REBCO AC Loss: Hysteresis, Coupling And Mitigation With Striation

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Background and Research Objectives

REBCO (Rare-Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconductivity technology, offering critical current densities exceeding 10^6 A/cm² at 77K and fields up to 30T. These second-generation high-temperature superconductors (2G HTS) have evolved considerably since their initial development in the 1980s, with YBCO (Yttrium Barium Copper Oxide) emerging as the most commercially viable variant.

The layered structure of REBCO superconductors, typically consisting of a thin superconducting layer deposited on buffered metallic substrates, enables their application in various high-field magnets and power systems. However, when exposed to alternating current (AC) or time-varying magnetic fields, these materials experience energy dissipation known as AC losses, which significantly impacts their practical implementation in power applications.

AC losses in REBCO superconductors primarily manifest through hysteresis and coupling mechanisms. Hysteresis losses occur due to the penetration of magnetic flux into the superconductor and subsequent movement of flux vortices, while coupling losses arise from induced currents between adjacent superconducting filaments through resistive matrix materials. These losses generate heat, reducing the overall efficiency and potentially compromising the superconducting state.

The technical evolution of REBCO superconductors has focused on enhancing current-carrying capacity while simultaneously addressing AC loss challenges. Recent advancements include improved manufacturing techniques for longer and more uniform tapes, enhanced flux pinning mechanisms, and innovative architectures to mitigate AC losses.

Our research objectives center on comprehensively understanding the fundamental mechanisms of AC losses in REBCO superconductors, with particular emphasis on hysteresis and coupling phenomena. We aim to quantify these losses under various operating conditions relevant to practical applications and develop effective mitigation strategies.

Striation, the process of dividing the superconducting layer into multiple filaments, represents a promising approach for AC loss reduction. By creating narrower current paths, striation reduces the effective width of superconducting regions, thereby decreasing hysteresis losses proportionally. However, this technique introduces additional complexities, including potential coupling losses between filaments and manufacturing challenges.

This research seeks to establish optimal striation patterns and configurations that minimize total AC losses while maintaining high critical current capacity. We will investigate various striation geometries, filament widths, and inter-filament resistances to determine their impact on overall performance. Additionally, we will explore complementary techniques such as flux diverters and novel winding methods that may further enhance AC loss reduction.

The outcomes of this research will directly contribute to advancing REBCO technology for practical applications in power systems, including transformers, fault current limiters, and rotating machinery, where AC loss mitigation is crucial for operational efficiency and economic viability.

The layered structure of REBCO superconductors, typically consisting of a thin superconducting layer deposited on buffered metallic substrates, enables their application in various high-field magnets and power systems. However, when exposed to alternating current (AC) or time-varying magnetic fields, these materials experience energy dissipation known as AC losses, which significantly impacts their practical implementation in power applications.

AC losses in REBCO superconductors primarily manifest through hysteresis and coupling mechanisms. Hysteresis losses occur due to the penetration of magnetic flux into the superconductor and subsequent movement of flux vortices, while coupling losses arise from induced currents between adjacent superconducting filaments through resistive matrix materials. These losses generate heat, reducing the overall efficiency and potentially compromising the superconducting state.

The technical evolution of REBCO superconductors has focused on enhancing current-carrying capacity while simultaneously addressing AC loss challenges. Recent advancements include improved manufacturing techniques for longer and more uniform tapes, enhanced flux pinning mechanisms, and innovative architectures to mitigate AC losses.

Our research objectives center on comprehensively understanding the fundamental mechanisms of AC losses in REBCO superconductors, with particular emphasis on hysteresis and coupling phenomena. We aim to quantify these losses under various operating conditions relevant to practical applications and develop effective mitigation strategies.

Striation, the process of dividing the superconducting layer into multiple filaments, represents a promising approach for AC loss reduction. By creating narrower current paths, striation reduces the effective width of superconducting regions, thereby decreasing hysteresis losses proportionally. However, this technique introduces additional complexities, including potential coupling losses between filaments and manufacturing challenges.

This research seeks to establish optimal striation patterns and configurations that minimize total AC losses while maintaining high critical current capacity. We will investigate various striation geometries, filament widths, and inter-filament resistances to determine their impact on overall performance. Additionally, we will explore complementary techniques such as flux diverters and novel winding methods that may further enhance AC loss reduction.

