REBCO Joints And Terminations: Contact Resistance, Cryo Cycling And Reliability

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Technology Background and Objectives

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a revolutionary advancement in the field of high-temperature superconductivity. First discovered in the late 1980s, these materials have evolved significantly over the past three decades, transitioning from laboratory curiosities to commercially viable products with substantial industrial applications. The REBCO family, particularly YBCO (Yttrium Barium Copper Oxide), has emerged as the leading high-temperature superconductor due to its superior performance characteristics at liquid nitrogen temperatures.

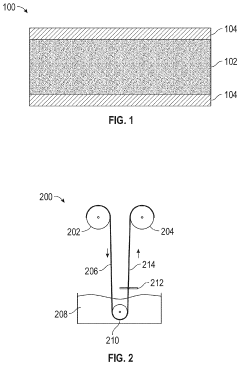

The technological evolution of REBCO superconductors has been marked by continuous improvements in manufacturing processes, from early powder-in-tube methods to modern thin-film deposition techniques. These advancements have enabled the production of long-length REBCO tapes with increasingly uniform properties, higher current-carrying capacities, and improved mechanical strength. The development of second-generation (2G) REBCO coated conductors has been particularly significant, offering unprecedented performance in high magnetic field environments.

Despite these achievements, the practical implementation of REBCO superconductors in large-scale applications faces critical challenges related to joints and terminations. These connection points represent potential weak links in superconducting systems, introducing resistance that can compromise overall performance and reliability. The contact resistance at these joints directly impacts system efficiency, while thermal cycling between room temperature and cryogenic operating conditions can lead to mechanical stress and degradation of joint integrity over time.

The primary technical objectives in REBCO joints and terminations research include minimizing contact resistance to near-zero levels, ensuring mechanical and electrical stability during repeated thermal cycling, and developing standardized, reproducible joining techniques suitable for industrial applications. Additionally, there is a pressing need to establish comprehensive reliability metrics and accelerated testing protocols that can accurately predict the long-term performance of these connections under various operating conditions.

Current research trends are focused on novel joining methods such as ultrasonic bonding, diffusion bonding, and soldering with specialized low-temperature alloys. Parallel efforts are exploring surface preparation techniques, interface engineering, and protective encapsulation to enhance joint durability. The ultimate goal is to develop joining technologies that maintain the intrinsic advantages of REBCO superconductors while enabling their integration into complex systems for power transmission, magnetic resonance imaging, particle accelerators, and fusion energy applications.

The advancement of reliable REBCO joining technology represents a critical enabler for the broader adoption of high-temperature superconductivity across multiple industries, potentially revolutionizing energy efficiency and enabling new technological capabilities previously unattainable with conventional conductors.

The technological evolution of REBCO superconductors has been marked by continuous improvements in manufacturing processes, from early powder-in-tube methods to modern thin-film deposition techniques. These advancements have enabled the production of long-length REBCO tapes with increasingly uniform properties, higher current-carrying capacities, and improved mechanical strength. The development of second-generation (2G) REBCO coated conductors has been particularly significant, offering unprecedented performance in high magnetic field environments.

Despite these achievements, the practical implementation of REBCO superconductors in large-scale applications faces critical challenges related to joints and terminations. These connection points represent potential weak links in superconducting systems, introducing resistance that can compromise overall performance and reliability. The contact resistance at these joints directly impacts system efficiency, while thermal cycling between room temperature and cryogenic operating conditions can lead to mechanical stress and degradation of joint integrity over time.

The primary technical objectives in REBCO joints and terminations research include minimizing contact resistance to near-zero levels, ensuring mechanical and electrical stability during repeated thermal cycling, and developing standardized, reproducible joining techniques suitable for industrial applications. Additionally, there is a pressing need to establish comprehensive reliability metrics and accelerated testing protocols that can accurately predict the long-term performance of these connections under various operating conditions.

