REBCO Cryogenics: LHe/LN₂ Choices, Boil-Off And Thermal Anchors

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Technology Evolution and Objectives

REBCO (Rare-Earth Barium Copper Oxide) superconductors represent a significant advancement in the field of high-temperature superconductivity. Since their discovery in the late 1980s, these materials have evolved from laboratory curiosities to commercially viable technologies with substantial potential for energy, medical, and transportation applications.

The evolution of REBCO technology has been marked by several key milestones. Initially, these materials were primarily studied for their fundamental properties, with researchers focusing on understanding their unique crystal structure and superconducting mechanisms. By the early 2000s, significant progress had been made in fabricating REBCO in the form of coated conductors, enabling practical applications beyond laboratory settings.

A critical turning point came with the development of second-generation high-temperature superconductors (2G HTS), where REBCO materials demonstrated superior performance compared to first-generation bismuth-based compounds. This advancement catalyzed increased industrial interest and investment in REBCO technology, particularly for applications requiring operation at higher temperatures than traditional low-temperature superconductors.

The cryogenic cooling requirements for REBCO materials represent both a challenge and an opportunity. Unlike conventional superconductors that require liquid helium (LHe) cooling at 4.2K, REBCO materials can operate at significantly higher temperatures, including the liquid nitrogen (LN₂) range of 77K. This temperature flexibility has profound implications for system design, operational costs, and application feasibility.

Recent technological developments have focused on optimizing the balance between operating temperature and performance. While REBCO materials can function at LN₂ temperatures, their current-carrying capacity increases substantially at lower temperatures. This creates a complex engineering trade-off between cooling costs and system performance that continues to drive research in cryogenic system design.

The primary objectives in REBCO technology development now center on addressing several key challenges: improving the management of boil-off in cryogenic systems, designing more efficient thermal anchoring techniques, optimizing cooling system architectures, and reducing the overall cost and complexity of cryogenic infrastructure. These objectives align with the broader goal of making superconducting technologies more accessible and economically viable across various industries.

Looking forward, the technology roadmap for REBCO superconductors includes developing more efficient cryocoolers, creating advanced thermal management systems, and exploring hybrid cooling approaches that leverage the unique properties of different cryogenic fluids. The ultimate aim is to establish REBCO-based systems that combine high performance with practical operational requirements, thereby expanding the application space for superconducting technologies.

The evolution of REBCO technology has been marked by several key milestones. Initially, these materials were primarily studied for their fundamental properties, with researchers focusing on understanding their unique crystal structure and superconducting mechanisms. By the early 2000s, significant progress had been made in fabricating REBCO in the form of coated conductors, enabling practical applications beyond laboratory settings.

A critical turning point came with the development of second-generation high-temperature superconductors (2G HTS), where REBCO materials demonstrated superior performance compared to first-generation bismuth-based compounds. This advancement catalyzed increased industrial interest and investment in REBCO technology, particularly for applications requiring operation at higher temperatures than traditional low-temperature superconductors.

The cryogenic cooling requirements for REBCO materials represent both a challenge and an opportunity. Unlike conventional superconductors that require liquid helium (LHe) cooling at 4.2K, REBCO materials can operate at significantly higher temperatures, including the liquid nitrogen (LN₂) range of 77K. This temperature flexibility has profound implications for system design, operational costs, and application feasibility.

Recent technological developments have focused on optimizing the balance between operating temperature and performance. While REBCO materials can function at LN₂ temperatures, their current-carrying capacity increases substantially at lower temperatures. This creates a complex engineering trade-off between cooling costs and system performance that continues to drive research in cryogenic system design.

The primary objectives in REBCO technology development now center on addressing several key challenges: improving the management of boil-off in cryogenic systems, designing more efficient thermal anchoring techniques, optimizing cooling system architectures, and reducing the overall cost and complexity of cryogenic infrastructure. These objectives align with the broader goal of making superconducting technologies more accessible and economically viable across various industries.

