REBCO Magnet Co-Design: Turn-To-Turn Insulation, Impregnation And Thermal Paths

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Magnet Technology Background and Objectives

REBCO (Rare Earth Barium Copper Oxide) superconducting magnets represent a revolutionary advancement in high-field magnet technology, offering unprecedented magnetic field strengths that far exceed the capabilities of traditional low-temperature superconductors. The development of REBCO technology began in the late 1980s with the discovery of high-temperature superconductors, but significant engineering challenges have limited their widespread application until recent years.

The evolution of REBCO magnet technology has been marked by progressive improvements in manufacturing processes, particularly in the production of long-length REBCO tapes with consistent properties. Early iterations suffered from limited current-carrying capacity and mechanical fragility, but modern REBCO conductors can now sustain critical current densities exceeding 500 A/mm² at 20 Tesla and 4.2 Kelvin, enabling compact high-field magnet designs previously unattainable.

A critical aspect of REBCO magnet development has been the ongoing refinement of turn-to-turn insulation systems. Traditional insulation approaches borrowed from low-temperature superconductor technology have proven inadequate for the unique operational characteristics of REBCO magnets, particularly under high mechanical stresses and during quench events. The technical community has progressively shifted toward innovative insulation solutions that balance electrical isolation requirements with thermal and mechanical considerations.

Impregnation techniques for REBCO magnets have similarly evolved from conventional epoxy systems to specialized formulations designed to accommodate the anisotropic thermal contraction properties of REBCO tapes. This evolution reflects growing recognition that proper impregnation is essential not only for mechanical stability but also for managing thermal gradients during operation and potential quench scenarios.

The management of thermal paths within REBCO magnets represents perhaps the most significant technical challenge facing the field today. Unlike traditional superconducting magnets, REBCO systems must balance contradictory requirements: sufficient thermal isolation to maintain cryogenic operating temperatures while simultaneously providing adequate thermal conduction paths to dissipate heat during normal operation and potential quench events.

The primary technical objective in REBCO magnet co-design is to develop integrated solutions that simultaneously address insulation, impregnation, and thermal management challenges. This holistic approach aims to overcome the limitations of current designs, which often optimize one parameter at the expense of others. Success in this domain would enable more reliable, higher-performance magnets capable of sustained operation at field strengths exceeding 20 Tesla.

Recent technological milestones, including the successful demonstration of 32 Tesla all-superconducting magnets at the National High Magnetic Field Laboratory, highlight the transformative potential of advanced REBCO magnet technology across scientific and industrial applications.

The evolution of REBCO magnet technology has been marked by progressive improvements in manufacturing processes, particularly in the production of long-length REBCO tapes with consistent properties. Early iterations suffered from limited current-carrying capacity and mechanical fragility, but modern REBCO conductors can now sustain critical current densities exceeding 500 A/mm² at 20 Tesla and 4.2 Kelvin, enabling compact high-field magnet designs previously unattainable.

A critical aspect of REBCO magnet development has been the ongoing refinement of turn-to-turn insulation systems. Traditional insulation approaches borrowed from low-temperature superconductor technology have proven inadequate for the unique operational characteristics of REBCO magnets, particularly under high mechanical stresses and during quench events. The technical community has progressively shifted toward innovative insulation solutions that balance electrical isolation requirements with thermal and mechanical considerations.

Impregnation techniques for REBCO magnets have similarly evolved from conventional epoxy systems to specialized formulations designed to accommodate the anisotropic thermal contraction properties of REBCO tapes. This evolution reflects growing recognition that proper impregnation is essential not only for mechanical stability but also for managing thermal gradients during operation and potential quench scenarios.

The management of thermal paths within REBCO magnets represents perhaps the most significant technical challenge facing the field today. Unlike traditional superconducting magnets, REBCO systems must balance contradictory requirements: sufficient thermal isolation to maintain cryogenic operating temperatures while simultaneously providing adequate thermal conduction paths to dissipate heat during normal operation and potential quench events.

The primary technical objective in REBCO magnet co-design is to develop integrated solutions that simultaneously address insulation, impregnation, and thermal management challenges. This holistic approach aims to overcome the limitations of current designs, which often optimize one parameter at the expense of others. Success in this domain would enable more reliable, higher-performance magnets capable of sustained operation at field strengths exceeding 20 Tesla.

