REBCO Tape Architecture: Substrates, Buffers And Stabilizers Trade-Offs

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Tape Evolution and Development Objectives

REBCO (Rare Earth Barium Copper Oxide) superconducting tapes have evolved significantly since their inception in the late 1980s, transforming from laboratory curiosities to commercially viable products with remarkable current-carrying capabilities. The evolution of REBCO tape architecture represents one of the most significant advancements in applied superconductivity over the past three decades.

Initially, REBCO materials were primarily studied in bulk form, with limited practical applications due to weak links between grains. The breakthrough came with the development of epitaxial thin film deposition techniques in the 1990s, allowing for aligned crystal growth on suitable substrates. This marked the beginning of the first generation of REBCO coated conductors.

The early 2000s witnessed the emergence of industrial-scale manufacturing processes, including Rolling Assisted Biaxially Textured Substrates (RABiTS) and Ion Beam Assisted Deposition (IBAD). These technologies enabled the production of long-length REBCO tapes with increasingly uniform properties, setting the foundation for commercial applications.

By the 2010s, second-generation REBCO tapes achieved critical current densities exceeding 3 MA/cm² at 77K in self-field, representing a remarkable improvement over first-generation Bi-based superconductors. This period also saw significant advancements in substrate engineering and buffer layer architectures to enhance mechanical properties and reduce manufacturing costs.

The current development objectives for REBCO tape architecture focus on several key areas. First, improving the engineering current density (Je) through thinner substrates and enhanced superconducting layer thickness without sacrificing performance. Second, optimizing buffer layer compositions and deposition techniques to ensure better lattice matching while reducing production complexity and cost.

Another critical objective is enhancing mechanical stability through advanced stabilizer designs that provide protection against thermal quenches without compromising flexibility or adding excessive non-superconducting material. Researchers are also working on improving in-field performance at intermediate temperatures (20-50K) to expand application potential in areas such as compact fusion devices and high-field magnets.

Cost reduction remains a paramount goal, with efforts directed toward simplifying manufacturing processes, increasing production yields, and developing less expensive substrate and buffer layer materials. The target price point of $10-15/kA-m would make REBCO tapes competitive with conventional conductors for many applications.

Looking forward, the field aims to achieve REBCO tapes with Je values exceeding 1000 A/mm² at 20K and 20T, with improved mechanical properties capable of withstanding the extreme stresses encountered in high-field magnet applications. These advancements would revolutionize numerous fields, from medical imaging to fusion energy and next-generation electric machines.

Initially, REBCO materials were primarily studied in bulk form, with limited practical applications due to weak links between grains. The breakthrough came with the development of epitaxial thin film deposition techniques in the 1990s, allowing for aligned crystal growth on suitable substrates. This marked the beginning of the first generation of REBCO coated conductors.

The early 2000s witnessed the emergence of industrial-scale manufacturing processes, including Rolling Assisted Biaxially Textured Substrates (RABiTS) and Ion Beam Assisted Deposition (IBAD). These technologies enabled the production of long-length REBCO tapes with increasingly uniform properties, setting the foundation for commercial applications.

By the 2010s, second-generation REBCO tapes achieved critical current densities exceeding 3 MA/cm² at 77K in self-field, representing a remarkable improvement over first-generation Bi-based superconductors. This period also saw significant advancements in substrate engineering and buffer layer architectures to enhance mechanical properties and reduce manufacturing costs.

The current development objectives for REBCO tape architecture focus on several key areas. First, improving the engineering current density (Je) through thinner substrates and enhanced superconducting layer thickness without sacrificing performance. Second, optimizing buffer layer compositions and deposition techniques to ensure better lattice matching while reducing production complexity and cost.

Another critical objective is enhancing mechanical stability through advanced stabilizer designs that provide protection against thermal quenches without compromising flexibility or adding excessive non-superconducting material. Researchers are also working on improving in-field performance at intermediate temperatures (20-50K) to expand application potential in areas such as compact fusion devices and high-field magnets.

Cost reduction remains a paramount goal, with efforts directed toward simplifying manufacturing processes, increasing production yields, and developing less expensive substrate and buffer layer materials. The target price point of $10-15/kA-m would make REBCO tapes competitive with conventional conductors for many applications.

