MXene-enhanced High-Voltage Dielectrics for Energy Storage

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Dielectrics Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material for high-voltage dielectrics in energy storage applications. The development of MXene-enhanced dielectrics represents a significant advancement in the field of energy storage technology, addressing the growing demand for more efficient and high-capacity energy storage solutions.

The evolution of MXene technology can be traced back to 2011 when it was first discovered by researchers at Drexel University. Since then, MXenes have garnered substantial attention due to their unique properties, including high electrical conductivity, mechanical strength, and surface functionality. These characteristics make MXenes particularly suitable for enhancing the performance of dielectric materials in high-voltage applications.

The primary objective of research on MXene-enhanced high-voltage dielectrics is to develop materials with improved energy density, breakdown strength, and overall performance in energy storage devices. This aligns with the broader goal of advancing energy storage technologies to meet the increasing demands of renewable energy integration, electric vehicles, and portable electronics.

Current trends in MXene dielectric research focus on several key areas. One is the optimization of MXene synthesis and processing techniques to achieve better control over the material's structure and properties. Another trend involves the exploration of various MXene compositions and surface modifications to tailor the dielectric properties for specific applications.

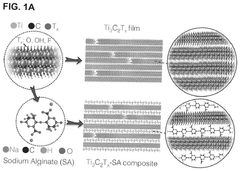

The integration of MXenes into polymer matrices to create nanocomposite dielectrics is another significant area of investigation. This approach aims to combine the high dielectric constant of MXenes with the flexibility and processability of polymers, potentially leading to a new generation of high-performance dielectric materials.

Researchers are also exploring the fundamental mechanisms underlying the enhanced dielectric properties of MXene-based materials. Understanding these mechanisms is crucial for designing and optimizing MXene dielectrics for specific energy storage applications.

The development of MXene-enhanced high-voltage dielectrics is expected to have a substantial impact on various sectors, including renewable energy storage, electric vehicle technology, and advanced electronics. As research progresses, the goal is to achieve dielectric materials with significantly higher energy densities, improved thermal stability, and enhanced reliability compared to conventional dielectrics.

In conclusion, the research on MXene-enhanced high-voltage dielectrics for energy storage represents a cutting-edge field with immense potential for technological advancement. The ongoing efforts in this area are driven by the need for more efficient and high-capacity energy storage solutions, which are critical for addressing global energy challenges and enabling the widespread adoption of sustainable technologies.

The evolution of MXene technology can be traced back to 2011 when it was first discovered by researchers at Drexel University. Since then, MXenes have garnered substantial attention due to their unique properties, including high electrical conductivity, mechanical strength, and surface functionality. These characteristics make MXenes particularly suitable for enhancing the performance of dielectric materials in high-voltage applications.

The primary objective of research on MXene-enhanced high-voltage dielectrics is to develop materials with improved energy density, breakdown strength, and overall performance in energy storage devices. This aligns with the broader goal of advancing energy storage technologies to meet the increasing demands of renewable energy integration, electric vehicles, and portable electronics.

Current trends in MXene dielectric research focus on several key areas. One is the optimization of MXene synthesis and processing techniques to achieve better control over the material's structure and properties. Another trend involves the exploration of various MXene compositions and surface modifications to tailor the dielectric properties for specific applications.

The integration of MXenes into polymer matrices to create nanocomposite dielectrics is another significant area of investigation. This approach aims to combine the high dielectric constant of MXenes with the flexibility and processability of polymers, potentially leading to a new generation of high-performance dielectric materials.

Researchers are also exploring the fundamental mechanisms underlying the enhanced dielectric properties of MXene-based materials. Understanding these mechanisms is crucial for designing and optimizing MXene dielectrics for specific energy storage applications.

The development of MXene-enhanced high-voltage dielectrics is expected to have a substantial impact on various sectors, including renewable energy storage, electric vehicle technology, and advanced electronics. As research progresses, the goal is to achieve dielectric materials with significantly higher energy densities, improved thermal stability, and enhanced reliability compared to conventional dielectrics.

In conclusion, the research on MXene-enhanced high-voltage dielectrics for energy storage represents a cutting-edge field with immense potential for technological advancement. The ongoing efforts in this area are driven by the need for more efficient and high-capacity energy storage solutions, which are critical for addressing global energy challenges and enabling the widespread adoption of sustainable technologies.

