REBCO Quench Protection: Normal Zone Propagation, Detection And Energy Dump

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Quench Protection Background and Objectives

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting (HTS) technology, offering critical current densities at high magnetic fields and temperatures that far exceed those of conventional low-temperature superconductors. This technological breakthrough has opened new possibilities for compact, high-field magnets in applications ranging from fusion energy systems to medical imaging and particle accelerators.

The phenomenon of quench—a sudden transition from superconducting to normal resistive state—poses one of the most significant challenges in REBCO applications. Unlike traditional low-temperature superconductors, REBCO materials exhibit extremely slow normal zone propagation velocities (typically 1-10 cm/s compared to meters per second in LTS materials), making quench detection particularly challenging. This slow propagation can lead to highly localized heating that may cause irreversible damage to the superconducting coil before conventional detection systems can identify the problem.

Historical developments in quench protection have primarily focused on low-temperature superconductors, with established methodologies that are not directly transferable to REBCO systems due to their fundamentally different electromagnetic and thermal behaviors. The unique properties of REBCO tapes—including their anisotropic structure, high thermal stability, and low normal zone propagation velocity—necessitate novel approaches to quench protection.

The primary objective of this technical research is to develop comprehensive understanding and innovative solutions for REBCO quench protection through three interconnected aspects: normal zone propagation mechanisms, advanced detection methodologies, and efficient energy dump strategies. Specifically, we aim to characterize the factors influencing normal zone propagation in REBCO conductors under various operating conditions, develop ultra-sensitive detection systems capable of identifying quench events at their earliest stages, and design energy extraction systems that can rapidly and safely dissipate stored magnetic energy.

Additionally, this research seeks to establish standardized testing protocols and performance metrics for REBCO quench protection systems, enabling meaningful comparisons between different protection strategies. The ultimate goal is to develop protection technologies that can ensure the safe and reliable operation of high-field REBCO magnets, thereby removing a critical barrier to their widespread commercial implementation.

By addressing these challenges, we anticipate enabling the next generation of compact, high-field superconducting magnets that can operate reliably in demanding applications, particularly in the emerging fields of compact fusion energy systems and advanced medical diagnostics where the unique properties of REBCO superconductors offer transformative potential.

The phenomenon of quench—a sudden transition from superconducting to normal resistive state—poses one of the most significant challenges in REBCO applications. Unlike traditional low-temperature superconductors, REBCO materials exhibit extremely slow normal zone propagation velocities (typically 1-10 cm/s compared to meters per second in LTS materials), making quench detection particularly challenging. This slow propagation can lead to highly localized heating that may cause irreversible damage to the superconducting coil before conventional detection systems can identify the problem.

Historical developments in quench protection have primarily focused on low-temperature superconductors, with established methodologies that are not directly transferable to REBCO systems due to their fundamentally different electromagnetic and thermal behaviors. The unique properties of REBCO tapes—including their anisotropic structure, high thermal stability, and low normal zone propagation velocity—necessitate novel approaches to quench protection.

The primary objective of this technical research is to develop comprehensive understanding and innovative solutions for REBCO quench protection through three interconnected aspects: normal zone propagation mechanisms, advanced detection methodologies, and efficient energy dump strategies. Specifically, we aim to characterize the factors influencing normal zone propagation in REBCO conductors under various operating conditions, develop ultra-sensitive detection systems capable of identifying quench events at their earliest stages, and design energy extraction systems that can rapidly and safely dissipate stored magnetic energy.

Additionally, this research seeks to establish standardized testing protocols and performance metrics for REBCO quench protection systems, enabling meaningful comparisons between different protection strategies. The ultimate goal is to develop protection technologies that can ensure the safe and reliable operation of high-field REBCO magnets, thereby removing a critical barrier to their widespread commercial implementation.

By addressing these challenges, we anticipate enabling the next generation of compact, high-field superconducting magnets that can operate reliably in demanding applications, particularly in the emerging fields of compact fusion energy systems and advanced medical diagnostics where the unique properties of REBCO superconductors offer transformative potential.