Looking forward, the field aims to achieve REBCO tapes with Je values exceeding 1000 A/mm² at 20K and 20T, with improved mechanical properties capable of withstanding the extreme stresses encountered in high-field magnet applications. These advancements would revolutionize numerous fields, from medical imaging to fusion energy and next-generation electric machines.

Market Applications and Demand Analysis for REBCO Superconductors

The global market for REBCO (Rare Earth Barium Copper Oxide) superconductors has been experiencing significant growth, driven primarily by increasing demand in energy, healthcare, transportation, and research sectors. The unique properties of REBCO materials, particularly their ability to maintain superconductivity at relatively higher temperatures compared to traditional superconductors, position them as critical components for next-generation applications.

In the energy sector, REBCO tapes are becoming essential for power transmission systems, fault current limiters, and energy storage solutions. The global power grid modernization efforts, valued at approximately $300 billion through 2030, represent a substantial market opportunity. Particularly, superconducting fault current limiters using REBCO technology are projected to reach a market size of $5.8 billion by 2028, growing at a CAGR of 9.2%.

Healthcare applications, specifically in MRI and NMR systems, constitute another significant market segment. The medical imaging market utilizing superconducting magnets is expected to reach $45 billion by 2027. REBCO-based systems offer advantages in terms of reduced cooling costs and improved field strength, potentially disrupting the conventional liquid helium-cooled systems market.

Transportation represents an emerging but rapidly growing application area. Superconducting motors for electric aircraft and marine propulsion systems are gaining traction, with projected market value exceeding $2.3 billion by 2030. Additionally, magnetic levitation train systems utilizing REBCO technology are being developed in Japan, China, and Europe, with combined project investments surpassing $80 billion over the next decade.

Research facilities, particularly high-energy physics installations and fusion energy research, continue to be significant consumers of REBCO tapes. The ITER project alone represents a multi-billion dollar investment in fusion technology where REBCO materials play a crucial role in magnet systems.

Regional analysis indicates Asia-Pacific as the fastest-growing market for REBCO applications, with China, Japan, and South Korea making substantial investments in superconductor technology. North America and Europe maintain strong positions in research applications and specialized industrial uses.

The demand for REBCO tapes is heavily influenced by performance-to-cost ratio improvements. Current market constraints include high production costs, with REBCO tapes priced between $100-300/kA-m depending on performance specifications. Industry analysts project that reaching a price point below $50/kA-m would trigger exponential market growth, potentially expanding applications into consumer electronics and broader power infrastructure.

In the energy sector, REBCO tapes are becoming essential for power transmission systems, fault current limiters, and energy storage solutions. The global power grid modernization efforts, valued at approximately $300 billion through 2030, represent a substantial market opportunity. Particularly, superconducting fault current limiters using REBCO technology are projected to reach a market size of $5.8 billion by 2028, growing at a CAGR of 9.2%.

Healthcare applications, specifically in MRI and NMR systems, constitute another significant market segment. The medical imaging market utilizing superconducting magnets is expected to reach $45 billion by 2027. REBCO-based systems offer advantages in terms of reduced cooling costs and improved field strength, potentially disrupting the conventional liquid helium-cooled systems market.

Transportation represents an emerging but rapidly growing application area. Superconducting motors for electric aircraft and marine propulsion systems are gaining traction, with projected market value exceeding $2.3 billion by 2030. Additionally, magnetic levitation train systems utilizing REBCO technology are being developed in Japan, China, and Europe, with combined project investments surpassing $80 billion over the next decade.

Research facilities, particularly high-energy physics installations and fusion energy research, continue to be significant consumers of REBCO tapes. The ITER project alone represents a multi-billion dollar investment in fusion technology where REBCO materials play a crucial role in magnet systems.

Regional analysis indicates Asia-Pacific as the fastest-growing market for REBCO applications, with China, Japan, and South Korea making substantial investments in superconductor technology. North America and Europe maintain strong positions in research applications and specialized industrial uses.