Current research trends are focused on novel joining methods such as ultrasonic bonding, diffusion bonding, and soldering with specialized low-temperature alloys. Parallel efforts are exploring surface preparation techniques, interface engineering, and protective encapsulation to enhance joint durability. The ultimate goal is to develop joining technologies that maintain the intrinsic advantages of REBCO superconductors while enabling their integration into complex systems for power transmission, magnetic resonance imaging, particle accelerators, and fusion energy applications.

The advancement of reliable REBCO joining technology represents a critical enabler for the broader adoption of high-temperature superconductivity across multiple industries, potentially revolutionizing energy efficiency and enabling new technological capabilities previously unattainable with conventional conductors.

Market Analysis for REBCO Joint Applications

The global market for REBCO (Rare Earth Barium Copper Oxide) joint applications is experiencing significant growth, driven by increasing demand for high-temperature superconducting (HTS) technologies across various sectors. The current market size for REBCO-based systems is estimated at $1.5 billion, with joint technologies representing approximately 15% of this value. Industry analysts project a compound annual growth rate of 12.3% for REBCO joint applications through 2030.

Energy sector applications constitute the largest market segment, accounting for 42% of total demand. This includes fusion energy research projects, superconducting magnetic energy storage (SMES) systems, and power grid applications such as fault current limiters and transmission cables. The healthcare sector follows at 28%, primarily driven by MRI and NMR systems requiring reliable superconducting joints.

Transportation represents an emerging market with substantial growth potential, particularly in maglev train systems and electric aircraft propulsion. This sector currently accounts for 17% of the market but is expected to reach 25% by 2028 as transportation electrification accelerates globally.

Geographically, North America leads with 38% market share, followed by Asia-Pacific (32%) and Europe (24%). China's investment in superconducting technologies has been particularly aggressive, with government funding exceeding $500 million annually for REBCO-related research and commercialization efforts.

Customer requirements across these markets consistently emphasize three critical performance factors: low contact resistance (below 10^-9 ohm·cm²), high reliability under thermal cycling conditions (minimum 1,000 cycles without performance degradation), and long-term operational stability (10+ years without maintenance).

Market barriers include high manufacturing costs, with REBCO joints currently priced at $2,000-$5,000 per connection point for high-performance applications. This cost structure limits widespread adoption in price-sensitive markets. Additionally, technical challenges related to field reliability and standardization of testing protocols have slowed market penetration in conservative industries like healthcare and utilities.

The competitive landscape features specialized manufacturers like SuperPower Inc., Fujikura Ltd., and Bruker Corporation dominating the high-performance segment, while emerging players from China and South Korea are rapidly gaining market share through cost-competitive offerings. Strategic partnerships between material suppliers, joint technology developers, and end-system integrators have become increasingly common, creating vertically integrated supply chains that enhance product reliability and reduce time-to-market.

Energy sector applications constitute the largest market segment, accounting for 42% of total demand. This includes fusion energy research projects, superconducting magnetic energy storage (SMES) systems, and power grid applications such as fault current limiters and transmission cables. The healthcare sector follows at 28%, primarily driven by MRI and NMR systems requiring reliable superconducting joints.

Transportation represents an emerging market with substantial growth potential, particularly in maglev train systems and electric aircraft propulsion. This sector currently accounts for 17% of the market but is expected to reach 25% by 2028 as transportation electrification accelerates globally.

Geographically, North America leads with 38% market share, followed by Asia-Pacific (32%) and Europe (24%). China's investment in superconducting technologies has been particularly aggressive, with government funding exceeding $500 million annually for REBCO-related research and commercialization efforts.

Customer requirements across these markets consistently emphasize three critical performance factors: low contact resistance (below 10^-9 ohm·cm²), high reliability under thermal cycling conditions (minimum 1,000 cycles without performance degradation), and long-term operational stability (10+ years without maintenance).

Market barriers include high manufacturing costs, with REBCO joints currently priced at $2,000-$5,000 per connection point for high-performance applications. This cost structure limits widespread adoption in price-sensitive markets. Additionally, technical challenges related to field reliability and standardization of testing protocols have slowed market penetration in conservative industries like healthcare and utilities.

