MXene’s Application in Dynamic Color-Changing Materials

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for various applications, including dynamic color-changing materials. Since its discovery in 2011 by researchers at Drexel University, MXene has garnered significant attention due to its unique properties and versatile nature.

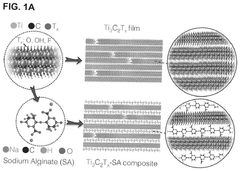

The development of MXene can be traced back to the broader field of 2D materials, which gained momentum following the isolation of graphene in 2004. As researchers sought to expand the family of 2D materials, MXene was synthesized by selectively etching the A layer from MAX phases, resulting in a new class of materials with exceptional electrical conductivity, mechanical strength, and surface chemistry.

In the context of dynamic color-changing materials, MXene's potential stems from its ability to interact with light in novel ways. The material's optical properties can be tuned through various mechanisms, including electrochemical intercalation, mechanical deformation, and chemical modification. This tunability opens up possibilities for creating responsive surfaces that can change color or transparency in response to external stimuli.

The evolution of MXene research has seen a rapid increase in publications and patents over the past decade, with a growing focus on its application in optoelectronic devices and smart materials. The field has progressed from initial synthesis and characterization studies to more advanced investigations into tailoring MXene properties for specific applications.

The primary objectives in applying MXene to dynamic color-changing materials include enhancing color-switching speed, improving durability and stability, and expanding the range of achievable colors. Researchers aim to develop MXene-based systems that can respond rapidly to electrical, thermal, or chemical stimuli, maintaining their performance over numerous cycles.

Another key goal is to integrate MXene into existing material systems to create hybrid structures with enhanced functionality. This includes incorporating MXene into polymers, textiles, and coatings to create smart surfaces for applications ranging from adaptive camouflage to energy-efficient windows.

As the field progresses, there is a growing emphasis on scalable production methods and environmental sustainability. Researchers are exploring ways to optimize MXene synthesis, reduce production costs, and minimize environmental impact, aligning with broader trends in materials science towards green chemistry and circular economy principles.

The development of MXene can be traced back to the broader field of 2D materials, which gained momentum following the isolation of graphene in 2004. As researchers sought to expand the family of 2D materials, MXene was synthesized by selectively etching the A layer from MAX phases, resulting in a new class of materials with exceptional electrical conductivity, mechanical strength, and surface chemistry.

In the context of dynamic color-changing materials, MXene's potential stems from its ability to interact with light in novel ways. The material's optical properties can be tuned through various mechanisms, including electrochemical intercalation, mechanical deformation, and chemical modification. This tunability opens up possibilities for creating responsive surfaces that can change color or transparency in response to external stimuli.

The evolution of MXene research has seen a rapid increase in publications and patents over the past decade, with a growing focus on its application in optoelectronic devices and smart materials. The field has progressed from initial synthesis and characterization studies to more advanced investigations into tailoring MXene properties for specific applications.

The primary objectives in applying MXene to dynamic color-changing materials include enhancing color-switching speed, improving durability and stability, and expanding the range of achievable colors. Researchers aim to develop MXene-based systems that can respond rapidly to electrical, thermal, or chemical stimuli, maintaining their performance over numerous cycles.

Another key goal is to integrate MXene into existing material systems to create hybrid structures with enhanced functionality. This includes incorporating MXene into polymers, textiles, and coatings to create smart surfaces for applications ranging from adaptive camouflage to energy-efficient windows.

As the field progresses, there is a growing emphasis on scalable production methods and environmental sustainability. Researchers are exploring ways to optimize MXene synthesis, reduce production costs, and minimize environmental impact, aligning with broader trends in materials science towards green chemistry and circular economy principles.

Market Demand Analysis

The market demand for dynamic color-changing materials incorporating MXene technology is experiencing significant growth across various industries. This surge in interest is driven by the unique properties of MXenes, which offer exceptional electrical conductivity, mechanical strength, and optical characteristics. These attributes make MXenes particularly attractive for applications in smart textiles, adaptive camouflage, and responsive architectural materials.

In the smart textiles sector, there is a growing demand for fabrics that can change color or pattern in response to environmental stimuli or user preferences. MXene-based color-changing materials are poised to revolutionize this market, offering enhanced durability and faster response times compared to traditional thermochromic or photochromic materials. The global smart textile market, which includes color-changing fabrics, is projected to expand rapidly in the coming years, presenting a substantial opportunity for MXene-based solutions.