The demand for REBCO tapes is heavily influenced by performance-to-cost ratio improvements. Current market constraints include high production costs, with REBCO tapes priced between $100-300/kA-m depending on performance specifications. Industry analysts project that reaching a price point below $50/kA-m would trigger exponential market growth, potentially expanding applications into consumer electronics and broader power infrastructure.

Current Technical Challenges in REBCO Tape Manufacturing

Despite significant advancements in REBCO (Rare Earth Barium Copper Oxide) tape manufacturing, several critical technical challenges persist that impede widespread commercial adoption and performance optimization. The primary manufacturing challenge involves maintaining consistent superconducting properties across long tape lengths. Current production processes struggle to achieve homogeneous critical current density (Jc) throughout kilometers of tape, with variations often exceeding 15% along a single production batch.

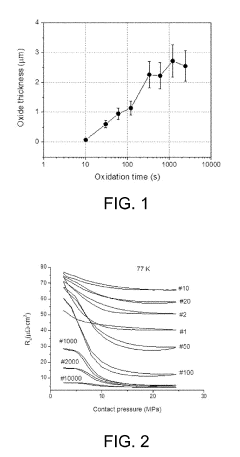

Substrate-related challenges remain particularly problematic. Achieving atomically smooth surfaces on metallic substrates like Hastelloy or stainless steel requires complex polishing techniques that significantly increase production costs. Surface roughness exceeding 5nm can create nucleation sites for defects in subsequent buffer and superconducting layers, dramatically reducing performance. Additionally, maintaining substrate flexibility while ensuring dimensional stability during high-temperature deposition processes (700-800°C) presents contradictory material requirements.

Buffer layer engineering faces challenges in creating effective diffusion barriers while promoting epitaxial growth. The multi-layer buffer architecture (typically Y2O3/YSZ/CeO2) must prevent metal ion migration from the substrate while providing appropriate lattice matching for REBCO growth. Current deposition techniques struggle with interface control between these layers, often resulting in oxygen vacancies and structural defects that compromise superconducting performance.

The REBCO layer itself presents formidable manufacturing hurdles. Controlling stoichiometry during deposition remains difficult, particularly maintaining the correct oxygen content which directly impacts critical temperature (Tc). Nano-engineering of flux pinning centers—crucial for high-field applications—lacks scalable manufacturing protocols. Current approaches using BaZrO3 or BaHfO3 nanoparticles show promising results in laboratory settings but face reproducibility issues in industrial production.

Stabilizer integration represents another significant challenge. Conventional electroplating of copper stabilizers often creates weak interfacial bonding with the superconducting layer, leading to delamination during thermal cycling. Alternative approaches using surround-copper stabilizers increase manufacturing complexity and cost. The industry still lacks cost-effective techniques to apply uniform, strongly-bonded stabilizers without damaging the underlying REBCO layer.

Production scaling presents perhaps the most significant barrier to widespread adoption. Current manufacturing throughput remains limited to approximately 100-300 meters per hour, with yields of high-performance tape (>400 A/cm-width) below 70%. This results in prohibitively high costs exceeding $100/kA-m, compared to conventional superconductors at $1-5/kA-m. Addressing these technical challenges requires interdisciplinary approaches combining materials science, process engineering, and advanced characterization techniques.

Substrate-related challenges remain particularly problematic. Achieving atomically smooth surfaces on metallic substrates like Hastelloy or stainless steel requires complex polishing techniques that significantly increase production costs. Surface roughness exceeding 5nm can create nucleation sites for defects in subsequent buffer and superconducting layers, dramatically reducing performance. Additionally, maintaining substrate flexibility while ensuring dimensional stability during high-temperature deposition processes (700-800°C) presents contradictory material requirements.

Buffer layer engineering faces challenges in creating effective diffusion barriers while promoting epitaxial growth. The multi-layer buffer architecture (typically Y2O3/YSZ/CeO2) must prevent metal ion migration from the substrate while providing appropriate lattice matching for REBCO growth. Current deposition techniques struggle with interface control between these layers, often resulting in oxygen vacancies and structural defects that compromise superconducting performance.

