REBCO Coated Conductors: Critical Current, n-Value And Angular Dependence

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Technology Evolution and Research Objectives

REBCO (Rare Earth Barium Copper Oxide) coated conductors represent a significant advancement in superconducting materials technology, evolving from early high-temperature superconductor (HTS) discoveries in the late 1980s. The journey began with the landmark discovery of YBa₂Cu₃O₇₋ₓ (YBCO) by researchers at IBM Zurich and the University of Alabama, which demonstrated superconductivity above liquid nitrogen temperature (77K).

The technological evolution of REBCO conductors has progressed through several distinct phases. Initially, bulk ceramic materials showed promise but were limited by their brittleness and poor current-carrying capacity. The breakthrough came with the development of thin film deposition techniques in the 1990s, allowing REBCO materials to be formed as flexible tapes with significantly improved performance characteristics.

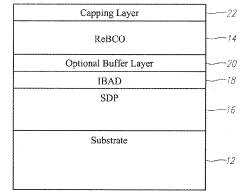

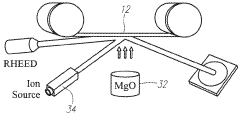

By the early 2000s, second-generation (2G) HTS wires based on REBCO emerged, utilizing epitaxial growth on textured substrates. This represented a paradigm shift from first-generation bismuth-based conductors, offering superior performance in magnetic fields and at higher temperatures. The introduction of ion beam assisted deposition (IBAD) and rolling-assisted biaxially textured substrates (RABiTS) technologies marked critical milestones in manufacturing scalability.

Current research objectives focus on several key parameters that define REBCO conductor performance. Critical current (Ic) enhancement remains paramount, with efforts directed toward increasing current-carrying capacity under various operating conditions. The n-value, which characterizes the sharpness of the superconducting transition, is crucial for applications requiring stable operation near critical conditions. Angular dependence of critical current represents another vital research area, as REBCO materials exhibit anisotropic behavior in magnetic fields due to their layered crystal structure.

The field is now moving toward optimizing these parameters through nanoscale engineering of the superconducting layer. Artificial pinning centers (APCs), strategic dopants, and controlled defect structures are being investigated to enhance flux pinning capabilities. Concurrently, researchers aim to develop manufacturing processes that maintain high performance while reducing production costs, which remain a significant barrier to widespread commercial adoption.

The ultimate research objective is to achieve REBCO conductors with consistently high critical currents exceeding 1000 A/cm-width at 77K in self-field, with minimal angular dependence in applied magnetic fields, and n-values above 30 across all operating conditions. These improvements would enable transformative applications in energy, transportation, and medical sectors, particularly in high-field magnets for fusion energy and next-generation MRI systems.

The technological evolution of REBCO conductors has progressed through several distinct phases. Initially, bulk ceramic materials showed promise but were limited by their brittleness and poor current-carrying capacity. The breakthrough came with the development of thin film deposition techniques in the 1990s, allowing REBCO materials to be formed as flexible tapes with significantly improved performance characteristics.

By the early 2000s, second-generation (2G) HTS wires based on REBCO emerged, utilizing epitaxial growth on textured substrates. This represented a paradigm shift from first-generation bismuth-based conductors, offering superior performance in magnetic fields and at higher temperatures. The introduction of ion beam assisted deposition (IBAD) and rolling-assisted biaxially textured substrates (RABiTS) technologies marked critical milestones in manufacturing scalability.

Current research objectives focus on several key parameters that define REBCO conductor performance. Critical current (Ic) enhancement remains paramount, with efforts directed toward increasing current-carrying capacity under various operating conditions. The n-value, which characterizes the sharpness of the superconducting transition, is crucial for applications requiring stable operation near critical conditions. Angular dependence of critical current represents another vital research area, as REBCO materials exhibit anisotropic behavior in magnetic fields due to their layered crystal structure.

The field is now moving toward optimizing these parameters through nanoscale engineering of the superconducting layer. Artificial pinning centers (APCs), strategic dopants, and controlled defect structures are being investigated to enhance flux pinning capabilities. Concurrently, researchers aim to develop manufacturing processes that maintain high performance while reducing production costs, which remain a significant barrier to widespread commercial adoption.