Market Demand Analysis for Advanced Superconductor Protection

The global market for advanced superconductor protection systems, particularly for REBCO (Rare-Earth Barium Copper Oxide) technology, is experiencing significant growth driven by expanding applications in multiple sectors. Current market analysis indicates that the demand for reliable quench protection systems is primarily fueled by the increasing deployment of high-temperature superconductors in energy, healthcare, transportation, and research applications.

In the energy sector, superconducting magnetic energy storage systems and fault current limiters represent growing market segments requiring sophisticated quench protection. The transition toward renewable energy integration has accelerated the need for more efficient energy storage solutions, where protected REBCO superconductors offer substantial advantages over conventional technologies.

Healthcare applications, particularly in MRI and NMR systems, constitute another major market driver. The medical imaging market continues to expand globally, with advanced superconducting magnets requiring increasingly sophisticated protection mechanisms to safeguard expensive equipment and ensure patient safety. Hospitals and diagnostic centers are willing to invest in superior protection systems that minimize downtime and extend equipment lifespan.

The emerging market for superconducting applications in transportation, especially in magnetic levitation trains and electric aircraft propulsion systems, presents substantial growth opportunities. These applications demand highly reliable quench protection due to their critical safety requirements and the catastrophic consequences of protection failure.

Research facilities and large-scale scientific installations represent another significant market segment. Projects like fusion reactors, particle accelerators, and high-field research magnets require advanced quench protection systems capable of handling the extreme operating conditions of REBCO superconductors.

Market analysis reveals a growing preference for integrated protection solutions that combine rapid normal zone propagation enhancement, sensitive detection methods, and efficient energy dump mechanisms. End-users increasingly demand systems that minimize false positives while ensuring rapid response to genuine quench events.

Regional market assessment shows North America and Europe leading in adoption, primarily driven by research applications, while Asia-Pacific demonstrates the fastest growth rate due to increasing investments in transportation and energy infrastructure utilizing superconducting technology.

The market for REBCO quench protection systems faces certain constraints, including high implementation costs and technical complexity. However, these barriers are gradually diminishing as standardization efforts progress and economies of scale begin to take effect. Industry experts project that as REBCO technology matures and becomes more widespread, the demand for sophisticated protection systems will continue to expand proportionally.

In the energy sector, superconducting magnetic energy storage systems and fault current limiters represent growing market segments requiring sophisticated quench protection. The transition toward renewable energy integration has accelerated the need for more efficient energy storage solutions, where protected REBCO superconductors offer substantial advantages over conventional technologies.

Healthcare applications, particularly in MRI and NMR systems, constitute another major market driver. The medical imaging market continues to expand globally, with advanced superconducting magnets requiring increasingly sophisticated protection mechanisms to safeguard expensive equipment and ensure patient safety. Hospitals and diagnostic centers are willing to invest in superior protection systems that minimize downtime and extend equipment lifespan.

The emerging market for superconducting applications in transportation, especially in magnetic levitation trains and electric aircraft propulsion systems, presents substantial growth opportunities. These applications demand highly reliable quench protection due to their critical safety requirements and the catastrophic consequences of protection failure.

Research facilities and large-scale scientific installations represent another significant market segment. Projects like fusion reactors, particle accelerators, and high-field research magnets require advanced quench protection systems capable of handling the extreme operating conditions of REBCO superconductors.

Market analysis reveals a growing preference for integrated protection solutions that combine rapid normal zone propagation enhancement, sensitive detection methods, and efficient energy dump mechanisms. End-users increasingly demand systems that minimize false positives while ensuring rapid response to genuine quench events.

Regional market assessment shows North America and Europe leading in adoption, primarily driven by research applications, while Asia-Pacific demonstrates the fastest growth rate due to increasing investments in transportation and energy infrastructure utilizing superconducting technology.

The market for REBCO quench protection systems faces certain constraints, including high implementation costs and technical complexity. However, these barriers are gradually diminishing as standardization efforts progress and economies of scale begin to take effect. Industry experts project that as REBCO technology matures and becomes more widespread, the demand for sophisticated protection systems will continue to expand proportionally.