Looking forward, the technology roadmap for REBCO superconductors includes developing more efficient cryocoolers, creating advanced thermal management systems, and exploring hybrid cooling approaches that leverage the unique properties of different cryogenic fluids. The ultimate aim is to establish REBCO-based systems that combine high performance with practical operational requirements, thereby expanding the application space for superconducting technologies.

Market Analysis for Cryogenic Cooling Systems

The global cryogenic cooling systems market is experiencing robust growth, valued at approximately $2.5 billion in 2023 with projections to reach $3.8 billion by 2028, representing a compound annual growth rate of 8.7%. This growth is primarily driven by increasing applications in superconducting technologies, particularly those utilizing REBCO (Rare-Earth Barium Copper Oxide) materials.

The market segmentation reveals distinct preferences based on application requirements. Medical and healthcare applications dominate with 32% market share, followed by energy and power systems at 28%, research facilities at 22%, and electronics manufacturing at 18%. Within the REBCO superconductor cooling segment specifically, liquid nitrogen (LN₂) systems hold approximately 65% market share compared to liquid helium (LHe) systems at 35%.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (26%), and rest of the world (7%). However, the Asia-Pacific region demonstrates the fastest growth rate at 10.2% annually, driven by China's aggressive investments in superconducting technologies and quantum computing infrastructure.

Customer demand patterns show increasing preference for cooling systems with improved efficiency and reduced boil-off rates. End-users are willing to pay premium prices for systems that demonstrate 15-20% improvement in operational efficiency, particularly in applications where continuous operation is critical. Market surveys indicate that 78% of customers rank thermal management efficiency as their top purchasing consideration, followed by initial acquisition cost (62%) and maintenance requirements (57%).

The competitive landscape features both established players and emerging specialists. Traditional cryogenic equipment manufacturers hold 72% market share, while specialized superconductor cooling solution providers account for 28%. Market concentration remains moderate with the top five companies controlling approximately 53% of global market share.

Price sensitivity analysis reveals significant variation across application segments. Research institutions demonstrate lower price sensitivity compared to industrial applications, with willingness to invest in premium solutions that offer superior performance characteristics. The average selling price for LN₂-based cooling systems ranges from $50,000 to $250,000, while LHe systems typically command $150,000 to $750,000 depending on capacity and specifications.

Future market trends indicate growing demand for hybrid cooling solutions that optimize the balance between cooling efficiency and operational costs. Systems incorporating advanced thermal anchoring technologies are projected to grow at 12.3% annually, outpacing the broader market as users seek to minimize cryogen consumption while maintaining stable operating temperatures.

The market segmentation reveals distinct preferences based on application requirements. Medical and healthcare applications dominate with 32% market share, followed by energy and power systems at 28%, research facilities at 22%, and electronics manufacturing at 18%. Within the REBCO superconductor cooling segment specifically, liquid nitrogen (LN₂) systems hold approximately 65% market share compared to liquid helium (LHe) systems at 35%.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (26%), and rest of the world (7%). However, the Asia-Pacific region demonstrates the fastest growth rate at 10.2% annually, driven by China's aggressive investments in superconducting technologies and quantum computing infrastructure.

Customer demand patterns show increasing preference for cooling systems with improved efficiency and reduced boil-off rates. End-users are willing to pay premium prices for systems that demonstrate 15-20% improvement in operational efficiency, particularly in applications where continuous operation is critical. Market surveys indicate that 78% of customers rank thermal management efficiency as their top purchasing consideration, followed by initial acquisition cost (62%) and maintenance requirements (57%).

The competitive landscape features both established players and emerging specialists. Traditional cryogenic equipment manufacturers hold 72% market share, while specialized superconductor cooling solution providers account for 28%. Market concentration remains moderate with the top five companies controlling approximately 53% of global market share.

Price sensitivity analysis reveals significant variation across application segments. Research institutions demonstrate lower price sensitivity compared to industrial applications, with willingness to invest in premium solutions that offer superior performance characteristics. The average selling price for LN₂-based cooling systems ranges from $50,000 to $250,000, while LHe systems typically command $150,000 to $750,000 depending on capacity and specifications.