The ultimate research objective is to achieve REBCO conductors with consistently high critical currents exceeding 1000 A/cm-width at 77K in self-field, with minimal angular dependence in applied magnetic fields, and n-values above 30 across all operating conditions. These improvements would enable transformative applications in energy, transportation, and medical sectors, particularly in high-field magnets for fusion energy and next-generation MRI systems.

Market Analysis for High-Temperature Superconductors

The high-temperature superconductor (HTS) market has been experiencing significant growth, with the global market value reaching approximately $6.8 billion in 2022 and projected to exceed $12 billion by 2030, representing a compound annual growth rate of 7.5%. This growth is primarily driven by increasing applications in energy, healthcare, transportation, and research sectors.

REBCO (Rare Earth Barium Copper Oxide) coated conductors, particularly those based on YBCO (Yttrium Barium Copper Oxide), have emerged as the dominant commercial HTS materials due to their superior performance characteristics. The market for these materials is particularly robust in regions with advanced technological infrastructure, including North America, Europe, East Asia, and increasingly in emerging economies investing in advanced energy and medical technologies.

The demand for REBCO coated conductors is segmented across several key application areas. The energy sector represents the largest market share at approximately 35%, encompassing applications in power transmission, energy storage systems, and fusion energy research. Medical applications follow at 28%, primarily for MRI systems where the angular dependence properties of REBCO conductors are crucial for magnetic field stability.

Transportation applications, particularly in maglev train systems and electric propulsion, constitute about 20% of the market. Research institutions and scientific facilities account for 15%, while emerging applications in quantum computing and other advanced technologies make up the remaining 2%.

Market analysis indicates that critical current capacity and n-value characteristics of REBCO conductors directly correlate with pricing structures in the market. Premium-grade conductors with higher critical current values and more stable n-values command price premiums of 30-40% over standard grades. The angular dependence property has become increasingly important as applications requiring precise magnetic field control expand.

Regional market distribution shows East Asia leading manufacturing capacity with 45% of global production, followed by North America (25%), Europe (20%), and other regions (10%). However, consumption patterns differ, with North America and Europe collectively accounting for over 60% of global demand due to their advanced research infrastructure and commercial applications.

Market forecasts suggest that demand for REBCO conductors with enhanced angular dependence properties will grow at 9.2% annually through 2030, outpacing the overall market growth. This is driven by increasingly sophisticated applications in medical imaging, quantum technologies, and next-generation fusion energy projects where magnetic field precision is paramount.

REBCO (Rare Earth Barium Copper Oxide) coated conductors, particularly those based on YBCO (Yttrium Barium Copper Oxide), have emerged as the dominant commercial HTS materials due to their superior performance characteristics. The market for these materials is particularly robust in regions with advanced technological infrastructure, including North America, Europe, East Asia, and increasingly in emerging economies investing in advanced energy and medical technologies.

The demand for REBCO coated conductors is segmented across several key application areas. The energy sector represents the largest market share at approximately 35%, encompassing applications in power transmission, energy storage systems, and fusion energy research. Medical applications follow at 28%, primarily for MRI systems where the angular dependence properties of REBCO conductors are crucial for magnetic field stability.

Transportation applications, particularly in maglev train systems and electric propulsion, constitute about 20% of the market. Research institutions and scientific facilities account for 15%, while emerging applications in quantum computing and other advanced technologies make up the remaining 2%.

Market analysis indicates that critical current capacity and n-value characteristics of REBCO conductors directly correlate with pricing structures in the market. Premium-grade conductors with higher critical current values and more stable n-values command price premiums of 30-40% over standard grades. The angular dependence property has become increasingly important as applications requiring precise magnetic field control expand.

Regional market distribution shows East Asia leading manufacturing capacity with 45% of global production, followed by North America (25%), Europe (20%), and other regions (10%). However, consumption patterns differ, with North America and Europe collectively accounting for over 60% of global demand due to their advanced research infrastructure and commercial applications.

Market forecasts suggest that demand for REBCO conductors with enhanced angular dependence properties will grow at 9.2% annually through 2030, outpacing the overall market growth. This is driven by increasingly sophisticated applications in medical imaging, quantum technologies, and next-generation fusion energy projects where magnetic field precision is paramount.

