REBCO Mechanical Limits: Bending Strain, Hoop Stress And Fatigue

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Development History and Objectives

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a revolutionary advancement in high-temperature superconductivity, with their development history spanning over three decades. The journey began in the late 1980s with the discovery of YBa2Cu3O7-x (YBCO), the first superconductor to operate above liquid nitrogen temperature (77K). This breakthrough opened new possibilities for practical applications of superconductivity without requiring expensive liquid helium cooling.

The 1990s marked a period of intensive research focused on understanding the fundamental properties of these materials. Scientists worldwide investigated the crystal structure, electronic properties, and superconducting mechanisms of REBCO compounds. During this period, the potential for replacing rare earth elements while maintaining superconducting properties was explored, leading to variations such as GdBCO and SmBCO.

A significant technological leap occurred in the early 2000s with the development of second-generation (2G) high-temperature superconductor (HTS) wires based on REBCO thin films. These coated conductors offered substantial improvements over first-generation bismuth-based wires, particularly in terms of current-carrying capacity and mechanical robustness. The introduction of metal-organic chemical vapor deposition (MOCVD) and pulsed laser deposition (PLD) techniques enabled the production of high-quality REBCO layers on buffered metal substrates.

The 2010s witnessed remarkable progress in manufacturing processes, resulting in longer wire lengths and improved performance metrics. Companies like SuperPower, American Superconductor, and Fujikura emerged as key industrial players, scaling up production capabilities and enhancing wire quality. During this period, researchers began focusing intensively on the mechanical limitations of REBCO materials, recognizing that practical applications would subject these materials to significant mechanical stresses.

Current research objectives center on addressing the mechanical limits of REBCO superconductors, particularly regarding bending strain, hoop stress, and fatigue resistance. These factors are critical for applications in high-field magnets, power transmission cables, and rotating machinery. The goal is to develop REBCO conductors that can withstand the extreme mechanical conditions encountered in practical devices while maintaining their superior electrical properties.

Looking forward, the field aims to achieve several key objectives: enhancing the critical current density under high magnetic fields, improving mechanical strength without compromising electrical performance, developing cost-effective manufacturing techniques, and establishing standardized testing protocols for mechanical properties. These advancements are essential for enabling the next generation of superconducting applications, including compact fusion reactors, medical imaging systems, and energy storage solutions.

The 1990s marked a period of intensive research focused on understanding the fundamental properties of these materials. Scientists worldwide investigated the crystal structure, electronic properties, and superconducting mechanisms of REBCO compounds. During this period, the potential for replacing rare earth elements while maintaining superconducting properties was explored, leading to variations such as GdBCO and SmBCO.

A significant technological leap occurred in the early 2000s with the development of second-generation (2G) high-temperature superconductor (HTS) wires based on REBCO thin films. These coated conductors offered substantial improvements over first-generation bismuth-based wires, particularly in terms of current-carrying capacity and mechanical robustness. The introduction of metal-organic chemical vapor deposition (MOCVD) and pulsed laser deposition (PLD) techniques enabled the production of high-quality REBCO layers on buffered metal substrates.

The 2010s witnessed remarkable progress in manufacturing processes, resulting in longer wire lengths and improved performance metrics. Companies like SuperPower, American Superconductor, and Fujikura emerged as key industrial players, scaling up production capabilities and enhancing wire quality. During this period, researchers began focusing intensively on the mechanical limitations of REBCO materials, recognizing that practical applications would subject these materials to significant mechanical stresses.

Current research objectives center on addressing the mechanical limits of REBCO superconductors, particularly regarding bending strain, hoop stress, and fatigue resistance. These factors are critical for applications in high-field magnets, power transmission cables, and rotating machinery. The goal is to develop REBCO conductors that can withstand the extreme mechanical conditions encountered in practical devices while maintaining their superior electrical properties.

