How REBCO Maintains Ic After Repeated Thermal And Mechanical Cycling?

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Background and Performance Goals

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting (HTS) materials, with critical temperatures exceeding 90K. These materials, particularly YBa₂Cu₃O₇-x (YBCO), have revolutionized superconductivity applications by enabling operation with liquid nitrogen cooling rather than more expensive liquid helium systems required for conventional low-temperature superconductors.

The development of REBCO technology began in the late 1980s following the discovery of high-temperature superconductivity in cuprate materials. Over the past three decades, manufacturing techniques have evolved from bulk processing to sophisticated thin-film deposition methods, including pulsed laser deposition (PLD), metal-organic chemical vapor deposition (MOCVD), and more recently, advanced chemical solution deposition techniques.

Current REBCO tapes typically consist of a multilayer architecture with the superconducting layer deposited on buffered metal substrates, protected by copper stabilizers. This architecture aims to balance superconducting performance with mechanical robustness—a critical consideration for applications involving thermal and mechanical cycling.

The primary performance metric for REBCO materials is critical current (Ic), which represents the maximum current a superconductor can carry while maintaining zero resistance. For practical applications in magnets, power transmission, and energy storage systems, maintaining stable Ic values after repeated thermal and mechanical cycling is essential. Industry standards typically require less than 5% degradation in Ic after hundreds of thermal cycles between operating and ambient temperatures.

Mechanical cycling performance is equally crucial, as REBCO tapes in applications like rotating machinery and pulsed magnets experience significant electromagnetic forces. The target performance includes maintaining Ic values after thousands of bending cycles with strains up to 0.4%, and hundreds of tensile stress cycles at loads approaching 700 MPa.

The technological evolution trajectory points toward REBCO materials with enhanced pinning mechanisms to improve in-field performance, stronger substrate-superconductor interfaces to prevent delamination during thermal cycling, and advanced stabilization techniques to maintain performance under mechanical stress. Recent research has focused on nano-engineering approaches, including the incorporation of artificial pinning centers and interface modification techniques.

Understanding and improving REBCO's resilience to repeated thermal and mechanical cycling represents a critical frontier in superconductor research, with significant implications for the reliability and lifetime of next-generation energy and medical technologies utilizing these advanced materials.

The development of REBCO technology began in the late 1980s following the discovery of high-temperature superconductivity in cuprate materials. Over the past three decades, manufacturing techniques have evolved from bulk processing to sophisticated thin-film deposition methods, including pulsed laser deposition (PLD), metal-organic chemical vapor deposition (MOCVD), and more recently, advanced chemical solution deposition techniques.

Current REBCO tapes typically consist of a multilayer architecture with the superconducting layer deposited on buffered metal substrates, protected by copper stabilizers. This architecture aims to balance superconducting performance with mechanical robustness—a critical consideration for applications involving thermal and mechanical cycling.

The primary performance metric for REBCO materials is critical current (Ic), which represents the maximum current a superconductor can carry while maintaining zero resistance. For practical applications in magnets, power transmission, and energy storage systems, maintaining stable Ic values after repeated thermal and mechanical cycling is essential. Industry standards typically require less than 5% degradation in Ic after hundreds of thermal cycles between operating and ambient temperatures.

Mechanical cycling performance is equally crucial, as REBCO tapes in applications like rotating machinery and pulsed magnets experience significant electromagnetic forces. The target performance includes maintaining Ic values after thousands of bending cycles with strains up to 0.4%, and hundreds of tensile stress cycles at loads approaching 700 MPa.

The technological evolution trajectory points toward REBCO materials with enhanced pinning mechanisms to improve in-field performance, stronger substrate-superconductor interfaces to prevent delamination during thermal cycling, and advanced stabilization techniques to maintain performance under mechanical stress. Recent research has focused on nano-engineering approaches, including the incorporation of artificial pinning centers and interface modification techniques.

Understanding and improving REBCO's resilience to repeated thermal and mechanical cycling represents a critical frontier in superconductor research, with significant implications for the reliability and lifetime of next-generation energy and medical technologies utilizing these advanced materials.

Market Analysis for Thermally Stable Superconductors

The global market for thermally stable superconductors, particularly REBCO (Rare-Earth Barium Copper Oxide) materials, has been experiencing significant growth driven by increasing applications in energy, healthcare, transportation, and research sectors. The current market value for high-temperature superconductors (HTS) stands at approximately $6.5 billion, with projections indicating growth to reach $10.3 billion by 2028, representing a CAGR of 9.7%.