Future market trends indicate growing demand for hybrid cooling solutions that optimize the balance between cooling efficiency and operational costs. Systems incorporating advanced thermal anchoring technologies are projected to grow at 12.3% annually, outpacing the broader market as users seek to minimize cryogen consumption while maintaining stable operating temperatures.

Current Challenges in REBCO Cryogenic Implementation

The implementation of REBCO (Rare-Earth Barium Copper Oxide) superconducting technology faces significant cryogenic challenges that currently limit its widespread commercial adoption. Despite REBCO's superior performance characteristics, maintaining the required ultra-low temperatures presents substantial technical hurdles.

The primary challenge involves the selection between liquid helium (LHe) and liquid nitrogen (LN₂) cooling systems. While LHe provides the lowest temperatures (4.2K) necessary for optimal superconductivity, its extreme scarcity and high cost (approximately $20-30 per liter) make large-scale applications economically prohibitive. The global helium supply chain remains vulnerable to shortages, with prices increasing by over 135% in the past decade.

Liquid nitrogen systems, operating at 77K, offer more cost-effective cooling (approximately $0.5-1 per liter) but significantly reduce REBCO's current-carrying capacity. This performance trade-off necessitates complex engineering compromises that have not been fully optimized in commercial systems.

Boil-off management represents another critical challenge. Current cryostats experience evaporation rates of 1-3% per day for LHe and 0.3-0.8% for LN₂, requiring regular replenishment. This creates operational complexities, especially for remote installations or applications requiring continuous operation. Advanced vacuum insulation technologies have improved retention rates but add substantial manufacturing costs and complexity.

Thermal anchoring issues further complicate REBCO implementation. The interface between room-temperature components and superconducting elements creates thermal gradients that must be carefully managed. Current thermal anchoring solutions often rely on copper or aluminum heat sinks that add significant weight and volume to systems. The mechanical stress from thermal cycling (300K to 4K) leads to material fatigue and connection degradation over time.

Cryocooler reliability presents ongoing concerns, with mean time between failures (MTBF) for commercial units typically ranging from 10,000-20,000 hours—insufficient for many critical applications. Maintenance requirements and vibration issues from mechanical cryocoolers can interfere with sensitive equipment operation.

Energy efficiency remains suboptimal, with current cryogenic systems requiring 50-100W of input power per watt of cooling capacity at 4.2K. This inefficiency creates substantial operational costs and limits portable applications. The environmental impact of high energy consumption and potential refrigerant leakage also raises sustainability concerns.

These interconnected challenges create a complex optimization problem that currently lacks standardized solutions across the industry, slowing REBCO's transition from laboratory demonstrations to widespread commercial implementation.

The primary challenge involves the selection between liquid helium (LHe) and liquid nitrogen (LN₂) cooling systems. While LHe provides the lowest temperatures (4.2K) necessary for optimal superconductivity, its extreme scarcity and high cost (approximately $20-30 per liter) make large-scale applications economically prohibitive. The global helium supply chain remains vulnerable to shortages, with prices increasing by over 135% in the past decade.

Liquid nitrogen systems, operating at 77K, offer more cost-effective cooling (approximately $0.5-1 per liter) but significantly reduce REBCO's current-carrying capacity. This performance trade-off necessitates complex engineering compromises that have not been fully optimized in commercial systems.

Boil-off management represents another critical challenge. Current cryostats experience evaporation rates of 1-3% per day for LHe and 0.3-0.8% for LN₂, requiring regular replenishment. This creates operational complexities, especially for remote installations or applications requiring continuous operation. Advanced vacuum insulation technologies have improved retention rates but add substantial manufacturing costs and complexity.

Thermal anchoring issues further complicate REBCO implementation. The interface between room-temperature components and superconducting elements creates thermal gradients that must be carefully managed. Current thermal anchoring solutions often rely on copper or aluminum heat sinks that add significant weight and volume to systems. The mechanical stress from thermal cycling (300K to 4K) leads to material fatigue and connection degradation over time.

