MXene Applications in High-Resolution Printing Technologies

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Printing Background

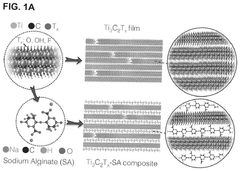

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for various applications, including high-resolution printing technologies. The journey of MXene in printing began with its discovery in 2011 by researchers at Drexel University. Since then, MXene has garnered significant attention due to its unique properties, such as high electrical conductivity, mechanical strength, and tunable surface chemistry.

The evolution of MXene in printing technologies has been driven by the increasing demand for flexible, wearable, and high-performance electronic devices. Traditional printing methods often face limitations in terms of resolution, conductivity, and compatibility with various substrates. MXene's exceptional properties have positioned it as a potential solution to these challenges, opening up new possibilities in the field of printed electronics.

MXene's layered structure and high surface area make it particularly suitable for ink formulations. The ability to exfoliate MXene into nanosheets allows for the creation of stable colloidal suspensions, which can be easily processed into printable inks. This characteristic has led to the development of MXene-based inks for various printing techniques, including inkjet printing, screen printing, and aerosol jet printing.

The primary goal of incorporating MXene in high-resolution printing technologies is to achieve superior performance in printed electronic components. Researchers aim to leverage MXene's high electrical conductivity to create conductive patterns with enhanced resolution and reduced resistance. Additionally, the material's mechanical flexibility and stability make it an attractive option for flexible and stretchable electronics, which are crucial for next-generation wearable devices and sensors.

Another significant aspect of MXene's application in printing is its potential for scalability and cost-effectiveness. As a relatively new material, efforts are being made to optimize synthesis methods and ink formulations to ensure large-scale production feasibility. The ability to print MXene-based electronic components using conventional printing techniques could lead to more accessible and affordable manufacturing processes for advanced electronic devices.

The integration of MXene in high-resolution printing technologies also aligns with the broader trend of sustainable and environmentally friendly manufacturing. MXene's water-based ink formulations offer a more eco-friendly alternative to traditional solvent-based inks, addressing growing concerns about environmental impact in the electronics industry.

The evolution of MXene in printing technologies has been driven by the increasing demand for flexible, wearable, and high-performance electronic devices. Traditional printing methods often face limitations in terms of resolution, conductivity, and compatibility with various substrates. MXene's exceptional properties have positioned it as a potential solution to these challenges, opening up new possibilities in the field of printed electronics.

MXene's layered structure and high surface area make it particularly suitable for ink formulations. The ability to exfoliate MXene into nanosheets allows for the creation of stable colloidal suspensions, which can be easily processed into printable inks. This characteristic has led to the development of MXene-based inks for various printing techniques, including inkjet printing, screen printing, and aerosol jet printing.

The primary goal of incorporating MXene in high-resolution printing technologies is to achieve superior performance in printed electronic components. Researchers aim to leverage MXene's high electrical conductivity to create conductive patterns with enhanced resolution and reduced resistance. Additionally, the material's mechanical flexibility and stability make it an attractive option for flexible and stretchable electronics, which are crucial for next-generation wearable devices and sensors.

Another significant aspect of MXene's application in printing is its potential for scalability and cost-effectiveness. As a relatively new material, efforts are being made to optimize synthesis methods and ink formulations to ensure large-scale production feasibility. The ability to print MXene-based electronic components using conventional printing techniques could lead to more accessible and affordable manufacturing processes for advanced electronic devices.

The integration of MXene in high-resolution printing technologies also aligns with the broader trend of sustainable and environmentally friendly manufacturing. MXene's water-based ink formulations offer a more eco-friendly alternative to traditional solvent-based inks, addressing growing concerns about environmental impact in the electronics industry.

Market Demand Analysis

The market demand for high-resolution printing technologies has been steadily growing, driven by various industries seeking advanced manufacturing processes and improved product quality. MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for high-resolution printing applications, attracting significant attention from both academia and industry.