Recent technological milestones, including the successful demonstration of 32 Tesla all-superconducting magnets at the National High Magnetic Field Laboratory, highlight the transformative potential of advanced REBCO magnet technology across scientific and industrial applications.

Market Applications and Demand Analysis for REBCO Magnets

The global market for REBCO (Rare Earth Barium Copper Oxide) superconducting magnets has been experiencing significant growth, driven primarily by advancements in fusion energy research, medical imaging technologies, and high-energy physics applications. Current market estimates value the superconducting magnet sector at approximately $7.5 billion, with REBCO-based systems representing a rapidly expanding segment projected to grow at a compound annual rate of 12-15% over the next decade.

Fusion energy research constitutes the most substantial demand driver for high-performance REBCO magnets. Organizations like ITER, Commonwealth Fusion Systems, and Tokamak Energy require magnets capable of generating extremely high magnetic fields (>20 Tesla) while maintaining stable operation under intense neutron radiation and thermal cycling. The fusion energy sector alone is expected to require thousands of tons of REBCO tape over the coming decades as commercial fusion approaches viability.

The healthcare sector represents another significant market, particularly for MRI systems where REBCO magnets offer potential advantages in field strength, stability, and reduced helium consumption compared to traditional low-temperature superconductors. The transition toward helium-free MRI systems is accelerating demand for reliable REBCO magnet solutions with enhanced thermal management capabilities.

Research facilities and particle accelerators constitute a specialized but high-value market segment. Organizations like CERN, Fermilab, and various national laboratories require advanced magnet systems for next-generation particle accelerators and detectors. These applications demand exceptional performance in terms of field uniformity, stability, and radiation hardness.

Industrial applications are emerging as a promising growth area, with potential uses in magnetic separation, materials processing, and energy storage systems. The industrial sector values the reduced operational costs associated with higher-temperature operation of REBCO systems compared to traditional superconductors.

Transportation represents a developing market, with interest in REBCO magnets for magnetic levitation train systems and potential future applications in electric aircraft propulsion. These applications particularly value the weight reduction and increased efficiency that REBCO magnets can provide.

Market analysis indicates that demand for REBCO magnets is increasingly focused on systems with optimized turn-to-turn insulation, effective impregnation techniques, and enhanced thermal pathways. These technical features directly impact system reliability, operational lifetime, and overall cost-effectiveness—key considerations for commercial adoption across all market segments.

Fusion energy research constitutes the most substantial demand driver for high-performance REBCO magnets. Organizations like ITER, Commonwealth Fusion Systems, and Tokamak Energy require magnets capable of generating extremely high magnetic fields (>20 Tesla) while maintaining stable operation under intense neutron radiation and thermal cycling. The fusion energy sector alone is expected to require thousands of tons of REBCO tape over the coming decades as commercial fusion approaches viability.

The healthcare sector represents another significant market, particularly for MRI systems where REBCO magnets offer potential advantages in field strength, stability, and reduced helium consumption compared to traditional low-temperature superconductors. The transition toward helium-free MRI systems is accelerating demand for reliable REBCO magnet solutions with enhanced thermal management capabilities.

Research facilities and particle accelerators constitute a specialized but high-value market segment. Organizations like CERN, Fermilab, and various national laboratories require advanced magnet systems for next-generation particle accelerators and detectors. These applications demand exceptional performance in terms of field uniformity, stability, and radiation hardness.

Industrial applications are emerging as a promising growth area, with potential uses in magnetic separation, materials processing, and energy storage systems. The industrial sector values the reduced operational costs associated with higher-temperature operation of REBCO systems compared to traditional superconductors.

Transportation represents a developing market, with interest in REBCO magnets for magnetic levitation train systems and potential future applications in electric aircraft propulsion. These applications particularly value the weight reduction and increased efficiency that REBCO magnets can provide.

Market analysis indicates that demand for REBCO magnets is increasingly focused on systems with optimized turn-to-turn insulation, effective impregnation techniques, and enhanced thermal pathways. These technical features directly impact system reliability, operational lifetime, and overall cost-effectiveness—key considerations for commercial adoption across all market segments.