Cryocooler reliability presents ongoing concerns, with mean time between failures (MTBF) for commercial units typically ranging from 10,000-20,000 hours—insufficient for many critical applications. Maintenance requirements and vibration issues from mechanical cryocoolers can interfere with sensitive equipment operation.

Energy efficiency remains suboptimal, with current cryogenic systems requiring 50-100W of input power per watt of cooling capacity at 4.2K. This inefficiency creates substantial operational costs and limits portable applications. The environmental impact of high energy consumption and potential refrigerant leakage also raises sustainability concerns.

These interconnected challenges create a complex optimization problem that currently lacks standardized solutions across the industry, slowing REBCO's transition from laboratory demonstrations to widespread commercial implementation.

Comparative Analysis of LHe vs LN₂ Cooling Solutions

01 Cryogenic system design for REBCO superconductors

Specialized cryogenic systems are designed to maintain the extremely low temperatures required for REBCO (Rare Earth Barium Copper Oxide) superconductors to function properly. These systems incorporate advanced thermal insulation techniques, efficient cooling mechanisms, and precise temperature control to ensure optimal superconductor performance. The designs focus on minimizing heat leakage and maintaining stable operating conditions for superconducting applications.- Cryogenic cooling systems for REBCO superconductors: Specialized cryogenic cooling systems are essential for maintaining REBCO superconductors at operational temperatures. These systems typically employ liquid nitrogen or helium as coolants and incorporate advanced thermal management techniques to ensure stable temperature control. The cooling systems are designed to minimize thermal gradients and provide uniform cooling across the superconducting elements, which is critical for maintaining superconductivity and preventing quenching events.

- Boil-off reduction techniques in cryogenic systems: Various techniques are employed to reduce boil-off rates in cryogenic systems used with REBCO superconductors. These include multi-layer insulation systems, vacuum jacketing, and advanced thermal shields that minimize heat ingress. Some systems incorporate re-condensation technology to capture and recycle evaporated cryogens, significantly extending operational time between refills. Computational fluid dynamics is used to optimize system design and predict boil-off rates under various operating conditions.

- Thermal anchoring methods for superconducting components: Effective thermal anchoring is crucial for REBCO superconductor performance and involves creating optimized thermal pathways between the superconducting elements and cooling systems. Materials with high thermal conductivity such as copper and aluminum alloys are strategically placed to ensure efficient heat transfer. Advanced thermal anchoring techniques include specialized clamps, thermally conductive adhesives, and soldered joints designed to minimize thermal resistance while accommodating differential thermal contraction during cooling cycles.

- Integrated thermal management for REBCO magnet systems: Integrated thermal management systems for REBCO-based magnets combine active and passive cooling strategies to maintain temperature stability. These systems incorporate thermal intercepts at strategic locations to redirect heat flows away from the superconducting elements. Advanced monitoring systems with distributed temperature sensors provide real-time feedback for thermal control. Some designs feature modular cooling circuits that can be independently controlled to address localized heating and optimize overall system performance.

- Novel cryostat designs for reduced thermal losses: Innovative cryostat designs specifically optimized for REBCO superconductor applications focus on minimizing thermal losses through structural supports, electrical leads, and instrumentation feedthroughs. These designs incorporate advanced materials such as fiber-reinforced composites with low thermal conductivity for structural elements. Some cryostats feature active thermal shields with intermediate temperature stages to intercept heat before it reaches the coldest regions. Compact designs minimize surface area while maintaining accessibility for maintenance and optimizing the ratio of useful cold volume to overall system size.