In the electronics sector, there is a strong demand for MXene-based high-resolution printing technologies. The miniaturization trend in consumer electronics, coupled with the need for flexible and wearable devices, has created a market for printed electronics with higher resolution and improved performance. MXene's excellent electrical conductivity and mechanical flexibility make it an ideal candidate for printing conductive patterns, sensors, and electrodes for various electronic components.

The energy storage industry also shows considerable interest in MXene applications for high-resolution printing. As the demand for more efficient and compact energy storage devices grows, manufacturers are exploring ways to print high-performance electrodes and other components for batteries and supercapacitors. MXene's high surface area and rapid ion transport properties make it particularly attractive for these applications, potentially leading to improved energy density and faster charging capabilities.

In the biomedical field, there is an increasing need for high-resolution printing technologies to fabricate biosensors, drug delivery systems, and tissue engineering scaffolds. MXene's biocompatibility and unique surface chemistry offer opportunities for creating precisely controlled structures at the micro and nanoscale, which could revolutionize personalized medicine and diagnostic tools.

The aerospace and automotive industries are also potential markets for MXene-based high-resolution printing technologies. These sectors require lightweight, high-strength materials with multifunctional properties. MXene's ability to be printed into complex structures while maintaining excellent mechanical and electrical properties could lead to the development of advanced composite materials and smart coatings for vehicles and aircraft.

Furthermore, the additive manufacturing industry is continuously seeking new materials to expand the capabilities of 3D printing. MXene's printability and unique properties make it an attractive option for creating high-resolution 3D structures with enhanced functionality, potentially opening up new applications in rapid prototyping and customized manufacturing.

As environmental concerns grow, there is also a market demand for sustainable and eco-friendly printing technologies. MXene's water-based processing and potential for recyclability align well with this trend, making it an attractive option for companies looking to reduce their environmental footprint while maintaining high-quality printing capabilities.

In the electronics sector, there is a strong demand for MXene-based high-resolution printing technologies. The miniaturization trend in consumer electronics, coupled with the need for flexible and wearable devices, has created a market for printed electronics with higher resolution and improved performance. MXene's excellent electrical conductivity and mechanical flexibility make it an ideal candidate for printing conductive patterns, sensors, and electrodes for various electronic components.

The energy storage industry also shows considerable interest in MXene applications for high-resolution printing. As the demand for more efficient and compact energy storage devices grows, manufacturers are exploring ways to print high-performance electrodes and other components for batteries and supercapacitors. MXene's high surface area and rapid ion transport properties make it particularly attractive for these applications, potentially leading to improved energy density and faster charging capabilities.

In the biomedical field, there is an increasing need for high-resolution printing technologies to fabricate biosensors, drug delivery systems, and tissue engineering scaffolds. MXene's biocompatibility and unique surface chemistry offer opportunities for creating precisely controlled structures at the micro and nanoscale, which could revolutionize personalized medicine and diagnostic tools.

The aerospace and automotive industries are also potential markets for MXene-based high-resolution printing technologies. These sectors require lightweight, high-strength materials with multifunctional properties. MXene's ability to be printed into complex structures while maintaining excellent mechanical and electrical properties could lead to the development of advanced composite materials and smart coatings for vehicles and aircraft.

Furthermore, the additive manufacturing industry is continuously seeking new materials to expand the capabilities of 3D printing. MXene's printability and unique properties make it an attractive option for creating high-resolution 3D structures with enhanced functionality, potentially opening up new applications in rapid prototyping and customized manufacturing.

As environmental concerns grow, there is also a market demand for sustainable and eco-friendly printing technologies. MXene's water-based processing and potential for recyclability align well with this trend, making it an attractive option for companies looking to reduce their environmental footprint while maintaining high-quality printing capabilities.

MXene Printing Challenges

Despite the promising potential of MXene in high-resolution printing technologies, several significant challenges hinder its widespread adoption and application. One of the primary obstacles is the difficulty in achieving stable MXene ink formulations. MXene's unique two-dimensional structure and surface chemistry make it prone to aggregation and sedimentation, which can lead to clogging of printer nozzles and inconsistent print quality. Developing ink formulations that maintain MXene's dispersion stability over extended periods while preserving its exceptional properties remains a complex task.