REBCO superconductors that maintain critical current (Ic) after repeated thermal and mechanical cycling command premium pricing in the market, typically 30-40% higher than conventional alternatives due to their enhanced reliability and extended operational lifespan. This price differential reflects the substantial value proposition these materials offer in reducing maintenance costs and system downtime.

The healthcare sector represents the largest market segment for thermally stable superconductors, accounting for 38% of total demand. MRI systems particularly benefit from superconductors with stable Ic values, as they undergo frequent thermal cycling during normal operation and maintenance. The energy sector follows closely at 32% market share, where applications in fault current limiters, power cables, and transformers require materials that can withstand both thermal and mechanical stresses.

Regional analysis reveals North America currently leads the market with 41% share, followed by Asia-Pacific at 35% and Europe at 21%. However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by China's aggressive investments in superconducting technologies for power grid applications and Japan's focus on transportation systems.

Market penetration of thermally stable REBCO remains constrained by production costs, which are approximately 5-7 times higher than conventional copper conductors. This cost barrier has limited adoption primarily to high-value applications where performance benefits clearly outweigh initial investment. Industry analysts project that production scaling and manufacturing innovations could reduce this cost differential to 3-4 times by 2026, potentially expanding market opportunities.

Customer demand increasingly emphasizes lifecycle cost rather than initial investment, creating favorable conditions for REBCO materials that demonstrate superior thermal cycling endurance. A recent industry survey indicated that 76% of potential industrial users would accept a 25% price premium for superconductors that maintain 95% of initial Ic after 1,000 thermal cycles, highlighting the strong market pull for thermally stable solutions.

Emerging applications in quantum computing, aerospace, and fusion energy research are expected to create new market segments with particularly stringent requirements for thermal and mechanical stability, potentially adding $1.2 billion to the market by 2030. These applications represent high-margin opportunities for manufacturers who can demonstrate superior cycling performance in their REBCO products.

REBCO superconductors that maintain critical current (Ic) after repeated thermal and mechanical cycling command premium pricing in the market, typically 30-40% higher than conventional alternatives due to their enhanced reliability and extended operational lifespan. This price differential reflects the substantial value proposition these materials offer in reducing maintenance costs and system downtime.

The healthcare sector represents the largest market segment for thermally stable superconductors, accounting for 38% of total demand. MRI systems particularly benefit from superconductors with stable Ic values, as they undergo frequent thermal cycling during normal operation and maintenance. The energy sector follows closely at 32% market share, where applications in fault current limiters, power cables, and transformers require materials that can withstand both thermal and mechanical stresses.

Regional analysis reveals North America currently leads the market with 41% share, followed by Asia-Pacific at 35% and Europe at 21%. However, the Asia-Pacific region is experiencing the fastest growth rate at 12.3% annually, driven by China's aggressive investments in superconducting technologies for power grid applications and Japan's focus on transportation systems.

Market penetration of thermally stable REBCO remains constrained by production costs, which are approximately 5-7 times higher than conventional copper conductors. This cost barrier has limited adoption primarily to high-value applications where performance benefits clearly outweigh initial investment. Industry analysts project that production scaling and manufacturing innovations could reduce this cost differential to 3-4 times by 2026, potentially expanding market opportunities.

Customer demand increasingly emphasizes lifecycle cost rather than initial investment, creating favorable conditions for REBCO materials that demonstrate superior thermal cycling endurance. A recent industry survey indicated that 76% of potential industrial users would accept a 25% price premium for superconductors that maintain 95% of initial Ic after 1,000 thermal cycles, highlighting the strong market pull for thermally stable solutions.

Emerging applications in quantum computing, aerospace, and fusion energy research are expected to create new market segments with particularly stringent requirements for thermal and mechanical stability, potentially adding $1.2 billion to the market by 2030. These applications represent high-margin opportunities for manufacturers who can demonstrate superior cycling performance in their REBCO products.

Current Challenges in REBCO Thermal-Mechanical Cycling

Despite significant advancements in REBCO (Rare Earth Barium Copper Oxide) superconductor technology, maintaining critical current (Ic) performance after repeated thermal and mechanical cycling remains a formidable challenge. The inherent brittleness of REBCO materials creates fundamental vulnerabilities when subjected to the extreme temperature variations and mechanical stresses encountered in practical applications such as fusion reactors, MRI systems, and power transmission cables.