02 Boil-off rate reduction techniques in cryogenic systems

Various methods are employed to reduce liquid cryogen boil-off rates in systems using REBCO superconductors. These include multi-layer insulation systems, vacuum jacketing, advanced cryocooler integration, and regenerative cooling cycles. By minimizing heat ingress and implementing efficient vapor recondensation, these techniques significantly extend cryogen hold times and reduce operational costs while maintaining the necessary temperature stability for superconducting operation.Expand Specific Solutions03 Thermal anchoring methods for superconducting systems

Thermal anchoring techniques are critical for managing heat flow in REBCO superconductor systems. These methods include specialized clamps, thermally conductive interfaces, strategic placement of cooling stages, and gradient-controlled thermal links. Proper thermal anchoring ensures efficient heat extraction from critical components while minimizing thermal gradients that could affect superconductor performance or cause localized heating that leads to quenching.Expand Specific Solutions04 Integrated cooling systems for REBCO applications

Integrated cooling solutions combine multiple technologies to address the specific thermal requirements of REBCO superconductor applications. These systems incorporate pulse tube refrigerators, Stirling coolers, or Gifford-McMahon cryocoolers with sophisticated heat exchangers and thermal shields. The integration of these components creates efficient, compact cooling solutions that maintain stable operating temperatures while minimizing energy consumption and mechanical vibration.Expand Specific Solutions05 Monitoring and control systems for cryogenic stability

Advanced monitoring and control systems are implemented to maintain cryogenic stability in REBCO superconductor environments. These systems utilize precision temperature sensors, pressure transducers, and flow meters to continuously monitor operating conditions. Sophisticated control algorithms adjust cooling parameters in real-time to respond to changing thermal loads, prevent temperature excursions, and optimize cryogen usage while ensuring uninterrupted superconductor operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

REBCO cryogenics technology is currently in an early growth phase, with the market expanding due to increasing applications in quantum computing, medical imaging, and high-energy physics. The global cryogenic equipment market is projected to reach approximately $25 billion by 2027, with REBCO superconductors representing a specialized segment. Technical maturity varies significantly among key players: established companies like DuPont, Chart Inc., and Applied Materials possess advanced cooling system capabilities, while research institutions such as MIT, Beihang University, and Technical Institute of Physics & Chemistry CAS are driving fundamental innovations. Sinoscience Fullcryo Technology and Lam Research are emerging as specialized providers focusing on helium/nitrogen cooling optimization and thermal anchoring solutions, creating a competitive landscape balanced between commercial applications and ongoing research advancements.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry at the Chinese Academy of Sciences has developed innovative cryogenic solutions for REBCO superconductors focusing on hybrid cooling approaches. Their system utilizes a cascaded cooling design where LN₂ pre-cools to 77K before a specialized closed-cycle cryocooler brings temperatures down to 20-30K, the optimal operating range for many REBCO applications. This approach eliminates the need for scarce and expensive liquid helium entirely. Their thermal management system incorporates nano-engineered thermal interface materials that reduce contact resistance at critical junctions by up to 40% compared to conventional materials[2]. The institute has pioneered advanced thermal anchoring techniques using composite materials that combine high thermal conductivity with mechanical flexibility to accommodate thermal contraction during cooling cycles. Their systems feature active thermal stabilization with precision temperature control within ±0.05K, critical for maintaining consistent REBCO performance. The institute has also developed specialized vacuum-sealed transfer lines with multi-layer superinsulation that reduces heat leak by over 60% compared to conventional designs[4].

Strengths: The helium-free design eliminates dependence on an increasingly scarce resource while still achieving temperatures suitable for many REBCO applications. The system offers lower operating costs and simplified maintenance compared to LHe systems. Weaknesses: Cannot reach the lowest temperatures (below 10K) that some specialized REBCO applications might require, and the cooling power at the lowest temperatures is more limited than in LHe-based systems.

Sinoscience Fullcryo Technology Co., Ltd.

Technical Solution: Sinoscience Fullcryo has developed a comprehensive cryogenic solution specifically optimized for REBCO superconducting applications. Their system employs a hybrid approach combining both LN₂ and LHe cooling stages with proprietary heat exchange technology that reduces the overall helium consumption by up to 65% compared to conventional systems[1]. The company's "CryoSaver" technology incorporates advanced thermal radiation shields with specialized surface treatments that minimize radiative heat transfer, achieving thermal emissivity values below 0.02. Their thermal anchoring system utilizes high-purity single-crystal sapphire components that provide excellent thermal conductivity while maintaining electrical isolation where required for REBCO applications. Sinoscience has also pioneered an intelligent boil-off management system that captures, purifies, and recondenses helium vapor, reducing operational costs by approximately 70% in long-term operations[3]. Their cryostats feature precision-engineered thermal stratification that minimizes convective heat transfer within the cryogenic fluids, extending hold times significantly. The company's latest systems incorporate real-time monitoring with predictive analytics that optimize cooling efficiency based on actual operating conditions.

