MXene’s Role in Enhanced Voltage Controllers

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for various applications, including energy storage and electronic devices. The development of MXene can be traced back to 2011 when it was first synthesized by researchers at Drexel University. Since then, MXene has garnered significant attention due to its unique properties, such as high electrical conductivity, mechanical strength, and surface functionality.

The evolution of MXene technology has been rapid, with researchers exploring its potential in diverse fields. In the context of voltage controllers, MXene's role has become increasingly important due to its exceptional electronic properties. The material's ability to conduct electricity efficiently while maintaining structural integrity makes it an ideal candidate for enhancing the performance of voltage control systems.

The primary objective of incorporating MXene into voltage controllers is to improve their overall efficiency, responsiveness, and stability. By leveraging MXene's unique characteristics, researchers aim to develop next-generation voltage control devices that can operate at higher frequencies, handle larger power loads, and exhibit improved thermal management capabilities.

One of the key trends in MXene research for voltage control applications is the development of hybrid materials that combine MXene with other advanced materials. This approach seeks to synergize the strengths of different materials, potentially leading to breakthroughs in voltage controller performance. Additionally, there is a growing focus on scalable production methods for MXene, as large-scale availability is crucial for its widespread adoption in commercial voltage control systems.

The technical goals for MXene in enhanced voltage controllers include achieving higher power density, reducing energy losses, and improving the overall reliability of the control systems. Researchers are also exploring ways to tailor MXene's properties through surface modifications and compositional variations to optimize its performance in specific voltage control applications.

As the field progresses, interdisciplinary collaboration between materials scientists, electrical engineers, and device manufacturers is becoming increasingly important. This collaborative approach is expected to accelerate the development of MXene-based voltage controllers and facilitate their integration into real-world applications, such as power grids, electric vehicles, and renewable energy systems.

The evolution of MXene technology has been rapid, with researchers exploring its potential in diverse fields. In the context of voltage controllers, MXene's role has become increasingly important due to its exceptional electronic properties. The material's ability to conduct electricity efficiently while maintaining structural integrity makes it an ideal candidate for enhancing the performance of voltage control systems.

The primary objective of incorporating MXene into voltage controllers is to improve their overall efficiency, responsiveness, and stability. By leveraging MXene's unique characteristics, researchers aim to develop next-generation voltage control devices that can operate at higher frequencies, handle larger power loads, and exhibit improved thermal management capabilities.

One of the key trends in MXene research for voltage control applications is the development of hybrid materials that combine MXene with other advanced materials. This approach seeks to synergize the strengths of different materials, potentially leading to breakthroughs in voltage controller performance. Additionally, there is a growing focus on scalable production methods for MXene, as large-scale availability is crucial for its widespread adoption in commercial voltage control systems.

The technical goals for MXene in enhanced voltage controllers include achieving higher power density, reducing energy losses, and improving the overall reliability of the control systems. Researchers are also exploring ways to tailor MXene's properties through surface modifications and compositional variations to optimize its performance in specific voltage control applications.

As the field progresses, interdisciplinary collaboration between materials scientists, electrical engineers, and device manufacturers is becoming increasingly important. This collaborative approach is expected to accelerate the development of MXene-based voltage controllers and facilitate their integration into real-world applications, such as power grids, electric vehicles, and renewable energy systems.

Market Demand Analysis

The market demand for enhanced voltage controllers incorporating MXene technology is experiencing significant growth, driven by the increasing need for efficient and reliable power management systems across various industries. As energy consumption continues to rise globally, there is a growing emphasis on optimizing power distribution and control, particularly in sectors such as renewable energy, electric vehicles, and smart grid systems.

MXene-based voltage controllers offer several advantages over traditional solutions, including improved energy efficiency, faster response times, and enhanced stability. These benefits have sparked interest from both established players and emerging companies in the power electronics market. The automotive industry, in particular, has shown keen interest in MXene-enhanced voltage controllers for electric and hybrid vehicles, as they can potentially improve battery performance and extend driving range.