Current Challenges in REBCO Magnet Insulation and Thermal Management

REBCO (Rare-Earth Barium Copper Oxide) high-temperature superconducting magnets represent a significant advancement in magnet technology, offering unprecedented field strengths and operational capabilities. However, their widespread implementation faces several critical challenges related to insulation and thermal management that must be addressed to ensure reliable performance and longevity.

Turn-to-turn insulation in REBCO magnets presents unique difficulties compared to conventional superconducting magnets. The extremely thin nature of REBCO tapes (typically 0.1mm thick) makes traditional insulation methods inadequate. Current insulation materials often compromise the overall current density of the magnet, creating a fundamental trade-off between electrical isolation and magnetic performance. Additionally, these materials must withstand the extreme mechanical stresses during magnet operation, where forces can exceed several hundred megapascals.

Impregnation processes, essential for structural integrity, introduce their own set of challenges. The vacuum impregnation techniques commonly employed must ensure complete penetration of epoxy resins without creating voids or delamination between REBCO layers. Thermal contraction mismatches between the impregnation material and the REBCO tape during cooldown can induce significant internal stresses, potentially degrading superconductor performance or causing mechanical failure.

Thermal management represents perhaps the most critical challenge for REBCO magnet technology. Despite operating at higher temperatures than traditional superconductors, REBCO magnets still generate heat during operation, particularly during quench events. The anisotropic thermal conductivity of REBCO tapes complicates heat dissipation, with significantly better thermal conduction along the tape length than across its thickness.

The insulation and impregnation materials further exacerbate thermal challenges by creating barriers to efficient cooling. Most electrical insulators are also thermal insulators, trapping heat within the magnet windings. This thermal bottleneck increases the risk of localized heating that can trigger quench events, where sections of the magnet transition from superconducting to normal state, potentially causing catastrophic damage.

Current cooling strategies struggle to balance the competing requirements of electrical isolation and thermal conductivity. Conventional approaches using liquid cryogens face limitations in high-field applications, while conduction cooling methods often cannot provide sufficient heat removal capacity for large-scale magnets. The development of thermally conductive electrical insulators remains an active but challenging research area.

These interconnected challenges of turn-to-turn insulation, impregnation, and thermal management form a complex co-design problem that requires integrated solutions rather than isolated approaches. Addressing these issues is essential for realizing the full potential of REBCO magnet technology in applications ranging from fusion energy and medical imaging to high-energy physics research.

Turn-to-turn insulation in REBCO magnets presents unique difficulties compared to conventional superconducting magnets. The extremely thin nature of REBCO tapes (typically 0.1mm thick) makes traditional insulation methods inadequate. Current insulation materials often compromise the overall current density of the magnet, creating a fundamental trade-off between electrical isolation and magnetic performance. Additionally, these materials must withstand the extreme mechanical stresses during magnet operation, where forces can exceed several hundred megapascals.

Impregnation processes, essential for structural integrity, introduce their own set of challenges. The vacuum impregnation techniques commonly employed must ensure complete penetration of epoxy resins without creating voids or delamination between REBCO layers. Thermal contraction mismatches between the impregnation material and the REBCO tape during cooldown can induce significant internal stresses, potentially degrading superconductor performance or causing mechanical failure.

Thermal management represents perhaps the most critical challenge for REBCO magnet technology. Despite operating at higher temperatures than traditional superconductors, REBCO magnets still generate heat during operation, particularly during quench events. The anisotropic thermal conductivity of REBCO tapes complicates heat dissipation, with significantly better thermal conduction along the tape length than across its thickness.

The insulation and impregnation materials further exacerbate thermal challenges by creating barriers to efficient cooling. Most electrical insulators are also thermal insulators, trapping heat within the magnet windings. This thermal bottleneck increases the risk of localized heating that can trigger quench events, where sections of the magnet transition from superconducting to normal state, potentially causing catastrophic damage.

Current cooling strategies struggle to balance the competing requirements of electrical isolation and thermal conductivity. Conventional approaches using liquid cryogens face limitations in high-field applications, while conduction cooling methods often cannot provide sufficient heat removal capacity for large-scale magnets. The development of thermally conductive electrical insulators remains an active but challenging research area.