Another critical challenge lies in controlling the rheological properties of MXene inks. The viscosity and surface tension of the ink must be precisely tuned to ensure compatibility with various printing techniques, such as inkjet, screen, and gravure printing. Achieving the right balance between fluidity for smooth printing and rapid solidification for high-resolution output is crucial. Moreover, the interaction between MXene particles and the substrate surface plays a vital role in print quality and adhesion, necessitating careful consideration of surface treatments and ink composition.

The oxidation sensitivity of MXene presents yet another hurdle in printing applications. MXene's tendency to oxidize when exposed to air or moisture can lead to degradation of its electrical and mechanical properties. This vulnerability necessitates the development of effective encapsulation methods or the incorporation of stabilizing agents to preserve MXene's performance in printed devices. Balancing these protective measures with the need to maintain MXene's functionality and printability adds another layer of complexity to ink formulation.

Scaling up MXene production for large-scale printing applications poses significant challenges. Current synthesis methods for high-quality MXene are often limited in yield and can be time-consuming. Developing efficient, cost-effective production techniques that maintain MXene's quality and consistency at industrial scales is crucial for its commercial viability in printing technologies. Additionally, ensuring uniform dispersion and preventing restacking of MXene sheets during the printing process becomes increasingly challenging as production volumes increase.

Lastly, the environmental stability and long-term performance of printed MXene structures remain areas of concern. MXene-based printed devices must withstand various environmental conditions, including temperature fluctuations, humidity, and mechanical stress, without significant degradation in performance. Developing strategies to enhance the durability and reliability of MXene prints, such as protective coatings or composite formulations, is essential for realizing their potential in practical applications. Addressing these multifaceted challenges requires interdisciplinary collaboration and innovative approaches to unlock the full potential of MXene in high-resolution printing technologies.

Another critical challenge lies in controlling the rheological properties of MXene inks. The viscosity and surface tension of the ink must be precisely tuned to ensure compatibility with various printing techniques, such as inkjet, screen, and gravure printing. Achieving the right balance between fluidity for smooth printing and rapid solidification for high-resolution output is crucial. Moreover, the interaction between MXene particles and the substrate surface plays a vital role in print quality and adhesion, necessitating careful consideration of surface treatments and ink composition.

The oxidation sensitivity of MXene presents yet another hurdle in printing applications. MXene's tendency to oxidize when exposed to air or moisture can lead to degradation of its electrical and mechanical properties. This vulnerability necessitates the development of effective encapsulation methods or the incorporation of stabilizing agents to preserve MXene's performance in printed devices. Balancing these protective measures with the need to maintain MXene's functionality and printability adds another layer of complexity to ink formulation.

Scaling up MXene production for large-scale printing applications poses significant challenges. Current synthesis methods for high-quality MXene are often limited in yield and can be time-consuming. Developing efficient, cost-effective production techniques that maintain MXene's quality and consistency at industrial scales is crucial for its commercial viability in printing technologies. Additionally, ensuring uniform dispersion and preventing restacking of MXene sheets during the printing process becomes increasingly challenging as production volumes increase.

Lastly, the environmental stability and long-term performance of printed MXene structures remain areas of concern. MXene-based printed devices must withstand various environmental conditions, including temperature fluctuations, humidity, and mechanical stress, without significant degradation in performance. Developing strategies to enhance the durability and reliability of MXene prints, such as protective coatings or composite formulations, is essential for realizing their potential in practical applications. Addressing these multifaceted challenges requires interdisciplinary collaboration and innovative approaches to unlock the full potential of MXene in high-resolution printing technologies.

Current MXene Solutions

01 Synthesis and preparation of MXene materials

Various methods for synthesizing and preparing MXene materials with improved resolution and properties. This includes techniques for exfoliation, etching, and surface modification to enhance the structural and functional characteristics of MXenes.- Synthesis and preparation of MXene materials: Various methods for synthesizing and preparing MXene materials are described, including etching processes, exfoliation techniques, and optimization of reaction conditions to achieve desired MXene structures and properties. These processes aim to control the thickness, size, and composition of MXene sheets for specific applications.