Current Challenges in REBCO Coated Conductor Development

Despite significant advancements in REBCO (Rare-Earth Barium Copper Oxide) coated conductor technology, several critical challenges persist that impede their widespread commercial adoption and optimal performance in high-field applications. The most pressing issue remains the inconsistency in critical current (Ic) values across manufactured tapes, with variations of up to 20% observed within the same production batch. This inconsistency creates significant engineering challenges when designing large-scale magnet systems that require predictable performance parameters.

The angular dependence of critical current presents another major hurdle. REBCO conductors exhibit strong anisotropy in their superconducting properties, with Ic values varying dramatically depending on the orientation of the applied magnetic field relative to the tape surface. This anisotropy necessitates complex design considerations for applications where magnetic field orientation changes, such as in rotating machinery or certain magnet configurations.

The n-value, which characterizes the sharpness of the superconducting transition, continues to be a challenge to control consistently during manufacturing. Lower n-values indicate a broader transition from the superconducting to the normal state, which can lead to increased AC losses and thermal instabilities in applications. Current manufacturing processes struggle to maintain high n-values (>30) consistently across long tape lengths, particularly at the higher operating temperatures preferred for cost-effective cooling systems.

Production scalability remains problematic, with current manufacturing techniques unable to produce kilometer-length tapes with uniform properties throughout. The substrate preparation, buffer layer deposition, and REBCO layer growth all introduce potential defects that can create weak links in the superconducting path, reducing overall performance. These defects become more prevalent as production scales increase, creating a significant barrier to mass production.

Mechanical properties present additional challenges, as REBCO tapes are inherently brittle and sensitive to strain. The critical current degrades significantly under tensile strain exceeding 0.4-0.5%, limiting their application in high-stress environments. While various reinforcement techniques have been developed, they often come at the cost of reduced engineering current density, creating design trade-offs.

Cost remains perhaps the most significant barrier to widespread adoption. Current production methods involve complex multi-step processes requiring precise control of deposition parameters and expensive equipment. The price of REBCO tapes (typically $50-100/kA-m at 77K, self-field) is still an order of magnitude higher than conventional superconductors like NbTi, making them economically viable only for specialized applications where their superior performance is essential.

The angular dependence of critical current presents another major hurdle. REBCO conductors exhibit strong anisotropy in their superconducting properties, with Ic values varying dramatically depending on the orientation of the applied magnetic field relative to the tape surface. This anisotropy necessitates complex design considerations for applications where magnetic field orientation changes, such as in rotating machinery or certain magnet configurations.

The n-value, which characterizes the sharpness of the superconducting transition, continues to be a challenge to control consistently during manufacturing. Lower n-values indicate a broader transition from the superconducting to the normal state, which can lead to increased AC losses and thermal instabilities in applications. Current manufacturing processes struggle to maintain high n-values (>30) consistently across long tape lengths, particularly at the higher operating temperatures preferred for cost-effective cooling systems.

Production scalability remains problematic, with current manufacturing techniques unable to produce kilometer-length tapes with uniform properties throughout. The substrate preparation, buffer layer deposition, and REBCO layer growth all introduce potential defects that can create weak links in the superconducting path, reducing overall performance. These defects become more prevalent as production scales increase, creating a significant barrier to mass production.

Mechanical properties present additional challenges, as REBCO tapes are inherently brittle and sensitive to strain. The critical current degrades significantly under tensile strain exceeding 0.4-0.5%, limiting their application in high-stress environments. While various reinforcement techniques have been developed, they often come at the cost of reduced engineering current density, creating design trade-offs.

Cost remains perhaps the most significant barrier to widespread adoption. Current production methods involve complex multi-step processes requiring precise control of deposition parameters and expensive equipment. The price of REBCO tapes (typically $50-100/kA-m at 77K, self-field) is still an order of magnitude higher than conventional superconductors like NbTi, making them economically viable only for specialized applications where their superior performance is essential.

Current Methodologies for Critical Current Enhancement

01 Critical current measurement and characterization in REBCO coated conductors

Various methods and systems for measuring and characterizing the critical current in REBCO (Rare Earth Barium Copper Oxide) coated conductors. These techniques allow for precise determination of critical current values under different conditions, which is essential for understanding the performance limits of superconducting materials. The measurements typically involve specialized equipment that can detect small voltage signals while applying controlled current through the superconductor.- Critical current measurement and characterization in REBCO coated conductors: Methods and systems for measuring and characterizing the critical current in REBCO (Rare Earth Barium Copper Oxide) coated conductors. These techniques involve specialized equipment and procedures to accurately determine the critical current values under various conditions, which is essential for evaluating the performance of superconducting materials. The measurements help in understanding the current-carrying capacity of REBCO conductors and their suitability for different applications.