Energy Storage Market Analysis

The energy storage market has been experiencing significant growth in recent years, driven by the increasing demand for renewable energy integration, grid stability, and electrification of transportation. The global energy storage market was valued at approximately $162 billion in 2019 and is projected to reach $546 billion by 2035, with a compound annual growth rate (CAGR) of 8.1% during this period.

The market for high-voltage dielectrics, a crucial component in energy storage systems, is expected to grow in tandem with the overall energy storage market. The demand for advanced dielectric materials, such as MXene-enhanced composites, is particularly strong due to their potential to improve energy density, efficiency, and reliability of storage devices.

In the context of MXene-enhanced high-voltage dielectrics for energy storage, the market is primarily driven by the need for more efficient and compact energy storage solutions. The automotive sector, especially electric vehicles (EVs), represents a significant market opportunity. The global EV market is projected to grow at a CAGR of 29% from 2021 to 2026, creating a substantial demand for high-performance energy storage systems.

The utility-scale energy storage market is another key driver for MXene-enhanced dielectrics. As renewable energy sources like wind and solar become more prevalent, the need for large-scale energy storage solutions to manage grid stability and peak demand is increasing. The utility-scale energy storage market is expected to grow at a CAGR of 24% from 2020 to 2025.

Consumer electronics is also a significant market segment for high-voltage dielectrics. The growing demand for longer-lasting batteries in smartphones, laptops, and wearable devices is pushing manufacturers to explore advanced materials like MXene-enhanced dielectrics to improve energy storage capacity and charging speeds.

Geographically, Asia-Pacific is expected to dominate the energy storage market, followed by North America and Europe. China, in particular, is investing heavily in energy storage technologies, with a target to deploy 30 GW of new energy storage capacity by 2025.

The market trends indicate a shift towards more sustainable and efficient energy storage solutions. MXene-enhanced high-voltage dielectrics align well with this trend, offering the potential for higher energy density, improved thermal management, and enhanced cycling stability. As research in this field progresses, it is likely to attract significant investment from both private and public sectors, further driving market growth and technological advancements.

The market for high-voltage dielectrics, a crucial component in energy storage systems, is expected to grow in tandem with the overall energy storage market. The demand for advanced dielectric materials, such as MXene-enhanced composites, is particularly strong due to their potential to improve energy density, efficiency, and reliability of storage devices.

In the context of MXene-enhanced high-voltage dielectrics for energy storage, the market is primarily driven by the need for more efficient and compact energy storage solutions. The automotive sector, especially electric vehicles (EVs), represents a significant market opportunity. The global EV market is projected to grow at a CAGR of 29% from 2021 to 2026, creating a substantial demand for high-performance energy storage systems.

The utility-scale energy storage market is another key driver for MXene-enhanced dielectrics. As renewable energy sources like wind and solar become more prevalent, the need for large-scale energy storage solutions to manage grid stability and peak demand is increasing. The utility-scale energy storage market is expected to grow at a CAGR of 24% from 2020 to 2025.

Consumer electronics is also a significant market segment for high-voltage dielectrics. The growing demand for longer-lasting batteries in smartphones, laptops, and wearable devices is pushing manufacturers to explore advanced materials like MXene-enhanced dielectrics to improve energy storage capacity and charging speeds.

Geographically, Asia-Pacific is expected to dominate the energy storage market, followed by North America and Europe. China, in particular, is investing heavily in energy storage technologies, with a target to deploy 30 GW of new energy storage capacity by 2025.

The market trends indicate a shift towards more sustainable and efficient energy storage solutions. MXene-enhanced high-voltage dielectrics align well with this trend, offering the potential for higher energy density, improved thermal management, and enhanced cycling stability. As research in this field progresses, it is likely to attract significant investment from both private and public sectors, further driving market growth and technological advancements.

MXene Dielectric Challenges

MXene-enhanced high-voltage dielectrics for energy storage face several significant challenges that need to be addressed to fully realize their potential. One of the primary obstacles is the optimization of MXene's surface chemistry and structure to enhance its dielectric properties. The unique 2D structure of MXenes offers high surface area and excellent electrical conductivity, but these properties can also lead to increased leakage current and reduced breakdown strength in dielectric applications.

Another critical challenge lies in the integration of MXenes into polymer matrices to form composite dielectrics. Achieving uniform dispersion and strong interfacial interactions between MXenes and the polymer host is crucial for maximizing the dielectric performance. Poor dispersion can result in agglomeration, leading to localized field enhancement and premature breakdown. Moreover, the compatibility between MXenes and various polymer systems needs to be carefully studied to ensure optimal synergy and prevent degradation of the composite's properties over time.