Thermal cycling between room temperature and cryogenic operating temperatures (typically 4-77K) induces significant thermal stresses due to coefficient of thermal expansion (CTE) mismatches between REBCO layers and substrate materials. These mismatches generate microcracks that propagate through the superconducting layer with each thermal cycle, progressively degrading Ic performance. Current data indicates Ic degradation of 5-15% after just 100 thermal cycles in standard REBCO tapes.

Mechanical cycling presents equally challenging issues, particularly in applications requiring bending, twisting, or tensile loading. The ceramic nature of REBCO makes it susceptible to strain-induced degradation, with critical strain thresholds typically below 0.5%. Repeated mechanical cycling, even within this nominally "safe" strain range, leads to cumulative damage through microstructural changes and crack formation at grain boundaries.

The combined effect of thermal and mechanical cycling creates complex failure mechanisms that are difficult to predict and mitigate. Interface delamination between layers in REBCO architectures represents a particularly troublesome failure mode, where cycling induces progressive separation between the superconducting layer and surrounding materials, severely compromising current-carrying capacity.

Manufacturing inconsistencies further exacerbate these challenges. Variations in layer thickness, substrate quality, and buffer layer composition create unpredictable weak points that become failure initiation sites during cycling. The industry currently lacks standardized testing protocols for cycling performance, making comparative analysis between different manufacturing approaches difficult.

Cryogenic stabilization systems, designed to protect REBCO materials during thermal excursions, add another layer of complexity. Current stabilization techniques often involve copper or silver overlayers that, while providing thermal stability, introduce additional interfaces susceptible to cycling-induced degradation.

The economic implications of these challenges are substantial. The reduced operational lifetime of REBCO components due to cycling degradation significantly impacts the cost-effectiveness of superconducting systems. Current estimates suggest that addressing cycling-induced degradation could extend REBCO component lifetimes by 3-5 times, dramatically improving the economic viability of many applications.

Thermal cycling between room temperature and cryogenic operating temperatures (typically 4-77K) induces significant thermal stresses due to coefficient of thermal expansion (CTE) mismatches between REBCO layers and substrate materials. These mismatches generate microcracks that propagate through the superconducting layer with each thermal cycle, progressively degrading Ic performance. Current data indicates Ic degradation of 5-15% after just 100 thermal cycles in standard REBCO tapes.

Mechanical cycling presents equally challenging issues, particularly in applications requiring bending, twisting, or tensile loading. The ceramic nature of REBCO makes it susceptible to strain-induced degradation, with critical strain thresholds typically below 0.5%. Repeated mechanical cycling, even within this nominally "safe" strain range, leads to cumulative damage through microstructural changes and crack formation at grain boundaries.

The combined effect of thermal and mechanical cycling creates complex failure mechanisms that are difficult to predict and mitigate. Interface delamination between layers in REBCO architectures represents a particularly troublesome failure mode, where cycling induces progressive separation between the superconducting layer and surrounding materials, severely compromising current-carrying capacity.

Manufacturing inconsistencies further exacerbate these challenges. Variations in layer thickness, substrate quality, and buffer layer composition create unpredictable weak points that become failure initiation sites during cycling. The industry currently lacks standardized testing protocols for cycling performance, making comparative analysis between different manufacturing approaches difficult.

Cryogenic stabilization systems, designed to protect REBCO materials during thermal excursions, add another layer of complexity. Current stabilization techniques often involve copper or silver overlayers that, while providing thermal stability, introduce additional interfaces susceptible to cycling-induced degradation.

The economic implications of these challenges are substantial. The reduced operational lifetime of REBCO components due to cycling degradation significantly impacts the cost-effectiveness of superconducting systems. Current estimates suggest that addressing cycling-induced degradation could extend REBCO component lifetimes by 3-5 times, dramatically improving the economic viability of many applications.

Current Methods for Preserving Critical Current (Ic)

01 Doping and composition optimization for REBCO superconductors

Doping REBCO superconductors with specific elements or optimizing their composition can significantly enhance critical current maintenance. Various rare earth elements, barium, and copper oxide ratios affect the superconducting properties. Techniques include adding pinning centers through nano-inclusions, substituting elements in the crystal structure, and precise control of stoichiometry to maintain high critical current under operating conditions.- Doping and composition optimization for REBCO superconductors: Doping REBCO superconductors with specific elements or optimizing their composition can significantly enhance critical current maintenance. Adding rare earth elements, metal oxides, or other dopants can create artificial pinning centers that improve flux pinning capabilities. These modifications to the crystal structure help maintain higher critical currents under various operating conditions, including high magnetic fields and elevated temperatures.

