How REBCO Minimizes AC Loss In Rotating Machinery And SMES?

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

REBCO Superconductor Background and Objectives

REBCO (Rare Earth Barium Copper Oxide) superconductors represent a significant advancement in high-temperature superconducting (HTS) materials, offering critical advantages for power applications. Since their discovery in the late 1980s, these materials have evolved from laboratory curiosities to commercially viable components in advanced electrical systems. The technological trajectory of REBCO has been marked by continuous improvements in manufacturing processes, resulting in enhanced current-carrying capacity and mechanical properties.

The development of REBCO superconductors has been driven by their exceptional performance characteristics, including the ability to operate at relatively high temperatures (77K) compared to conventional low-temperature superconductors. This property significantly reduces cooling requirements, making REBCO-based systems more economically viable for practical applications. Furthermore, REBCO materials exhibit remarkable current density capabilities and strong magnetic field tolerance, positioning them as ideal candidates for high-performance electrical machinery and energy storage systems.

In rotating machinery applications, REBCO superconductors enable the design of more compact, lightweight, and efficient motors and generators. These benefits are particularly valuable in sectors such as transportation, renewable energy generation, and industrial manufacturing, where power density and efficiency are paramount considerations. Similarly, in Superconducting Magnetic Energy Storage (SMES) systems, REBCO materials facilitate higher energy storage densities and reduced system footprints compared to conventional technologies.

However, a significant challenge in deploying REBCO superconductors in AC applications is minimizing AC losses. These losses, which manifest as heat generation within the superconducting material when exposed to time-varying currents or magnetic fields, can compromise system efficiency and necessitate additional cooling capacity. The technical objective of this research is to comprehensively understand the mechanisms of AC loss in REBCO superconductors and explore innovative approaches to mitigate these losses in rotating machinery and SMES applications.

The investigation aims to evaluate various strategies for AC loss reduction, including advanced conductor architectures, novel winding configurations, and optimized electromagnetic designs. By addressing this critical technical challenge, we seek to unlock the full potential of REBCO superconductors in next-generation power systems, enabling higher efficiency, greater power density, and improved reliability. This research aligns with broader industry trends toward electrification, decarbonization, and energy efficiency across multiple sectors.

The development of REBCO superconductors has been driven by their exceptional performance characteristics, including the ability to operate at relatively high temperatures (77K) compared to conventional low-temperature superconductors. This property significantly reduces cooling requirements, making REBCO-based systems more economically viable for practical applications. Furthermore, REBCO materials exhibit remarkable current density capabilities and strong magnetic field tolerance, positioning them as ideal candidates for high-performance electrical machinery and energy storage systems.

In rotating machinery applications, REBCO superconductors enable the design of more compact, lightweight, and efficient motors and generators. These benefits are particularly valuable in sectors such as transportation, renewable energy generation, and industrial manufacturing, where power density and efficiency are paramount considerations. Similarly, in Superconducting Magnetic Energy Storage (SMES) systems, REBCO materials facilitate higher energy storage densities and reduced system footprints compared to conventional technologies.

However, a significant challenge in deploying REBCO superconductors in AC applications is minimizing AC losses. These losses, which manifest as heat generation within the superconducting material when exposed to time-varying currents or magnetic fields, can compromise system efficiency and necessitate additional cooling capacity. The technical objective of this research is to comprehensively understand the mechanisms of AC loss in REBCO superconductors and explore innovative approaches to mitigate these losses in rotating machinery and SMES applications.

The investigation aims to evaluate various strategies for AC loss reduction, including advanced conductor architectures, novel winding configurations, and optimized electromagnetic designs. By addressing this critical technical challenge, we seek to unlock the full potential of REBCO superconductors in next-generation power systems, enabling higher efficiency, greater power density, and improved reliability. This research aligns with broader industry trends toward electrification, decarbonization, and energy efficiency across multiple sectors.

Market Analysis for Low-AC-Loss Superconducting Applications

The global market for low-AC-loss superconducting applications is experiencing significant growth, driven by increasing demand for efficient energy storage and power transmission systems. The superconducting materials market, valued at approximately $1.2 billion in 2022, is projected to reach $3.4 billion by 2030, with REBCO (Rare-Earth Barium Copper Oxide) superconductors representing a rapidly expanding segment due to their superior performance in minimizing AC losses.

The energy storage sector presents a particularly promising market for REBCO technology. Superconducting Magnetic Energy Storage (SMES) systems offer advantages of rapid response times, high efficiency, and unlimited charge-discharge cycles compared to conventional energy storage technologies. The global SMES market is expected to grow at a CAGR of 7.8% through 2028, with applications in grid stabilization and renewable energy integration driving adoption.