The REBCO layer itself presents formidable manufacturing hurdles. Controlling stoichiometry during deposition remains difficult, particularly maintaining the correct oxygen content which directly impacts critical temperature (Tc). Nano-engineering of flux pinning centers—crucial for high-field applications—lacks scalable manufacturing protocols. Current approaches using BaZrO3 or BaHfO3 nanoparticles show promising results in laboratory settings but face reproducibility issues in industrial production.

Stabilizer integration represents another significant challenge. Conventional electroplating of copper stabilizers often creates weak interfacial bonding with the superconducting layer, leading to delamination during thermal cycling. Alternative approaches using surround-copper stabilizers increase manufacturing complexity and cost. The industry still lacks cost-effective techniques to apply uniform, strongly-bonded stabilizers without damaging the underlying REBCO layer.

Production scaling presents perhaps the most significant barrier to widespread adoption. Current manufacturing throughput remains limited to approximately 100-300 meters per hour, with yields of high-performance tape (>400 A/cm-width) below 70%. This results in prohibitively high costs exceeding $100/kA-m, compared to conventional superconductors at $1-5/kA-m. Addressing these technical challenges requires interdisciplinary approaches combining materials science, process engineering, and advanced characterization techniques.

Comparative Analysis of Current REBCO Tape Designs

01 Substrate materials and structures for REBCO tapes

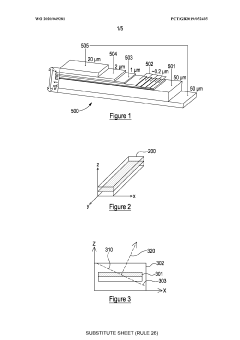

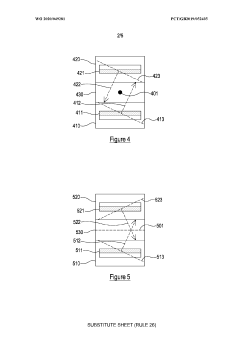

Various substrate materials and structures are used as the foundation for REBCO superconducting tapes. These substrates provide mechanical support and serve as templates for subsequent layer deposition. Common substrate materials include nickel-tungsten alloys, stainless steel, and hastelloy, which offer good mechanical properties and compatibility with high-temperature processing. Textured substrates with specific crystallographic orientations are particularly important as they influence the alignment of the superconducting layer, directly affecting the current-carrying capacity of the final tape.- Substrate materials and structures for REBCO tapes: Various substrate materials and structures are used as the foundation for REBCO superconducting tapes. These substrates provide mechanical support and serve as templates for subsequent layer deposition. Common substrate materials include nickel-tungsten alloys, stainless steel, and textured metal tapes. The substrate's crystallographic orientation and surface quality are critical for achieving high-performance superconducting properties in the final REBCO layer. Biaxially textured substrates are particularly important for ensuring proper crystal alignment in the superconducting layer.

- Buffer layer compositions and deposition techniques: Buffer layers are essential components in REBCO tape architecture that serve as chemical barriers between the substrate and the superconducting layer while promoting epitaxial growth. These layers typically consist of oxide materials such as yttria-stabilized zirconia (YSZ), cerium oxide (CeO₂), and lanthanum zirconate (LZO). Multiple buffer layers with different compositions are often used to gradually transition from the substrate to the REBCO layer. Various deposition techniques including pulsed laser deposition, chemical solution deposition, and sputtering are employed to create these buffer layers with precise thickness and crystallographic orientation.