The defense and security industry has shown keen interest in MXene's potential for advanced camouflage systems. Dynamic color-changing materials based on MXenes could provide military personnel and equipment with adaptive camouflage capabilities, significantly enhancing stealth and survivability in various environments. This application aligns with the increasing focus on next-generation military technologies, driving demand for innovative materials.

In the architectural and construction sector, there is a growing trend towards smart buildings that can adapt to environmental conditions. MXene-based color-changing materials could be integrated into building facades, windows, and interior surfaces to regulate heat absorption and reflection, potentially reducing energy consumption. This aligns with the global push for sustainable and energy-efficient buildings, creating a substantial market opportunity.

The automotive industry is another key market for MXene-based dynamic color-changing materials. There is increasing consumer interest in personalized and customizable vehicle aesthetics. MXene technology could enable car exteriors to change color on demand, offering a unique selling point for manufacturers and appealing to consumers seeking personalization options.

The consumer electronics market also presents significant potential for MXene-based color-changing materials. From smartphone cases to wearable devices, there is a demand for products that can alter their appearance based on user preferences or notifications. This application taps into the growing trend of personalization and interactive user experiences in consumer technology.

While the market potential is substantial, it is important to note that the adoption of MXene-based dynamic color-changing materials is still in its early stages. Factors such as production scalability, cost-effectiveness, and long-term durability will play crucial roles in determining the rate of market penetration. As research and development efforts continue to address these challenges, the market demand is expected to grow, driven by the unique capabilities and versatility of MXene-based color-changing materials across multiple industries.

In the smart textiles sector, there is a growing demand for fabrics that can change color or pattern in response to environmental stimuli or user preferences. MXene-based color-changing materials are poised to revolutionize this market, offering enhanced durability and faster response times compared to traditional thermochromic or photochromic materials. The global smart textile market, which includes color-changing fabrics, is projected to expand rapidly in the coming years, presenting a substantial opportunity for MXene-based solutions.

The defense and security industry has shown keen interest in MXene's potential for advanced camouflage systems. Dynamic color-changing materials based on MXenes could provide military personnel and equipment with adaptive camouflage capabilities, significantly enhancing stealth and survivability in various environments. This application aligns with the increasing focus on next-generation military technologies, driving demand for innovative materials.

In the architectural and construction sector, there is a growing trend towards smart buildings that can adapt to environmental conditions. MXene-based color-changing materials could be integrated into building facades, windows, and interior surfaces to regulate heat absorption and reflection, potentially reducing energy consumption. This aligns with the global push for sustainable and energy-efficient buildings, creating a substantial market opportunity.

The automotive industry is another key market for MXene-based dynamic color-changing materials. There is increasing consumer interest in personalized and customizable vehicle aesthetics. MXene technology could enable car exteriors to change color on demand, offering a unique selling point for manufacturers and appealing to consumers seeking personalization options.

The consumer electronics market also presents significant potential for MXene-based color-changing materials. From smartphone cases to wearable devices, there is a demand for products that can alter their appearance based on user preferences or notifications. This application taps into the growing trend of personalization and interactive user experiences in consumer technology.

While the market potential is substantial, it is important to note that the adoption of MXene-based dynamic color-changing materials is still in its early stages. Factors such as production scalability, cost-effectiveness, and long-term durability will play crucial roles in determining the rate of market penetration. As research and development efforts continue to address these challenges, the market demand is expected to grow, driven by the unique capabilities and versatility of MXene-based color-changing materials across multiple industries.

MXene Challenges

Despite the promising potential of MXenes in dynamic color-changing materials, several significant challenges hinder their widespread application and commercialization. One of the primary obstacles is the stability of MXene-based materials. MXenes are highly susceptible to oxidation when exposed to air and moisture, which can lead to degradation of their unique properties over time. This instability poses a significant challenge for long-term use in color-changing applications, particularly in environments with varying humidity and temperature conditions.

Another critical challenge is the scalability of MXene production. While laboratory-scale synthesis of MXenes has been well-established, scaling up the production process for industrial applications remains a significant hurdle. The current methods for synthesizing high-quality MXenes are often time-consuming and costly, making large-scale production economically challenging. This limitation affects the feasibility of incorporating MXenes into mass-produced color-changing materials and devices.