The outcomes of this research will directly contribute to advancing REBCO technology for practical applications in power systems, including transformers, fault current limiters, and rotating machinery, where AC loss mitigation is crucial for operational efficiency and economic viability.

Market Analysis for REBCO Applications

The REBCO (Rare-Earth Barium Copper Oxide) superconductor market is experiencing significant growth driven by increasing demand for high-performance superconducting applications. The global superconductor market, valued at approximately $7.5 billion in 2023, is projected to reach $14.9 billion by 2030, with REBCO materials capturing an expanding share due to their superior performance characteristics.

Energy sector applications represent the largest market segment for REBCO technology, with power transmission, energy storage systems, and fault current limiters as primary applications. The growing focus on renewable energy integration and grid modernization has accelerated demand for REBCO-based solutions that can handle high current densities while minimizing AC losses.

Healthcare applications form another substantial market segment, particularly in magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR) systems. REBCO's ability to operate at higher temperatures than traditional superconductors translates to reduced cooling costs and operational expenses, driving adoption in medical imaging equipment where the global market exceeds $8 billion annually.

Transportation represents an emerging high-potential market for REBCO technology. Maglev train systems in Japan and China have demonstrated successful implementation of REBCO-based components, while electric aircraft and maritime propulsion systems are exploring REBCO solutions to achieve higher power densities and efficiency.

Research and scientific instrumentation constitute a specialized but growing market segment. High-energy physics facilities, fusion energy research, and quantum computing applications increasingly rely on REBCO materials for high-field magnets and other critical components.

The market for striated REBCO tapes specifically is expanding as AC loss mitigation becomes crucial for commercial applications. Industry analysts estimate that striated REBCO products command a premium of 15-30% over standard tapes, reflecting their enhanced performance characteristics and reduced operational costs in AC applications.

Regional analysis indicates Asia-Pacific dominates REBCO manufacturing, with Japan, China, and South Korea as key production hubs. North America and Europe lead in research and specialized applications, particularly in scientific and medical fields. The market shows a trend toward vertical integration, with major players expanding across the supply chain from material production to system integration.

Competitive pricing remains a significant market challenge, with REBCO materials still commanding substantially higher prices than conventional conductors. However, ongoing manufacturing improvements and economies of scale are gradually reducing this gap, with production costs decreasing by approximately 8-12% annually over the past five years.

Energy sector applications represent the largest market segment for REBCO technology, with power transmission, energy storage systems, and fault current limiters as primary applications. The growing focus on renewable energy integration and grid modernization has accelerated demand for REBCO-based solutions that can handle high current densities while minimizing AC losses.

Healthcare applications form another substantial market segment, particularly in magnetic resonance imaging (MRI) and nuclear magnetic resonance (NMR) systems. REBCO's ability to operate at higher temperatures than traditional superconductors translates to reduced cooling costs and operational expenses, driving adoption in medical imaging equipment where the global market exceeds $8 billion annually.

Transportation represents an emerging high-potential market for REBCO technology. Maglev train systems in Japan and China have demonstrated successful implementation of REBCO-based components, while electric aircraft and maritime propulsion systems are exploring REBCO solutions to achieve higher power densities and efficiency.

Research and scientific instrumentation constitute a specialized but growing market segment. High-energy physics facilities, fusion energy research, and quantum computing applications increasingly rely on REBCO materials for high-field magnets and other critical components.

The market for striated REBCO tapes specifically is expanding as AC loss mitigation becomes crucial for commercial applications. Industry analysts estimate that striated REBCO products command a premium of 15-30% over standard tapes, reflecting their enhanced performance characteristics and reduced operational costs in AC applications.

Regional analysis indicates Asia-Pacific dominates REBCO manufacturing, with Japan, China, and South Korea as key production hubs. North America and Europe lead in research and specialized applications, particularly in scientific and medical fields. The market shows a trend toward vertical integration, with major players expanding across the supply chain from material production to system integration.

Competitive pricing remains a significant market challenge, with REBCO materials still commanding substantially higher prices than conventional conductors. However, ongoing manufacturing improvements and economies of scale are gradually reducing this gap, with production costs decreasing by approximately 8-12% annually over the past five years.

Current AC Loss Challenges in REBCO Superconductors

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting technology, offering superior current-carrying capabilities and magnetic field performance. However, these materials face substantial challenges related to AC losses when operating in alternating current environments or changing magnetic fields, which significantly impacts their practical applications in power systems, medical devices, and transportation.