These interconnected challenges of turn-to-turn insulation, impregnation, and thermal management form a complex co-design problem that requires integrated solutions rather than isolated approaches. Addressing these issues is essential for realizing the full potential of REBCO magnet technology in applications ranging from fusion energy and medical imaging to high-energy physics research.

Current Co-Design Approaches for REBCO Magnet Systems

01 Turn-to-turn insulation materials for REBCO magnets

Various insulation materials can be used between turns of REBCO superconducting magnets to prevent electrical shorts while maintaining necessary mechanical and thermal properties. These materials include specialized polymers, ceramic-based insulators, and composite materials that can withstand cryogenic temperatures and high magnetic fields. The insulation must be thin enough to maintain high current density while providing sufficient dielectric strength to prevent electrical breakdown between adjacent turns.- Turn-to-turn insulation materials for REBCO magnets: Various insulation materials are used between turns in REBCO superconducting magnets to prevent electrical shorts while maintaining mechanical stability. These materials include specialized polymers, ceramic-based insulators, and composite materials that can withstand cryogenic temperatures and high magnetic fields. The insulation thickness and properties are optimized to balance electrical isolation requirements with the need for efficient thermal conduction paths.

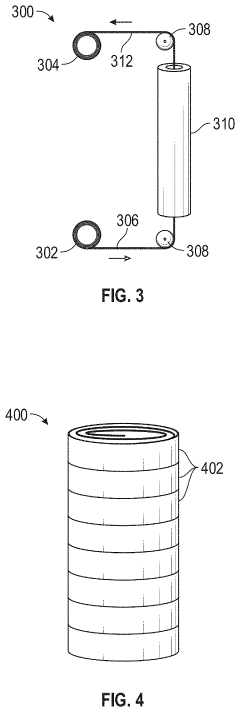

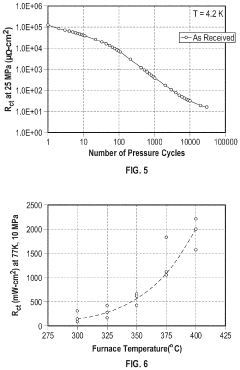

- Vacuum impregnation techniques for REBCO coils: Vacuum impregnation processes are employed to fill voids between REBCO tape layers with epoxy resins or other binding materials. This technique enhances mechanical stability, prevents movement during operation, and improves thermal conductivity across the magnet structure. The impregnation process typically involves placing the coil assembly in a vacuum chamber, introducing the impregnation material, and then curing under controlled temperature conditions to ensure complete penetration and proper bonding.

- Thermal path optimization in REBCO magnet systems: Efficient thermal paths are critical in REBCO magnet systems to manage heat generation and ensure proper cooling. This involves strategic placement of high thermal conductivity materials, cooling channels, and heat exchangers within the magnet structure. Advanced thermal management solutions include the use of metallic thermal bridges, specialized cooling circuits, and thermally conductive interfaces that maintain low temperatures while allowing for thermal expansion and contraction during operation.

- Cryogenic cooling systems for REBCO magnets: Specialized cryogenic cooling systems are designed to maintain REBCO magnets at their optimal operating temperatures. These systems utilize liquid helium, liquid nitrogen, or cryocoolers to remove heat and maintain superconducting conditions. The cooling architecture includes thermally conductive pathways from the REBCO tapes to the cooling medium, with careful consideration of thermal gradients and cooling efficiency to prevent quenching and ensure stable operation of the magnet system.

- Mechanical support structures for REBCO coil assemblies: Robust mechanical support structures are essential for REBCO magnet systems to withstand electromagnetic forces during operation. These structures incorporate reinforcement materials, stress management features, and specialized mounting systems that maintain coil geometry while accommodating thermal contraction. The design includes consideration of material compatibility with cryogenic environments, structural integrity under high magnetic fields, and integration with thermal management systems to ensure reliable long-term operation.