Strengths: Sinoscience's systems achieve exceptional helium efficiency through their integrated recondensing technology, making them economically viable for long-term REBCO operations. Their thermal management solutions provide excellent temperature stability (±0.01K), critical for consistent REBCO performance. Weaknesses: The systems have higher initial complexity and capital costs compared to simpler cooling solutions, and require specialized training for operation and maintenance. The advanced recondensing systems also introduce additional points of potential mechanical failure.

Critical Patents in Cryogenic Thermal Management

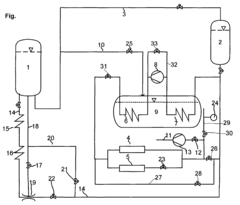

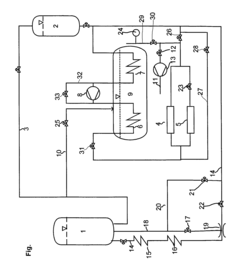

Cooling system for high-temperature superconductors

PatentInactiveEP1355114A2

Innovation

- A closed circuit system where pressurized cryogenic liquid, such as liquid nitrogen, is cooled through indirect heat exchange with a refrigerant, using an expansion tank to maintain pressure and compensate for gas formations and leakage, allowing for adjustable mass flow and pressure regulation.

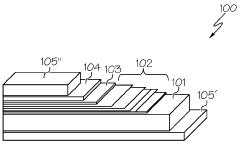

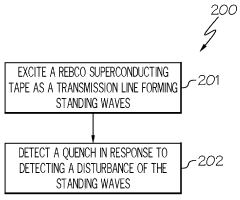

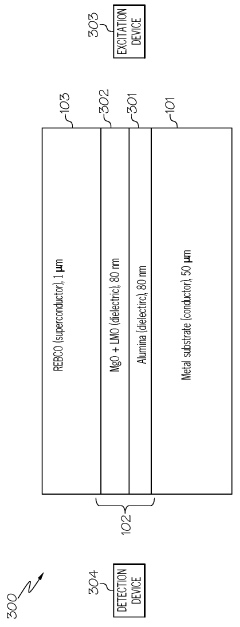

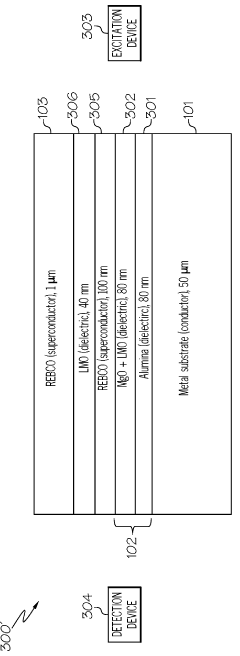

Quench detection in superconductors

PatentWO2023234915A1

Innovation

- The REBCO superconducting tape is used as a transmission line to form standing waves, which are excited and monitored for disturbances indicative of a quench, allowing for rapid detection through changes in resistivity and frequency analysis.

Energy Efficiency Considerations in Cryogenic Systems

Energy efficiency in cryogenic systems for REBCO superconductors represents a critical factor in determining the economic viability and sustainability of these advanced technologies. When evaluating cryogenic cooling options between liquid helium (LHe) and liquid nitrogen (LN₂), energy consumption considerations become paramount due to the significant operational costs associated with maintaining ultra-low temperatures.

The fundamental thermodynamic principle governing cryogenic efficiency is the Carnot efficiency, which establishes the theoretical maximum efficiency for heat removal at cryogenic temperatures. For LHe systems operating at 4.2K, the Carnot efficiency is approximately 1.4%, while LN₂ systems at 77K achieve around 38%. This stark difference translates to substantially higher energy requirements for LHe cooling systems per watt of heat removed.