The primary AC loss mechanisms in REBCO superconductors include hysteresis losses, coupling losses, and eddy current losses. Hysteresis losses occur due to the penetration of magnetic flux into the superconductor during AC cycles, resulting in irreversible energy dissipation. These losses are particularly problematic in REBCO materials due to their anisotropic properties and complex microstructure, which create preferential paths for flux penetration.

Coupling losses present another significant challenge, especially in multi-filamentary REBCO tapes and coated conductors. These losses arise from induced currents flowing between superconducting filaments through the normal metal matrix or substrate. The unique layered architecture of REBCO tapes, typically consisting of a superconducting layer deposited on metallic substrates with various buffer layers, creates complex coupling pathways that are difficult to model and mitigate.

The presence of metallic components in REBCO architectures, such as copper stabilizers and silver overlayers, contributes to eddy current losses. These components, while necessary for thermal stability and protection against quenching, create additional pathways for energy dissipation during AC operation. The trade-off between stabilization requirements and AC loss reduction represents a fundamental engineering challenge.

Current density distribution in REBCO conductors under AC conditions further complicates the loss landscape. The non-uniform current distribution, influenced by the conductor geometry and the presence of defects, leads to localized heating and potential degradation of superconducting properties. This non-uniformity becomes more pronounced at higher frequencies and in complex magnetic field environments.

Temperature dependencies add another layer of complexity to AC loss behavior in REBCO materials. As operating temperatures approach the critical temperature, AC losses increase dramatically due to reduced pinning forces and increased flux creep. This temperature sensitivity narrows the operational window for many applications and necessitates more sophisticated cooling systems.

Scale-up challenges persist in the manufacturing of low-AC-loss REBCO conductors. While laboratory-scale demonstrations have shown promising results with various loss mitigation techniques, translating these approaches to industrial-scale production while maintaining consistent performance remains difficult. The balance between manufacturing cost, production yield, and AC loss performance continues to be a critical consideration for commercial viability.

The primary AC loss mechanisms in REBCO superconductors include hysteresis losses, coupling losses, and eddy current losses. Hysteresis losses occur due to the penetration of magnetic flux into the superconductor during AC cycles, resulting in irreversible energy dissipation. These losses are particularly problematic in REBCO materials due to their anisotropic properties and complex microstructure, which create preferential paths for flux penetration.

Coupling losses present another significant challenge, especially in multi-filamentary REBCO tapes and coated conductors. These losses arise from induced currents flowing between superconducting filaments through the normal metal matrix or substrate. The unique layered architecture of REBCO tapes, typically consisting of a superconducting layer deposited on metallic substrates with various buffer layers, creates complex coupling pathways that are difficult to model and mitigate.

The presence of metallic components in REBCO architectures, such as copper stabilizers and silver overlayers, contributes to eddy current losses. These components, while necessary for thermal stability and protection against quenching, create additional pathways for energy dissipation during AC operation. The trade-off between stabilization requirements and AC loss reduction represents a fundamental engineering challenge.

Current density distribution in REBCO conductors under AC conditions further complicates the loss landscape. The non-uniform current distribution, influenced by the conductor geometry and the presence of defects, leads to localized heating and potential degradation of superconducting properties. This non-uniformity becomes more pronounced at higher frequencies and in complex magnetic field environments.

Temperature dependencies add another layer of complexity to AC loss behavior in REBCO materials. As operating temperatures approach the critical temperature, AC losses increase dramatically due to reduced pinning forces and increased flux creep. This temperature sensitivity narrows the operational window for many applications and necessitates more sophisticated cooling systems.

Scale-up challenges persist in the manufacturing of low-AC-loss REBCO conductors. While laboratory-scale demonstrations have shown promising results with various loss mitigation techniques, translating these approaches to industrial-scale production while maintaining consistent performance remains difficult. The balance between manufacturing cost, production yield, and AC loss performance continues to be a critical consideration for commercial viability.