- MXene-based composites and nanostructures: Development of MXene-based composites and nanostructures by combining MXenes with other materials such as polymers, metals, or carbon-based materials. These composites aim to enhance the mechanical, electrical, or thermal properties of MXenes for applications in energy storage, sensing, and electromagnetic shielding.

- Surface functionalization and modification of MXenes: Techniques for modifying the surface of MXene sheets through functionalization or chemical treatments to tailor their properties for specific applications. This includes introducing functional groups, doping with heteroatoms, or creating defects to enhance reactivity, selectivity, or compatibility with other materials.

- MXene-based energy storage devices: Application of MXenes in energy storage devices such as supercapacitors, batteries, and fuel cells. The high conductivity, large surface area, and tunable properties of MXenes make them promising materials for improving the performance and efficiency of various energy storage systems.

- MXene-based sensors and electronic devices: Utilization of MXenes in the development of sensors and electronic devices, leveraging their unique electrical and optical properties. This includes applications in gas sensing, biosensing, flexible electronics, and electromagnetic interference shielding, where MXenes offer advantages in sensitivity, selectivity, and miniaturization.

02 MXene-based composites and nanostructures

Development of MXene-based composites and nanostructures with enhanced resolution and performance. This involves combining MXenes with other materials to create hybrid structures with improved electrical, mechanical, or optical properties.Expand Specific Solutions03 MXene applications in energy storage and conversion

Utilization of MXenes in energy storage and conversion devices with high resolution and efficiency. This includes applications in supercapacitors, batteries, and fuel cells, leveraging the unique properties of MXenes to enhance device performance.Expand Specific Solutions04 MXene-based sensors and electronic devices

Integration of MXenes into sensors and electronic devices with improved resolution and sensitivity. This involves developing MXene-based components for various sensing applications and electronic systems, exploiting the material's conductivity and surface properties.Expand Specific Solutions05 Functionalization and surface modification of MXenes

Techniques for functionalizing and modifying the surface of MXenes to enhance their resolution and tailor their properties for specific applications. This includes chemical treatments and surface engineering methods to improve the material's performance and compatibility with other systems.Expand Specific Solutions

Key Industry Players

The MXene applications in high-resolution printing technologies market is in its early growth stage, characterized by rapid technological advancements and expanding applications. The market size is projected to grow significantly due to MXene's unique properties and versatility in printing. While the technology is still evolving, it shows promising maturity in certain areas. Key players driving innovation include academic institutions like Drexel University, Wuhan University of Technology, and Huazhong University of Science & Technology, alongside industry leaders such as Murata Manufacturing Co. Ltd. These organizations are actively researching and developing MXene-based printing solutions, indicating a competitive landscape with both academic and commercial interests vying for technological breakthroughs and market share.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has made significant advancements in MXene applications for high-resolution printing technologies. Their research focuses on developing novel MXene-based composite inks that enhance both conductivity and printability[8]. They have successfully created a MXene/silver nanoparticle hybrid ink that achieves high resolution (up to 5 micrometers) and excellent conductivity in printed patterns[9]. The university has also explored the use of MXene inks in 3D printing, developing a method to create hierarchical porous structures with applications in energy storage and catalysis[10]. Additionally, they have investigated the use of MXene-based inks for printing flexible and stretchable electronics, demonstrating devices that maintain performance under mechanical deformation[11].

Strengths: Strong focus on MXene composite materials, expertise in both 2D and 3D printing techniques, and innovative approaches to enhancing MXene ink properties. Weaknesses: Potential challenges in scaling up production and translating research findings into commercial applications.

Drexel University

Technical Solution: Drexel University has pioneered the development of MXene materials for high-resolution printing technologies. Their approach involves creating MXene inks with optimized rheological properties for various printing methods, including inkjet and screen printing[1]. They have successfully demonstrated the fabrication of highly conductive and flexible MXene-based printed electronics with resolutions down to 20 micrometers[2]. The university has also developed a method for producing aerosol-jet printable MXene inks, enabling 3D printing of complex MXene structures with feature sizes as small as 10 micrometers[3]. Additionally, Drexel researchers have explored the use of MXene inks for printing energy storage devices, such as microsupercapacitors, with high capacitance and excellent cycling stability[4].