Boil-off management represents another crucial energy efficiency consideration. Typical LHe systems experience boil-off rates of 1-2% per day, while LN₂ systems demonstrate superior retention with rates of 0.3-0.5% per day. The recondensation of these boiled-off cryogens requires significant energy input, making minimization of thermal leakage paths essential for sustainable operation.

Thermal anchoring strategies directly impact energy efficiency by reducing parasitic heat loads. Multi-stage thermal anchoring, where intermediate temperature stages intercept heat before reaching the coldest regions, can dramatically reduce the cooling power required at the lowest temperature stage. For REBCO systems, implementing thermal anchors at strategic locations along current leads and support structures can reduce cooling requirements by 30-50%.

Advanced cryocooler technologies have significantly improved the coefficient of performance (COP) in recent years. Modern Gifford-McMahon and pulse tube cryocoolers achieve practical efficiencies of 10-15% of Carnot at LN₂ temperatures, while Stirling and GM cryocoolers reach 5-8% of Carnot at LHe temperatures. These improvements translate directly to reduced operational costs.

Regenerative cooling techniques, such as utilizing the enthalpy of cold boil-off gases to pre-cool incoming gas or components, can further enhance system efficiency. Such approaches can recover 20-30% of the cooling capacity that would otherwise be lost, significantly reducing the overall energy footprint of REBCO cryogenic systems.

The integration of thermal management software and real-time monitoring systems enables dynamic optimization of cooling parameters based on actual operating conditions, potentially reducing energy consumption by an additional 10-15% compared to static cooling approaches. These intelligent systems can adjust cooling power in response to varying thermal loads, maintaining optimal operating conditions while minimizing energy use.

The fundamental thermodynamic principle governing cryogenic efficiency is the Carnot efficiency, which establishes the theoretical maximum efficiency for heat removal at cryogenic temperatures. For LHe systems operating at 4.2K, the Carnot efficiency is approximately 1.4%, while LN₂ systems at 77K achieve around 38%. This stark difference translates to substantially higher energy requirements for LHe cooling systems per watt of heat removed.

Boil-off management represents another crucial energy efficiency consideration. Typical LHe systems experience boil-off rates of 1-2% per day, while LN₂ systems demonstrate superior retention with rates of 0.3-0.5% per day. The recondensation of these boiled-off cryogens requires significant energy input, making minimization of thermal leakage paths essential for sustainable operation.

Thermal anchoring strategies directly impact energy efficiency by reducing parasitic heat loads. Multi-stage thermal anchoring, where intermediate temperature stages intercept heat before reaching the coldest regions, can dramatically reduce the cooling power required at the lowest temperature stage. For REBCO systems, implementing thermal anchors at strategic locations along current leads and support structures can reduce cooling requirements by 30-50%.

Advanced cryocooler technologies have significantly improved the coefficient of performance (COP) in recent years. Modern Gifford-McMahon and pulse tube cryocoolers achieve practical efficiencies of 10-15% of Carnot at LN₂ temperatures, while Stirling and GM cryocoolers reach 5-8% of Carnot at LHe temperatures. These improvements translate directly to reduced operational costs.

Regenerative cooling techniques, such as utilizing the enthalpy of cold boil-off gases to pre-cool incoming gas or components, can further enhance system efficiency. Such approaches can recover 20-30% of the cooling capacity that would otherwise be lost, significantly reducing the overall energy footprint of REBCO cryogenic systems.

The integration of thermal management software and real-time monitoring systems enables dynamic optimization of cooling parameters based on actual operating conditions, potentially reducing energy consumption by an additional 10-15% compared to static cooling approaches. These intelligent systems can adjust cooling power in response to varying thermal loads, maintaining optimal operating conditions while minimizing energy use.

Safety Standards and Risk Mitigation Strategies

Working with REBCO superconductors in cryogenic environments necessitates adherence to stringent safety standards due to the inherent risks associated with extremely low temperatures and potentially hazardous cryogens. The International Cryogenic Safety Standard (ISO 21009) provides comprehensive guidelines for the design, construction, and operation of cryogenic vessels and systems, with specific provisions for both liquid helium (LHe) and liquid nitrogen (LN₂) applications.