Existing Striation Methods for AC Loss Reduction

01 AC loss reduction in REBCO superconductors through geometric design

The AC loss in REBCO superconductors can be reduced through specific geometric designs and configurations. These include optimizing the aspect ratio of superconducting tapes, implementing striated or filamentary structures, and designing specific conductor arrangements. Such geometric modifications help to reduce eddy currents and hysteresis losses in alternating current applications, improving the overall efficiency of REBCO superconductor systems.- AC loss reduction in REBCO superconductors through geometric design: The geometric design of REBCO superconductors significantly impacts AC loss characteristics. Various configurations such as striated tapes, filamentary structures, and optimized aspect ratios can effectively reduce hysteresis losses. These designs minimize the cross-sectional area exposed to changing magnetic fields, thereby reducing eddy currents and associated energy dissipation. Techniques like laser scribing to create narrow filaments and specific winding geometries for coils are employed to achieve lower AC losses in high-temperature superconducting applications.

- Multilayer and composite structures for AC loss minimization: Multilayer and composite structures in REBCO superconductors offer significant advantages for AC loss reduction. These designs incorporate buffer layers, stabilizing metals, and specific substrate materials to optimize electromagnetic performance. By engineering the interfaces between different material layers and controlling the thickness ratios, the superconducting properties can be enhanced while simultaneously reducing AC losses. These composite structures also improve mechanical stability and thermal management, which are critical for maintaining superconductivity under varying electromagnetic conditions.

- Flux pinning enhancement techniques for AC loss control: Enhancing flux pinning in REBCO superconductors is a crucial approach for controlling AC losses. By introducing artificial pinning centers, such as nanoparticles, nanorods, or engineered defects, the movement of magnetic flux vortices can be restricted. This restriction reduces flux creep and flux flow losses under alternating current conditions. Various doping methods with rare earth elements or metal oxides can modify the microstructure to create effective pinning sites. These techniques improve the critical current density while simultaneously reducing the energy dissipation during AC operation.

- Cryogenic and cooling system designs for AC loss management: Effective cryogenic and cooling system designs are essential for managing AC losses in REBCO superconductors. Advanced cooling configurations, including forced flow cooling, subcooled liquid nitrogen, and cryocooler integration, help dissipate the heat generated by AC losses. Thermal stabilization techniques and optimized heat exchange surfaces prevent local hotspots that could trigger quenching. The cooling system design must account for the specific operating conditions, including frequency, current amplitude, and magnetic field environment, to maintain stable superconducting performance while minimizing the overall energy consumption of the system.

- Measurement and modeling techniques for AC loss characterization: Accurate measurement and modeling techniques are critical for characterizing AC losses in REBCO superconductors. Various experimental methods, including electrical, calorimetric, and magnetization measurements, provide complementary data on loss mechanisms. Advanced computational models based on finite element analysis, H-formulation, and T-A formulation enable prediction of AC losses under complex operating conditions. These models account for anisotropic properties, field dependencies, and geometric factors to optimize superconductor designs. Real-time monitoring systems can detect changes in AC loss behavior, allowing for adaptive control strategies in practical applications.

02 Multilayer and composite structures for AC loss minimization

Multilayer and composite structures incorporating REBCO superconductors can effectively minimize AC losses. These structures typically involve combinations of superconducting layers with stabilizing metals, buffer layers, and substrate materials. By carefully engineering these multilayer structures, the electromagnetic properties can be optimized to reduce hysteresis losses and coupling losses between layers, resulting in improved performance in AC applications.Expand Specific Solutions03 Cooling systems and thermal management for REBCO superconductors

Effective cooling systems and thermal management are crucial for minimizing AC losses in REBCO superconductors. These include cryogenic cooling techniques, heat transfer mechanisms, and temperature stabilization methods. Proper thermal management ensures that the superconductors operate at optimal temperatures, preventing thermal runaway and maintaining superconductivity even under AC conditions, which significantly reduces losses associated with temperature fluctuations.Expand Specific Solutions04 Magnetic field control and shielding techniques

Controlling magnetic fields around REBCO superconductors is essential for reducing AC losses. This includes magnetic shielding designs, field orientation optimization, and flux pinning enhancement. By managing the magnetic field distribution and penetration into the superconductor, these techniques minimize hysteresis losses and improve the current-carrying capacity under alternating current conditions, leading to more efficient operation in power applications.Expand Specific Solutions05 Manufacturing processes and material composition optimization

Advanced manufacturing processes and optimized material compositions significantly impact AC loss characteristics in REBCO superconductors. These include precise control of rare earth element ratios, doping with pinning centers, and specialized deposition techniques. Improvements in manufacturing processes lead to more homogeneous superconducting properties, reduced defects, and enhanced grain boundary characteristics, all contributing to lower AC losses in practical applications.Expand Specific Solutions