- Angular dependence of critical current in REBCO superconductors: The critical current in REBCO coated conductors exhibits significant angular dependence due to the anisotropic nature of these materials. This angular dependence is influenced by factors such as the orientation of applied magnetic fields relative to the crystallographic axes of the REBCO layer. Understanding this angular dependence is crucial for designing superconducting devices that operate under varying field orientations and for optimizing the performance of REBCO conductors in practical applications.

- n-Value characterization and improvement in REBCO conductors: The n-value is a critical parameter that describes the sharpness of the transition from the superconducting to the normal state in REBCO conductors. Higher n-values indicate a sharper transition and better quality superconductors. Various methods and compositions have been developed to improve the n-value of REBCO coated conductors, including optimized fabrication processes, buffer layer engineering, and controlled doping. Enhanced n-values lead to more stable and reliable superconducting performance in high-current applications.

- Fabrication techniques for high-performance REBCO coated conductors: Advanced fabrication methods for producing REBCO coated conductors with enhanced critical current properties. These techniques include specialized deposition processes, substrate preparation methods, and post-processing treatments that optimize the superconducting layer structure. The fabrication approaches focus on creating well-aligned crystal structures, minimizing defects, and incorporating artificial pinning centers to improve current-carrying capabilities under various operating conditions.

- Magnetic field effects on REBCO conductor performance: The influence of magnetic fields on the critical current and n-value of REBCO coated conductors. Magnetic fields can significantly affect the performance of these superconductors, with the impact varying based on field strength, orientation, and temperature. Research has focused on understanding these effects and developing REBCO conductors with improved field tolerance through methods such as artificial pinning center introduction, compositional modifications, and microstructural engineering to enhance flux pinning capabilities.

02 Angular dependence of critical current in REBCO conductors

The critical current of REBCO coated conductors exhibits significant angular dependence relative to applied magnetic fields. This anisotropic behavior is due to the layered crystal structure of REBCO materials and the presence of artificial pinning centers. Understanding this angular dependence is crucial for designing applications where the superconductor will experience magnetic fields at various orientations, such as in rotating machinery or magnet systems with complex field configurations.Expand Specific Solutions03 n-Value characterization and improvement techniques

The n-value is a critical parameter that describes the sharpness of the superconducting transition in REBCO materials. Higher n-values indicate a sharper transition from the superconducting to the normal state. Various techniques have been developed to characterize and improve the n-value in REBCO coated conductors, including specialized heat treatments, doping with specific elements, and controlling the microstructure during fabrication. Accurate measurement of n-values requires precise voltage-current characterization.Expand Specific Solutions04 Artificial pinning centers for enhanced critical current

Introducing artificial pinning centers in REBCO coated conductors significantly enhances their critical current capacity and improves performance in magnetic fields. These pinning centers can be created through various methods including nanoparticle inclusion, controlled defect formation, and columnar defect engineering. The size, distribution, and type of pinning centers can be optimized to improve the angular dependence of critical current, particularly for applications in high magnetic fields.Expand Specific Solutions05 Fabrication methods affecting critical current properties

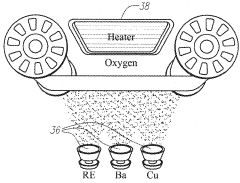

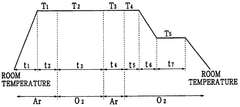

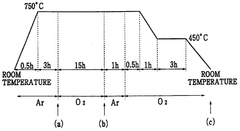

The fabrication process of REBCO coated conductors significantly impacts their critical current properties, n-value, and angular dependence. Key manufacturing parameters include deposition temperature, oxygen annealing conditions, buffer layer composition, substrate selection, and thickness control. Advanced techniques such as pulsed laser deposition, metal organic chemical vapor deposition, and solution-based methods have been developed to optimize the microstructure and interfaces within the conductor, directly affecting superconducting performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in REBCO Field

The REBCO coated conductors market is in a growth phase, characterized by increasing demand for high-temperature superconductors in energy, medical, and transportation applications. The global market is projected to expand significantly due to advancements in critical current performance and angular dependence properties. Leading academic institutions like MIT, Southwest Jiaotong University, and Texas A&M collaborate with industrial players to advance the technology. Key commercial entities include Sumitomo Electric, Shanghai Superconductor Technology, and Nexans SA, who are developing manufacturing processes to enhance n-value stability and angular performance. Research organizations such as UT-Battelle and International Superconductivity Technology Center are bridging fundamental research with commercial applications, focusing on improving conductor performance for next-generation magnet systems.