Current Challenges in REBCO Quench Protection Systems

Despite significant advancements in REBCO (Rare-Earth Barium Copper Oxide) superconducting technology, quench protection remains one of the most critical challenges limiting its widespread application in high-field magnets. The fundamental issue stems from REBCO's extremely slow normal zone propagation velocity (NZPV), typically 10-100 times slower than traditional low-temperature superconductors like NbTi or Nb3Sn. This slow propagation makes quench detection exceptionally difficult as the normal zone remains highly localized.

Current detection systems struggle with the signal-to-noise ratio problem when monitoring REBCO magnets. Conventional voltage-based detection methods often fail to distinguish between actual quench signals and electromagnetic noise, leading to either missed quenches or false alarms. This challenge is particularly pronounced in large-scale applications where noise levels increase proportionally with system size.

The energy dump mechanism presents another significant hurdle. When a quench occurs, the stored magnetic energy must be safely dissipated to prevent thermal runaway and potential damage to the superconducting material. However, REBCO's low normal zone propagation means energy dissipation is concentrated in a small area, creating dangerous hot spots that can exceed 400K within milliseconds, well above the critical damage threshold of approximately 250K.

Current protection schemes often rely on external heaters to artificially expand the normal zone, but these add complexity, weight, and potential points of failure to the system. Additionally, the activation time of these heaters may not be fast enough to prevent localized damage in high-current density applications.

The integration of reliable sensors within REBCO tapes presents manufacturing challenges. Fiber optic temperature sensors offer promising alternatives to voltage-based detection but face implementation difficulties in the thin, layered structure of REBCO conductors without compromising their superconducting properties.

Another persistent challenge is the development of accurate predictive models for quench behavior in complex REBCO magnet geometries. Current simulation tools struggle to account for the anisotropic properties of REBCO and the influence of mechanical stresses on quench initiation and propagation.

The economic aspect cannot be overlooked, as sophisticated quench protection systems significantly increase the overall cost of REBCO-based applications. This cost factor becomes particularly prohibitive for large-scale implementations such as fusion reactors or medical MRI systems, where hundreds of meters of REBCO tape might be employed.

Current detection systems struggle with the signal-to-noise ratio problem when monitoring REBCO magnets. Conventional voltage-based detection methods often fail to distinguish between actual quench signals and electromagnetic noise, leading to either missed quenches or false alarms. This challenge is particularly pronounced in large-scale applications where noise levels increase proportionally with system size.

The energy dump mechanism presents another significant hurdle. When a quench occurs, the stored magnetic energy must be safely dissipated to prevent thermal runaway and potential damage to the superconducting material. However, REBCO's low normal zone propagation means energy dissipation is concentrated in a small area, creating dangerous hot spots that can exceed 400K within milliseconds, well above the critical damage threshold of approximately 250K.

Current protection schemes often rely on external heaters to artificially expand the normal zone, but these add complexity, weight, and potential points of failure to the system. Additionally, the activation time of these heaters may not be fast enough to prevent localized damage in high-current density applications.

The integration of reliable sensors within REBCO tapes presents manufacturing challenges. Fiber optic temperature sensors offer promising alternatives to voltage-based detection but face implementation difficulties in the thin, layered structure of REBCO conductors without compromising their superconducting properties.

Another persistent challenge is the development of accurate predictive models for quench behavior in complex REBCO magnet geometries. Current simulation tools struggle to account for the anisotropic properties of REBCO and the influence of mechanical stresses on quench initiation and propagation.

The economic aspect cannot be overlooked, as sophisticated quench protection systems significantly increase the overall cost of REBCO-based applications. This cost factor becomes particularly prohibitive for large-scale implementations such as fusion reactors or medical MRI systems, where hundreds of meters of REBCO tape might be employed.

Existing Quench Detection and Energy Dump Solutions

01 Quench detection systems for REBCO superconductors

Various methods and systems have been developed to detect quenches in REBCO superconductors. These include voltage-based detection, temperature monitoring, and optical fiber sensing technologies. Early detection is critical to prevent damage to the superconducting coils. Advanced detection systems incorporate multiple sensors and signal processing algorithms to distinguish between normal operating fluctuations and actual quench events, enabling faster response times and improved protection of the superconducting system.- Quench detection systems for REBCO superconductors: Various methods and systems for detecting quench events in REBCO superconductors have been developed. These include voltage-based detection, temperature monitoring, and optical fiber sensing technologies that can identify the early stages of a normal zone formation. Advanced detection systems incorporate real-time monitoring capabilities with high sensitivity to voltage fluctuations and temperature changes, allowing for rapid response to potential quench conditions before they can cause damage to the superconducting system.