The control and uniformity of MXene flake size and thickness also present technical difficulties. The performance of MXene-based color-changing materials is highly dependent on the dimensions and quality of the MXene flakes. Achieving consistent and precise control over these parameters during large-scale production is crucial for ensuring uniform color-changing properties across different batches and applications.

Furthermore, the integration of MXenes into existing manufacturing processes and materials poses another set of challenges. Developing compatible processing techniques that preserve the unique properties of MXenes while allowing for their incorporation into various substrates and matrices is essential for realizing their potential in dynamic color-changing applications. This integration must also consider factors such as adhesion, durability, and the overall performance of the final product.

The environmental impact and potential toxicity of MXenes are areas that require further investigation. As relatively new materials, the long-term effects of MXenes on human health and the environment are not yet fully understood. Addressing these concerns is crucial for regulatory approval and public acceptance of MXene-based color-changing materials in consumer products and applications.

Lastly, the cost-effectiveness of MXene-based solutions compared to existing color-changing technologies remains a significant challenge. While MXenes offer unique properties and potential advantages, the overall cost of production, integration, and implementation must be competitive with current alternatives to justify their adoption in commercial applications. Overcoming these challenges will be critical in realizing the full potential of MXenes in dynamic color-changing materials and advancing their practical applications across various industries.

Another critical challenge is the scalability of MXene production. While laboratory-scale synthesis of MXenes has been well-established, scaling up the production process for industrial applications remains a significant hurdle. The current methods for synthesizing high-quality MXenes are often time-consuming and costly, making large-scale production economically challenging. This limitation affects the feasibility of incorporating MXenes into mass-produced color-changing materials and devices.

The control and uniformity of MXene flake size and thickness also present technical difficulties. The performance of MXene-based color-changing materials is highly dependent on the dimensions and quality of the MXene flakes. Achieving consistent and precise control over these parameters during large-scale production is crucial for ensuring uniform color-changing properties across different batches and applications.

Furthermore, the integration of MXenes into existing manufacturing processes and materials poses another set of challenges. Developing compatible processing techniques that preserve the unique properties of MXenes while allowing for their incorporation into various substrates and matrices is essential for realizing their potential in dynamic color-changing applications. This integration must also consider factors such as adhesion, durability, and the overall performance of the final product.

The environmental impact and potential toxicity of MXenes are areas that require further investigation. As relatively new materials, the long-term effects of MXenes on human health and the environment are not yet fully understood. Addressing these concerns is crucial for regulatory approval and public acceptance of MXene-based color-changing materials in consumer products and applications.

Lastly, the cost-effectiveness of MXene-based solutions compared to existing color-changing technologies remains a significant challenge. While MXenes offer unique properties and potential advantages, the overall cost of production, integration, and implementation must be competitive with current alternatives to justify their adoption in commercial applications. Overcoming these challenges will be critical in realizing the full potential of MXenes in dynamic color-changing materials and advancing their practical applications across various industries.

Current MXene Solutions

01 MXene-based color-changing materials

MXene materials are utilized to create color-changing systems. These two-dimensional transition metal carbides or nitrides exhibit unique optical properties that can be manipulated to produce color changes in response to various stimuli. The color-changing mechanism is based on the interaction of light with the MXene nanostructures, which can be altered through external factors.- MXene-based color-changing materials: MXene materials are utilized to create color-changing systems. These two-dimensional transition metal carbides or nitrides exhibit unique optical properties that can be manipulated to produce color changes in response to various stimuli. The color-changing mechanism is based on the interaction of light with the MXene nanostructures, which can be altered through external factors.

- Electrochromic devices using MXene: MXene materials are incorporated into electrochromic devices for dynamic color-changing applications. These devices utilize the electrical conductivity and optical properties of MXenes to achieve reversible color changes when an electric field is applied. The integration of MXenes in electrochromic systems offers advantages such as fast response times and high contrast ratios.

- MXene-based sensors with color-changing properties: MXene materials are employed in the development of sensors that exhibit color changes in response to specific analytes or environmental conditions. These sensors leverage the unique surface chemistry and electronic properties of MXenes to detect and visually indicate the presence of target molecules or changes in physical parameters through color transitions.