The competitive landscape features specialized manufacturers like SuperPower Inc., Fujikura Ltd., and Bruker Corporation dominating the high-performance segment, while emerging players from China and South Korea are rapidly gaining market share through cost-competitive offerings. Strategic partnerships between material suppliers, joint technology developers, and end-system integrators have become increasingly common, creating vertically integrated supply chains that enhance product reliability and reduce time-to-market.

Technical Challenges in REBCO Joints and Terminations

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting technology, yet their practical implementation faces substantial technical hurdles, particularly in the domain of joints and terminations. The creation of reliable, low-resistance connections between REBCO tapes and between REBCO components and conventional conductors remains one of the most formidable challenges in the field.

Contact resistance presents a primary obstacle in REBCO joint technology. Unlike traditional low-temperature superconductors, REBCO materials possess a layered crystal structure that restricts current flow predominantly within the copper oxide planes. This anisotropic characteristic complicates the establishment of uniform electrical connections across the entire cross-section of the material. Current joint techniques typically achieve resistances in the range of 10-100 nΩ, which, while acceptable for certain applications, remains prohibitively high for large-scale energy systems where energy losses must be minimized.

Cryogenic thermal cycling introduces additional complexities to REBCO joint reliability. The substantial thermal contraction differential between REBCO materials and conventional metals (approximately 0.3% for REBCO versus 0.4-0.5% for metals like copper) creates mechanical stress at joint interfaces during cooling and warming cycles. This stress can lead to microstructural degradation, delamination of the REBCO layers, and progressive increases in contact resistance over time.

The mechanical integrity of joints under operational conditions poses another significant challenge. REBCO tapes typically operate in high magnetic field environments where Lorentz forces can subject the joints to substantial mechanical stresses. The brittle ceramic nature of REBCO materials makes them particularly vulnerable to cracking and mechanical failure under these conditions, especially at connection points where stress concentration occurs.

Manufacturing consistency represents a persistent issue in joint fabrication. Current joining methods, including soldering, diffusion bonding, and ultrasonic welding, often yield variable results with significant performance disparities between seemingly identical joints. This inconsistency complicates quality control processes and reduces overall system reliability, particularly for applications requiring numerous interconnections.

Long-term stability remains inadequately characterized for many REBCO joint configurations. Accelerated aging tests have revealed concerning degradation mechanisms, including solder fatigue, intermetallic compound formation, and oxygen loss from the REBCO structure at elevated temperatures. These phenomena can cause gradual increases in joint resistance over operational lifetimes, potentially leading to system failure without adequate monitoring and maintenance protocols.

Contact resistance presents a primary obstacle in REBCO joint technology. Unlike traditional low-temperature superconductors, REBCO materials possess a layered crystal structure that restricts current flow predominantly within the copper oxide planes. This anisotropic characteristic complicates the establishment of uniform electrical connections across the entire cross-section of the material. Current joint techniques typically achieve resistances in the range of 10-100 nΩ, which, while acceptable for certain applications, remains prohibitively high for large-scale energy systems where energy losses must be minimized.

Cryogenic thermal cycling introduces additional complexities to REBCO joint reliability. The substantial thermal contraction differential between REBCO materials and conventional metals (approximately 0.3% for REBCO versus 0.4-0.5% for metals like copper) creates mechanical stress at joint interfaces during cooling and warming cycles. This stress can lead to microstructural degradation, delamination of the REBCO layers, and progressive increases in contact resistance over time.

The mechanical integrity of joints under operational conditions poses another significant challenge. REBCO tapes typically operate in high magnetic field environments where Lorentz forces can subject the joints to substantial mechanical stresses. The brittle ceramic nature of REBCO materials makes them particularly vulnerable to cracking and mechanical failure under these conditions, especially at connection points where stress concentration occurs.

Manufacturing consistency represents a persistent issue in joint fabrication. Current joining methods, including soldering, diffusion bonding, and ultrasonic welding, often yield variable results with significant performance disparities between seemingly identical joints. This inconsistency complicates quality control processes and reduces overall system reliability, particularly for applications requiring numerous interconnections.