- Normal zone propagation management in REBCO materials: The management of normal zone propagation in REBCO superconductors involves techniques to control how resistive regions spread through the material during a quench event. This includes engineered stabilization layers, specialized substrate materials, and geometric designs that influence heat and current distribution. By controlling the propagation velocity and direction of normal zones, these technologies help prevent localized hotspots and ensure more uniform distribution of thermal energy during quench events, reducing the risk of permanent damage to the superconducting elements.

- Energy dump and protection circuits for REBCO systems: Energy dump systems for REBCO superconductors provide controlled pathways to safely dissipate stored magnetic energy during quench events. These protection circuits include fast-acting switches, shunt resistors, and sophisticated control algorithms that can rapidly redirect current away from the superconducting coil. Some advanced systems incorporate superconducting fault current limiters and hybrid protection schemes that combine passive and active elements to achieve optimal protection while minimizing recovery time after a quench event.

- Thermal stabilization and cooling strategies for quench resilience: Thermal management is critical for quench protection in REBCO superconductors. Various cooling strategies have been developed, including advanced cryogenic systems, heat-conducting interfaces, and thermally conductive matrices that surround the superconducting material. These approaches enhance the thermal stability of REBCO systems by improving heat transfer away from potential hotspots, increasing the overall heat capacity of the system, and maintaining more uniform temperature distribution throughout the superconducting components during both normal operation and quench events.

- Structural and material innovations for enhanced quench tolerance: Material and structural innovations have been developed to enhance the quench tolerance of REBCO superconductors. These include novel rare earth element compositions, specialized buffer layers, and engineered microstructures that improve current sharing during normal zone formation. Advanced manufacturing techniques such as controlled defect introduction and lamination processes create REBCO conductors with improved mechanical stability under thermal stress. These innovations result in superconducting systems with higher critical current densities while maintaining robust performance during transient events that might otherwise trigger catastrophic quenches.

02 Normal zone propagation characteristics in REBCO tapes

The propagation of normal zones in REBCO superconductors has unique characteristics compared to conventional superconductors. REBCO materials typically exhibit slow normal zone propagation velocities, which presents challenges for quench protection. Research has focused on understanding the thermal and electromagnetic factors affecting propagation speed, including the effects of stabilizer materials, substrate properties, and operating conditions. Enhancing normal zone propagation velocity through material engineering and design optimization is crucial for improving the overall safety of REBCO-based systems.Expand Specific Solutions03 Energy dump and discharge systems for quench protection

Energy dump systems are essential components of quench protection strategies for REBCO superconductors. When a quench is detected, these systems rapidly extract and safely dissipate the stored magnetic energy to prevent damage. Various circuit configurations have been developed, including external dump resistors, active crowbar systems, and capacitive discharge networks. The design of energy dump systems must consider the high inductance of superconducting magnets and the need for fast response times to effectively protect the REBCO coils during quench events.Expand Specific Solutions04 Thermal stabilization and cooling strategies

Thermal management is critical for quench protection in REBCO superconductors. Various cooling strategies have been developed, including conduction cooling, forced flow cooling, and hybrid approaches. The integration of high thermal conductivity materials and optimized cooling channels helps to dissipate heat during normal operation and quench events. Advanced cryogenic systems with rapid response capabilities can prevent the spread of normal zones by maintaining temperature stability. Proper thermal design also includes consideration of thermal interfaces and heat transfer mechanisms specific to REBCO tape architectures.Expand Specific Solutions05 Integrated protection systems and control strategies

Comprehensive protection of REBCO superconductors requires integrated systems that combine detection, analysis, and response functions. These systems incorporate redundant sensors, real-time monitoring, and automated protection sequences. Advanced control algorithms can predict potential quench conditions based on operating parameters and take preventive actions. Protection strategies may include active current sharing, partial energy extraction, and coordinated multi-stage responses. The integration of machine learning techniques has also improved the reliability and speed of quench protection systems for REBCO-based applications.Expand Specific Solutions