Looking forward, the field aims to achieve several key objectives: enhancing the critical current density under high magnetic fields, improving mechanical strength without compromising electrical performance, developing cost-effective manufacturing techniques, and establishing standardized testing protocols for mechanical properties. These advancements are essential for enabling the next generation of superconducting applications, including compact fusion reactors, medical imaging systems, and energy storage solutions.

Market Analysis for High-Field Superconducting Applications

The high-field superconducting market is experiencing significant growth driven by advancements in REBCO (Rare-Earth Barium Copper Oxide) technology. This market encompasses several key application segments including magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR) systems, particle accelerators, fusion energy research, and power transmission systems. Each of these segments presents unique opportunities and challenges for REBCO implementation, particularly regarding mechanical limits.

The global superconducting wire market was valued at approximately $1.3 billion in 2022 and is projected to grow at a CAGR of 7-8% through 2030. High-field applications represent the fastest-growing segment within this market, with REBCO materials gaining significant traction due to their superior performance at higher magnetic fields compared to traditional low-temperature superconductors.

Medical imaging represents the largest current commercial application, with high-field MRI systems (>3T) demanding advanced superconducting materials that can withstand the mechanical stresses of operation. The medical superconducting magnet market alone exceeds $5 billion annually, with research institutions and healthcare facilities increasingly investing in higher field systems that require REBCO technology.

Scientific research applications, particularly in high-energy physics and fusion energy, constitute another major market segment. ITER and other fusion projects represent multi-billion dollar investments where REBCO's mechanical performance under extreme conditions is critical. The ability of these materials to withstand bending strain, hoop stress, and fatigue directly impacts the feasibility and cost-effectiveness of these large-scale scientific endeavors.

Industrial applications are emerging as a promising growth area, with superconducting fault current limiters, motors, and generators representing potential mass-market applications. However, these applications require REBCO materials to demonstrate reliable mechanical performance under repeated thermal and electromagnetic cycling conditions.

Market penetration of REBCO technology remains constrained by production costs and mechanical reliability concerns. Current prices range from $100-400 per meter depending on performance specifications, with mechanical robustness commanding premium pricing. Manufacturers who can demonstrate superior mechanical limits in their REBCO products can command price premiums of 30-50% in high-stress application environments.

Regional analysis shows North America and Asia-Pacific leading in market adoption, with Europe following closely. Japan and South Korea have made significant investments in REBCO manufacturing capabilities, while China is rapidly expanding its domestic production capacity to meet growing demand in both scientific and industrial applications.

The global superconducting wire market was valued at approximately $1.3 billion in 2022 and is projected to grow at a CAGR of 7-8% through 2030. High-field applications represent the fastest-growing segment within this market, with REBCO materials gaining significant traction due to their superior performance at higher magnetic fields compared to traditional low-temperature superconductors.

Medical imaging represents the largest current commercial application, with high-field MRI systems (>3T) demanding advanced superconducting materials that can withstand the mechanical stresses of operation. The medical superconducting magnet market alone exceeds $5 billion annually, with research institutions and healthcare facilities increasingly investing in higher field systems that require REBCO technology.

Scientific research applications, particularly in high-energy physics and fusion energy, constitute another major market segment. ITER and other fusion projects represent multi-billion dollar investments where REBCO's mechanical performance under extreme conditions is critical. The ability of these materials to withstand bending strain, hoop stress, and fatigue directly impacts the feasibility and cost-effectiveness of these large-scale scientific endeavors.

Industrial applications are emerging as a promising growth area, with superconducting fault current limiters, motors, and generators representing potential mass-market applications. However, these applications require REBCO materials to demonstrate reliable mechanical performance under repeated thermal and electromagnetic cycling conditions.

Market penetration of REBCO technology remains constrained by production costs and mechanical reliability concerns. Current prices range from $100-400 per meter depending on performance specifications, with mechanical robustness commanding premium pricing. Manufacturers who can demonstrate superior mechanical limits in their REBCO products can command price premiums of 30-50% in high-stress application environments.