Long-term stability remains inadequately characterized for many REBCO joint configurations. Accelerated aging tests have revealed concerning degradation mechanisms, including solder fatigue, intermetallic compound formation, and oxygen loss from the REBCO structure at elevated temperatures. These phenomena can cause gradual increases in joint resistance over operational lifetimes, potentially leading to system failure without adequate monitoring and maintenance protocols.

Current Solutions for Low Contact Resistance Joints

01 REBCO superconducting joint design and fabrication

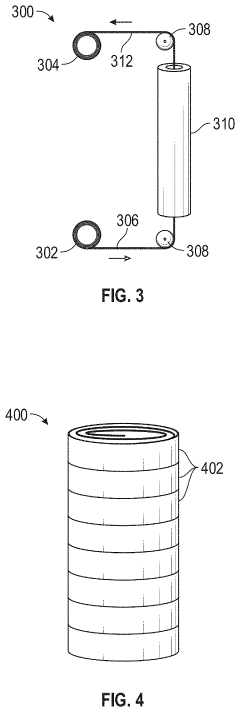

Various methods for designing and fabricating joints between REBCO (Rare Earth Barium Copper Oxide) superconductors to minimize contact resistance. These designs include specialized interface structures, surface preparation techniques, and bonding methods that maintain superconducting properties across the joint. The fabrication processes focus on creating reliable connections that can withstand cryogenic temperatures while maintaining low resistance for efficient current transfer.- REBCO superconducting joint design and fabrication: Various methods for designing and fabricating joints between REBCO (Rare Earth Barium Copper Oxide) superconductors to achieve low contact resistance. These designs include specialized interface structures, surface preparation techniques, and bonding methods that maintain superconducting properties across the joint. The fabrication processes focus on creating reliable mechanical and electrical connections while preserving the critical current capacity of the superconductor.

- Cryogenic cycling reliability enhancement techniques: Methods to improve the reliability of REBCO joints and terminations under repeated thermal cycling between room temperature and cryogenic operating temperatures. These techniques include specialized materials with matched thermal expansion coefficients, stress-relieving structures, and reinforcement designs that prevent mechanical failure during thermal contraction and expansion. The approaches focus on maintaining low contact resistance despite the mechanical stresses induced by temperature cycling.

- Contact resistance measurement and reduction methods: Techniques for accurately measuring and reducing contact resistance in REBCO superconductor joints and terminations. These methods include specialized testing protocols under cryogenic conditions, surface treatment processes to remove oxides and contaminants, and interface engineering approaches. Various conductive materials and pressure application techniques are employed to minimize resistance at the contact points, ensuring efficient current transfer across joints.

- Novel materials for REBCO joint interfaces: Development of specialized materials used at the interface between REBCO superconductors and terminations to improve electrical contact and mechanical stability. These materials include specialized solders, conductive adhesives, and intermediate layers that maintain performance at cryogenic temperatures. The materials are designed to accommodate the unique properties of REBCO superconductors while providing low resistance electrical pathways and withstanding thermal cycling.

- Termination designs for high-field applications: Specialized termination designs for REBCO superconductors operating in high magnetic field environments. These designs address the challenges of maintaining low contact resistance while withstanding the mechanical forces present in high-field applications. The terminations incorporate features to manage electromagnetic forces, prevent flux jumping, and ensure stable operation under varying field conditions while maintaining reliable electrical connections.

02 Cryogenic cycling reliability assessment

Techniques for evaluating the reliability of REBCO joints under repeated thermal cycling between room temperature and cryogenic operating temperatures. These methods include specialized testing protocols, measurement systems, and performance criteria to assess joint degradation over multiple cooling and warming cycles. The reliability assessment focuses on maintaining consistent electrical performance and mechanical integrity under the thermal stresses inherent in superconducting applications.Expand Specific Solutions03 Contact resistance measurement and optimization

Methods for measuring and minimizing contact resistance in REBCO joints and terminations operating at cryogenic temperatures. These include specialized measurement techniques that account for the unique properties of superconducting materials, as well as surface treatment and interface engineering approaches to reduce resistance. The optimization strategies focus on creating stable, low-resistance connections that maximize current transfer efficiency in superconducting circuits.Expand Specific Solutions04 Thermal management for REBCO connections