Leading Institutions and Companies in REBCO Technology

The REBCO AC loss technology landscape is currently in a transitional phase, moving from research to early commercialization, with an estimated market size of $300-500 million that is projected to grow significantly as superconducting applications expand. The technology maturity varies across players, with research institutions like University of Houston, Karlsruher Institut für Technologie, and Huazhong University leading fundamental research on hysteresis loss reduction. Companies including SuperPower (Furukawa Electric subsidiary), TDK Corp., and Samsung Electronics are advancing in striation techniques for coupling loss mitigation, while industrial players such as Toshiba, Nexans, and Prysmian are focusing on practical implementation in power systems. The competitive dynamics show collaboration between academic institutions and commercial entities to overcome technical challenges in AC loss reduction for high-temperature superconductors.

University of Houston

Technical Solution: The University of Houston's Superconductivity Center has developed significant innovations in REBCO AC loss reduction through their patented "Controlled Striation and Bridging" technique. This approach combines precise filamentization with strategic superconducting bridges between filaments to optimize electromagnetic performance. Their research has demonstrated that carefully designed striation patterns with varying widths and spacing can reduce hysteresis losses by up to 85% while maintaining over 95% of the original critical current. The university's technology incorporates specialized buffer layer engineering that reduces substrate-induced coupling effects, a common challenge in striated REBCO tapes. Their process includes post-striation treatment that heals micro-damage at filament edges, preserving superconducting properties at the boundaries. Additionally, they've pioneered computational models that accurately predict AC loss behavior across different operating frequencies and magnetic field orientations, enabling application-specific optimization. Recent publications have shown their striated REBCO conductors perform exceptionally well in dynamic applications with rapidly changing magnetic fields.

Strengths: Exceptional balance between AC loss reduction and critical current preservation; sophisticated modeling capabilities for application-specific optimization; innovative bridging technique that addresses mechanical stability concerns. Weaknesses: Technology primarily developed at research scale; potential challenges in scaling to commercial production volumes; higher complexity in manufacturing process compared to conventional approaches.

Advanced Industrial Science & Technology

Technical Solution: The National Institute of Advanced Industrial Science and Technology (AIST) of Japan has developed a comprehensive REBCO AC loss mitigation system through their "Multi-Scale Striation and Interface Engineering" approach. Their technology addresses the fundamental mechanisms of both hysteresis and coupling losses through precisely controlled filamentization combined with advanced interface management between layers. AIST's process employs proprietary laser patterning techniques that create optimized filament geometries with minimal damage to the superconducting layer, achieving filament widths below 100 micrometers while preserving over 95% of the original critical current. Their innovation includes specialized interlayer materials that provide electrical resistance between filaments while maintaining excellent mechanical properties and thermal conductivity. AIST researchers have developed sophisticated electromagnetic-thermal coupled models that accurately predict AC loss behavior under various operating conditions, enabling application-specific optimization of striation patterns. Their technology has demonstrated particularly impressive performance in reducing magnetization losses in perpendicular fields, achieving reductions of up to 85% compared to non-striated tapes in representative power application scenarios.

Strengths: Excellent balance between AC loss reduction and preservation of critical current; sophisticated modeling capabilities that enable application-specific optimization; effective integration with existing manufacturing processes. Weaknesses: Higher production complexity requiring specialized equipment; potential challenges in quality control across large production volumes; increased manufacturing costs compared to standard REBCO conductors.