02 Vacuum impregnation techniques for REBCO coils

Vacuum impregnation processes are critical for REBCO magnet manufacturing to eliminate voids and ensure structural integrity. The process typically involves placing the wound coil in a vacuum chamber, evacuating air, and then introducing epoxy resin or other impregnation materials that penetrate between turns. Special attention must be paid to the viscosity and curing characteristics of the impregnation material to ensure complete penetration without damaging the delicate REBCO tapes or their coatings.Expand Specific Solutions03 Thermal management pathways in REBCO magnet systems

Effective thermal pathways are essential in REBCO magnets to manage heat generation and dissipation, particularly during quench events. These pathways can be engineered through strategic placement of high thermal conductivity materials, cooling channels, and heat exchangers. The design must balance electrical insulation requirements with sufficient thermal conductivity to prevent localized heating that could damage the superconducting material. Advanced cooling techniques including conduction cooling, forced flow cooling, and cryogenic fluid circulation are implemented to maintain operating temperatures.Expand Specific Solutions04 Mechanical reinforcement and strain management

REBCO magnets require careful mechanical reinforcement to handle electromagnetic forces during operation. Strain management techniques include co-winding with reinforcement materials, external structural supports, and specialized impregnation formulations that provide both electrical insulation and mechanical strength. The design must account for differential thermal contraction between materials during cooldown to cryogenic temperatures and prevent delamination or cracking of the brittle REBCO layers.Expand Specific Solutions05 Novel composite structures for integrated functionality

Advanced composite structures are being developed that simultaneously address insulation, thermal, and mechanical requirements in REBCO magnets. These multi-functional materials incorporate nanomaterials, engineered interfaces, and graded structures to optimize performance across multiple parameters. Some designs feature thermally conductive particles embedded in electrically insulating matrices, while others use layered structures with different functional properties. These composite approaches aim to overcome traditional trade-offs between electrical insulation and thermal conductivity in superconducting magnet systems.Expand Specific Solutions

Leading Organizations in REBCO Magnet Development

The REBCO magnet co-design market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding as superconducting magnet applications grow in medical imaging, fusion energy, and transportation sectors. Technologically, the field remains in development with significant challenges in turn-to-turn insulation, impregnation, and thermal management. Leading players include research institutions like North China Electric Power University, Shanghai Jiao Tong University, and Korea Advanced Institute of Science & Technology, alongside industrial players such as General Electric, Toshiba, and Siemens Energy. Chinese companies like Zhongtian Group Shanghai Superconducting Technology and Jiangsu Zhongtian Technology are emerging as significant competitors, leveraging their expertise in materials and electrical systems to advance REBCO magnet technology.

Zhongtian Group Shanghai Superconducting Technology Co., Ltd.

Technical Solution: Zhongtian Group Shanghai Superconducting Technology has developed a proprietary REBCO magnet co-design system that addresses the critical challenges of turn-to-turn insulation, impregnation, and thermal management. Their approach utilizes a nano-engineered composite insulation consisting of alumina nanoparticles (5-20nm) dispersed in a specialized epoxy matrix, achieving dielectric strength of >150kV/mm while maintaining thermal conductivity of approximately 1.2 W/m·K at cryogenic temperatures. This represents a significant improvement over conventional insulation materials. The company employs a multi-stage vacuum pressure impregnation process with carefully controlled temperature cycles to ensure complete penetration of the resin system throughout the coil structure, eliminating voids that could lead to electrical breakdown or mechanical failure. Their thermal path design incorporates strategically placed high-purity copper cooling elements that create direct thermal bridges from the REBCO tapes to the cryogenic cooling system, maintaining temperature gradients below 2K across the entire magnet assembly. This integrated approach has been successfully implemented in their commercial high-field magnets, demonstrating field strengths exceeding 20T with exceptional stability and reliability during operation.

Strengths: Superior thermal conductivity through the insulation layer while maintaining excellent dielectric properties; demonstrated long-term reliability in commercial applications; excellent mechanical stability under high electromagnetic forces. Weaknesses: Higher manufacturing complexity requiring specialized equipment and clean room facilities; increased production costs compared to conventional systems; limited flexibility for design modifications after impregnation process.