The stability of MXene-enhanced dielectrics under high-voltage conditions and prolonged use is another area of concern. MXenes may undergo oxidation or structural changes when exposed to high electric fields or elevated temperatures, potentially compromising their long-term performance and reliability. Developing strategies to enhance the chemical and thermal stability of MXenes in dielectric applications is essential for their practical implementation in energy storage devices.

Furthermore, scaling up the production of MXene-enhanced dielectrics presents significant manufacturing challenges. Current synthesis methods for MXenes are often limited to small-scale production, and translating these processes to industrial scales while maintaining consistent quality and properties is a complex task. Additionally, the cost-effectiveness of incorporating MXenes into dielectric materials needs to be carefully evaluated to ensure economic viability for large-scale energy storage applications.

The environmental impact and safety considerations of MXene-based dielectrics also pose challenges. As relatively new materials, the long-term environmental effects and potential health risks associated with MXenes are not yet fully understood. Comprehensive studies on their toxicity, biodegradability, and potential for environmental accumulation are necessary to address regulatory concerns and ensure sustainable development of MXene-enhanced dielectric technologies.

Lastly, the characterization and standardization of MXene-enhanced dielectrics present technical challenges. Developing reliable methods for measuring and predicting the dielectric properties of these composite materials, especially under high-voltage conditions, is crucial for their widespread adoption. Establishing industry standards and testing protocols specific to MXene-based dielectrics will be essential for quality control and performance benchmarking across different research and industrial applications.

Another critical challenge lies in the integration of MXenes into polymer matrices to form composite dielectrics. Achieving uniform dispersion and strong interfacial interactions between MXenes and the polymer host is crucial for maximizing the dielectric performance. Poor dispersion can result in agglomeration, leading to localized field enhancement and premature breakdown. Moreover, the compatibility between MXenes and various polymer systems needs to be carefully studied to ensure optimal synergy and prevent degradation of the composite's properties over time.

The stability of MXene-enhanced dielectrics under high-voltage conditions and prolonged use is another area of concern. MXenes may undergo oxidation or structural changes when exposed to high electric fields or elevated temperatures, potentially compromising their long-term performance and reliability. Developing strategies to enhance the chemical and thermal stability of MXenes in dielectric applications is essential for their practical implementation in energy storage devices.

Furthermore, scaling up the production of MXene-enhanced dielectrics presents significant manufacturing challenges. Current synthesis methods for MXenes are often limited to small-scale production, and translating these processes to industrial scales while maintaining consistent quality and properties is a complex task. Additionally, the cost-effectiveness of incorporating MXenes into dielectric materials needs to be carefully evaluated to ensure economic viability for large-scale energy storage applications.

The environmental impact and safety considerations of MXene-based dielectrics also pose challenges. As relatively new materials, the long-term environmental effects and potential health risks associated with MXenes are not yet fully understood. Comprehensive studies on their toxicity, biodegradability, and potential for environmental accumulation are necessary to address regulatory concerns and ensure sustainable development of MXene-enhanced dielectric technologies.

Lastly, the characterization and standardization of MXene-enhanced dielectrics present technical challenges. Developing reliable methods for measuring and predicting the dielectric properties of these composite materials, especially under high-voltage conditions, is crucial for their widespread adoption. Establishing industry standards and testing protocols specific to MXene-based dielectrics will be essential for quality control and performance benchmarking across different research and industrial applications.

Current MXene Dielectric Solutions

01 MXene-based dielectric materials for energy storage

MXene, a two-dimensional transition metal carbide/nitride, is used as a novel material for high-voltage dielectric energy storage. Its unique structure and properties contribute to enhanced energy density and improved dielectric performance in capacitors and other energy storage devices.- MXene-based composite materials for high-voltage dielectric energy storage: MXene, a two-dimensional transition metal carbide/nitride, is incorporated into composite materials to enhance high-voltage dielectric energy storage. These composites exhibit improved energy density, breakdown strength, and charge-discharge efficiency, making them suitable for advanced energy storage applications.

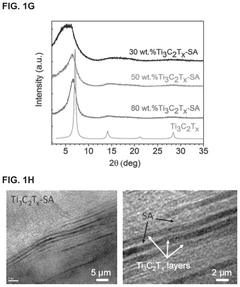

- Surface modification of MXene for enhanced dielectric properties: Surface modification techniques are applied to MXene to improve its dielectric properties. These modifications can include functionalization, doping, or coating, which enhance the material's compatibility with polymer matrices and improve its overall performance in high-voltage energy storage devices.