The renewable energy sector is another key driver of market demand for MXene-enhanced voltage controllers. As solar and wind power installations continue to expand worldwide, there is an increasing need for advanced power management solutions that can handle the intermittent nature of these energy sources. MXene-based controllers offer the potential to improve grid stability and optimize energy storage systems, making them attractive for large-scale renewable energy projects.

In the industrial sector, the demand for more precise and efficient voltage control is growing, especially in manufacturing processes that require high-precision equipment. MXene-enhanced controllers can provide better voltage regulation and faster response times, leading to improved product quality and reduced energy waste. This has led to increased interest from industries such as semiconductor manufacturing, aerospace, and advanced materials production.

The telecommunications industry is also emerging as a potential market for MXene-enhanced voltage controllers. With the ongoing rollout of 5G networks and the increasing power demands of data centers, there is a growing need for more efficient and reliable power management solutions. MXene-based controllers could help address these challenges by offering improved performance and energy efficiency in telecommunications infrastructure.

While the market potential for MXene-enhanced voltage controllers is significant, it is important to note that the technology is still in its early stages of commercialization. As research and development efforts continue to advance, it is expected that the market demand will further increase as more applications and use cases are identified. The growing focus on sustainability and energy efficiency across industries is likely to be a key driver of this demand in the coming years.

MXene-based voltage controllers offer several advantages over traditional solutions, including improved energy efficiency, faster response times, and enhanced stability. These benefits have sparked interest from both established players and emerging companies in the power electronics market. The automotive industry, in particular, has shown keen interest in MXene-enhanced voltage controllers for electric and hybrid vehicles, as they can potentially improve battery performance and extend driving range.

The renewable energy sector is another key driver of market demand for MXene-enhanced voltage controllers. As solar and wind power installations continue to expand worldwide, there is an increasing need for advanced power management solutions that can handle the intermittent nature of these energy sources. MXene-based controllers offer the potential to improve grid stability and optimize energy storage systems, making them attractive for large-scale renewable energy projects.

In the industrial sector, the demand for more precise and efficient voltage control is growing, especially in manufacturing processes that require high-precision equipment. MXene-enhanced controllers can provide better voltage regulation and faster response times, leading to improved product quality and reduced energy waste. This has led to increased interest from industries such as semiconductor manufacturing, aerospace, and advanced materials production.

The telecommunications industry is also emerging as a potential market for MXene-enhanced voltage controllers. With the ongoing rollout of 5G networks and the increasing power demands of data centers, there is a growing need for more efficient and reliable power management solutions. MXene-based controllers could help address these challenges by offering improved performance and energy efficiency in telecommunications infrastructure.

While the market potential for MXene-enhanced voltage controllers is significant, it is important to note that the technology is still in its early stages of commercialization. As research and development efforts continue to advance, it is expected that the market demand will further increase as more applications and use cases are identified. The growing focus on sustainability and energy efficiency across industries is likely to be a key driver of this demand in the coming years.

MXene Technology Status

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for enhancing voltage controllers. The current technology status of MXene in this application is characterized by rapid advancements and growing interest from both academia and industry.

MXenes have demonstrated exceptional electrical conductivity, high surface area, and tunable surface chemistry, making them ideal candidates for improving the performance of voltage controllers. Recent research has shown that MXene-based electrodes can significantly enhance the response time and stability of voltage control systems.

One of the key developments in MXene technology for voltage controllers is the synthesis of high-quality, large-scale MXene sheets. Researchers have made substantial progress in optimizing the exfoliation and delamination processes, resulting in MXene flakes with improved uniformity and reduced defects. This advancement has directly contributed to the enhanced performance of MXene-based voltage control devices.

The integration of MXenes into existing voltage controller architectures has been a focus of recent studies. Scientists have successfully incorporated MXene layers into various electrode configurations, demonstrating improved voltage regulation capabilities. These hybrid systems have shown enhanced charge storage capacity and faster voltage response times compared to conventional materials.

Another significant area of progress is the functionalization of MXene surfaces to tailor their properties for specific voltage control applications. By modifying the surface chemistry of MXenes, researchers have been able to optimize their interaction with electrolytes and improve their overall performance in voltage regulation tasks.