Regional analysis shows North America and Asia-Pacific leading in market adoption, with Europe following closely. Japan and South Korea have made significant investments in REBCO manufacturing capabilities, while China is rapidly expanding its domestic production capacity to meet growing demand in both scientific and industrial applications.

Current Mechanical Challenges in REBCO Technology

REBCO (Rare-Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting technology, yet their widespread application faces substantial mechanical challenges. The mechanical properties of REBCO tapes are critical factors limiting their performance in high-field magnets and other applications requiring complex geometries.

Bending strain presents a primary mechanical limitation for REBCO conductors. These materials exhibit brittle ceramic characteristics, with critical current degradation occurring at strain levels as low as 0.3-0.5%. This constraint significantly impacts the minimum bending radius achievable in applications such as compact magnet designs, where sharp bends are often necessary. The layered structure of REBCO tapes, consisting of the superconducting layer deposited on metallic substrates, creates inherent stress concentrations at interfaces that can lead to microcracking under relatively modest strain conditions.

Hoop stress represents another critical challenge, particularly in magnet applications where REBCO tapes experience substantial electromagnetic forces. Under operational conditions in high-field magnets (>20T), the Lorentz forces generate significant hoop stresses that can exceed 500 MPa. Current REBCO architectures typically incorporate high-strength substrates like Hastelloy, but even these materials approach their mechanical limits in ultra-high field applications exceeding 30T. The stress management becomes particularly problematic at cryogenic temperatures, where material properties change significantly.

Fatigue behavior presents a long-term reliability concern that remains inadequately characterized. REBCO systems experience cyclic loading during repeated magnet ramping operations or in applications with pulsed fields. Current data indicates performance degradation can occur at cycle counts well below what traditional mechanical fatigue models would predict, suggesting unique degradation mechanisms at the microstructural level. The complex interaction between thermal cycling, electromagnetic cycling, and mechanical stress creates cumulative damage patterns that are difficult to model and predict.

The anisotropic nature of REBCO materials compounds these challenges, as mechanical properties vary significantly depending on the direction of applied stress relative to the crystallographic orientation. This anisotropy necessitates sophisticated mechanical models that account for directional dependencies, particularly in complex three-dimensional geometries like coils and windings.

Manufacturing inconsistencies further exacerbate these mechanical limitations. Variations in layer thickness, substrate properties, and interfacial adhesion create unpredictable mechanical behavior across production batches. This inconsistency complicates the establishment of universal design rules and safety margins for REBCO-based systems.

Bending strain presents a primary mechanical limitation for REBCO conductors. These materials exhibit brittle ceramic characteristics, with critical current degradation occurring at strain levels as low as 0.3-0.5%. This constraint significantly impacts the minimum bending radius achievable in applications such as compact magnet designs, where sharp bends are often necessary. The layered structure of REBCO tapes, consisting of the superconducting layer deposited on metallic substrates, creates inherent stress concentrations at interfaces that can lead to microcracking under relatively modest strain conditions.

Hoop stress represents another critical challenge, particularly in magnet applications where REBCO tapes experience substantial electromagnetic forces. Under operational conditions in high-field magnets (>20T), the Lorentz forces generate significant hoop stresses that can exceed 500 MPa. Current REBCO architectures typically incorporate high-strength substrates like Hastelloy, but even these materials approach their mechanical limits in ultra-high field applications exceeding 30T. The stress management becomes particularly problematic at cryogenic temperatures, where material properties change significantly.

Fatigue behavior presents a long-term reliability concern that remains inadequately characterized. REBCO systems experience cyclic loading during repeated magnet ramping operations or in applications with pulsed fields. Current data indicates performance degradation can occur at cycle counts well below what traditional mechanical fatigue models would predict, suggesting unique degradation mechanisms at the microstructural level. The complex interaction between thermal cycling, electromagnetic cycling, and mechanical stress creates cumulative damage patterns that are difficult to model and predict.