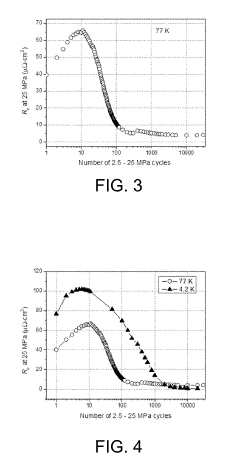

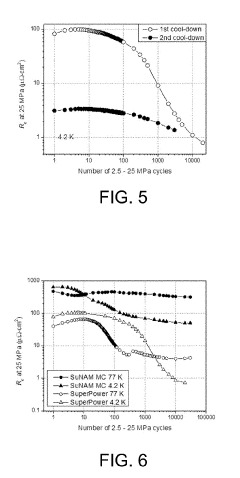

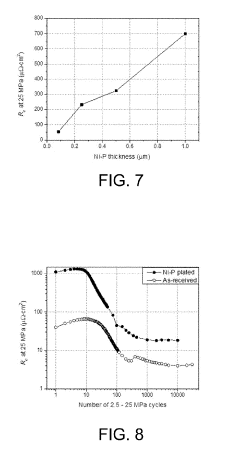

- Stabilizer materials and lamination methods: Stabilizer layers are critical components added to REBCO tapes to improve thermal and electrical stability during operation. These layers, typically made of copper, silver, or other highly conductive materials, provide alternative current paths during quench events and enhance thermal management. Various lamination and electroplating techniques are used to apply these stabilizer layers to the superconducting tape structure. The thickness and configuration of stabilizer layers are carefully designed to balance mechanical properties, current sharing capabilities, and overall tape flexibility.

- REBCO layer deposition and crystallization processes: The REBCO (Rare Earth Barium Copper Oxide) layer is the functional superconducting component of the tape architecture. Various deposition methods including metal-organic chemical vapor deposition (MOCVD), pulsed laser deposition (PLD), and chemical solution deposition are used to create this layer. The crystallization process is critical for achieving the desired superconducting properties, with precise control of temperature, oxygen partial pressure, and deposition rate. Post-deposition heat treatments are often employed to optimize oxygen content and crystal structure in the REBCO layer, which directly impacts the critical current density of the tape.

- Protective capping layers and environmental barriers: Protective capping layers are applied to REBCO tapes to prevent degradation from environmental factors such as moisture, oxygen, and mechanical damage. These layers typically consist of noble metals like silver or gold, or protective oxides that serve as diffusion barriers. In addition to environmental protection, these layers can enhance electrical contact between the superconducting layer and stabilizer materials. Advanced multilayer protective structures are being developed to improve long-term stability and performance of REBCO tapes under various operating conditions.

02 Buffer layer compositions and deposition techniques

Buffer layers are critical components in REBCO tape architecture that serve multiple functions: preventing diffusion between the substrate and superconducting layer, providing appropriate lattice matching, and transferring texture from the substrate to the superconducting layer. These layers typically consist of oxide materials such as cerium oxide (CeO2), yttria-stabilized zirconia (YSZ), and lanthanum zirconate (La2Zr2O7). Various deposition techniques are employed for buffer layers, including pulsed laser deposition, chemical solution deposition, and sputtering, each offering different advantages in terms of uniformity, scalability, and cost-effectiveness.Expand Specific Solutions03 Stabilizer materials and configurations

Stabilizers are essential components added to REBCO tapes to enhance thermal stability, protect the superconducting layer during quench events, and provide alternative current paths. Common stabilizer materials include copper, silver, and stainless steel, which are selected based on their electrical conductivity, thermal properties, and compatibility with other tape components. Various configurations are employed, including surround stabilizers that completely encase the tape, laminated structures, and electroplated layers. The thickness and arrangement of stabilizers significantly impact the tape's performance in high-current applications and magnetic field environments.Expand Specific Solutions04 Multi-layer architecture optimization

The optimization of multi-layer architecture in REBCO tapes involves careful engineering of the interfaces between different functional layers to maximize superconducting performance. This includes controlling layer thicknesses, minimizing defects at interfaces, and ensuring proper crystallographic alignment throughout the structure. Advanced designs incorporate gradient compositions at interfaces to reduce lattice mismatch and strain. Some architectures also feature protective capping layers to prevent degradation of the superconducting material during processing and operation. The overall stack design must balance superconducting properties with mechanical robustness and manufacturing feasibility.Expand Specific Solutions05 Novel fabrication methods for enhanced performance

Innovative fabrication methods are being developed to enhance the performance of REBCO tapes. These include advanced deposition techniques such as metal organic chemical vapor deposition (MOCVD), reactive co-evaporation, and solution-based approaches that enable precise control over composition and microstructure. Post-processing treatments like oxygen annealing, irradiation, and nanoparticle incorporation are employed to introduce artificial pinning centers that improve current-carrying capacity in magnetic fields. Roll-to-roll continuous processing technologies are being refined to increase production throughput while maintaining high quality, enabling wider commercial adoption of these advanced superconducting materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions in REBCO Technology