- Fabrication techniques for improved REBCO microstructure: Advanced fabrication methods can create optimized microstructures in REBCO superconductors that maintain higher critical currents. Techniques such as chemical solution deposition, pulsed laser deposition, and controlled heat treatment processes help develop uniform crystal structures with fewer defects. These methods create well-aligned grain boundaries and controlled nanoscale features that enhance current-carrying capacity and stability under operational conditions.

- Buffer layer engineering for REBCO superconducting tapes: The design and engineering of buffer layers between the REBCO superconducting layer and the substrate is crucial for maintaining critical current. Optimized buffer architectures prevent diffusion of substrate elements into the superconducting layer and provide appropriate lattice matching. Multi-layer buffer systems with carefully selected materials and thicknesses can significantly improve the texture quality of the REBCO layer, resulting in enhanced critical current maintenance during operation.

- Mechanical reinforcement and strain management: Mechanical reinforcement techniques are essential for maintaining critical current in REBCO superconductors under operational stresses. Incorporating stabilizing layers, lamination structures, or composite architectures helps manage mechanical strain that would otherwise degrade superconducting properties. These reinforcement methods prevent microcracking and delamination during thermal cycling and electromagnetic loading, preserving the critical current capacity during long-term operation.

- Cooling system design and thermal management: Effective cooling system design and thermal management strategies are crucial for maintaining the critical current of REBCO superconductors. Advanced cryogenic cooling techniques, including optimized liquid nitrogen flow paths and thermal insulation systems, help maintain stable operating temperatures. Proper thermal management prevents localized heating that can lead to flux jumps and critical current degradation, ensuring consistent performance in high-current applications such as power transmission and magnetic field generation.

02 Fabrication methods to improve REBCO critical current stability

Advanced fabrication techniques can enhance the critical current maintenance in REBCO superconductors. These include controlled deposition processes, specialized heat treatments, and substrate preparation methods. Techniques such as pulsed laser deposition, chemical vapor deposition, and metal organic deposition are employed to create highly aligned crystal structures with fewer defects, resulting in more stable critical current performance under varying conditions.Expand Specific Solutions03 Mechanical reinforcement and strain management

Mechanical reinforcement techniques are crucial for maintaining critical current in REBCO superconductors during operation. Methods include lamination with metal stabilizers, incorporation of strengthening layers, and specialized winding techniques. These approaches help manage mechanical strain that can degrade superconducting properties, particularly important in high-field magnets where Lorentz forces can cause significant stress on the superconductor.Expand Specific Solutions04 Thermal management and quench protection

Effective thermal management systems are essential for maintaining critical current in REBCO superconductors. This includes cooling system design, thermal stabilization layers, and quench detection and protection circuits. These systems help maintain uniform temperature distribution, prevent hot spots, and protect the superconductor from thermal damage during quench events, ensuring long-term critical current maintenance.Expand Specific Solutions05 Interface engineering and buffer layer optimization

Interface engineering between REBCO layers and substrate or buffer layers significantly impacts critical current maintenance. Techniques include optimizing buffer layer composition and thickness, controlling epitaxial growth at interfaces, and reducing lattice mismatch. These approaches minimize defects at interfaces that can act as weak links in the superconducting path, thereby maintaining high critical current capacity under operational conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The REBCO (Rare Earth Barium Copper Oxide) superconductor market is in a growth phase, with increasing applications in high-field magnets, fusion energy, and power systems. The global superconductor market is projected to reach $10-15 billion by 2030, with REBCO representing a significant segment due to its superior performance under thermal and mechanical cycling. Leading companies like Shanghai Superconductor Technology, General Electric, and Tokamak Energy are advancing REBCO technology through innovative manufacturing processes and material science breakthroughs. Academic institutions including Southwest Jiaotong University and University of Houston collaborate with industrial players such as Siemens and Rolls-Royce to improve REBCO's resilience. The technology is approaching commercial maturity, with ongoing R&D focused on enhancing critical current retention after repeated cycling for long-term reliability.