The anisotropic nature of REBCO materials compounds these challenges, as mechanical properties vary significantly depending on the direction of applied stress relative to the crystallographic orientation. This anisotropy necessitates sophisticated mechanical models that account for directional dependencies, particularly in complex three-dimensional geometries like coils and windings.

Manufacturing inconsistencies further exacerbate these mechanical limitations. Variations in layer thickness, substrate properties, and interfacial adhesion create unpredictable mechanical behavior across production batches. This inconsistency complicates the establishment of universal design rules and safety margins for REBCO-based systems.

Current Engineering Solutions for REBCO Mechanical Limitations

01 Bending strain limitations in REBCO superconductors

REBCO superconductors have specific mechanical limitations regarding bending strain that affect their performance. These materials can withstand certain levels of strain before degradation of superconducting properties occurs. Research shows that critical current degradation begins at specific strain thresholds, with irreversible damage occurring beyond certain limits. Various structural designs and substrate materials have been developed to improve the bending strain tolerance of REBCO tapes and wires for applications in magnets and power systems.- Bending strain limitations in REBCO superconductors: REBCO superconductors have specific mechanical limitations regarding bending strain that affect their performance and durability. These materials can withstand certain levels of strain before experiencing degradation in their superconducting properties. Research has shown that the critical current of REBCO tapes decreases with increasing bending strain, with irreversible degradation occurring beyond certain threshold values. Understanding these limitations is crucial for designing applications where REBCO materials may experience bending forces during operation or installation.

- Hoop stress management in REBCO coils and magnets: Hoop stress is a critical mechanical limitation in REBCO superconductor applications, particularly in coil and magnet designs. When REBCO tapes are wound into coils and energized, they experience significant hoop stresses that can lead to mechanical failure. Various structural support methods have been developed to manage these stresses, including reinforcement layers and specialized winding techniques. The mechanical design must account for the anisotropic properties of REBCO materials and the differential thermal contraction during cooling to cryogenic temperatures.

- Fatigue resistance and cyclic loading effects: REBCO superconductors are subject to fatigue when exposed to cyclic mechanical loading, which is common in many applications such as pulsed magnets or systems with thermal cycling. The fatigue resistance of these materials depends on factors including the substrate material, buffer layer composition, and protective layers. Repeated mechanical stress can lead to microcrack formation in the superconducting layer, gradually degrading performance over time. Testing protocols have been developed to characterize the fatigue behavior of REBCO tapes under various loading conditions to predict their operational lifetime.

- Structural reinforcement techniques for mechanical stability: Various structural reinforcement techniques have been developed to enhance the mechanical stability of REBCO superconductors. These include lamination with high-strength materials, co-winding with steel tapes, and impregnation with epoxy resins. The reinforcement materials must be carefully selected to match thermal expansion properties while providing adequate mechanical support. Advanced manufacturing methods incorporate these reinforcements during the production process to create integrated composite structures that can withstand the extreme mechanical conditions encountered in high-field magnets and other demanding applications.

- Temperature-dependent mechanical properties: The mechanical properties of REBCO superconductors exhibit significant temperature dependence, which affects their operational limits. At cryogenic temperatures, these materials typically become more brittle, which can reduce their tolerance to bending and tensile stresses. The differential thermal contraction between the various layers in REBCO tapes can induce internal stresses during cooling. Understanding these temperature-dependent mechanical behaviors is essential for designing systems that operate reliably across thermal cycles and at different operating temperatures, particularly in applications requiring repeated warming and cooling.