REBCO tape architecture competition is currently in the growth phase, with a rapidly expanding market driven by fusion energy and superconducting applications. The global market shows significant potential, estimated to reach several billion dollars by 2030. Technologically, the field demonstrates varying maturity levels across players. Leading companies like American Superconductor and Tokamak Energy have achieved commercial-scale production with advanced substrate-buffer-stabilizer configurations, while research institutions including MIT, Texas A&M, and Shanghai Jiao Tong University are developing next-generation architectures. Electronics & Telecommunications Research Institute and Suzhou New Materials Research Institute are emerging with innovative buffer layer technologies. The competition features both established manufacturers and specialized startups, with increasing collaboration between academic institutions and industry partners to overcome technical challenges in substrate flexibility, buffer layer uniformity, and stabilizer integration.

Tokamak Energy Ltd.

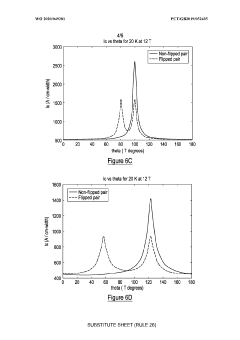

Technical Solution: Tokamak Energy has developed innovative REBCO tape architectures optimized for fusion energy applications. Their approach focuses on high-performance REBCO tapes with specialized buffer layers that enhance current-carrying capacity under strong magnetic fields. The company employs a multi-layer buffer system with yttria-stabilized zirconia (YSZ) and cerium oxide (CeO2) on Hastelloy substrates, creating an effective diffusion barrier while maintaining excellent lattice matching with the REBCO layer. Their proprietary stabilizer design incorporates copper and silver layers with optimized thickness ratios to balance thermal stability and mechanical strength. Tokamak Energy's tapes are engineered to withstand the extreme conditions of fusion environments, with particular attention to minimizing AC losses and maximizing critical current density at high magnetic fields (>20T) and operating temperatures relevant to compact spherical tokamaks [1][3].

Strengths: Specialized design for high magnetic field applications; excellent performance in fusion-relevant conditions; superior mechanical properties for tokamak coil applications. Weaknesses: Higher production costs compared to conventional superconductors; limited production scale compared to larger manufacturers; specialized design may limit versatility for non-fusion applications.

American Superconductor Corp.

Technical Solution: American Superconductor (AMSC) has pioneered advanced REBCO tape architectures through their proprietary MOD/RABiTS™ (Metal Organic Deposition/Rolling Assisted Biaxially Textured Substrates) technology. Their approach utilizes nickel-tungsten alloy substrates with carefully engineered texture to promote epitaxial growth of subsequent layers. AMSC's buffer stack typically consists of Y2O3, YSZ, and CeO2 layers deposited in sequence to provide both chemical isolation and structural compatibility. For stabilization, AMSC employs a surround-copper stabilizer configuration that encapsulates the REBCO tape, providing superior thermal and electrical stability while maintaining mechanical flexibility. Their manufacturing process incorporates real-time monitoring and quality control systems to ensure consistent performance across production batches. AMSC's tapes are optimized for both high engineering current density (Je) and mechanical durability, with special attention to minimizing substrate/buffer interfacial defects that can limit performance [2][4].

Strengths: Mature, scalable manufacturing process; excellent mechanical properties including bend strain tolerance; consistent quality across production runs. Weaknesses: Higher cost compared to conventional superconductors; performance limitations at the highest magnetic fields (>25T); susceptibility to degradation under certain thermal cycling conditions.

Critical Patents and Breakthroughs in REBCO Tape Components

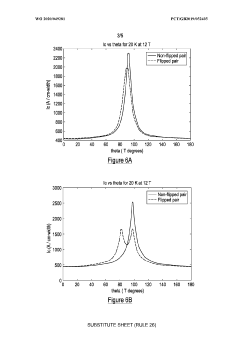

Alignment of HTS tapes

PatentWO2020049281A1

Innovation

- The tapes are arranged in pairs with reflective symmetry about a plane parallel to and equidistant from each tape, allowing the c-axis of one tape to be at a non-zero angle to the perpendicular, and a copper layer is placed between them to facilitate current transfer and reduce resistance.