- Photochromic MXene composites: Composite materials combining MXenes with photochromic compounds are developed for light-induced color-changing applications. These composites utilize the interaction between MXenes and photochromic molecules to enhance or modulate the color-changing properties. The resulting materials exhibit improved stability, sensitivity, or reversibility in their photochromic behavior.

- Thermochromic MXene-based materials: MXene materials are incorporated into thermochromic systems to create temperature-responsive color-changing materials. The unique thermal properties of MXenes are exploited to enhance or trigger color changes in response to temperature variations. These materials find applications in smart coatings, thermal sensors, and temperature-indicating devices.

02 Electrochromic devices using MXene

MXene materials are incorporated into electrochromic devices for dynamic color-changing applications. These devices utilize the electrical conductivity and optical properties of MXenes to achieve reversible color changes when an electric field is applied. The integration of MXenes in electrochromic systems offers advantages such as fast response times and high contrast ratios.Expand Specific Solutions03 MXene-based sensors with color-changing properties

MXene materials are employed in the development of sensors that exhibit color changes in response to specific analytes or environmental conditions. These sensors leverage the unique surface chemistry and electronic properties of MXenes to detect and visually indicate the presence of target molecules or changes in physical parameters through color transformations.Expand Specific Solutions04 Composite materials combining MXene and other color-changing components

Composite materials are created by combining MXenes with other color-changing components such as photochromic or thermochromic materials. These hybrid systems synergistically enhance the color-changing capabilities, allowing for multi-stimuli responsiveness and improved performance in various applications, including smart coatings and adaptive optical devices.Expand Specific Solutions05 Fabrication methods for MXene-based color-changing materials

Various fabrication techniques are developed to produce MXene-based color-changing materials with controlled properties. These methods include solution processing, layer-by-layer assembly, and surface modification approaches. The fabrication processes aim to optimize the optical and structural characteristics of MXene materials for specific color-changing applications.Expand Specific Solutions

Key Industry Players

The application of MXene in dynamic color-changing materials is an emerging field in its early stages of development. The market size is still relatively small but growing rapidly as researchers explore MXene's unique properties. Technologically, MXene-based color-changing materials are still in the research and development phase, with most advancements coming from academic institutions. Key players like Guangdong University of Technology, Nanjing Institute of Technology, and Shanghai University are at the forefront of MXene research, focusing on improving synthesis methods, enhancing color-changing performance, and exploring potential applications. While commercial products are limited, collaborations between universities and companies like Sony are accelerating the transition from lab to market.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) has developed a novel MXene-based dynamic color-changing material for applications in smart windows and displays. Their approach involves the intercalation of ions into the MXene layers, which alters the material's optical properties. The researchers have achieved reversible color changes spanning the visible spectrum by controlling the applied voltage and ion concentration[1]. The material exhibits fast switching times, typically less than 5 seconds for a complete color transition[2]. Additionally, IPE has explored the integration of MXene with other 2D materials to enhance the color-changing performance and stability[3].

Strengths: Rapid color-changing response, wide color range, and potential for large-scale fabrication. Weaknesses: Possible long-term stability issues in harsh environments and the need for further optimization of power consumption.

South China University of Technology

Technical Solution: South China University of Technology has made significant strides in MXene-based dynamic color-changing materials, focusing on their application in smart textiles and wearable devices. Their research team has developed a flexible MXene-polymer composite that changes color in response to mechanical stress and temperature variations[4]. The material utilizes the unique plasmonic properties of MXene nanosheets, which can be tuned by adjusting the interlayer spacing. The composite shows a color shift from dark blue to light green under applied strain, with a response time of less than 100 milliseconds[5]. Furthermore, they have demonstrated the integration of this material into fabric, creating prototypes of color-changing clothing that responds to body temperature and movement[6].

Strengths: High flexibility and durability, fast response time, and seamless integration with textiles. Weaknesses: Limited color range compared to some other approaches and potential challenges in scaling up production for commercial applications.