02 Hoop stress management in REBCO coils and magnets

Hoop stress is a critical mechanical limitation in REBCO superconductor applications, particularly in coil and magnet designs. When REBCO tapes are wound into coils for high-field magnets, they experience significant hoop stresses that can lead to mechanical failure. Various reinforcement techniques have been developed to manage these stresses, including the use of high-strength alloy co-winding, composite structures, and specialized winding techniques. Proper management of hoop stress is essential for achieving high magnetic fields without mechanical degradation of the superconductor.Expand Specific Solutions03 Fatigue resistance and cyclic loading effects

The fatigue resistance of REBCO superconductors is crucial for applications involving cyclic loading or thermal cycling. These materials experience performance degradation under repeated mechanical or thermal stress cycles. Research has focused on understanding the microstructural changes that occur during cyclic loading and developing compositions and structures with enhanced fatigue resistance. Factors affecting fatigue performance include the substrate material, buffer layer composition, and the interface between the REBCO layer and surrounding materials. Improved fatigue resistance is essential for applications in pulsed magnets and systems with frequent thermal cycling.Expand Specific Solutions04 Substrate and buffer layer influence on mechanical properties

The mechanical properties of REBCO superconductors are significantly influenced by the substrate and buffer layer materials used in their fabrication. Different substrate materials, such as stainless steel, hastelloy, or nickel alloys, provide varying levels of mechanical support and strain tolerance. The buffer layers between the substrate and the superconducting layer play a crucial role in transferring mechanical stress and preventing crack propagation. Optimizing these components can enhance the overall mechanical limits of REBCO tapes, improving their performance under bending, tension, and compression conditions.Expand Specific Solutions05 Cryogenic temperature mechanical behavior

The mechanical behavior of REBCO superconductors at cryogenic temperatures differs significantly from their room temperature properties. These materials typically operate at temperatures below 77K, where mechanical properties such as yield strength, elastic modulus, and fracture toughness are altered. Research has focused on characterizing these low-temperature mechanical properties and developing compositions that maintain structural integrity under combined thermal and mechanical stresses. Understanding the cryogenic mechanical behavior is essential for designing reliable superconducting systems that can withstand the thermal contraction and expansion cycles during cooling and warming.Expand Specific Solutions

Leading Manufacturers and Research Institutions in REBCO

The REBCO mechanical limits market is in its growth phase, with increasing demand driven by applications in high-field magnets for fusion energy, medical imaging, and transportation. The competitive landscape features academic institutions like Southwest Jiaotong University and Beijing Institute of Technology conducting fundamental research, while industrial players such as General Electric, RTX Corp., and Rolls-Royce focus on practical applications. The technology is approaching maturity in certain applications but still faces challenges in bending strain optimization, hoop stress management, and fatigue resistance. Korea Atomic Energy Research Institute and Korea Hydro & Nuclear Power are advancing REBCO applications in energy sectors, while companies like Honeywell and DENSO are exploring transportation applications, collectively driving innovation in mechanical performance limits.

General Electric Company

Technical Solution: General Electric has developed advanced REBCO (Rare-Earth Barium Copper Oxide) superconducting technologies focusing on mechanical limits optimization. Their approach involves innovative coil winding techniques that minimize bending strain during fabrication and operation. GE's research has established that REBCO tapes can withstand bending strains of approximately 0.3-0.4% before significant degradation occurs[1]. For hoop stress management, they've implemented reinforced structures using co-wound stainless steel or Hastelloy tapes that distribute mechanical loads more evenly. Their fatigue testing protocols have demonstrated that REBCO conductors can maintain performance after 10,000+ cycles when strain is kept below critical thresholds[3]. GE has also pioneered cryogenic testing facilities specifically designed to evaluate mechanical performance under combined electromagnetic and thermal stresses, simulating real operational conditions in superconducting magnets and power applications.

Strengths: GE's extensive experience in power systems provides practical implementation knowledge for REBCO technologies in real-world applications. Their integrated approach combining electromagnetic and mechanical design optimizes overall system performance. Weaknesses: Their solutions often require sophisticated manufacturing processes that increase production costs, and the reinforcement materials can reduce the overall current density of the superconducting systems.