North China Electric Power University

Technical Solution: North China Electric Power University has developed innovative REBCO coated conductor technology specifically optimized for power grid applications. Their approach utilizes a modified chemical solution deposition method with precise control of rare earth element ratios and copper content to enhance critical current performance. Their conductors demonstrate critical current values of 250-350 A/cm-width at 77K in self-field, with n-values typically in the 20-30 range. A key innovation in their technology is the development of composite pinning structures combining BaZrO3 nanorods with Y2BaCuO5 (Y211) nanoparticles, creating a complex pinning landscape that reduces the angular dependence of critical current. Their research has demonstrated that this approach maintains at least 70% of the maximum critical current across a 90° angular range in applied fields up to 5T. Additionally, they've developed specialized copper stabilization techniques that enhance thermal stability while maintaining mechanical flexibility, crucial for power transmission applications where thermal cycling and mechanical stress are significant factors.

Strengths: Excellent performance-to-cost ratio compared to many competitors; optimized design for power grid applications; good thermal and mechanical stability under operational conditions. Weaknesses: Somewhat lower n-values compared to top-tier research conductors; challenges in very long length production with consistent properties; limited performance in extremely high magnetic fields.

UT-Battelle LLC

Technical Solution: UT-Battelle, operating Oak Ridge National Laboratory, has pioneered significant advancements in REBCO coated conductor technology through their continuous flow deposition system. Their approach utilizes metal organic chemical vapor deposition (MOCVD) to create highly textured REBCO films with exceptional in-field performance. Their conductors exhibit critical current values exceeding 400 A/cm-width at 77K in self-field, with remarkably high n-values (>30) indicating sharp superconducting transitions. A distinctive feature of their technology is the engineered angular dependence through controlled defect structures, including columnar defects aligned with the c-axis and planar defects parallel to the ab-plane. This creates effective pinning landscapes that maintain high critical currents across various field orientations. Their research has demonstrated that controlled doping with elements such as Zr, Sn, and Hf creates nanoscale defects that significantly enhance flux pinning, resulting in less pronounced angular dependence of critical current in applied magnetic fields.

Strengths: Superior flux pinning capabilities through engineered nanostructures; excellent performance in variable field orientations; high n-values indicating quality superconducting transitions. Weaknesses: Higher manufacturing complexity compared to some competing technologies; challenges in scaling to industrial production volumes; relatively higher cost structure for commercial applications.

Key Innovations in n-Value and Angular Dependence Control

Coated conductor high temperature superconductor carrying high critical current under magnetic field by intrinsic pinning centers, and methods of manufacture of same

PatentActiveUS9362025B1

Innovation

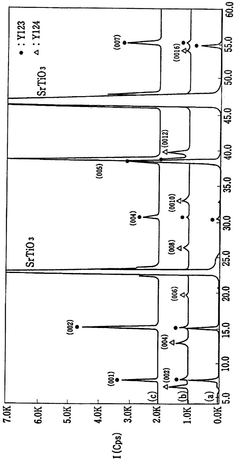

- A second-generation HTS coated conductor with a rare earth barium copper oxide (REBCO) superconductor supported by a substrate, utilizing intrinsic pinning centers and a multilayer structure formed through reactive co-evaporation-cyclic deposition and reaction (RCE-CDR) process, with optional ion beam assisted deposition (IBAD) and solution deposition planarization, to achieve high critical current density without additional elements, scalable for industrial applications.

Method of manufacturing an oxide superconductor with high critical current density

PatentInactiveUS5665682A

Innovation

- A method involving the decomposition of the Y1Ba2Cu4O8 phase into Y1Ba2Cu3O7-x phase and CuO phase, with CuO and micro-defects acting as pinning centers, is used to form a superconductive layer on a substrate, allowing for lower temperature heat treatment and uniform distribution of pinning centers, thereby enhancing critical current density.