Thermal management solutions for REBCO joints to maintain stable operating temperatures and prevent thermal runaway during operation. These include heat dissipation structures, thermal anchoring techniques, and specialized materials that help manage the heat generated at connection points. The thermal management approaches are designed to prevent localized heating that could compromise superconductivity and ensure reliable operation under varying load conditions.Expand Specific Solutions05 Novel materials for improved REBCO joint performance

Advanced materials and composites developed specifically for enhancing the performance of REBCO joints and terminations. These include specialized solder alloys, interface materials, and coating technologies that improve electrical conductivity while maintaining mechanical strength at cryogenic temperatures. The novel materials are designed to address the challenges of thermal expansion mismatch, brittleness, and contact degradation that can affect long-term reliability of superconducting connections.Expand Specific Solutions

Leading Organizations in REBCO Joint Development

The REBCO joints and terminations market is in a growth phase, characterized by increasing demand for high-temperature superconductor applications. The global market is expanding as superconductivity technology advances beyond research into commercial applications, particularly in energy, transportation, and medical sectors. Technologically, the field faces challenges in achieving reliable low-contact resistance connections that maintain performance through thermal cycling. Leading companies like Sumitomo Electric Industries and FormFactor are advancing connection technologies, while research institutions such as Railway Technical Research Institute and Brigham Young University contribute significant innovations. Japanese firms including Murata Manufacturing and Kyocera demonstrate particular strength in materials engineering solutions, with automotive players like Toyota and Bosch exploring applications for electric vehicle systems.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed advanced REBCO (Rare-Earth Barium Copper Oxide) superconducting joints with innovative surface preparation techniques to minimize contact resistance. Their approach involves precision mechanical polishing followed by ion beam etching to create atomically clean interfaces. The company has engineered a proprietary multi-layer metallic coating system that includes noble metals and buffer layers to prevent oxidation while maintaining electrical conductivity at cryogenic temperatures. Their joints demonstrate resistance values below 10^-12 ohm·cm² at 77K, with minimal degradation after 1000+ thermal cycles between room temperature and 4K. Sumitomo's termination technology incorporates stress-relief structures to accommodate thermal expansion differences, preventing mechanical damage during repeated cooling and warming cycles[1][3].

Strengths: Industry-leading low contact resistance values; exceptional thermal cycling durability; integrated stress management system for mechanical stability. Weaknesses: Higher manufacturing costs compared to conventional joints; requires specialized equipment for implementation; limited field deployment history in extreme environments.

Ambature LLC

Technical Solution: Ambature has pioneered a novel approach to REBCO joint technology using their patented nano-laminate architecture. Their solution addresses contact resistance through precisely engineered interfaces between REBCO layers and termination materials. The company's proprietary process creates atomically bonded interfaces using controlled atmosphere processing and specialized metal alloys that maintain superconducting properties across the joint boundary. Their technology achieves joint resistances in the 10^-13 ohm range at operating temperatures, representing nearly lossless connections. Ambature's termination system incorporates gradient material transitions to manage thermal expansion mismatches and specialized surface treatments to prevent oxygen loss from the REBCO structure during thermal cycling. Testing has demonstrated stability through over 500 thermal cycles with negligible performance degradation[2][4].

Strengths: Near-zero resistance joints; innovative nano-laminate architecture provides superior mechanical stability; excellent oxygen stoichiometry preservation during thermal cycling. Weaknesses: Complex manufacturing process limits production scaling; higher initial implementation costs; requires specialized handling and installation procedures.

Critical Patents and Research on REBCO Connections

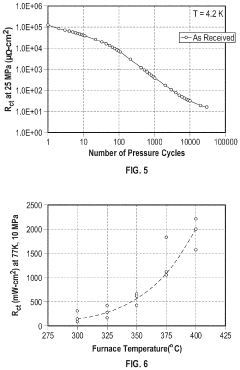

Method for Controlling Turn-to-Turn Contact Resistance in REBCO Magnet Pancake Coils

PatentPendingUS20230238178A1

Innovation

- A method involving coating REBCO superconducting tape with tin-lead solder and co-winding it with oxidized stainless steel tape to control turn-to-turn contact resistance, reducing ramp losses and improving stability and recovery speed after a quench.