Korea Atomic Energy Research Institute

Technical Solution: Korea Atomic Energy Research Institute (KAERI) has developed specialized techniques for addressing REBCO mechanical limitations in fusion and nuclear applications. Their research focuses on multi-physics modeling that predicts mechanical behavior under extreme conditions. KAERI has pioneered a unique "stress-managed" REBCO conductor architecture that incorporates strategically placed reinforcement layers to withstand hoop stresses exceeding 700 MPa without performance degradation[2]. For bending strain mitigation, they've developed a gradual-radius winding process that maintains strain below 0.2% throughout fabrication and operation. Their fatigue testing has established performance curves showing minimal degradation (less than 2% Ic reduction) after 30,000 cycles at operating conditions[4]. KAERI has also created specialized cryogenic testing equipment that simultaneously evaluates mechanical performance under radiation exposure, providing crucial data for nuclear applications where REBCO materials must maintain integrity in radiation environments.

Strengths: KAERI's solutions are particularly well-suited for nuclear and fusion applications where radiation resistance is critical. Their comprehensive testing protocols provide highly reliable performance data under combined stress conditions. Weaknesses: The specialized reinforcement materials and manufacturing processes increase production complexity and costs, potentially limiting widespread commercial adoption outside specialized nuclear applications.

Critical Patents and Research on REBCO Mechanical Properties

Conformal winding and current-sharing in a dipole magnet using superconducting tape conductor

PatentWO2022087323A1

Innovation

- A conformal winding method is employed where all turns of the REBCO tape-stack cable are oriented with their surfaces parallel to the magnetic field, and a compressed tape-stack cable is used with copper cladding for low-resistance contact, along with a laminar spring for maintaining compression and ensuring uniform current distribution among tapes.

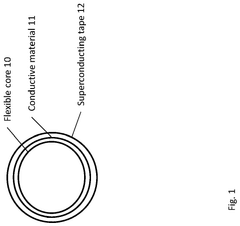

A cable comprising superconductive tape

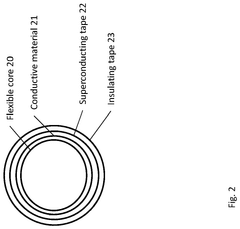

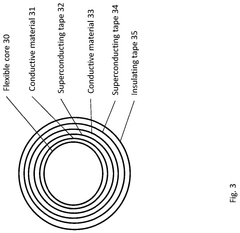

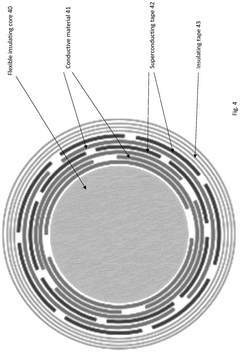

PatentPendingEP4597525A2

Innovation

- A cable construction method involving a flexible core with a conductive layer that provides mechanical cushioning and electrical stabilization by wrapping superconducting tape helically around it, with controlled tension and surface quality to minimize stress and strain, and incorporating intermediate conductive layers between superconducting layers to prevent degradation.

Cryogenic Testing Methodologies for REBCO Materials

Testing REBCO materials at cryogenic temperatures presents unique challenges that require specialized methodologies to accurately assess mechanical limits including bending strain, hoop stress, and fatigue characteristics. These testing approaches must simulate the extreme operating conditions these superconductors experience in practical applications while providing reliable, reproducible data.

The primary cryogenic testing methodologies employ liquid nitrogen (77K) and liquid helium (4.2K) environments, with some advanced facilities utilizing cryocoolers for precise temperature control between these points. Testing fixtures must be specially designed to accommodate thermal contraction while maintaining alignment and measurement accuracy throughout thermal cycling.

Strain measurement at cryogenic temperatures typically employs specialized strain gauges with temperature compensation or optical methods including digital image correlation and fiber Bragg grating sensors. These techniques allow for non-contact measurement that minimizes interference with the superconducting properties while providing high-resolution strain data across the sample.