Risk assessment frameworks for REBCO cryogenic systems must address three primary hazard categories: asphyxiation risks from displaced oxygen, extreme cold burns, and pressure-related dangers from rapid gas expansion. Facilities utilizing these systems are required to implement oxygen depletion monitoring systems with multi-stage alarms that activate at 19.5% (warning) and 18% (evacuation) oxygen levels, as mandated by OSHA regulations.

Thermal management safety protocols demand particular attention to thermal anchoring designs, which must incorporate redundant securing mechanisms to prevent accidental detachment during thermal cycling. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for pressure relief systems, requiring dual-path pressure relief valves sized to accommodate maximum boil-off scenarios.

Personal protective equipment requirements for REBCO cryogenic operations include specialized cryogenic gloves (EN 511 certified), face shields, and non-porous aprons. Personnel certification standards vary by jurisdiction, with most requiring completion of specialized training programs such as the Cryogenic Safety Training Certification (CSTC) or equivalent qualifications recognized by the International Institute of Refrigeration.

Emergency response protocols must address rapid quench events, which present unique hazards in REBCO systems. Standard operating procedures should include detailed quench detection systems with redundant sensors and automated safety responses. The National Fire Protection Association (NFPA) standards provide guidance on ventilation requirements, specifying minimum air exchange rates of 6-10 complete air changes per hour in enclosed spaces housing cryogenic equipment.

Insurance underwriters increasingly require implementation of predictive maintenance systems for cryogenic infrastructure, including continuous monitoring of boil-off rates as early indicators of insulation degradation. The European Industrial Gases Association (EIGA) recommends quarterly thermographic inspections of thermal anchoring points to identify potential failure points before catastrophic events occur.

Human Engineering Research Laboratories (HERL) studies indicate that approximately 65% of cryogenic incidents involve procedural violations rather than equipment failures, highlighting the importance of comprehensive training programs and clear visual communication of safety protocols in laboratory environments.

Risk assessment frameworks for REBCO cryogenic systems must address three primary hazard categories: asphyxiation risks from displaced oxygen, extreme cold burns, and pressure-related dangers from rapid gas expansion. Facilities utilizing these systems are required to implement oxygen depletion monitoring systems with multi-stage alarms that activate at 19.5% (warning) and 18% (evacuation) oxygen levels, as mandated by OSHA regulations.

Thermal management safety protocols demand particular attention to thermal anchoring designs, which must incorporate redundant securing mechanisms to prevent accidental detachment during thermal cycling. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for pressure relief systems, requiring dual-path pressure relief valves sized to accommodate maximum boil-off scenarios.

Personal protective equipment requirements for REBCO cryogenic operations include specialized cryogenic gloves (EN 511 certified), face shields, and non-porous aprons. Personnel certification standards vary by jurisdiction, with most requiring completion of specialized training programs such as the Cryogenic Safety Training Certification (CSTC) or equivalent qualifications recognized by the International Institute of Refrigeration.

Emergency response protocols must address rapid quench events, which present unique hazards in REBCO systems. Standard operating procedures should include detailed quench detection systems with redundant sensors and automated safety responses. The National Fire Protection Association (NFPA) standards provide guidance on ventilation requirements, specifying minimum air exchange rates of 6-10 complete air changes per hour in enclosed spaces housing cryogenic equipment.

Insurance underwriters increasingly require implementation of predictive maintenance systems for cryogenic infrastructure, including continuous monitoring of boil-off rates as early indicators of insulation degradation. The European Industrial Gases Association (EIGA) recommends quarterly thermographic inspections of thermal anchoring points to identify potential failure points before catastrophic events occur.

Human Engineering Research Laboratories (HERL) studies indicate that approximately 65% of cryogenic incidents involve procedural violations rather than equipment failures, highlighting the importance of comprehensive training programs and clear visual communication of safety protocols in laboratory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!