- MXene-polymer nanocomposites for flexible energy storage devices: MXene is combined with various polymers to create flexible nanocomposites suitable for high-voltage dielectric energy storage. These materials offer a balance of mechanical flexibility and electrical performance, making them ideal for wearable and portable energy storage applications.

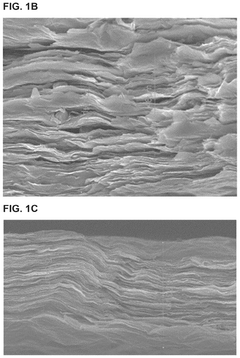

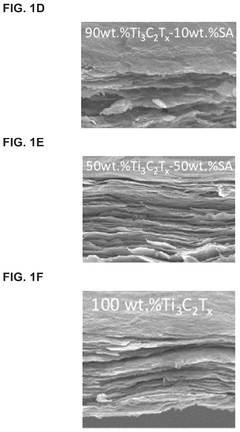

- Multilayer structures incorporating MXene for enhanced energy storage: Multilayer structures are developed using MXene and other dielectric materials to create high-performance energy storage devices. These structures can include alternating layers of MXene and polymers or other 2D materials, resulting in improved energy density and breakdown strength.

- MXene-based supercapacitors for high-voltage energy storage: MXene is utilized in the development of supercapacitors capable of high-voltage energy storage. These devices leverage the unique properties of MXene, such as high conductivity and large surface area, to achieve rapid charge-discharge cycles and high energy density.

02 Composite structures incorporating MXene for improved dielectric properties

Composite materials combining MXene with other dielectric materials, such as polymers or ceramics, are developed to enhance the overall dielectric performance. These composites leverage the synergistic effects of different materials to achieve higher energy storage capacity and voltage stability.Expand Specific Solutions03 Surface modification and functionalization of MXene for dielectric applications

Various surface modification techniques are applied to MXene to tailor its properties for high-voltage dielectric applications. These modifications can improve the compatibility with matrix materials, enhance the dielectric constant, and reduce dielectric loss.Expand Specific Solutions04 MXene-enhanced capacitor designs for high-voltage energy storage

Novel capacitor designs incorporating MXene-based materials are developed to achieve high-voltage energy storage. These designs focus on optimizing electrode structures, electrolyte compositions, and packaging to maximize energy density and operational voltage range.Expand Specific Solutions05 Manufacturing processes for MXene-based dielectric materials

Innovative manufacturing techniques are developed to produce MXene-based dielectric materials at scale. These processes focus on controlling the synthesis, exfoliation, and integration of MXene into dielectric structures while maintaining its unique properties for high-voltage energy storage applications.Expand Specific Solutions

Key Players in MXene Research

The research on MXene-enhanced high-voltage dielectrics for energy storage is in an emerging phase, with significant potential for growth. The market is expanding rapidly due to increasing demand for advanced energy storage solutions. While the technology is still developing, it has shown promising results in laboratory settings. Key players in this field include academic institutions like Jilin University, Drexel University, and Soochow University, as well as research organizations such as the Chinese Academy of Sciences. These institutions are at the forefront of MXene research, focusing on improving dielectric properties and energy density. The involvement of both Chinese and international universities indicates a global effort to advance this technology, with collaborations likely driving innovation in this competitive landscape.

Jilin University

Technical Solution: Jilin University has made significant contributions to the field of MXene-enhanced high-voltage dielectrics for energy storage. Their research focuses on developing novel MXene-based nanocomposites with enhanced dielectric properties. The university has pioneered a unique approach of combining MXenes with other 2D materials, such as boron nitride nanosheets, to create hybrid fillers for polymer matrices[4]. This strategy has led to nanocomposites with improved breakdown strength and energy storage efficiency. Jilin University researchers have also explored the use of surface-modified MXenes to enhance compatibility with various polymer matrices, resulting in better dispersion and interfacial interactions[5]. Their studies have demonstrated that MXene-based nanocomposites can achieve discharge energy densities exceeding 10 J/cm3 at high electric fields, making them promising candidates for high-voltage capacitor applications[6].

Strengths: Innovative approach in combining MXenes with other 2D materials; expertise in surface modification of MXenes; demonstrated high energy density in nanocomposites. Weaknesses: Potential challenges in large-scale production of hybrid fillers; need for further optimization of material processing techniques.