Materials Science Fundamentals of REBCO Conductors

REBCO (Rare Earth Barium Copper Oxide) coated conductors represent a significant advancement in superconducting materials science. These materials, typically composed of compounds like YBa₂Cu₃O₇₋ₓ (YBCO) or similar rare earth substitutions, exhibit remarkable superconducting properties at relatively high temperatures compared to conventional superconductors.

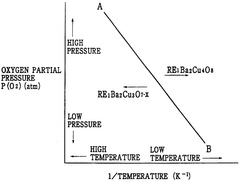

The crystalline structure of REBCO materials plays a crucial role in their performance characteristics. These materials possess a layered perovskite structure with copper-oxygen planes that facilitate superconducting current flow. The rare earth elements (such as yttrium, gadolinium, or samarium) occupy specific lattice positions that influence the overall electronic properties of the material. This unique crystal structure creates highly anisotropic superconducting behavior, which directly impacts the angular dependence of critical current.

Oxygen stoichiometry represents another fundamental aspect affecting REBCO performance. The oxygen content and ordering within the crystal lattice significantly influence the transition temperature and current-carrying capacity. Precise control of oxygen during manufacturing processes is essential for optimizing superconducting properties. Variations in oxygen content can create pinning centers that enhance flux pinning capabilities, directly affecting the n-value and critical current density.

The substrate and buffer layer architecture form the foundation for high-performance REBCO conductors. These components provide the necessary template for epitaxial growth of the superconducting layer while preventing unwanted chemical reactions and diffusion between layers. Common substrate materials include nickel-tungsten alloys, stainless steel, or single-crystal materials that offer appropriate lattice matching and mechanical stability.

Grain boundaries and their management represent a critical challenge in REBCO materials science. These boundaries can significantly limit current flow by acting as weak links in the superconducting path. Advanced manufacturing techniques focus on creating biaxially textured substrates and buffer layers to minimize high-angle grain boundaries, thereby enhancing critical current capacity across the conductor.

Flux pinning mechanisms in REBCO materials determine their performance in magnetic fields. Natural defects, artificially introduced nanoscale inclusions, and controlled dopants create effective pinning centers that immobilize magnetic flux vortices. These pinning sites directly influence the critical current density and its angular dependence, particularly in applied magnetic fields. The strength and distribution of these pinning centers also affect the n-value, which characterizes the sharpness of the superconducting transition.

The crystalline structure of REBCO materials plays a crucial role in their performance characteristics. These materials possess a layered perovskite structure with copper-oxygen planes that facilitate superconducting current flow. The rare earth elements (such as yttrium, gadolinium, or samarium) occupy specific lattice positions that influence the overall electronic properties of the material. This unique crystal structure creates highly anisotropic superconducting behavior, which directly impacts the angular dependence of critical current.

Oxygen stoichiometry represents another fundamental aspect affecting REBCO performance. The oxygen content and ordering within the crystal lattice significantly influence the transition temperature and current-carrying capacity. Precise control of oxygen during manufacturing processes is essential for optimizing superconducting properties. Variations in oxygen content can create pinning centers that enhance flux pinning capabilities, directly affecting the n-value and critical current density.

The substrate and buffer layer architecture form the foundation for high-performance REBCO conductors. These components provide the necessary template for epitaxial growth of the superconducting layer while preventing unwanted chemical reactions and diffusion between layers. Common substrate materials include nickel-tungsten alloys, stainless steel, or single-crystal materials that offer appropriate lattice matching and mechanical stability.

Grain boundaries and their management represent a critical challenge in REBCO materials science. These boundaries can significantly limit current flow by acting as weak links in the superconducting path. Advanced manufacturing techniques focus on creating biaxially textured substrates and buffer layers to minimize high-angle grain boundaries, thereby enhancing critical current capacity across the conductor.

Flux pinning mechanisms in REBCO materials determine their performance in magnetic fields. Natural defects, artificially introduced nanoscale inclusions, and controlled dopants create effective pinning centers that immobilize magnetic flux vortices. These pinning sites directly influence the critical current density and its angular dependence, particularly in applied magnetic fields. The strength and distribution of these pinning centers also affect the n-value, which characterizes the sharpness of the superconducting transition.