The scalability of MXene production has also seen notable improvements. Several research groups and companies have developed methods for large-scale synthesis of MXenes, paving the way for their commercial application in voltage controllers. This progress has addressed one of the major challenges in MXene technology adoption.

Recent studies have explored the use of MXenes in flexible and wearable voltage control devices. The unique mechanical properties of MXenes, combined with their excellent electrical characteristics, have enabled the development of highly efficient and durable flexible voltage controllers.

Despite these advancements, challenges remain in fully realizing the potential of MXenes in voltage control applications. Issues such as long-term stability, cost-effective production, and integration with existing manufacturing processes are active areas of research and development.

In conclusion, the current technology status of MXene in enhanced voltage controllers is marked by significant progress and promising results. The material's unique properties and ongoing research efforts suggest a bright future for MXene-based voltage control systems, with potential applications ranging from energy storage to advanced electronics.

MXenes have demonstrated exceptional electrical conductivity, high surface area, and tunable surface chemistry, making them ideal candidates for improving the performance of voltage controllers. Recent research has shown that MXene-based electrodes can significantly enhance the response time and stability of voltage control systems.

One of the key developments in MXene technology for voltage controllers is the synthesis of high-quality, large-scale MXene sheets. Researchers have made substantial progress in optimizing the exfoliation and delamination processes, resulting in MXene flakes with improved uniformity and reduced defects. This advancement has directly contributed to the enhanced performance of MXene-based voltage control devices.

The integration of MXenes into existing voltage controller architectures has been a focus of recent studies. Scientists have successfully incorporated MXene layers into various electrode configurations, demonstrating improved voltage regulation capabilities. These hybrid systems have shown enhanced charge storage capacity and faster voltage response times compared to conventional materials.

Another significant area of progress is the functionalization of MXene surfaces to tailor their properties for specific voltage control applications. By modifying the surface chemistry of MXenes, researchers have been able to optimize their interaction with electrolytes and improve their overall performance in voltage regulation tasks.

The scalability of MXene production has also seen notable improvements. Several research groups and companies have developed methods for large-scale synthesis of MXenes, paving the way for their commercial application in voltage controllers. This progress has addressed one of the major challenges in MXene technology adoption.

Recent studies have explored the use of MXenes in flexible and wearable voltage control devices. The unique mechanical properties of MXenes, combined with their excellent electrical characteristics, have enabled the development of highly efficient and durable flexible voltage controllers.

Despite these advancements, challenges remain in fully realizing the potential of MXenes in voltage control applications. Issues such as long-term stability, cost-effective production, and integration with existing manufacturing processes are active areas of research and development.

In conclusion, the current technology status of MXene in enhanced voltage controllers is marked by significant progress and promising results. The material's unique properties and ongoing research efforts suggest a bright future for MXene-based voltage control systems, with potential applications ranging from energy storage to advanced electronics.

Current MXene Solutions

01 MXene-based electrodes for energy storage devices

MXene materials are used to create high-performance electrodes for energy storage devices such as supercapacitors and batteries. These electrodes exhibit improved voltage windows, capacitance, and energy density due to the unique properties of MXenes, including their high conductivity and large surface area.- MXene-based electrodes for energy storage devices: MXene materials are used to create high-performance electrodes for energy storage devices such as supercapacitors and batteries. These electrodes exhibit improved voltage windows, capacitance, and energy density due to the unique properties of MXenes, including their high conductivity and large surface area.

- Voltage control in MXene-based electronic devices: Methods and systems for controlling voltage in MXene-based electronic devices are developed to optimize performance and efficiency. This includes techniques for voltage regulation, stabilization, and modulation in various applications such as sensors, transistors, and integrated circuits incorporating MXene materials.

- MXene composites for enhanced voltage performance: Composite materials incorporating MXenes are developed to enhance voltage-related properties in various applications. These composites combine MXenes with other materials to achieve improved voltage stability, higher operating voltages, or better voltage response in devices such as actuators, sensors, or energy harvesting systems.