Leading Research Institutions and Manufacturers in REBCO Technology

The REBCO quench protection technology market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global superconductor market, valued at approximately $7 billion, is expected to grow significantly as REBCO materials gain traction in energy, transportation, and medical sectors. From a technical maturity perspective, the field is transitioning from research to practical implementation, with academic institutions like MIT, Central South University, and University of Houston leading fundamental research, while companies such as Siemens, Mitsubishi Heavy Industries, and State Grid Corporation of China are developing commercial applications. The collaboration between research institutions and industrial players indicates the technology is approaching commercial viability, though challenges in quench detection speed and energy dissipation remain significant barriers to widespread adoption.

University of Houston

Technical Solution: The University of Houston has developed a comprehensive REBCO quench protection framework centered on their patented "multi-scale detection architecture." This system integrates both microscale and macroscale sensors to monitor REBCO superconductors across different dimensional scales. Their approach addresses the fundamental challenge of slow normal zone propagation in REBCO materials (typically 1-10 cm/s compared to 10-100 m/s in traditional LTS materials) by implementing a distributed sensing network that can detect localized temperature rises before they propagate extensively. The university's research has yielded a hybrid protection system that combines passive and active elements - using both traditional voltage taps and advanced optical fiber sensors with Rayleigh backscattering technology to achieve sub-centimeter spatial resolution. For energy dump mechanisms, they've developed a coordinated discharge system that can handle the high stored energy densities of REBCO magnets (often exceeding 40 kJ/kg) while maintaining temperature gradients below critical thresholds.

Strengths: Exceptional spatial resolution in quench detection; integrated multi-scale approach addressing both local and global monitoring needs; proven effectiveness in high-field applications above 20T. Weaknesses: System complexity requires specialized expertise for implementation and maintenance; higher computational demands for real-time data processing; relatively higher cost compared to conventional protection systems.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced REBCO quench protection systems focusing on early detection and rapid response mechanisms. Their approach combines distributed temperature sensing (DTS) with fiber optic technology to monitor temperature profiles across REBCO tapes with millisecond response times. MIT's research has demonstrated that normal zone propagation (NZP) velocities in REBCO are significantly slower than in LTS materials (typically 10-100 times slower), necessitating novel detection methods. Their system employs a multi-sensor network that can detect temperature rises as small as 5K above operating temperature, triggering protection circuits before irreversible damage occurs. MIT has also pioneered active quench protection systems that introduce localized heating to accelerate normal zone propagation when a quench is detected, effectively distributing the energy across larger areas to prevent hotspot formation. Their energy dump systems utilize advanced switching technology capable of diverting current within microseconds of quench detection.

Strengths: Superior early detection capabilities through fiber optic sensing networks; innovative active quench propagation techniques; comprehensive system integration with both detection and response mechanisms. Weaknesses: Complex implementation requiring specialized equipment; higher initial cost compared to conventional systems; requires precise calibration for specific REBCO configurations.

Critical Patents and Research on Normal Zone Propagation

Superconductor quench measuring system

PatentInactiveEP0499429A3

Innovation

- A sensor system composed of superconducting wire with a dielectric coating, acting as a transmission line in heat transfer communication with the coil, generates and receives echo pulses to detect impedance mismatches, allowing for precise location and severity assessment of quench zones with minimal dewar penetrations.

External means for detecting normal zones in superconducting magnets or coils

PatentInactiveUS4371943A

Innovation

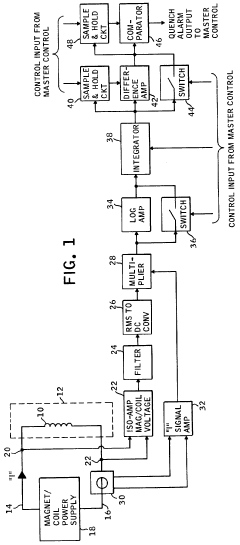

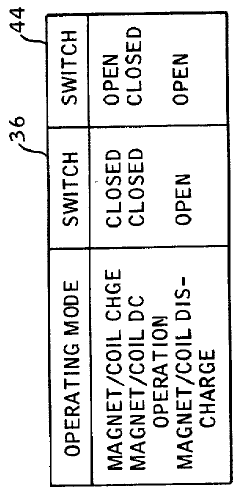

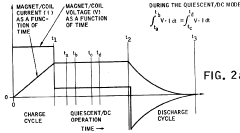

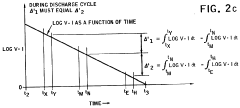

- Monitoring energy consumption per unit time by comparing values during charging, quiescent, and discharge phases using external quench detection circuitry, eliminating the need for internal components by measuring voltage and current from the power supply lines and processing these values to detect normal zone formation.