Drexel University

Technical Solution: Drexel University has pioneered research on MXene-enhanced high-voltage dielectrics for energy storage. Their approach involves synthesizing MXene nanosheets and incorporating them into polymer matrices to create nanocomposites with enhanced dielectric properties. The university has developed a method to control the surface termination of MXenes, which allows for better dispersion in polymer matrices and improved interfacial interactions[1]. This results in nanocomposites with higher dielectric constants and breakdown strengths. Drexel's researchers have also explored the use of different MXene compositions, such as Ti3C2Tx and Ti2CTx, to optimize the energy storage capabilities of the resulting materials[2]. Their studies have shown that MXene-polymer nanocomposites can achieve energy densities up to 35 J/cm3, which is significantly higher than traditional polymer dielectrics[3].

Strengths: Pioneering research in MXene synthesis and functionalization; expertise in nanocomposite fabrication; demonstrated high energy density achievements. Weaknesses: Potential scalability issues for large-scale production; long-term stability of MXene-based materials needs further investigation.

MXene Dielectric Innovations

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

Environmental Impact of MXenes

The environmental impact of MXenes, particularly in the context of high-voltage dielectrics for energy storage, is a critical consideration as these materials gain prominence in advanced applications. MXenes, a class of two-dimensional transition metal carbides and nitrides, have shown remarkable potential in various fields, including energy storage. However, their widespread adoption necessitates a thorough assessment of their environmental implications throughout their lifecycle.

The production of MXenes involves chemical etching processes that typically use hydrofluoric acid or other strong etchants. These processes can generate hazardous waste streams containing fluoride compounds and heavy metals, which require careful management and disposal to prevent environmental contamination. Additionally, the synthesis of MXenes often requires energy-intensive procedures, contributing to indirect environmental impacts through increased energy consumption and associated greenhouse gas emissions.

During their use phase in high-voltage dielectric applications, MXenes demonstrate promising characteristics that could lead to more efficient energy storage systems. This improved efficiency could potentially reduce overall energy consumption and, consequently, the environmental footprint of energy storage technologies. However, the long-term stability and degradation mechanisms of MXene-enhanced dielectrics under high-voltage conditions are not yet fully understood, raising questions about their lifespan and potential for material leaching into the environment.

The end-of-life considerations for MXene-based materials present both challenges and opportunities. On one hand, the complex composition of MXenes may complicate recycling efforts, potentially leading to increased electronic waste if not properly managed. On the other hand, the high value of the constituent elements in MXenes, such as titanium, could incentivize the development of specialized recycling processes, promoting a more circular economy approach to their use.

Research into the ecotoxicological effects of MXenes is still in its early stages. Preliminary studies suggest that while MXenes may exhibit lower toxicity compared to some other nanomaterials, their small size and unique surface properties could potentially lead to bioaccumulation in aquatic ecosystems. Further investigation is needed to fully understand their fate and behavior in different environmental compartments and their potential impacts on various organisms.

As the development of MXene-enhanced high-voltage dielectrics progresses, it is crucial to adopt a life cycle assessment approach to comprehensively evaluate their environmental impact. This should include considerations of raw material extraction, synthesis processes, use-phase efficiency gains, and end-of-life management. Such assessments will be instrumental in guiding the sustainable development and implementation of MXene-based technologies in energy storage applications.

The production of MXenes involves chemical etching processes that typically use hydrofluoric acid or other strong etchants. These processes can generate hazardous waste streams containing fluoride compounds and heavy metals, which require careful management and disposal to prevent environmental contamination. Additionally, the synthesis of MXenes often requires energy-intensive procedures, contributing to indirect environmental impacts through increased energy consumption and associated greenhouse gas emissions.

During their use phase in high-voltage dielectric applications, MXenes demonstrate promising characteristics that could lead to more efficient energy storage systems. This improved efficiency could potentially reduce overall energy consumption and, consequently, the environmental footprint of energy storage technologies. However, the long-term stability and degradation mechanisms of MXene-enhanced dielectrics under high-voltage conditions are not yet fully understood, raising questions about their lifespan and potential for material leaching into the environment.

The end-of-life considerations for MXene-based materials present both challenges and opportunities. On one hand, the complex composition of MXenes may complicate recycling efforts, potentially leading to increased electronic waste if not properly managed. On the other hand, the high value of the constituent elements in MXenes, such as titanium, could incentivize the development of specialized recycling processes, promoting a more circular economy approach to their use.