For bending strain assessment, four-point bend tests conducted within cryostats have become the industry standard. These tests simultaneously monitor mechanical deformation and critical current degradation, establishing the strain tolerance limits of REBCO tapes. Advanced facilities incorporate in-situ electro-mechanical measurements where critical current is continuously monitored during mechanical loading.

Hoop stress testing requires specialized mandrel systems that can apply controlled tensile stresses to REBCO tapes at cryogenic temperatures. These systems often incorporate pressure vessels or specialized winding fixtures that simulate the electromagnetic forces experienced in magnet applications. Acoustic emission monitoring during these tests provides valuable insights into microstructural damage progression.

Fatigue testing methodologies have evolved to include high-cycle testing apparatus capable of operating at liquid helium temperatures. These systems typically employ electromechanical or pneumatic actuators with specialized load transfer mechanisms designed to minimize heat leakage. Long-duration fatigue tests often incorporate periodic critical current measurements to track performance degradation over thousands of cycles.

Recent methodological advances include the development of multiaxial stress testing platforms that can simultaneously apply combinations of tensile, compressive, and shear stresses at cryogenic temperatures. These systems better replicate the complex stress states experienced in practical applications such as high-field magnets and rotating machinery.

Standardization efforts are underway through organizations like VAMAS (Versailles Project on Advanced Materials and Standards) to establish uniform testing protocols that ensure comparability of results between different research institutions and manufacturers, addressing a significant challenge in the field.

The primary cryogenic testing methodologies employ liquid nitrogen (77K) and liquid helium (4.2K) environments, with some advanced facilities utilizing cryocoolers for precise temperature control between these points. Testing fixtures must be specially designed to accommodate thermal contraction while maintaining alignment and measurement accuracy throughout thermal cycling.

Strain measurement at cryogenic temperatures typically employs specialized strain gauges with temperature compensation or optical methods including digital image correlation and fiber Bragg grating sensors. These techniques allow for non-contact measurement that minimizes interference with the superconducting properties while providing high-resolution strain data across the sample.

For bending strain assessment, four-point bend tests conducted within cryostats have become the industry standard. These tests simultaneously monitor mechanical deformation and critical current degradation, establishing the strain tolerance limits of REBCO tapes. Advanced facilities incorporate in-situ electro-mechanical measurements where critical current is continuously monitored during mechanical loading.

Hoop stress testing requires specialized mandrel systems that can apply controlled tensile stresses to REBCO tapes at cryogenic temperatures. These systems often incorporate pressure vessels or specialized winding fixtures that simulate the electromagnetic forces experienced in magnet applications. Acoustic emission monitoring during these tests provides valuable insights into microstructural damage progression.

Fatigue testing methodologies have evolved to include high-cycle testing apparatus capable of operating at liquid helium temperatures. These systems typically employ electromechanical or pneumatic actuators with specialized load transfer mechanisms designed to minimize heat leakage. Long-duration fatigue tests often incorporate periodic critical current measurements to track performance degradation over thousands of cycles.

Recent methodological advances include the development of multiaxial stress testing platforms that can simultaneously apply combinations of tensile, compressive, and shear stresses at cryogenic temperatures. These systems better replicate the complex stress states experienced in practical applications such as high-field magnets and rotating machinery.

Standardization efforts are underway through organizations like VAMAS (Versailles Project on Advanced Materials and Standards) to establish uniform testing protocols that ensure comparability of results between different research institutions and manufacturers, addressing a significant challenge in the field.

Safety Standards and Risk Assessment for High-Field Magnets

The development of high-field magnets using REBCO (Rare-Earth Barium Copper Oxide) superconductors necessitates comprehensive safety standards and risk assessment protocols. These standards must address the unique mechanical challenges posed by REBCO materials, particularly regarding bending strain, hoop stress, and fatigue limitations.