Cryogenic System Integration and Reliability Considerations

The integration of REBCO quench protection systems with cryogenic infrastructure presents unique challenges that significantly impact overall system reliability. Cryogenic systems for REBCO superconductors typically operate at temperatures between 4.2K and 77K, requiring sophisticated cooling mechanisms that must maintain stable temperature profiles even during quench events.

Reliable cryogenic integration demands careful consideration of thermal interfaces between the superconducting elements and cooling systems. Heat transfer efficiency at these interfaces directly affects normal zone propagation velocities, which are notably slower in REBCO compared to traditional low-temperature superconductors. This slower propagation necessitates cryogenic systems capable of rapid response to localized temperature increases while maintaining stability across the remainder of the system.

Cryogenic reliability considerations must address both steady-state operation and transient conditions during quench events. Cooling system redundancy becomes critical, as failure of cryogenic components could trigger widespread quenching. Modern designs increasingly incorporate parallel cooling paths and backup systems to prevent cascading failures that might otherwise lead to catastrophic energy dumps.

Temperature stability across REBCO components presents another significant challenge. Non-uniform cooling can create thermal gradients that affect quench detection sensitivity and normal zone propagation patterns. Advanced cryogenic systems now employ distributed cooling architectures with multiple temperature sensors to ensure uniform thermal conditions and enable more precise quench detection algorithms.

Helium consumption optimization represents a major operational consideration for REBCO systems. During quench events, significant helium boil-off can occur, requiring sophisticated recovery systems to minimize operational costs. Recent innovations include closed-loop helium recovery systems that can recapture up to 95% of helium during normal operation and 80% during quench events.

Maintenance protocols for integrated cryogenic-quench protection systems must address both scheduled service intervals and emergency scenarios. Accessibility of critical components while maintaining cryogenic conditions presents unique engineering challenges. Modern designs increasingly feature modular cryogenic components that can be isolated and serviced without warming the entire system, significantly reducing downtime after protection system activation.

Long-term reliability testing indicates that thermal cycling between room temperature and operating conditions represents one of the greatest stresses on integrated REBCO-cryogenic systems. Protection systems must therefore account for material fatigue and thermal expansion differences across thousands of cycles throughout the operational lifetime.

Reliable cryogenic integration demands careful consideration of thermal interfaces between the superconducting elements and cooling systems. Heat transfer efficiency at these interfaces directly affects normal zone propagation velocities, which are notably slower in REBCO compared to traditional low-temperature superconductors. This slower propagation necessitates cryogenic systems capable of rapid response to localized temperature increases while maintaining stability across the remainder of the system.

Cryogenic reliability considerations must address both steady-state operation and transient conditions during quench events. Cooling system redundancy becomes critical, as failure of cryogenic components could trigger widespread quenching. Modern designs increasingly incorporate parallel cooling paths and backup systems to prevent cascading failures that might otherwise lead to catastrophic energy dumps.

Temperature stability across REBCO components presents another significant challenge. Non-uniform cooling can create thermal gradients that affect quench detection sensitivity and normal zone propagation patterns. Advanced cryogenic systems now employ distributed cooling architectures with multiple temperature sensors to ensure uniform thermal conditions and enable more precise quench detection algorithms.

Helium consumption optimization represents a major operational consideration for REBCO systems. During quench events, significant helium boil-off can occur, requiring sophisticated recovery systems to minimize operational costs. Recent innovations include closed-loop helium recovery systems that can recapture up to 95% of helium during normal operation and 80% during quench events.