Rare earth barium copper oxide magnet coils and methods

PatentActiveUS20190267172A1

Innovation

- The implementation of REBCO superconducting tapes coated with thin resistive layers of copper oxide, Cr, Ni, or Ni—P, or the use of stainless steel tapes with nickel or copper plating as interlayers between REBCO tapes, to increase turn-to-turn contact resistivity and optimize coil performance.

Material Science Advancements for Enhanced REBCO Performance

Recent advancements in material science have significantly enhanced the performance capabilities of REBCO (Rare Earth Barium Copper Oxide) superconductors. These improvements have focused primarily on optimizing the microstructural properties and chemical composition of REBCO materials to achieve higher critical current densities and improved mechanical stability under operational conditions.

The development of nanoscale engineering techniques has enabled precise control over the formation of artificial pinning centers within the REBCO matrix. By introducing controlled defects such as BaZrO3 nanoparticles, Y2O3 precipitates, and columnar defects, researchers have successfully enhanced flux pinning capabilities, resulting in substantial improvements in critical current performance under applied magnetic fields.

Surface modification techniques have emerged as another crucial area of advancement. Novel approaches involving surface functionalization with specialized polymers and metal oxide layers have demonstrated remarkable success in protecting REBCO materials from environmental degradation while maintaining optimal superconducting properties. These protective layers effectively mitigate oxygen loss and prevent moisture penetration without compromising the electrical connectivity of the superconducting layer.

Compositional engineering has yielded promising results through partial substitution of rare earth elements. The strategic replacement of yttrium with gadolinium, europium, or samarium has shown to enhance the superconducting transition temperature and improve flux pinning characteristics. Additionally, controlled doping with silver and copper has demonstrated beneficial effects on grain boundary connectivity and overall current-carrying capacity.

Advanced thin-film deposition techniques have revolutionized the fabrication of REBCO materials with unprecedented precision. Methods such as pulsed laser deposition, metal-organic chemical vapor deposition, and advanced sputtering techniques now allow for atomic-level control over layer thickness and composition, resulting in highly textured REBCO films with minimal defects and superior superconducting properties.

Strain engineering approaches have addressed the mechanical limitations of REBCO materials. By developing specialized substrate materials with tailored thermal expansion coefficients and incorporating elastically compliant buffer layers, researchers have significantly reduced the formation of microcracks during thermal cycling. This has substantially improved the mechanical durability and operational lifetime of REBCO tapes in practical applications.

The development of nanoscale engineering techniques has enabled precise control over the formation of artificial pinning centers within the REBCO matrix. By introducing controlled defects such as BaZrO3 nanoparticles, Y2O3 precipitates, and columnar defects, researchers have successfully enhanced flux pinning capabilities, resulting in substantial improvements in critical current performance under applied magnetic fields.

Surface modification techniques have emerged as another crucial area of advancement. Novel approaches involving surface functionalization with specialized polymers and metal oxide layers have demonstrated remarkable success in protecting REBCO materials from environmental degradation while maintaining optimal superconducting properties. These protective layers effectively mitigate oxygen loss and prevent moisture penetration without compromising the electrical connectivity of the superconducting layer.

Compositional engineering has yielded promising results through partial substitution of rare earth elements. The strategic replacement of yttrium with gadolinium, europium, or samarium has shown to enhance the superconducting transition temperature and improve flux pinning characteristics. Additionally, controlled doping with silver and copper has demonstrated beneficial effects on grain boundary connectivity and overall current-carrying capacity.

Advanced thin-film deposition techniques have revolutionized the fabrication of REBCO materials with unprecedented precision. Methods such as pulsed laser deposition, metal-organic chemical vapor deposition, and advanced sputtering techniques now allow for atomic-level control over layer thickness and composition, resulting in highly textured REBCO films with minimal defects and superior superconducting properties.

Strain engineering approaches have addressed the mechanical limitations of REBCO materials. By developing specialized substrate materials with tailored thermal expansion coefficients and incorporating elastically compliant buffer layers, researchers have significantly reduced the formation of microcracks during thermal cycling. This has substantially improved the mechanical durability and operational lifetime of REBCO tapes in practical applications.