In rotating machinery applications, the market for superconducting motors and generators is gaining momentum in sectors requiring high power density and efficiency. The marine propulsion market represents a key opportunity, with superconducting motors offering significant space and weight savings compared to conventional systems. Additionally, the wind energy sector is exploring large-scale superconducting generators to reduce nacelle weight and increase reliability for offshore installations.

Regional analysis reveals Asia-Pacific as the fastest-growing market for low-AC-loss superconducting applications, with China, Japan, and South Korea making substantial investments in superconductivity research and commercialization. North America and Europe maintain strong positions through established research institutions and industrial partnerships focused on practical applications of REBCO technology.

Market barriers include high manufacturing costs of REBCO tapes, with current prices ranging from $100-300 per meter depending on performance specifications. The complexity of cryogenic systems also presents challenges to widespread adoption, though advancements in cryocooler technology are gradually addressing these limitations.

Customer segments show distinct requirements: utility companies prioritize reliability and long-term cost benefits, while industrial users focus on space efficiency and performance advantages. The transportation sector, particularly aviation and maritime industries, represents an emerging market with interest in lightweight, high-power-density propulsion systems utilizing REBCO technology.

Market forecasts indicate that as manufacturing processes mature and economies of scale improve, REBCO-based systems will become increasingly competitive with conventional technologies. The market inflection point is anticipated around 2026-2027, when production costs are expected to decrease by approximately 40% from current levels, significantly expanding commercial viability across multiple sectors.

The energy storage sector presents a particularly promising market for REBCO technology. Superconducting Magnetic Energy Storage (SMES) systems offer advantages of rapid response times, high efficiency, and unlimited charge-discharge cycles compared to conventional energy storage technologies. The global SMES market is expected to grow at a CAGR of 7.8% through 2028, with applications in grid stabilization and renewable energy integration driving adoption.

In rotating machinery applications, the market for superconducting motors and generators is gaining momentum in sectors requiring high power density and efficiency. The marine propulsion market represents a key opportunity, with superconducting motors offering significant space and weight savings compared to conventional systems. Additionally, the wind energy sector is exploring large-scale superconducting generators to reduce nacelle weight and increase reliability for offshore installations.

Regional analysis reveals Asia-Pacific as the fastest-growing market for low-AC-loss superconducting applications, with China, Japan, and South Korea making substantial investments in superconductivity research and commercialization. North America and Europe maintain strong positions through established research institutions and industrial partnerships focused on practical applications of REBCO technology.

Market barriers include high manufacturing costs of REBCO tapes, with current prices ranging from $100-300 per meter depending on performance specifications. The complexity of cryogenic systems also presents challenges to widespread adoption, though advancements in cryocooler technology are gradually addressing these limitations.

Customer segments show distinct requirements: utility companies prioritize reliability and long-term cost benefits, while industrial users focus on space efficiency and performance advantages. The transportation sector, particularly aviation and maritime industries, represents an emerging market with interest in lightweight, high-power-density propulsion systems utilizing REBCO technology.

Market forecasts indicate that as manufacturing processes mature and economies of scale improve, REBCO-based systems will become increasingly competitive with conventional technologies. The market inflection point is anticipated around 2026-2027, when production costs are expected to decrease by approximately 40% from current levels, significantly expanding commercial viability across multiple sectors.

Current Challenges in REBCO AC Loss Reduction

Despite significant advancements in REBCO (Rare-Earth Barium Copper Oxide) superconductor technology, several critical challenges persist in minimizing AC losses for rotating machinery and Superconducting Magnetic Energy Storage (SMES) applications. The primary technical obstacle remains the inherent anisotropic nature of REBCO materials, which creates complex loss mechanisms under alternating current conditions.

The most pressing challenge is the persistent presence of hysteresis losses in REBCO tapes. These losses occur due to the penetration of magnetic flux into the superconductor and are particularly problematic in rotating machinery where magnetic field orientations constantly change. Current manufacturing processes have not fully resolved the microstructural defects that serve as flux pinning centers, contributing significantly to these losses.

Coupling losses between filaments represent another major hurdle. While filamentization techniques have been developed to reduce eddy currents, the effective electrical isolation between filaments remains insufficient. The metallic substrate and stabilizer layers in REBCO tapes create additional paths for coupling currents, especially at the frequencies typical in rotating machinery applications.