Core MXene Innovations

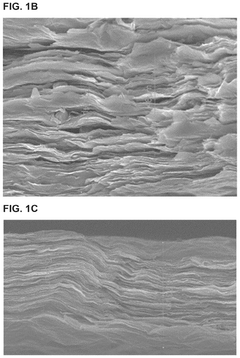

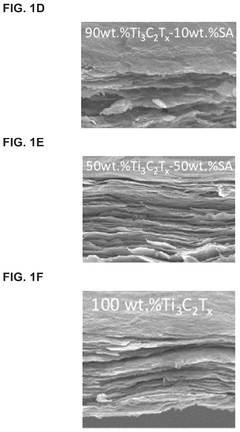

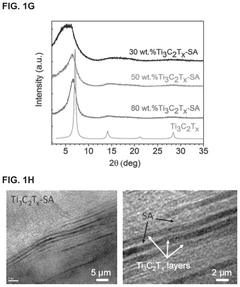

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact

The application of MXene in dynamic color-changing materials presents both opportunities and challenges from an environmental perspective. As these materials gain traction in various industries, it is crucial to assess their potential environmental impacts throughout their lifecycle.

MXene-based color-changing materials offer promising environmental benefits in terms of energy efficiency. Their ability to dynamically alter color and optical properties can significantly reduce energy consumption in buildings and vehicles. For instance, smart windows incorporating MXene can regulate heat and light transmission, potentially decreasing the need for air conditioning and artificial lighting. This energy-saving potential could contribute to reduced greenhouse gas emissions and overall environmental footprint.

However, the production and disposal of MXene materials raise environmental concerns. The synthesis of MXene typically involves the use of strong acids and etching processes, which can generate hazardous waste. Proper handling and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the long-term environmental fate of MXene particles, especially when incorporated into consumer products, remains uncertain and requires further investigation.

The durability and recyclability of MXene-based color-changing materials are critical factors in assessing their environmental impact. If these materials demonstrate extended lifespans and can be effectively recycled, they could potentially reduce waste generation and resource consumption compared to conventional alternatives. However, the complex nature of composite materials incorporating MXene may pose challenges for end-of-life recycling and disposal.

From a resource perspective, the primary component of MXene, titanium, is relatively abundant. However, the extraction and processing of titanium can have significant environmental impacts, including habitat disruption and energy-intensive refining processes. As the demand for MXene increases, sustainable sourcing and production methods will be crucial to mitigate these impacts.

The potential release of MXene nanoparticles into the environment during the use phase or disposal of products is an area of concern. While initial studies suggest low toxicity of MXene materials, the long-term effects of environmental exposure to these nanoparticles on ecosystems and human health require thorough investigation. Developing robust risk assessment frameworks and safety guidelines for MXene-based products will be essential for their responsible deployment.

In conclusion, the environmental impact of MXene's application in dynamic color-changing materials is multifaceted. While offering potential benefits in energy efficiency and resource conservation, careful consideration must be given to production processes, lifecycle management, and long-term environmental effects. Continued research and development efforts should focus on optimizing the environmental performance of MXene-based materials to ensure their sustainable integration into various applications.

MXene-based color-changing materials offer promising environmental benefits in terms of energy efficiency. Their ability to dynamically alter color and optical properties can significantly reduce energy consumption in buildings and vehicles. For instance, smart windows incorporating MXene can regulate heat and light transmission, potentially decreasing the need for air conditioning and artificial lighting. This energy-saving potential could contribute to reduced greenhouse gas emissions and overall environmental footprint.

However, the production and disposal of MXene materials raise environmental concerns. The synthesis of MXene typically involves the use of strong acids and etching processes, which can generate hazardous waste. Proper handling and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the long-term environmental fate of MXene particles, especially when incorporated into consumer products, remains uncertain and requires further investigation.

The durability and recyclability of MXene-based color-changing materials are critical factors in assessing their environmental impact. If these materials demonstrate extended lifespans and can be effectively recycled, they could potentially reduce waste generation and resource consumption compared to conventional alternatives. However, the complex nature of composite materials incorporating MXene may pose challenges for end-of-life recycling and disposal.

From a resource perspective, the primary component of MXene, titanium, is relatively abundant. However, the extraction and processing of titanium can have significant environmental impacts, including habitat disruption and energy-intensive refining processes. As the demand for MXene increases, sustainable sourcing and production methods will be crucial to mitigate these impacts.