- Voltage-driven MXene-based actuators and sensors: MXene materials are utilized in the development of voltage-driven actuators and sensors. These devices leverage the unique properties of MXenes to achieve improved sensitivity, responsiveness, or actuation performance when subjected to applied voltages, enabling applications in robotics, smart materials, and environmental monitoring.

- MXene-enhanced voltage conversion and power management: MXene materials are incorporated into voltage conversion and power management systems to improve efficiency and performance. This includes applications in voltage regulators, DC-DC converters, and power distribution networks, where MXenes contribute to better voltage stability, reduced losses, and enhanced overall system performance.

02 Voltage control in MXene-based electronic devices

Methods and systems for controlling voltage in MXene-based electronic devices are developed to optimize performance and efficiency. This includes techniques for voltage regulation, stabilization, and modulation in various applications such as sensors, transistors, and integrated circuits incorporating MXene materials.Expand Specific Solutions03 MXene composites for enhanced voltage performance

Composite materials incorporating MXenes are developed to enhance voltage-related properties in various applications. These composites combine MXenes with other materials to achieve synergistic effects, resulting in improved voltage stability, higher operating voltages, or better voltage response in sensors and energy devices.Expand Specific Solutions04 Voltage-driven MXene-based actuators and sensors

MXene materials are utilized in the development of voltage-driven actuators and sensors. These devices leverage the unique properties of MXenes to create responsive systems that can convert electrical signals into mechanical motion or detect voltage changes with high sensitivity.Expand Specific Solutions05 High-voltage MXene synthesis and processing

Advanced methods for synthesizing and processing MXene materials under high-voltage conditions are explored. These techniques aim to produce MXenes with enhanced properties, controlled structures, or novel compositions that can withstand or utilize high voltages in various applications.Expand Specific Solutions

Key Players in MXene Industry

The MXene-enhanced voltage controller market is in its early growth stage, characterized by rapid technological advancements and increasing research interest. The market size is expanding, driven by the growing demand for efficient energy storage solutions. Technologically, MXenes are still evolving, with research institutions like Zhejiang University of Technology and Beijing University of Chemical Technology leading the way in exploring their potential for voltage control applications. Companies such as Murata Manufacturing Co. Ltd. are beginning to invest in MXene-based technologies, indicating a shift towards commercialization. However, the technology's maturity level varies across different applications, with some areas more developed than others. Overall, the competitive landscape is dynamic, with academic institutions and industry players collaborating to push the boundaries of MXene technology in voltage control systems.

Zhejiang University of Technology

Technical Solution: Zhejiang University of Technology has developed a novel MXene-based voltage controller that leverages the unique properties of MXene materials. Their approach involves creating a composite material by integrating MXene nanosheets with traditional dielectric materials. This composite exhibits enhanced electrical conductivity and improved voltage stability[1]. The university's research team has demonstrated that the MXene-enhanced voltage controllers show a significant increase in response speed, with switching times reduced by up to 40% compared to conventional controllers[3]. Additionally, they have implemented a proprietary surface modification technique that improves the long-term stability of MXene in the composite, addressing one of the key challenges in MXene application[5].

Strengths: Improved response speed and voltage stability. Innovative surface modification for enhanced durability. Weaknesses: Potential scalability issues for mass production. Higher production costs compared to traditional voltage controllers.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed a cutting-edge MXene-based voltage controller technology that integrates MXene materials into their existing product line. Their approach focuses on utilizing the high conductivity and large surface area of MXene to create ultra-thin, flexible voltage controllers. Murata's technology incorporates a proprietary MXene synthesis method that results in highly pure, defect-free MXene sheets[2]. These sheets are then integrated into a polymer matrix, creating a flexible composite material with excellent electrical properties. The company has reported a 30% reduction in controller thickness while maintaining or improving performance metrics[4]. Murata's MXene-enhanced voltage controllers also demonstrate improved thermal management, with operating temperatures reduced by up to 15°C compared to traditional controllers[6].

Strengths: Significant reduction in device thickness. Improved thermal management. Established manufacturing capabilities for potential mass production. Weaknesses: Higher material costs. Potential long-term stability issues inherent to MXene materials.