Institute of Electrical Engineering, Chinese Academy of Sci

Technical Solution: The Institute of Electrical Engineering at the Chinese Academy of Sciences has developed a comprehensive REBCO magnet co-design approach addressing the critical challenges of turn-to-turn insulation, impregnation, and thermal management. Their proprietary technology utilizes a hybrid insulation system combining thin layers of polyimide film with ceramic-loaded epoxy resin, achieving dielectric strength exceeding 200 kV/mm while maintaining thermal conductivity of approximately 0.8 W/m·K at operating temperatures. The institute's vacuum-assisted resin transfer molding process ensures complete impregnation of complex coil geometries, eliminating voids that could lead to mechanical failure or electrical breakdown during operation. Their thermal path optimization incorporates strategically placed high-purity aluminum or copper heat sinks connected to the coil structure through thermally conductive interfaces, creating efficient cooling channels that maintain temperature uniformity across the magnet assembly. This integrated approach has been successfully implemented in their 24T all-superconducting magnet system, demonstrating exceptional stability during rapid field changes and resistance to thermal quenches.

Strengths: Excellent balance between electrical insulation and thermal conductivity; proven performance in high-field applications with minimal degradation; superior mechanical stability under electromagnetic forces. Weaknesses: Complex manufacturing process requires specialized equipment and expertise; higher initial costs compared to conventional insulation systems; limited flexibility for design modifications after impregnation.

Key Innovations in Turn-to-Turn Insulation Materials

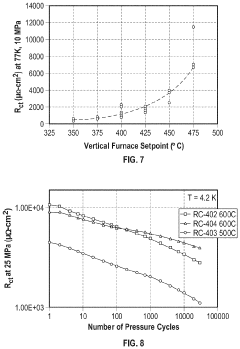

Method for Controlling Turn-to-Turn Contact Resistance in REBCO Magnet Pancake Coils

PatentPendingUS20230238178A1

Innovation

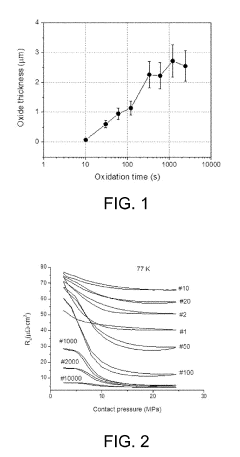

- A method involving coating REBCO superconducting tape with tin-lead solder and co-winding it with oxidized stainless steel tape to control turn-to-turn contact resistance, reducing ramp losses and improving stability and recovery speed after a quench.

Rare earth barium copper oxide magnet coils and methods

PatentActiveUS20190267172A1

Innovation

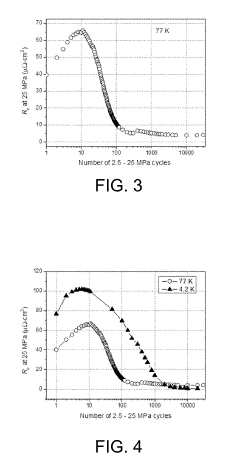

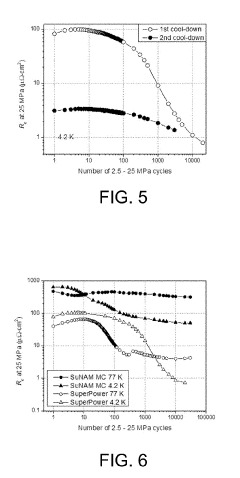

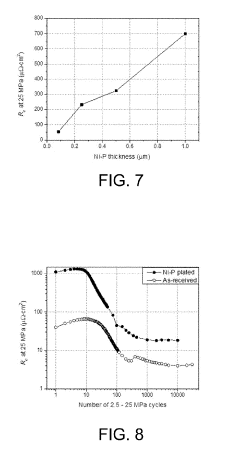

- The implementation of REBCO superconducting tapes coated with thin resistive layers of copper oxide, Cr, Ni, or Ni—P, or the use of stainless steel tapes with nickel or copper plating as interlayers between REBCO tapes, to increase turn-to-turn contact resistivity and optimize coil performance.

Cryogenic System Integration Considerations

The integration of REBCO magnets with cryogenic systems presents unique challenges that must be addressed through careful design considerations. The operational temperature of REBCO superconductors typically ranges between 4.2K and 77K, requiring sophisticated cryogenic infrastructure that balances cooling efficiency with system reliability.