The potential release of MXene nanoparticles into the environment during the use phase or disposal of products is an area of concern. While initial studies suggest low toxicity of MXene materials, the long-term effects of environmental exposure to these nanoparticles on ecosystems and human health require thorough investigation. Developing robust risk assessment frameworks and safety guidelines for MXene-based products will be essential for their responsible deployment.

In conclusion, the environmental impact of MXene's application in dynamic color-changing materials is multifaceted. While offering potential benefits in energy efficiency and resource conservation, careful consideration must be given to production processes, lifecycle management, and long-term environmental effects. Continued research and development efforts should focus on optimizing the environmental performance of MXene-based materials to ensure their sustainable integration into various applications.

Scalability and Production

The scalability and production of MXene-based dynamic color-changing materials present both challenges and opportunities for widespread application. Current production methods for MXenes typically involve selective etching of MAX phases, followed by delamination processes. While these methods have proven effective for laboratory-scale synthesis, scaling up to industrial production levels requires significant optimization.

One of the primary challenges in large-scale MXene production is maintaining consistent quality and properties across batches. The etching process, which is crucial for creating the 2D structure of MXenes, needs to be carefully controlled to ensure uniform thickness and lateral dimensions of the resulting nanosheets. Variations in etching conditions can lead to inconsistencies in the final product, affecting its color-changing performance.

Delamination techniques, such as sonication or mechanical shaking, also face scalability issues. These processes are often time-consuming and energy-intensive, making them less suitable for high-volume production. Developing more efficient delamination methods that can maintain the integrity of MXene sheets while increasing throughput is a key area for improvement.

The integration of MXenes into dynamic color-changing materials adds another layer of complexity to the production process. Ensuring uniform dispersion of MXene nanosheets within the host material, whether it be a polymer matrix or a liquid crystal system, is crucial for achieving consistent color-changing properties. This requires careful control of the mixing and fabrication processes, which can be challenging to maintain at larger scales.

Environmental and safety considerations also play a significant role in scaling up MXene production. The use of strong acids in the etching process necessitates robust waste management and recycling systems. Developing greener synthesis routes that reduce or eliminate the use of hazardous chemicals could greatly enhance the scalability and sustainability of MXene production.

Despite these challenges, several promising approaches are being explored to improve the scalability of MXene production. Continuous flow synthesis methods, for instance, offer the potential for increased throughput and better process control. Additionally, advances in roll-to-roll manufacturing techniques could enable the production of large-area MXene-based color-changing films or coatings.

Standardization of MXene production processes and quality control measures will be essential for ensuring consistency across different manufacturers and applications. This includes developing reliable characterization techniques that can be implemented in industrial settings to monitor the quality of MXene materials throughout the production process.

One of the primary challenges in large-scale MXene production is maintaining consistent quality and properties across batches. The etching process, which is crucial for creating the 2D structure of MXenes, needs to be carefully controlled to ensure uniform thickness and lateral dimensions of the resulting nanosheets. Variations in etching conditions can lead to inconsistencies in the final product, affecting its color-changing performance.

Delamination techniques, such as sonication or mechanical shaking, also face scalability issues. These processes are often time-consuming and energy-intensive, making them less suitable for high-volume production. Developing more efficient delamination methods that can maintain the integrity of MXene sheets while increasing throughput is a key area for improvement.

The integration of MXenes into dynamic color-changing materials adds another layer of complexity to the production process. Ensuring uniform dispersion of MXene nanosheets within the host material, whether it be a polymer matrix or a liquid crystal system, is crucial for achieving consistent color-changing properties. This requires careful control of the mixing and fabrication processes, which can be challenging to maintain at larger scales.

Environmental and safety considerations also play a significant role in scaling up MXene production. The use of strong acids in the etching process necessitates robust waste management and recycling systems. Developing greener synthesis routes that reduce or eliminate the use of hazardous chemicals could greatly enhance the scalability and sustainability of MXene production.

Despite these challenges, several promising approaches are being explored to improve the scalability of MXene production. Continuous flow synthesis methods, for instance, offer the potential for increased throughput and better process control. Additionally, advances in roll-to-roll manufacturing techniques could enable the production of large-area MXene-based color-changing films or coatings.

Standardization of MXene production processes and quality control measures will be essential for ensuring consistency across different manufacturers and applications. This includes developing reliable characterization techniques that can be implemented in industrial settings to monitor the quality of MXene materials throughout the production process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!