International safety standards for high-field magnets, such as those established by the IEEE, ASME, and IEC, provide baseline requirements for mechanical integrity. However, REBCO-specific standards remain in development as the technology advances. Current guidelines typically mandate safety factors of 2-3 for mechanical stress limits, with more stringent requirements for applications in medical or public-facing environments.

Risk assessment methodologies for REBCO-based magnets must incorporate failure mode and effects analysis (FMEA) with particular attention to mechanical failure scenarios. The assessment should evaluate potential consequences of exceeding bending strain limits (typically 0.3-0.5%), hoop stress thresholds (300-500 MPa), and fatigue cycle ratings. These mechanical parameters directly impact quench probability and overall system reliability.

Monitoring systems represent a critical component of safety infrastructure for high-field magnets. Real-time strain gauges, acoustic emission sensors, and fiber optic monitoring systems enable continuous assessment of mechanical conditions. These systems must be integrated with automated safety responses, including controlled discharge circuits that activate when mechanical parameters approach predefined thresholds.

Emergency protocols for high-field magnet facilities must address both mechanical and electromagnetic risks. Standard operating procedures should include rapid discharge protocols, personnel evacuation plans, and containment strategies for mechanical failures. Training requirements for facility operators should emphasize recognition of mechanical stress warning signs and appropriate response actions.

Certification processes for high-field magnet systems increasingly require documented mechanical testing results demonstrating compliance with strain and stress limitations. This includes cyclic loading tests to verify fatigue resistance and proof testing at specified percentages of design limits. Third-party verification is becoming standard practice for critical applications.

Future safety standard development is trending toward performance-based approaches rather than prescriptive requirements. This evolution acknowledges the rapid advancement in REBCO technology and allows for innovation while maintaining safety margins. Collaborative efforts between research institutions, regulatory bodies, and industry stakeholders are essential to establish appropriate mechanical safety thresholds that balance innovation with risk management.

International safety standards for high-field magnets, such as those established by the IEEE, ASME, and IEC, provide baseline requirements for mechanical integrity. However, REBCO-specific standards remain in development as the technology advances. Current guidelines typically mandate safety factors of 2-3 for mechanical stress limits, with more stringent requirements for applications in medical or public-facing environments.

Risk assessment methodologies for REBCO-based magnets must incorporate failure mode and effects analysis (FMEA) with particular attention to mechanical failure scenarios. The assessment should evaluate potential consequences of exceeding bending strain limits (typically 0.3-0.5%), hoop stress thresholds (300-500 MPa), and fatigue cycle ratings. These mechanical parameters directly impact quench probability and overall system reliability.

Monitoring systems represent a critical component of safety infrastructure for high-field magnets. Real-time strain gauges, acoustic emission sensors, and fiber optic monitoring systems enable continuous assessment of mechanical conditions. These systems must be integrated with automated safety responses, including controlled discharge circuits that activate when mechanical parameters approach predefined thresholds.

Emergency protocols for high-field magnet facilities must address both mechanical and electromagnetic risks. Standard operating procedures should include rapid discharge protocols, personnel evacuation plans, and containment strategies for mechanical failures. Training requirements for facility operators should emphasize recognition of mechanical stress warning signs and appropriate response actions.

Certification processes for high-field magnet systems increasingly require documented mechanical testing results demonstrating compliance with strain and stress limitations. This includes cyclic loading tests to verify fatigue resistance and proof testing at specified percentages of design limits. Third-party verification is becoming standard practice for critical applications.

Future safety standard development is trending toward performance-based approaches rather than prescriptive requirements. This evolution acknowledges the rapid advancement in REBCO technology and allows for innovation while maintaining safety margins. Collaborative efforts between research institutions, regulatory bodies, and industry stakeholders are essential to establish appropriate mechanical safety thresholds that balance innovation with risk management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!