Strengths: Cutting-edge research in MXene synthesis and ink formulation, expertise in multiple printing techniques, and proven track record in creating high-performance printed devices. Weaknesses: Potential challenges in scaling up production and commercialization of MXene-based printing technologies.

MXene Printing Innovations

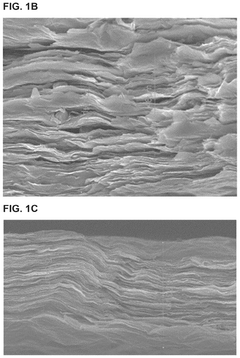

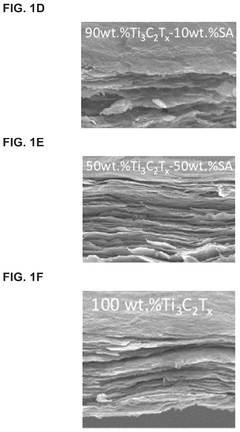

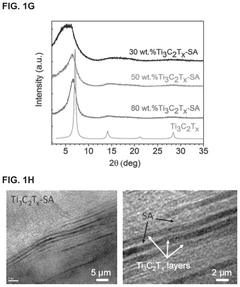

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact

The environmental impact of MXene applications in high-resolution printing technologies is a critical aspect that requires thorough consideration. MXenes, as two-dimensional transition metal carbides and nitrides, offer unique properties that make them promising for advanced printing applications. However, their production, use, and disposal can have significant environmental implications.

The synthesis of MXenes typically involves the use of strong acids and etching processes, which can generate hazardous waste and potentially harmful byproducts. These processes may contribute to water pollution and soil contamination if not properly managed. Additionally, the production of MXenes often requires energy-intensive procedures, potentially increasing the carbon footprint associated with their manufacturing.

On the positive side, MXene-based inks for high-resolution printing technologies can lead to more efficient and precise printing processes. This efficiency can result in reduced material waste and lower energy consumption during printing operations. The durability and stability of MXene-based printed materials may also contribute to longer-lasting products, potentially reducing the need for frequent replacements and minimizing overall waste generation.

The use of MXenes in printing technologies may also have implications for the recyclability and end-of-life management of printed products. While MXenes themselves are generally considered non-toxic, their integration into complex printed structures may complicate recycling processes. Research is needed to develop effective recycling methods for MXene-containing printed materials to ensure proper resource recovery and minimize environmental impact.

Furthermore, the potential release of MXene nanoparticles into the environment during the lifecycle of printed products raises concerns about their ecological effects. Studies on the environmental fate and behavior of MXenes are still limited, and more research is required to understand their long-term impacts on ecosystems and human health.

To address these environmental challenges, researchers and industry stakeholders are exploring green synthesis methods for MXenes, aiming to reduce the use of harsh chemicals and minimize waste generation. Additionally, efforts are being made to optimize MXene-based ink formulations to enhance their biodegradability and recyclability without compromising performance in high-resolution printing applications.

The synthesis of MXenes typically involves the use of strong acids and etching processes, which can generate hazardous waste and potentially harmful byproducts. These processes may contribute to water pollution and soil contamination if not properly managed. Additionally, the production of MXenes often requires energy-intensive procedures, potentially increasing the carbon footprint associated with their manufacturing.

On the positive side, MXene-based inks for high-resolution printing technologies can lead to more efficient and precise printing processes. This efficiency can result in reduced material waste and lower energy consumption during printing operations. The durability and stability of MXene-based printed materials may also contribute to longer-lasting products, potentially reducing the need for frequent replacements and minimizing overall waste generation.

The use of MXenes in printing technologies may also have implications for the recyclability and end-of-life management of printed products. While MXenes themselves are generally considered non-toxic, their integration into complex printed structures may complicate recycling processes. Research is needed to develop effective recycling methods for MXene-containing printed materials to ensure proper resource recovery and minimize environmental impact.

Furthermore, the potential release of MXene nanoparticles into the environment during the lifecycle of printed products raises concerns about their ecological effects. Studies on the environmental fate and behavior of MXenes are still limited, and more research is required to understand their long-term impacts on ecosystems and human health.