Thermal management represents a critical aspect of cryogenic system integration. The design must account for heat loads from various sources, including radiation, conduction through structural supports, and resistive heating at joints. Effective thermal anchoring strategies must be implemented at strategic locations to intercept heat before it reaches the superconducting windings.

Cryogen selection significantly impacts overall system performance. While liquid helium offers excellent cooling at 4.2K, its increasing scarcity and cost drive interest in alternative approaches. Cryocooler-based conduction cooling eliminates the need for liquid cryogens but introduces challenges related to thermal gradients and cooling power limitations. Hybrid systems utilizing liquid nitrogen pre-cooling with cryocoolers for final temperature reduction represent a promising middle ground.

Material compatibility across the cryogenic temperature range demands careful consideration. Differential thermal contraction between components can induce mechanical stress during cooldown, potentially damaging the brittle REBCO tapes. The insulation and impregnation materials must maintain their electrical and mechanical properties at cryogenic temperatures while facilitating efficient heat transfer to cooling surfaces.

Quench protection integration with the cryogenic system requires particular attention. During a quench event, rapid temperature rise necessitates effective heat extraction pathways to prevent permanent damage. The cryogenic system must be designed to handle these transient thermal loads while maintaining stable operation of non-quenched regions.

Instrumentation and monitoring systems must function reliably at cryogenic temperatures to provide real-time data on thermal conditions. Temperature sensors, flow meters, and pressure transducers need to be strategically placed to monitor system performance without introducing excessive heat loads through sensor wiring.

Maintenance considerations significantly impact cryogenic system design. Access points for inspection, repair, and potential component replacement must be incorporated without compromising thermal insulation. Modular designs that allow for servicing of critical components without complete system warmup can significantly reduce operational downtime.

The economic viability of REBCO magnet systems depends heavily on optimizing cryogenic efficiency. Energy consumption for cooling represents a substantial operational cost, driving the need for innovative approaches to thermal insulation and heat interception that minimize refrigeration requirements while maintaining stable superconducting operation.

Thermal management represents a critical aspect of cryogenic system integration. The design must account for heat loads from various sources, including radiation, conduction through structural supports, and resistive heating at joints. Effective thermal anchoring strategies must be implemented at strategic locations to intercept heat before it reaches the superconducting windings.

Cryogen selection significantly impacts overall system performance. While liquid helium offers excellent cooling at 4.2K, its increasing scarcity and cost drive interest in alternative approaches. Cryocooler-based conduction cooling eliminates the need for liquid cryogens but introduces challenges related to thermal gradients and cooling power limitations. Hybrid systems utilizing liquid nitrogen pre-cooling with cryocoolers for final temperature reduction represent a promising middle ground.

Material compatibility across the cryogenic temperature range demands careful consideration. Differential thermal contraction between components can induce mechanical stress during cooldown, potentially damaging the brittle REBCO tapes. The insulation and impregnation materials must maintain their electrical and mechanical properties at cryogenic temperatures while facilitating efficient heat transfer to cooling surfaces.

Quench protection integration with the cryogenic system requires particular attention. During a quench event, rapid temperature rise necessitates effective heat extraction pathways to prevent permanent damage. The cryogenic system must be designed to handle these transient thermal loads while maintaining stable operation of non-quenched regions.

Instrumentation and monitoring systems must function reliably at cryogenic temperatures to provide real-time data on thermal conditions. Temperature sensors, flow meters, and pressure transducers need to be strategically placed to monitor system performance without introducing excessive heat loads through sensor wiring.

Maintenance considerations significantly impact cryogenic system design. Access points for inspection, repair, and potential component replacement must be incorporated without compromising thermal insulation. Modular designs that allow for servicing of critical components without complete system warmup can significantly reduce operational downtime.

The economic viability of REBCO magnet systems depends heavily on optimizing cryogenic efficiency. Energy consumption for cooling represents a substantial operational cost, driving the need for innovative approaches to thermal insulation and heat interception that minimize refrigeration requirements while maintaining stable superconducting operation.