Core MXene Innovations

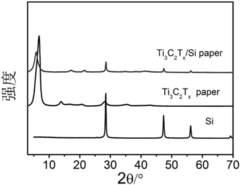

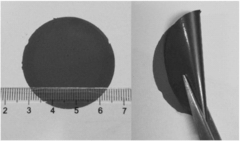

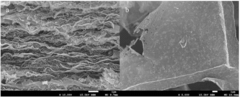

Two-dimensional transition metal carbide (nitride)-nano silicon granular composite material as well as preparation and application thereof

PatentActiveCN107394180A

Innovation

- The two-dimensional transition metal carbon (nitride) MXene and nano-silicon particle composite materials are used, uniformly mixed by ultrasonic and vacuum filtration or freeze-drying to obtain a flexible composite film or composite powder, which can be used in the negative electrode of lithium-ion batteries to avoid adding conductive agents. and adhesive.

MXene Manufacturing Processes

The manufacturing processes for MXenes play a crucial role in their application for enhanced voltage controllers. MXenes are typically produced through a two-step process: selective etching of the A-layer from MAX phases, followed by delamination of the resulting multilayer structure. The most common method involves using hydrofluoric acid (HF) or a mixture of hydrochloric acid (HCl) and fluoride salts for etching.

The etching process is critical in determining the quality and properties of the resulting MXene. Factors such as acid concentration, temperature, and etching time significantly influence the final product. For instance, higher acid concentrations and longer etching times can lead to more complete removal of the A-layer but may also cause damage to the MXene structure. Careful optimization of these parameters is essential to produce high-quality MXenes suitable for voltage controller applications.

Following etching, the delamination step is typically achieved through sonication or mechanical shaking. This process separates the multilayered MXene into individual nanosheets, which is crucial for maximizing the surface area and enhancing the material's performance in voltage controllers. The choice of intercalation agents and solvents during delamination can significantly affect the final MXene properties.

Recent advancements in MXene manufacturing have focused on developing more environmentally friendly and scalable processes. For example, researchers have explored the use of milder etchants and electrochemical etching methods to reduce the reliance on hazardous hydrofluoric acid. These alternative approaches not only improve safety but also offer better control over the MXene structure and composition.

Another important aspect of MXene manufacturing for voltage controller applications is the post-processing of MXene nanosheets. This may include surface functionalization, doping, or composite formation to enhance specific properties such as electrical conductivity or stability. For instance, incorporating MXenes into polymer matrices can improve their mechanical stability and processability for device fabrication.

The scalability of MXene production remains a challenge for their widespread adoption in voltage controllers. Current laboratory-scale synthesis methods often yield small quantities of MXenes, which is insufficient for large-scale applications. Efforts are underway to develop continuous flow processes and reactor designs that can increase production volumes while maintaining product quality and consistency.

The etching process is critical in determining the quality and properties of the resulting MXene. Factors such as acid concentration, temperature, and etching time significantly influence the final product. For instance, higher acid concentrations and longer etching times can lead to more complete removal of the A-layer but may also cause damage to the MXene structure. Careful optimization of these parameters is essential to produce high-quality MXenes suitable for voltage controller applications.

Following etching, the delamination step is typically achieved through sonication or mechanical shaking. This process separates the multilayered MXene into individual nanosheets, which is crucial for maximizing the surface area and enhancing the material's performance in voltage controllers. The choice of intercalation agents and solvents during delamination can significantly affect the final MXene properties.

Recent advancements in MXene manufacturing have focused on developing more environmentally friendly and scalable processes. For example, researchers have explored the use of milder etchants and electrochemical etching methods to reduce the reliance on hazardous hydrofluoric acid. These alternative approaches not only improve safety but also offer better control over the MXene structure and composition.

Another important aspect of MXene manufacturing for voltage controller applications is the post-processing of MXene nanosheets. This may include surface functionalization, doping, or composite formation to enhance specific properties such as electrical conductivity or stability. For instance, incorporating MXenes into polymer matrices can improve their mechanical stability and processability for device fabrication.