To address these environmental challenges, researchers and industry stakeholders are exploring green synthesis methods for MXenes, aiming to reduce the use of harsh chemicals and minimize waste generation. Additionally, efforts are being made to optimize MXene-based ink formulations to enhance their biodegradability and recyclability without compromising performance in high-resolution printing applications.

Scalability Assessment

The scalability of MXene applications in high-resolution printing technologies is a critical factor in determining their potential for widespread industrial adoption. Current research indicates promising results in laboratory settings, but significant challenges remain in scaling up production for commercial use.

One of the primary scalability concerns is the synthesis of MXene materials in large quantities while maintaining consistent quality and properties. The exfoliation process, which is crucial for producing two-dimensional MXene sheets, can be time-consuming and difficult to scale. Researchers are exploring various methods to optimize this process, including chemical and electrochemical exfoliation techniques that could potentially be adapted for large-scale production.

Another key aspect of scalability is the development of stable MXene inks suitable for high-resolution printing. The rheological properties of these inks must be carefully controlled to ensure compatibility with various printing techniques, such as inkjet, screen, and gravure printing. Achieving the right balance of viscosity, surface tension, and particle size distribution is essential for maintaining print quality at industrial scales.

The integration of MXene-based inks into existing printing infrastructure presents both opportunities and challenges. While MXenes show compatibility with many conventional printing methods, modifications to equipment and processes may be necessary to accommodate their unique properties. This could require significant investment in new or adapted machinery, potentially slowing widespread adoption.

Environmental stability is another crucial factor in scaling MXene applications. MXenes are known to be sensitive to oxidation, which can degrade their performance over time. Developing effective encapsulation methods or stabilizing additives that can withstand industrial processing conditions is vital for ensuring the long-term viability of MXene-printed products.

Cost considerations play a significant role in scalability assessment. While MXenes offer superior performance in many applications, their production costs must be competitive with existing materials to justify large-scale adoption. Efforts to reduce synthesis costs and improve material efficiency are ongoing, with researchers exploring alternative precursors and optimizing production processes.

Lastly, the scalability of MXene applications in high-resolution printing technologies depends on addressing regulatory and safety concerns. As production scales up, thorough assessments of environmental impact and potential health risks associated with MXene manufacturing and use will be necessary to ensure compliance with industry standards and regulations.

One of the primary scalability concerns is the synthesis of MXene materials in large quantities while maintaining consistent quality and properties. The exfoliation process, which is crucial for producing two-dimensional MXene sheets, can be time-consuming and difficult to scale. Researchers are exploring various methods to optimize this process, including chemical and electrochemical exfoliation techniques that could potentially be adapted for large-scale production.

Another key aspect of scalability is the development of stable MXene inks suitable for high-resolution printing. The rheological properties of these inks must be carefully controlled to ensure compatibility with various printing techniques, such as inkjet, screen, and gravure printing. Achieving the right balance of viscosity, surface tension, and particle size distribution is essential for maintaining print quality at industrial scales.

The integration of MXene-based inks into existing printing infrastructure presents both opportunities and challenges. While MXenes show compatibility with many conventional printing methods, modifications to equipment and processes may be necessary to accommodate their unique properties. This could require significant investment in new or adapted machinery, potentially slowing widespread adoption.

Environmental stability is another crucial factor in scaling MXene applications. MXenes are known to be sensitive to oxidation, which can degrade their performance over time. Developing effective encapsulation methods or stabilizing additives that can withstand industrial processing conditions is vital for ensuring the long-term viability of MXene-printed products.

Cost considerations play a significant role in scalability assessment. While MXenes offer superior performance in many applications, their production costs must be competitive with existing materials to justify large-scale adoption. Efforts to reduce synthesis costs and improve material efficiency are ongoing, with researchers exploring alternative precursors and optimizing production processes.

Lastly, the scalability of MXene applications in high-resolution printing technologies depends on addressing regulatory and safety concerns. As production scales up, thorough assessments of environmental impact and potential health risks associated with MXene manufacturing and use will be necessary to ensure compliance with industry standards and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!