Critical Patents and Research on Hysteresis and Coupling Loss

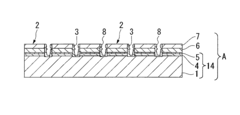

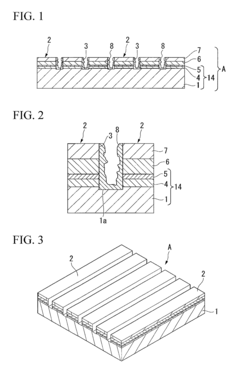

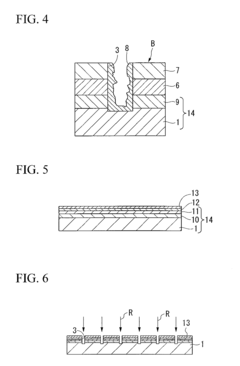

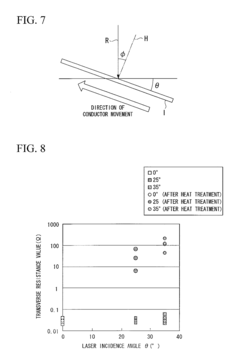

Low alternating-current loss oxide superconductor and fabricating method thereof

PatentInactiveUS8880135B2

Innovation

- The oxide superconducting layer is divided into filament conductors using laser scribing to form high-resistance dividing grooves that reach the substrate, with a stabilizing layer and intermediate layers for crystal orientation control, and heat treatment is applied to oxidize the molten coagulation, increasing resistance and reducing AC loss.

Cryogenic System Integration Considerations

The integration of REBCO superconducting systems with cryogenic cooling infrastructure presents unique challenges when considering AC loss mitigation strategies, particularly those involving striation techniques. Cryogenic system design must account for the thermal loads generated by hysteresis and coupling losses in REBCO tapes during operation under alternating current conditions.

Temperature stability is critical for maintaining REBCO performance, as even minor fluctuations can significantly impact critical current capacity and overall system efficiency. The cryogenic cooling system must be dimensioned to handle both steady-state heat loads and transient thermal spikes resulting from AC losses, which can vary substantially depending on the operating frequency, current amplitude, and magnetic field environment.

Striated REBCO tapes, while effective at reducing AC losses, introduce additional considerations for cryogenic integration. The modified geometry of striated conductors affects thermal conductivity pathways and can create localized hot spots if cooling is not uniformly distributed. Cryogenic system designers must ensure adequate cooling across the entire cross-section of striated conductors, particularly at the edges of individual filaments where current density may concentrate.

Liquid nitrogen cooling systems, commonly used for REBCO applications operating at 77K, must be evaluated for their heat transfer efficiency when interfacing with striated conductors. The reduced surface area available for direct cooling in striated designs may necessitate enhanced cooling strategies, such as forced flow cooling or the implementation of thermally conductive matrices between filaments.

For applications requiring lower operating temperatures (20-30K) to maximize REBCO performance, closed-cycle cryocoolers must be sized with sufficient margin to accommodate the variable heat loads associated with AC operation. The mechanical integration of cryocoolers with striated REBCO components requires careful consideration of thermal interfaces and mechanical stress management to prevent degradation of the superconducting properties.

Instrumentation and monitoring systems within the cryogenic environment must be designed to detect temperature gradients that might indicate ineffective cooling or unexpected AC loss behavior. Real-time thermal monitoring becomes particularly important when implementing novel striation patterns that have limited operational history.

The economic viability of striated REBCO systems depends heavily on optimizing the balance between AC loss reduction and increased cryogenic cooling requirements. Life-cycle cost analyses must consider both the capital investment in more sophisticated cooling infrastructure and the operational energy savings from reduced AC losses, particularly for large-scale applications such as power transmission systems or rotating machinery.

Temperature stability is critical for maintaining REBCO performance, as even minor fluctuations can significantly impact critical current capacity and overall system efficiency. The cryogenic cooling system must be dimensioned to handle both steady-state heat loads and transient thermal spikes resulting from AC losses, which can vary substantially depending on the operating frequency, current amplitude, and magnetic field environment.

Striated REBCO tapes, while effective at reducing AC losses, introduce additional considerations for cryogenic integration. The modified geometry of striated conductors affects thermal conductivity pathways and can create localized hot spots if cooling is not uniformly distributed. Cryogenic system designers must ensure adequate cooling across the entire cross-section of striated conductors, particularly at the edges of individual filaments where current density may concentrate.

Liquid nitrogen cooling systems, commonly used for REBCO applications operating at 77K, must be evaluated for their heat transfer efficiency when interfacing with striated conductors. The reduced surface area available for direct cooling in striated designs may necessitate enhanced cooling strategies, such as forced flow cooling or the implementation of thermally conductive matrices between filaments.

For applications requiring lower operating temperatures (20-30K) to maximize REBCO performance, closed-cycle cryocoolers must be sized with sufficient margin to accommodate the variable heat loads associated with AC operation. The mechanical integration of cryocoolers with striated REBCO components requires careful consideration of thermal interfaces and mechanical stress management to prevent degradation of the superconducting properties.