The scalability of MXene production remains a challenge for their widespread adoption in voltage controllers. Current laboratory-scale synthesis methods often yield small quantities of MXenes, which is insufficient for large-scale applications. Efforts are underway to develop continuous flow processes and reactor designs that can increase production volumes while maintaining product quality and consistency.

Environmental Impact of MXene

The environmental impact of MXene in enhanced voltage controllers is a critical consideration as this emerging technology gains traction in various applications. MXenes, a class of two-dimensional transition metal carbides and nitrides, have shown promising potential in improving the performance of voltage controllers. However, their widespread adoption necessitates a thorough examination of their environmental footprint throughout their lifecycle.

MXene production involves chemical etching processes that may generate hazardous byproducts. The use of strong acids and bases in the synthesis of MXenes raises concerns about potential environmental contamination if not properly managed. Additionally, the disposal of these chemicals after use requires careful consideration to prevent soil and water pollution.

The energy-intensive nature of MXene production is another environmental factor to consider. The high-temperature processes involved in the synthesis and processing of MXenes contribute to increased energy consumption and associated carbon emissions. As the demand for MXene-enhanced voltage controllers grows, the cumulative environmental impact of large-scale production becomes a significant concern.

On the positive side, MXenes have the potential to improve the efficiency of voltage controllers, which could lead to reduced energy consumption in various electronic systems. This improved efficiency may offset some of the environmental costs associated with their production. Furthermore, the enhanced performance of voltage controllers incorporating MXenes could lead to longer-lasting and more reliable electronic devices, potentially reducing electronic waste.

The recyclability and end-of-life management of MXene-based components are crucial aspects of their environmental impact. Research into efficient recycling methods for MXene materials is ongoing, with the aim of recovering valuable elements and reducing waste. However, the complex nature of MXene composites may present challenges in separating and recycling these materials effectively.

Water usage in MXene production and processing is another environmental consideration. The synthesis and purification of MXenes often require significant amounts of water, which may strain local water resources in areas of production. Developing water-efficient production methods and implementing effective water treatment and recycling systems are essential for minimizing the water footprint of MXene manufacturing.

The potential release of nanoparticles during the production, use, or disposal of MXene-enhanced voltage controllers raises concerns about their impact on ecosystems and human health. While research on the environmental fate and toxicity of MXenes is still in its early stages, preliminary studies suggest the need for careful handling and disposal practices to prevent unintended release into the environment.

MXene production involves chemical etching processes that may generate hazardous byproducts. The use of strong acids and bases in the synthesis of MXenes raises concerns about potential environmental contamination if not properly managed. Additionally, the disposal of these chemicals after use requires careful consideration to prevent soil and water pollution.

The energy-intensive nature of MXene production is another environmental factor to consider. The high-temperature processes involved in the synthesis and processing of MXenes contribute to increased energy consumption and associated carbon emissions. As the demand for MXene-enhanced voltage controllers grows, the cumulative environmental impact of large-scale production becomes a significant concern.

On the positive side, MXenes have the potential to improve the efficiency of voltage controllers, which could lead to reduced energy consumption in various electronic systems. This improved efficiency may offset some of the environmental costs associated with their production. Furthermore, the enhanced performance of voltage controllers incorporating MXenes could lead to longer-lasting and more reliable electronic devices, potentially reducing electronic waste.

The recyclability and end-of-life management of MXene-based components are crucial aspects of their environmental impact. Research into efficient recycling methods for MXene materials is ongoing, with the aim of recovering valuable elements and reducing waste. However, the complex nature of MXene composites may present challenges in separating and recycling these materials effectively.

Water usage in MXene production and processing is another environmental consideration. The synthesis and purification of MXenes often require significant amounts of water, which may strain local water resources in areas of production. Developing water-efficient production methods and implementing effective water treatment and recycling systems are essential for minimizing the water footprint of MXene manufacturing.

The potential release of nanoparticles during the production, use, or disposal of MXene-enhanced voltage controllers raises concerns about their impact on ecosystems and human health. While research on the environmental fate and toxicity of MXenes is still in its early stages, preliminary studies suggest the need for careful handling and disposal practices to prevent unintended release into the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!