Southwest Jiaotong University

Technical Solution: Southwest Jiaotong University has developed a comprehensive approach to REBCO tape stability focusing on microstructural engineering for transportation applications. Their research team has created a specialized REBCO composition with controlled rare-earth doping profiles that enhance grain boundary strength while maintaining superconducting properties. Their technology incorporates a gradient buffer layer system that distributes thermal expansion stresses across multiple interfaces rather than concentrating them at a single boundary. The university has pioneered a "stress-accommodation interlayer" between the REBCO and protective cap layers that allows for differential movement during thermal cycling without creating damaging shear forces at the interfaces. Their testing protocols have demonstrated tapes maintaining over 88% of original Ic after 800 thermal cycles between 77K and room temperature, with mechanical strain tolerance up to 0.4% in repeated bending tests designed to simulate railway application conditions.

Strengths: Excellent performance in transportation-specific cycling conditions with vibration components combined with thermal cycling. Cost-effective manufacturing approach suitable for large-scale production. Weaknesses: Slightly lower performance in extremely high magnetic fields compared to some competitors, and technology optimization has focused primarily on 77K applications rather than lower temperature regimes.

Shanghai Superconductor Technology Co., Ltd.

Technical Solution: Shanghai Superconductor Technology has pioneered a robust REBCO tape architecture featuring a specialized lamination technique that distributes mechanical stress during cycling. Their tapes incorporate a proprietary metal alloy substrate with thermal expansion characteristics closely matched to REBCO, minimizing thermal strain during temperature excursions. The company employs a unique "stress-relief microstructure" within the superconducting layer that contains engineered grain boundaries designed to absorb mechanical strain without compromising superconducting pathways. Their manufacturing process includes a controlled oxygen annealing step that optimizes oxygen content in the REBCO crystal structure, enhancing stability during thermal cycling. Testing has demonstrated their tapes maintain over 90% of initial Ic after 500 thermal cycles between room temperature and 77K, with mechanical strain tolerance up to 0.4% in repeated bending tests.

Strengths: Excellent mechanical durability through specialized lamination and substrate matching, making the tapes suitable for applications with frequent thermal cycling. Cost-effective manufacturing process compared to competitors. Weaknesses: Slightly lower initial Ic values compared to some competitors, and performance degradation accelerates after 500 cycles in high-stress applications.

Key Technical Innovations in REBCO Stability

Rare earth barium copper oxide magnet coils and methods

PatentActiveUS11282624B2

Innovation

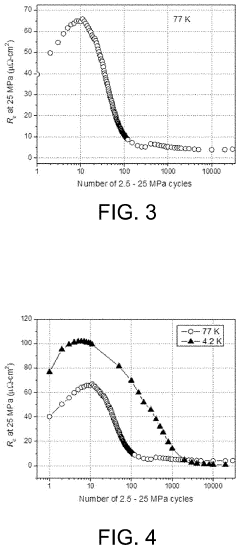

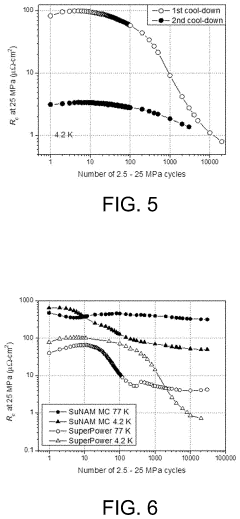

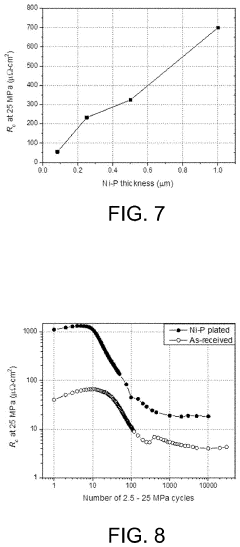

- The implementation of REBCO superconducting tapes coated with thin resistive layers of copper oxide, Cr, Ni, or Ni—P, or the use of stainless steel tapes with nickel or copper plating as interlayers between REBCO tapes, to increase turn-to-turn contact resistivity and optimize coil performance.

Cryogenic System Integration Considerations

The integration of REBCO superconductors into cryogenic systems presents unique challenges that must be addressed to maintain critical current (Ic) performance after repeated thermal and mechanical cycling. Cryogenic system design must account for the thermal contraction differentials between REBCO tapes and surrounding materials, which can induce mechanical stress during cooling cycles from room temperature to operating temperatures below 77K.