Cryogenic System Integration Considerations

The integration of REBCO coated conductors into cryogenic systems presents unique challenges that must be addressed for optimal performance. These superconducting materials require precise temperature control, typically operating at temperatures below 77K, necessitating sophisticated cryogenic infrastructure. The angular dependence of critical current in REBCO conductors significantly impacts the design of cooling systems, as performance variations with magnetic field orientation must be accommodated by appropriate thermal management strategies.

Cryogenic system designers must consider the n-value characteristics when developing cooling solutions, as the sharp superconducting transition represented by high n-values demands more precise temperature regulation to prevent unexpected quenching. Conversely, materials with lower n-values may offer more gradual transitions but require different cooling approaches to maintain stable operation within the desired performance range.

Thermal cycling effects present another critical consideration, as REBCO conductors experience mechanical stress during cooling and warming cycles. The differential thermal contraction between the substrate, buffer layers, and superconducting layer can lead to microcracking and performance degradation over time. Cryogenic systems must therefore incorporate design elements that minimize thermal gradients and mechanical strain during operation and maintenance procedures.

Heat load management represents a significant engineering challenge, particularly in applications where space and weight constraints exist. The critical current's angular dependence means that cooling requirements may vary based on the conductor's orientation relative to applied magnetic fields. This necessitates adaptive cooling strategies or design compromises that account for worst-case thermal scenarios across all possible field orientations.

Cryogen selection and delivery systems must be tailored to the specific application requirements. While liquid nitrogen cooling (77K) offers simplicity and cost advantages, many high-field applications require lower temperatures achievable with liquid helium (4.2K) or cryocoolers. The choice significantly impacts system complexity, operating costs, and maintenance requirements, with direct implications for how the angular dependence of critical current is managed.

Interface design between the REBCO conductors and cooling systems requires careful consideration of thermal contact resistance. Poor thermal interfaces can create localized hotspots that degrade performance, particularly problematic given the angular sensitivity of critical current. Advanced thermal interface materials and connection techniques must be employed to ensure uniform cooling across all conductor orientations.

Instrumentation and monitoring systems represent the final critical component, providing real-time data on temperature distribution, potential hotspots, and early warning of quench conditions. The angular dependence of critical current necessitates more comprehensive monitoring than might be required for isotropic superconductors, with temperature sensors strategically positioned to detect variations that might arise from field orientation effects.

Cryogenic system designers must consider the n-value characteristics when developing cooling solutions, as the sharp superconducting transition represented by high n-values demands more precise temperature regulation to prevent unexpected quenching. Conversely, materials with lower n-values may offer more gradual transitions but require different cooling approaches to maintain stable operation within the desired performance range.

Thermal cycling effects present another critical consideration, as REBCO conductors experience mechanical stress during cooling and warming cycles. The differential thermal contraction between the substrate, buffer layers, and superconducting layer can lead to microcracking and performance degradation over time. Cryogenic systems must therefore incorporate design elements that minimize thermal gradients and mechanical strain during operation and maintenance procedures.

Heat load management represents a significant engineering challenge, particularly in applications where space and weight constraints exist. The critical current's angular dependence means that cooling requirements may vary based on the conductor's orientation relative to applied magnetic fields. This necessitates adaptive cooling strategies or design compromises that account for worst-case thermal scenarios across all possible field orientations.

Cryogen selection and delivery systems must be tailored to the specific application requirements. While liquid nitrogen cooling (77K) offers simplicity and cost advantages, many high-field applications require lower temperatures achievable with liquid helium (4.2K) or cryocoolers. The choice significantly impacts system complexity, operating costs, and maintenance requirements, with direct implications for how the angular dependence of critical current is managed.

Interface design between the REBCO conductors and cooling systems requires careful consideration of thermal contact resistance. Poor thermal interfaces can create localized hotspots that degrade performance, particularly problematic given the angular sensitivity of critical current. Advanced thermal interface materials and connection techniques must be employed to ensure uniform cooling across all conductor orientations.

Instrumentation and monitoring systems represent the final critical component, providing real-time data on temperature distribution, potential hotspots, and early warning of quench conditions. The angular dependence of critical current necessitates more comprehensive monitoring than might be required for isotropic superconductors, with temperature sensors strategically positioned to detect variations that might arise from field orientation effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!