Material Science Advancements for Impregnation Solutions

Recent advancements in material science have significantly transformed impregnation solutions for REBCO magnets. Traditional epoxy resins, while providing excellent mechanical stability, often suffer from thermal contraction mismatches with REBCO tapes, leading to performance degradation. Modern cryogenic epoxy systems now incorporate nano-fillers such as silica and alumina particles, which reduce thermal contraction coefficients by up to 40% while maintaining adequate mechanical strength.

Ceramic-based impregnation materials represent another breakthrough, offering superior thermal conductivity compared to conventional epoxy systems. Aluminum nitride and boron nitride composites have demonstrated thermal conductivity values exceeding 1 W/m·K at 4.2K, nearly triple that of standard epoxy systems. These materials create efficient thermal pathways between turns while maintaining necessary electrical isolation properties.

Hybrid impregnation systems combining epoxy matrices with ceramic fillers have emerged as promising solutions. These systems balance mechanical support with enhanced thermal management capabilities. Research indicates that optimized hybrid systems can improve quench protection by reducing hot spot temperatures by 15-20K during transient events, significantly enhancing magnet safety margins.

Parylene coatings applied through vapor deposition processes offer exceptionally thin yet uniform insulation layers. These coatings, measuring just 5-10 μm in thickness, provide excellent dielectric strength while minimizing thermal barriers. The conformal nature of parylene deposition ensures complete coverage of complex geometries, addressing challenges in traditional vacuum impregnation techniques.

Cryogenic-specific elastomeric compounds represent another innovative approach. These materials maintain flexibility at extremely low temperatures, accommodating differential thermal contraction between magnet components. Silicone-based elastomers modified with specific additives have demonstrated remarkable strain tolerance at 4.2K, reducing mechanical stress on REBCO tapes during thermal cycling.

Advanced processing techniques have equally contributed to impregnation improvements. Vacuum-pressure impregnation systems with precise temperature control now achieve nearly void-free structures, eliminating potential failure points. Additionally, staged curing protocols with intermediate stress-relief cycles have proven effective in minimizing residual stresses in the final assembly.

The integration of self-healing capabilities into impregnation materials represents the cutting edge of this field. Microencapsulated healing agents that release upon microcrack formation show promise for extending magnet operational lifetimes under cyclic loading conditions, potentially addressing one of the most persistent challenges in high-field magnet reliability.

Ceramic-based impregnation materials represent another breakthrough, offering superior thermal conductivity compared to conventional epoxy systems. Aluminum nitride and boron nitride composites have demonstrated thermal conductivity values exceeding 1 W/m·K at 4.2K, nearly triple that of standard epoxy systems. These materials create efficient thermal pathways between turns while maintaining necessary electrical isolation properties.

Hybrid impregnation systems combining epoxy matrices with ceramic fillers have emerged as promising solutions. These systems balance mechanical support with enhanced thermal management capabilities. Research indicates that optimized hybrid systems can improve quench protection by reducing hot spot temperatures by 15-20K during transient events, significantly enhancing magnet safety margins.

Parylene coatings applied through vapor deposition processes offer exceptionally thin yet uniform insulation layers. These coatings, measuring just 5-10 μm in thickness, provide excellent dielectric strength while minimizing thermal barriers. The conformal nature of parylene deposition ensures complete coverage of complex geometries, addressing challenges in traditional vacuum impregnation techniques.

Cryogenic-specific elastomeric compounds represent another innovative approach. These materials maintain flexibility at extremely low temperatures, accommodating differential thermal contraction between magnet components. Silicone-based elastomers modified with specific additives have demonstrated remarkable strain tolerance at 4.2K, reducing mechanical stress on REBCO tapes during thermal cycling.

Advanced processing techniques have equally contributed to impregnation improvements. Vacuum-pressure impregnation systems with precise temperature control now achieve nearly void-free structures, eliminating potential failure points. Additionally, staged curing protocols with intermediate stress-relief cycles have proven effective in minimizing residual stresses in the final assembly.

The integration of self-healing capabilities into impregnation materials represents the cutting edge of this field. Microencapsulated healing agents that release upon microcrack formation show promise for extending magnet operational lifetimes under cyclic loading conditions, potentially addressing one of the most persistent challenges in high-field magnet reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!