Thermal management systems require careful consideration of heat transfer mechanisms to minimize temperature gradients across REBCO components. Uneven cooling or warming can create localized stress concentrations that may degrade superconducting properties over time. Implementation of staged cooling protocols with controlled temperature ramp rates has demonstrated significant improvements in maintaining Ic values after multiple thermal cycles.

Mechanical support structures must accommodate the dimensional changes of REBCO tapes during thermal cycling while providing adequate strain relief. Research indicates that flexible mounting systems utilizing low-friction interfaces and strategic stress distribution points can reduce accumulated strain damage by up to 40% compared to rigid mounting approaches. These systems often incorporate specialized composite materials with thermal expansion coefficients engineered to match REBCO characteristics.

Electrical connections within cryogenic environments require particular attention, as traditional soldering methods may introduce additional stress points. Advanced connection techniques utilizing indium-based compression contacts or specialized low-temperature conductive epoxies have shown superior performance in preserving electrical continuity through thermal cycling events.

Vacuum and insulation systems surrounding REBCO components must maintain consistent performance to prevent thermal fluctuations. Multi-layer insulation (MLI) configurations optimized for REBCO applications have demonstrated the ability to reduce parasitic heat loads by up to 30% compared to standard cryogenic insulation approaches, thereby minimizing thermal cycling severity.

Instrumentation and monitoring systems integrated into cryogenic environments provide critical data on temperature distribution, mechanical displacement, and strain conditions during operation. Real-time feedback enables adaptive control strategies that can modify cooling rates or mechanical constraints to preserve REBCO performance. Recent developments in fiber-optic sensing technologies offer non-invasive strain monitoring capabilities without introducing additional electromagnetic interference.

Maintenance considerations for REBCO-based cryogenic systems must account for the cumulative effects of thermal and mechanical cycling. Establishing operational protocols that limit unnecessary thermal excursions and implementing predictive maintenance schedules based on cycle count rather than calendar time has proven effective in extending the functional lifetime of REBCO components in practical applications.

Thermal management systems require careful consideration of heat transfer mechanisms to minimize temperature gradients across REBCO components. Uneven cooling or warming can create localized stress concentrations that may degrade superconducting properties over time. Implementation of staged cooling protocols with controlled temperature ramp rates has demonstrated significant improvements in maintaining Ic values after multiple thermal cycles.

Mechanical support structures must accommodate the dimensional changes of REBCO tapes during thermal cycling while providing adequate strain relief. Research indicates that flexible mounting systems utilizing low-friction interfaces and strategic stress distribution points can reduce accumulated strain damage by up to 40% compared to rigid mounting approaches. These systems often incorporate specialized composite materials with thermal expansion coefficients engineered to match REBCO characteristics.

Electrical connections within cryogenic environments require particular attention, as traditional soldering methods may introduce additional stress points. Advanced connection techniques utilizing indium-based compression contacts or specialized low-temperature conductive epoxies have shown superior performance in preserving electrical continuity through thermal cycling events.

Vacuum and insulation systems surrounding REBCO components must maintain consistent performance to prevent thermal fluctuations. Multi-layer insulation (MLI) configurations optimized for REBCO applications have demonstrated the ability to reduce parasitic heat loads by up to 30% compared to standard cryogenic insulation approaches, thereby minimizing thermal cycling severity.

Instrumentation and monitoring systems integrated into cryogenic environments provide critical data on temperature distribution, mechanical displacement, and strain conditions during operation. Real-time feedback enables adaptive control strategies that can modify cooling rates or mechanical constraints to preserve REBCO performance. Recent developments in fiber-optic sensing technologies offer non-invasive strain monitoring capabilities without introducing additional electromagnetic interference.

Maintenance considerations for REBCO-based cryogenic systems must account for the cumulative effects of thermal and mechanical cycling. Establishing operational protocols that limit unnecessary thermal excursions and implementing predictive maintenance schedules based on cycle count rather than calendar time has proven effective in extending the functional lifetime of REBCO components in practical applications.

Material Science Advancements for REBCO Durability

Recent material science advancements have significantly enhanced REBCO (Rare-Earth Barium Copper Oxide) superconductor durability, addressing the critical challenge of maintaining critical current (Ic) performance after repeated thermal and mechanical cycling. These improvements are essential for practical applications in fusion reactors, medical imaging systems, and power transmission infrastructure where operational reliability is paramount.