Maintenance protocols for integrated cryogenic-quench protection systems must address both scheduled service intervals and emergency scenarios. Accessibility of critical components while maintaining cryogenic conditions presents unique engineering challenges. Modern designs increasingly feature modular cryogenic components that can be isolated and serviced without warming the entire system, significantly reducing downtime after protection system activation.

Long-term reliability testing indicates that thermal cycling between room temperature and operating conditions represents one of the greatest stresses on integrated REBCO-cryogenic systems. Protection systems must therefore account for material fatigue and thermal expansion differences across thousands of cycles throughout the operational lifetime.

Safety Standards and Risk Assessment for Superconducting Applications

The safety landscape for superconducting applications, particularly those utilizing REBCO technology, has evolved significantly in response to the unique challenges posed by quench events. International standards such as IEC 61788 and IEEE 11-2019 provide comprehensive frameworks for safety requirements in superconducting systems, with specific provisions addressing quench protection mechanisms. These standards emphasize the critical importance of early detection systems and rapid energy dissipation protocols to prevent catastrophic damage.

Risk assessment methodologies for REBCO-based systems must account for the material's distinctive properties, including its relatively slow normal zone propagation velocity compared to traditional low-temperature superconductors. Failure Mode and Effects Analysis (FMEA) specifically tailored to REBCO applications has identified quench events as high-priority risks requiring multilayered protection strategies. The potential consequences of unmitigated quenches range from localized material degradation to complete system failure and safety hazards.

Insurance and regulatory bodies increasingly require quantitative risk assessments that demonstrate adequate quench protection measures before certifying superconducting installations. These assessments typically mandate redundant detection systems capable of identifying normal zones at their earliest formation stages, coupled with energy dump mechanisms that can safely dissipate stored magnetic energy within milliseconds of detection.

The safety threshold parameters for REBCO systems differ significantly from those established for LTS materials, necessitating revised safety margins. Current industry guidelines recommend maximum temperature rises during quench events be limited to 200K for REBCO tapes, with voltage detection thresholds set at significantly lower levels than traditional superconductors due to the slower propagation characteristics.

Recent developments in safety protocols have introduced the concept of "graceful degradation" for REBCO systems, where protection systems are designed to ensure that even in worst-case scenarios, failures occur in predictable, manageable ways that minimize risk to personnel and equipment. This approach has been incorporated into the latest iterations of safety standards, reflecting the industry's growing understanding of REBCO-specific quench behavior.

Compliance verification procedures for REBCO quench protection systems now typically include simulation-based validation followed by scaled testing under controlled conditions, with particular emphasis on verifying detection sensitivity and energy dump efficiency across various operating scenarios and potential failure modes.

Risk assessment methodologies for REBCO-based systems must account for the material's distinctive properties, including its relatively slow normal zone propagation velocity compared to traditional low-temperature superconductors. Failure Mode and Effects Analysis (FMEA) specifically tailored to REBCO applications has identified quench events as high-priority risks requiring multilayered protection strategies. The potential consequences of unmitigated quenches range from localized material degradation to complete system failure and safety hazards.

Insurance and regulatory bodies increasingly require quantitative risk assessments that demonstrate adequate quench protection measures before certifying superconducting installations. These assessments typically mandate redundant detection systems capable of identifying normal zones at their earliest formation stages, coupled with energy dump mechanisms that can safely dissipate stored magnetic energy within milliseconds of detection.

The safety threshold parameters for REBCO systems differ significantly from those established for LTS materials, necessitating revised safety margins. Current industry guidelines recommend maximum temperature rises during quench events be limited to 200K for REBCO tapes, with voltage detection thresholds set at significantly lower levels than traditional superconductors due to the slower propagation characteristics.

Recent developments in safety protocols have introduced the concept of "graceful degradation" for REBCO systems, where protection systems are designed to ensure that even in worst-case scenarios, failures occur in predictable, manageable ways that minimize risk to personnel and equipment. This approach has been incorporated into the latest iterations of safety standards, reflecting the industry's growing understanding of REBCO-specific quench behavior.

Compliance verification procedures for REBCO quench protection systems now typically include simulation-based validation followed by scaled testing under controlled conditions, with particular emphasis on verifying detection sensitivity and energy dump efficiency across various operating scenarios and potential failure modes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!