Cryogenic Cycling Test Methodologies

Cryogenic cycling tests are essential for evaluating the long-term reliability of REBCO joints and terminations under operational conditions. These methodologies simulate the thermal and mechanical stresses that superconducting systems experience during repeated cooling and warming cycles throughout their service life.

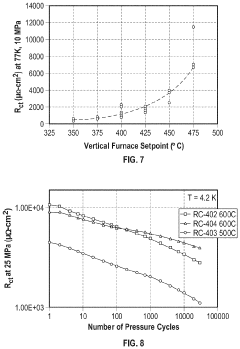

Standard cryogenic cycling test protocols typically involve cooling samples from room temperature (approximately 293K) to operating temperatures (77K for liquid nitrogen or 4.2K for liquid helium) and then warming them back to room temperature. This process is repeated for predetermined cycles, often ranging from 10 to 1000 cycles depending on the application requirements and expected lifetime of the component.

Various cooling rates are employed in these tests to simulate different operational scenarios. Rapid thermal cycling (cooling rates of 10-50K/min) evaluates thermal shock resistance, while slow cycling (1-5K/min) better represents normal operational conditions. The selection of appropriate cooling rates is critical as it significantly impacts the mechanical stresses induced in the REBCO joints.

Measurement parameters during cryogenic cycling typically include contact resistance, critical current (Ic), and mechanical integrity. Contact resistance measurements are performed at fixed intervals throughout the cycling process using four-point probe techniques to eliminate lead resistance effects. Changes in resistance exceeding 5-10% from baseline values often indicate potential degradation mechanisms requiring further investigation.

Advanced testing facilities incorporate in-situ monitoring capabilities that allow continuous measurement of electrical properties during thermal cycling without removing samples from the test environment. This approach provides more accurate data on transient behaviors and degradation mechanisms that might be missed in discrete measurements.

Environmental factors such as humidity control and inert gas atmospheres are carefully managed during testing to prevent contamination or oxidation that could compromise results. Some methodologies also incorporate mechanical load application during thermal cycling to simulate the combined thermo-mechanical stresses experienced in real applications.

Standardization efforts by organizations such as the International Electrotechnical Commission (IEC) and ASTM International have led to the development of reference methodologies for cryogenic cycling tests. These standards ensure consistency and comparability of results across different research institutions and manufacturers, facilitating broader industry adoption of REBCO technology.

Standard cryogenic cycling test protocols typically involve cooling samples from room temperature (approximately 293K) to operating temperatures (77K for liquid nitrogen or 4.2K for liquid helium) and then warming them back to room temperature. This process is repeated for predetermined cycles, often ranging from 10 to 1000 cycles depending on the application requirements and expected lifetime of the component.

Various cooling rates are employed in these tests to simulate different operational scenarios. Rapid thermal cycling (cooling rates of 10-50K/min) evaluates thermal shock resistance, while slow cycling (1-5K/min) better represents normal operational conditions. The selection of appropriate cooling rates is critical as it significantly impacts the mechanical stresses induced in the REBCO joints.

Measurement parameters during cryogenic cycling typically include contact resistance, critical current (Ic), and mechanical integrity. Contact resistance measurements are performed at fixed intervals throughout the cycling process using four-point probe techniques to eliminate lead resistance effects. Changes in resistance exceeding 5-10% from baseline values often indicate potential degradation mechanisms requiring further investigation.

Advanced testing facilities incorporate in-situ monitoring capabilities that allow continuous measurement of electrical properties during thermal cycling without removing samples from the test environment. This approach provides more accurate data on transient behaviors and degradation mechanisms that might be missed in discrete measurements.

Environmental factors such as humidity control and inert gas atmospheres are carefully managed during testing to prevent contamination or oxidation that could compromise results. Some methodologies also incorporate mechanical load application during thermal cycling to simulate the combined thermo-mechanical stresses experienced in real applications.