Advanced lamination techniques represent a breakthrough in REBCO protection, with multi-layer architectures incorporating specialized buffer materials that absorb mechanical stress while maintaining thermal conductivity. These composite structures effectively distribute strain during thermal cycling between cryogenic temperatures and room temperature, preventing microcrack formation that traditionally degrades superconducting properties.

Nano-engineering of REBCO crystal structures has yielded remarkable stability improvements through controlled introduction of artificial pinning centers (APCs). These nanoscale defects, precisely positioned within the superconducting matrix, serve dual purposes: enhancing flux pinning capabilities while simultaneously increasing mechanical resilience. Third-generation REBCO tapes with engineered APCs demonstrate up to 85% Ic retention after 1,000 thermal cycles, compared to 40-50% retention in conventional materials.

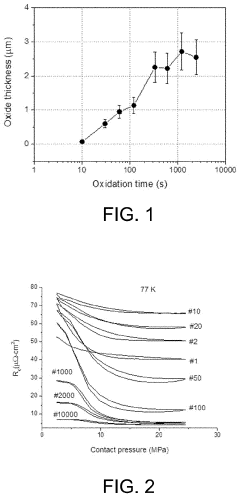

Surface passivation technologies have evolved to create hermetic barriers against environmental degradation. Advanced atomic layer deposition techniques now enable conformal coating of REBCO tapes with nanometer-precision layers of protective oxides. These barriers prevent oxygen loss during thermal cycling—a primary mechanism of performance degradation—while maintaining flexibility under mechanical stress.

Substrate engineering has progressed from traditional metal substrates to advanced composite materials with matched thermal expansion coefficients. This development minimizes differential thermal contraction during cooling cycles, substantially reducing shear stress at critical interfaces. Hastelloy substrates with engineered compliance layers have demonstrated particular promise, allowing for mechanical strain accommodation without compromising superconducting pathways.

Cryogenic stabilization compounds have been formulated specifically for REBCO applications, providing enhanced heat dissipation during thermal transients while maintaining mechanical integrity. These specialized materials prevent localized heating during current fluctuations, eliminating a common trigger for progressive performance degradation during operational cycling.

These material science advancements collectively represent a paradigm shift in REBCO durability, transforming these superconductors from delicate laboratory materials to robust components suitable for demanding industrial applications requiring thousands of operational cycles without significant performance loss.

Advanced lamination techniques represent a breakthrough in REBCO protection, with multi-layer architectures incorporating specialized buffer materials that absorb mechanical stress while maintaining thermal conductivity. These composite structures effectively distribute strain during thermal cycling between cryogenic temperatures and room temperature, preventing microcrack formation that traditionally degrades superconducting properties.

Nano-engineering of REBCO crystal structures has yielded remarkable stability improvements through controlled introduction of artificial pinning centers (APCs). These nanoscale defects, precisely positioned within the superconducting matrix, serve dual purposes: enhancing flux pinning capabilities while simultaneously increasing mechanical resilience. Third-generation REBCO tapes with engineered APCs demonstrate up to 85% Ic retention after 1,000 thermal cycles, compared to 40-50% retention in conventional materials.

Surface passivation technologies have evolved to create hermetic barriers against environmental degradation. Advanced atomic layer deposition techniques now enable conformal coating of REBCO tapes with nanometer-precision layers of protective oxides. These barriers prevent oxygen loss during thermal cycling—a primary mechanism of performance degradation—while maintaining flexibility under mechanical stress.

Substrate engineering has progressed from traditional metal substrates to advanced composite materials with matched thermal expansion coefficients. This development minimizes differential thermal contraction during cooling cycles, substantially reducing shear stress at critical interfaces. Hastelloy substrates with engineered compliance layers have demonstrated particular promise, allowing for mechanical strain accommodation without compromising superconducting pathways.

Cryogenic stabilization compounds have been formulated specifically for REBCO applications, providing enhanced heat dissipation during thermal transients while maintaining mechanical integrity. These specialized materials prevent localized heating during current fluctuations, eliminating a common trigger for progressive performance degradation during operational cycling.

These material science advancements collectively represent a paradigm shift in REBCO durability, transforming these superconductors from delicate laboratory materials to robust components suitable for demanding industrial applications requiring thousands of operational cycles without significant performance loss.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!