Cost-Performance Balance in Commercial REBCO Applications

The commercial viability of REBCO (Rare Earth Barium Copper Oxide) superconductors hinges on achieving an optimal balance between manufacturing costs and performance metrics. Current market analysis indicates that REBCO tape production costs remain significantly higher than conventional superconductors, with prices ranging from $100-400/kA-m depending on performance specifications and production volume.

Material selection represents approximately 40-60% of total manufacturing costs, with substrate materials (typically Hastelloy or stainless steel) accounting for 15-25% of this portion. The thickness of these substrates presents a critical trade-off: thinner substrates reduce material costs but compromise mechanical stability, while thicker substrates increase production expenses but enhance durability for applications requiring robust mechanical properties.

Buffer layer complexity significantly impacts production economics, with multi-layer architectures increasing manufacturing costs by 30-50% compared to simplified buffer systems. However, simplified buffer architectures often result in reduced current-carrying capacity, creating a direct performance-cost relationship that manufacturers must navigate based on intended application requirements.

Stabilizer materials (copper, silver, or stainless steel) contribute 20-30% to overall tape costs, with silver-based stabilizers commanding premium pricing but delivering superior thermal and electrical properties. Recent innovations in copper-based stabilizer technologies have narrowed this performance gap while offering cost reductions of 30-40%, making them increasingly attractive for commercial applications where cost sensitivity outweighs ultimate performance requirements.

Production scale economies present another crucial factor, with high-volume manufacturing potentially reducing unit costs by 40-60% compared to small-batch production. This economic reality favors established manufacturers with substantial production capacity and creates significant market entry barriers for new competitors, contributing to the current oligopolistic market structure dominated by a handful of major producers.

Application-specific requirements further complicate the cost-performance equation. High-field magnet applications demand premium performance characteristics and can absorb higher material costs, while grid applications require more cost-competitive solutions even at the expense of some performance metrics. This market segmentation has driven manufacturers to develop tiered product offerings with varying cost-performance profiles tailored to specific application domains.

Future cost reduction pathways include advanced deposition techniques that could reduce buffer layer complexity while maintaining performance, alternative substrate materials with improved cost-performance ratios, and novel stabilizer architectures that optimize thermal and mechanical properties at reduced material costs.

Material selection represents approximately 40-60% of total manufacturing costs, with substrate materials (typically Hastelloy or stainless steel) accounting for 15-25% of this portion. The thickness of these substrates presents a critical trade-off: thinner substrates reduce material costs but compromise mechanical stability, while thicker substrates increase production expenses but enhance durability for applications requiring robust mechanical properties.

Buffer layer complexity significantly impacts production economics, with multi-layer architectures increasing manufacturing costs by 30-50% compared to simplified buffer systems. However, simplified buffer architectures often result in reduced current-carrying capacity, creating a direct performance-cost relationship that manufacturers must navigate based on intended application requirements.

Stabilizer materials (copper, silver, or stainless steel) contribute 20-30% to overall tape costs, with silver-based stabilizers commanding premium pricing but delivering superior thermal and electrical properties. Recent innovations in copper-based stabilizer technologies have narrowed this performance gap while offering cost reductions of 30-40%, making them increasingly attractive for commercial applications where cost sensitivity outweighs ultimate performance requirements.

Production scale economies present another crucial factor, with high-volume manufacturing potentially reducing unit costs by 40-60% compared to small-batch production. This economic reality favors established manufacturers with substantial production capacity and creates significant market entry barriers for new competitors, contributing to the current oligopolistic market structure dominated by a handful of major producers.

Application-specific requirements further complicate the cost-performance equation. High-field magnet applications demand premium performance characteristics and can absorb higher material costs, while grid applications require more cost-competitive solutions even at the expense of some performance metrics. This market segmentation has driven manufacturers to develop tiered product offerings with varying cost-performance profiles tailored to specific application domains.

Future cost reduction pathways include advanced deposition techniques that could reduce buffer layer complexity while maintaining performance, alternative substrate materials with improved cost-performance ratios, and novel stabilizer architectures that optimize thermal and mechanical properties at reduced material costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!