integration in Electronic Devices

The integration of MXene in electronic devices represents a significant advancement in thermal management systems. MXene, a two-dimensional transition metal carbide or nitride, has garnered substantial attention due to its exceptional thermal conductivity and flexibility. These properties make it an ideal candidate for addressing the thermal challenges faced by modern electronic devices, which are becoming increasingly compact and powerful.

In the realm of electronic device integration, MXene films and coatings have shown remarkable potential. When applied to heat-generating components such as processors or power amplifiers, MXene can efficiently dissipate heat, preventing thermal throttling and extending device lifespan. The nanoscale thickness of MXene allows for seamless integration without significantly altering device dimensions, a crucial factor in maintaining the sleek profiles of contemporary electronics.

One of the most promising applications of MXene in electronic devices is in the development of advanced thermal interface materials (TIMs). Traditional TIMs often suffer from limited thermal conductivity and poor long-term stability. MXene-based TIMs, however, demonstrate superior thermal conductivity and maintain their performance over extended periods, even under thermal cycling conditions. This makes them particularly suitable for high-performance computing systems and data centers, where consistent thermal management is critical.

MXene's flexibility also opens up new possibilities in the realm of flexible and wearable electronics. As these devices often lack conventional cooling mechanisms, the integration of MXene can provide effective heat dissipation without compromising the device's flexibility. This is particularly valuable in applications such as smart textiles, where thermal management must be achieved without rigid components.

Furthermore, MXene's compatibility with various substrates and its ability to be processed into different forms (such as aerogels, films, or composites) allow for versatile integration strategies. This adaptability enables tailored thermal management solutions for a wide range of electronic devices, from smartphones to automotive electronics.

However, challenges remain in the large-scale integration of MXene in electronic devices. Issues such as long-term stability, cost-effective production, and standardization of integration processes need to be addressed. Ongoing research is focused on optimizing MXene synthesis methods, improving its environmental stability, and developing scalable manufacturing techniques for MXene-based thermal management components.

In the realm of electronic device integration, MXene films and coatings have shown remarkable potential. When applied to heat-generating components such as processors or power amplifiers, MXene can efficiently dissipate heat, preventing thermal throttling and extending device lifespan. The nanoscale thickness of MXene allows for seamless integration without significantly altering device dimensions, a crucial factor in maintaining the sleek profiles of contemporary electronics.

One of the most promising applications of MXene in electronic devices is in the development of advanced thermal interface materials (TIMs). Traditional TIMs often suffer from limited thermal conductivity and poor long-term stability. MXene-based TIMs, however, demonstrate superior thermal conductivity and maintain their performance over extended periods, even under thermal cycling conditions. This makes them particularly suitable for high-performance computing systems and data centers, where consistent thermal management is critical.

MXene's flexibility also opens up new possibilities in the realm of flexible and wearable electronics. As these devices often lack conventional cooling mechanisms, the integration of MXene can provide effective heat dissipation without compromising the device's flexibility. This is particularly valuable in applications such as smart textiles, where thermal management must be achieved without rigid components.

Furthermore, MXene's compatibility with various substrates and its ability to be processed into different forms (such as aerogels, films, or composites) allow for versatile integration strategies. This adaptability enables tailored thermal management solutions for a wide range of electronic devices, from smartphones to automotive electronics.

However, challenges remain in the large-scale integration of MXene in electronic devices. Issues such as long-term stability, cost-effective production, and standardization of integration processes need to be addressed. Ongoing research is focused on optimizing MXene synthesis methods, improving its environmental stability, and developing scalable manufacturing techniques for MXene-based thermal management components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!