Instrumentation and monitoring systems within the cryogenic environment must be designed to detect temperature gradients that might indicate ineffective cooling or unexpected AC loss behavior. Real-time thermal monitoring becomes particularly important when implementing novel striation patterns that have limited operational history.

The economic viability of striated REBCO systems depends heavily on optimizing the balance between AC loss reduction and increased cryogenic cooling requirements. Life-cycle cost analyses must consider both the capital investment in more sophisticated cooling infrastructure and the operational energy savings from reduced AC losses, particularly for large-scale applications such as power transmission systems or rotating machinery.

Economic Viability and Scaling Challenges

The economic viability of REBCO superconductors faces significant challenges despite their superior performance characteristics. Current manufacturing costs for REBCO tapes remain prohibitively high, ranging from $100-400/kA-m, compared to conventional copper conductors at approximately $10/kA-m. This cost differential presents a substantial barrier to widespread commercial adoption, particularly in price-sensitive applications such as power transmission and large-scale magnets.

AC loss mitigation through striation techniques introduces additional manufacturing complexity and costs. While striation effectively reduces hysteresis and coupling losses, the precision required for multifilamentary architectures demands sophisticated production equipment and quality control measures. These requirements further elevate production expenses, creating a challenging cost-benefit equation for manufacturers and end-users alike.

Scaling production to industrial levels presents another critical challenge. Current REBCO manufacturing processes remain largely semi-automated, with limited throughput capabilities. The intricate deposition processes required for high-quality REBCO layers demand precise control over multiple parameters simultaneously, making high-volume production technically challenging. Industry estimates suggest that a tenfold increase in production capacity would be necessary to achieve meaningful cost reductions through economies of scale.

Material efficiency represents another economic consideration. The rare earth elements in REBCO compositions, particularly yttrium and gadolinium, face supply chain vulnerabilities and price volatility. Additionally, the substrate and buffer layer materials contribute significantly to overall costs. Optimizing material usage while maintaining performance characteristics remains a delicate balance that impacts economic feasibility.

Energy consumption during manufacturing also affects economic viability. The high-temperature processes required for REBCO fabrication, particularly during the epitaxial growth phases, consume substantial energy. This energy intensity translates to higher production costs and environmental impacts, potentially offsetting some of the efficiency gains achieved through reduced AC losses in operation.

Market adoption patterns further complicate the economic landscape. While niche applications in scientific research and medical imaging have embraced REBCO technology despite higher costs, broader market penetration depends on demonstrating compelling value propositions. The economic benefits of reduced AC losses must outweigh the premium costs of striated REBCO conductors to drive adoption in commercial power applications and industrial systems.

AC loss mitigation through striation techniques introduces additional manufacturing complexity and costs. While striation effectively reduces hysteresis and coupling losses, the precision required for multifilamentary architectures demands sophisticated production equipment and quality control measures. These requirements further elevate production expenses, creating a challenging cost-benefit equation for manufacturers and end-users alike.

Scaling production to industrial levels presents another critical challenge. Current REBCO manufacturing processes remain largely semi-automated, with limited throughput capabilities. The intricate deposition processes required for high-quality REBCO layers demand precise control over multiple parameters simultaneously, making high-volume production technically challenging. Industry estimates suggest that a tenfold increase in production capacity would be necessary to achieve meaningful cost reductions through economies of scale.

Material efficiency represents another economic consideration. The rare earth elements in REBCO compositions, particularly yttrium and gadolinium, face supply chain vulnerabilities and price volatility. Additionally, the substrate and buffer layer materials contribute significantly to overall costs. Optimizing material usage while maintaining performance characteristics remains a delicate balance that impacts economic feasibility.

Energy consumption during manufacturing also affects economic viability. The high-temperature processes required for REBCO fabrication, particularly during the epitaxial growth phases, consume substantial energy. This energy intensity translates to higher production costs and environmental impacts, potentially offsetting some of the efficiency gains achieved through reduced AC losses in operation.

Market adoption patterns further complicate the economic landscape. While niche applications in scientific research and medical imaging have embraced REBCO technology despite higher costs, broader market penetration depends on demonstrating compelling value propositions. The economic benefits of reduced AC losses must outweigh the premium costs of striated REBCO conductors to drive adoption in commercial power applications and industrial systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!