Research into the ecotoxicological effects of MXenes is still in its early stages. Preliminary studies suggest that while MXenes may exhibit lower toxicity compared to some other nanomaterials, their small size and unique surface properties could potentially lead to bioaccumulation in aquatic ecosystems. Further investigation is needed to fully understand their fate and behavior in different environmental compartments and their potential impacts on various organisms.

As the development of MXene-enhanced high-voltage dielectrics progresses, it is crucial to adopt a life cycle assessment approach to comprehensively evaluate their environmental impact. This should include considerations of raw material extraction, synthesis processes, use-phase efficiency gains, and end-of-life management. Such assessments will be instrumental in guiding the sustainable development and implementation of MXene-based technologies in energy storage applications.

MXene Scalability and Production

The scalability and production of MXene materials are critical factors in their potential application for high-voltage dielectrics in energy storage systems. MXenes, a class of two-dimensional transition metal carbides and nitrides, have shown promising properties for enhancing dielectric performance. However, the transition from laboratory-scale synthesis to large-scale industrial production presents several challenges that need to be addressed.

Currently, the most common method for MXene synthesis is the selective etching of MAX phases, typically using hydrofluoric acid (HF) or fluoride-containing solutions. While this method is effective for small-scale production, it faces limitations in terms of scalability, safety, and environmental concerns. The use of hazardous chemicals and the generation of toxic by-products pose significant challenges for industrial-scale production.

To overcome these limitations, researchers are exploring alternative synthesis methods that are more amenable to large-scale production. One promising approach is the electrochemical etching of MAX phases, which offers better control over the etching process and reduces the use of hazardous chemicals. This method has shown potential for continuous production of MXene flakes, making it more suitable for industrial applications.

Another area of focus is the development of more environmentally friendly etching agents. For instance, the use of Lewis acid molten salts has been investigated as a fluorine-free alternative for MXene synthesis. This approach not only addresses safety concerns but also opens up possibilities for the production of new MXene compositions that were previously challenging to synthesize.

The delamination of MXene layers is another crucial step in the production process that affects scalability. Traditional methods often rely on sonication, which is energy-intensive and difficult to scale up. Recent advancements have introduced techniques such as shear-assisted delamination and chemical intercalation, which show promise for large-scale production of single-layer MXene sheets.

Post-synthesis processing and handling of MXenes also present challenges for scalability. MXenes are prone to oxidation and restacking, which can degrade their properties. Developing effective methods for stabilization, storage, and integration into composite materials is essential for their successful application in high-voltage dielectrics.

As research progresses, efforts are being made to optimize production parameters and develop standardized protocols for MXene synthesis and processing. This includes improving yield, reducing production time, and ensuring consistent quality across batches. Additionally, the development of in-line characterization techniques is crucial for quality control in large-scale production settings.

Currently, the most common method for MXene synthesis is the selective etching of MAX phases, typically using hydrofluoric acid (HF) or fluoride-containing solutions. While this method is effective for small-scale production, it faces limitations in terms of scalability, safety, and environmental concerns. The use of hazardous chemicals and the generation of toxic by-products pose significant challenges for industrial-scale production.

To overcome these limitations, researchers are exploring alternative synthesis methods that are more amenable to large-scale production. One promising approach is the electrochemical etching of MAX phases, which offers better control over the etching process and reduces the use of hazardous chemicals. This method has shown potential for continuous production of MXene flakes, making it more suitable for industrial applications.

Another area of focus is the development of more environmentally friendly etching agents. For instance, the use of Lewis acid molten salts has been investigated as a fluorine-free alternative for MXene synthesis. This approach not only addresses safety concerns but also opens up possibilities for the production of new MXene compositions that were previously challenging to synthesize.

The delamination of MXene layers is another crucial step in the production process that affects scalability. Traditional methods often rely on sonication, which is energy-intensive and difficult to scale up. Recent advancements have introduced techniques such as shear-assisted delamination and chemical intercalation, which show promise for large-scale production of single-layer MXene sheets.

Post-synthesis processing and handling of MXenes also present challenges for scalability. MXenes are prone to oxidation and restacking, which can degrade their properties. Developing effective methods for stabilization, storage, and integration into composite materials is essential for their successful application in high-voltage dielectrics.

As research progresses, efforts are being made to optimize production parameters and develop standardized protocols for MXene synthesis and processing. This includes improving yield, reducing production time, and ensuring consistent quality across batches. Additionally, the development of in-line characterization techniques is crucial for quality control in large-scale production settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!