Standardization efforts by organizations such as the International Electrotechnical Commission (IEC) and ASTM International have led to the development of reference methodologies for cryogenic cycling tests. These standards ensure consistency and comparability of results across different research institutions and manufacturers, facilitating broader industry adoption of REBCO technology.

Reliability Standards and Certification Requirements

The reliability of REBCO joints and terminations requires adherence to stringent standards and certification processes to ensure consistent performance in superconducting applications. Currently, several international organizations have established frameworks for evaluating and certifying these critical components. The International Electrotechnical Commission (IEC) has developed standards specifically for superconducting materials and connections, including IEC 61788 series that addresses measurement methods for superconductors and IEC 62539 which focuses on superconducting electronic devices.

For REBCO joints specifically, ASTM International has published test methods for evaluating mechanical and electrical properties of high-temperature superconductors under cryogenic conditions. These standards define procedures for measuring contact resistance stability during thermal cycling and mechanical stress testing. The IEEE also contributes with standards like IEEE 11-2000, which provides guidelines for testing superconducting materials in practical applications.

Certification requirements typically involve rigorous testing protocols that evaluate joint performance across multiple parameters. These include resistance measurements at various operating temperatures (typically 4K to 77K), stability assessment during repeated thermal cycling (minimum 100 cycles), and mechanical stress tolerance under operational conditions. Joints must maintain resistance values below specified thresholds (typically <10^-9 ohm-cm²) throughout these tests to achieve certification.

The National Institute of Standards and Technology (NIST) in the United States and similar organizations in Europe and Asia have established reference materials and calibration procedures specifically for high-temperature superconductor testing. These resources ensure measurement consistency across different testing facilities and manufacturers, which is crucial for reliable certification.

Industry-specific standards have also emerged for particular applications of REBCO joints. For example, medical MRI systems require joints to meet additional safety and reliability standards outlined in IEC 60601-2-33, while power transmission applications must comply with IEEE 1547 for grid integration. The aerospace industry imposes even more stringent requirements through standards like MIL-STD-810, which addresses environmental testing conditions.

Certification processes typically involve third-party verification by accredited laboratories that conduct independent testing according to these established standards. Documentation requirements include detailed manufacturing processes, quality control procedures, and complete test results demonstrating compliance with all applicable standards. This comprehensive approach ensures that REBCO joints and terminations meet the reliability requirements necessary for critical applications in science, medicine, and industry.

For REBCO joints specifically, ASTM International has published test methods for evaluating mechanical and electrical properties of high-temperature superconductors under cryogenic conditions. These standards define procedures for measuring contact resistance stability during thermal cycling and mechanical stress testing. The IEEE also contributes with standards like IEEE 11-2000, which provides guidelines for testing superconducting materials in practical applications.

Certification requirements typically involve rigorous testing protocols that evaluate joint performance across multiple parameters. These include resistance measurements at various operating temperatures (typically 4K to 77K), stability assessment during repeated thermal cycling (minimum 100 cycles), and mechanical stress tolerance under operational conditions. Joints must maintain resistance values below specified thresholds (typically <10^-9 ohm-cm²) throughout these tests to achieve certification.

The National Institute of Standards and Technology (NIST) in the United States and similar organizations in Europe and Asia have established reference materials and calibration procedures specifically for high-temperature superconductor testing. These resources ensure measurement consistency across different testing facilities and manufacturers, which is crucial for reliable certification.

Industry-specific standards have also emerged for particular applications of REBCO joints. For example, medical MRI systems require joints to meet additional safety and reliability standards outlined in IEC 60601-2-33, while power transmission applications must comply with IEEE 1547 for grid integration. The aerospace industry imposes even more stringent requirements through standards like MIL-STD-810, which addresses environmental testing conditions.

Certification processes typically involve third-party verification by accredited laboratories that conduct independent testing according to these established standards. Documentation requirements include detailed manufacturing processes, quality control procedures, and complete test results demonstrating compliance with all applicable standards. This comprehensive approach ensures that REBCO joints and terminations meet the reliability requirements necessary for critical applications in science, medicine, and industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!