The geometric configuration of REBCO coils presents unique challenges for AC loss reduction. The aspect ratio and arrangement of REBCO tapes in coil structures significantly impact the overall AC loss profile. Current design methodologies struggle to optimize these geometric factors while maintaining mechanical stability and current-carrying capacity.

Temperature fluctuations during operation constitute another significant challenge. The temperature dependence of AC losses in REBCO materials is non-linear, making loss prediction and mitigation strategies complex. This is particularly problematic in SMES systems where rapid charge and discharge cycles can create localized heating.

Scaling issues present formidable barriers when transitioning from laboratory-scale demonstrations to industrial applications. The behavior of AC losses in large REBCO assemblies differs substantially from small-scale tests, with emergent phenomena that are difficult to model accurately. Current simulation tools lack the capability to precisely predict these scaling effects.

Manufacturing consistency remains a persistent challenge. Variations in REBCO tape quality between batches and even within the same production run lead to unpredictable AC loss characteristics. The industry has yet to establish standardized quality control metrics specifically targeting AC loss parameters.

Finally, the integration of REBCO components with conventional electrical systems introduces interface challenges. The impedance matching and protection systems required to manage AC losses at these interfaces add complexity and reduce overall system efficiency. Current solutions often involve compromises that limit the full potential of REBCO technology in rotating machinery and SMES applications.

The most pressing challenge is the persistent presence of hysteresis losses in REBCO tapes. These losses occur due to the penetration of magnetic flux into the superconductor and are particularly problematic in rotating machinery where magnetic field orientations constantly change. Current manufacturing processes have not fully resolved the microstructural defects that serve as flux pinning centers, contributing significantly to these losses.

Coupling losses between filaments represent another major hurdle. While filamentization techniques have been developed to reduce eddy currents, the effective electrical isolation between filaments remains insufficient. The metallic substrate and stabilizer layers in REBCO tapes create additional paths for coupling currents, especially at the frequencies typical in rotating machinery applications.

The geometric configuration of REBCO coils presents unique challenges for AC loss reduction. The aspect ratio and arrangement of REBCO tapes in coil structures significantly impact the overall AC loss profile. Current design methodologies struggle to optimize these geometric factors while maintaining mechanical stability and current-carrying capacity.

Temperature fluctuations during operation constitute another significant challenge. The temperature dependence of AC losses in REBCO materials is non-linear, making loss prediction and mitigation strategies complex. This is particularly problematic in SMES systems where rapid charge and discharge cycles can create localized heating.

Scaling issues present formidable barriers when transitioning from laboratory-scale demonstrations to industrial applications. The behavior of AC losses in large REBCO assemblies differs substantially from small-scale tests, with emergent phenomena that are difficult to model accurately. Current simulation tools lack the capability to precisely predict these scaling effects.

Manufacturing consistency remains a persistent challenge. Variations in REBCO tape quality between batches and even within the same production run lead to unpredictable AC loss characteristics. The industry has yet to establish standardized quality control metrics specifically targeting AC loss parameters.

Finally, the integration of REBCO components with conventional electrical systems introduces interface challenges. The impedance matching and protection systems required to manage AC losses at these interfaces add complexity and reduce overall system efficiency. Current solutions often involve compromises that limit the full potential of REBCO technology in rotating machinery and SMES applications.

Existing AC Loss Reduction Techniques for REBCO

01 AC loss reduction in REBCO superconductors through structural design

Various structural designs can be implemented to reduce AC losses in REBCO superconductors. These include using striated conductors, twisted filaments, and special geometric configurations that minimize eddy currents. By optimizing the physical arrangement of REBCO materials, the magnetic field penetration can be controlled, resulting in significantly reduced AC losses during operation. These design approaches are particularly important for high-frequency applications where AC losses become a critical performance factor.- AC loss reduction in REBCO superconductors: Various methods are employed to reduce AC losses in REBCO superconductors, which is crucial for their application in power systems. These methods include optimizing the geometry and structure of the superconductor, such as using striated or filamentary designs that break up the superconducting layer into narrower paths. This approach effectively reduces eddy currents and hysteresis losses that occur under alternating current conditions, improving overall energy efficiency in REBCO-based devices.

- REBCO tape fabrication techniques for loss minimization: Specialized fabrication techniques for REBCO tapes focus on creating structures that inherently minimize AC losses. These include methods for producing multi-filamentary REBCO conductors, laser scribing techniques to create controlled striations, and deposition processes that optimize the superconducting layer thickness and uniformity. Advanced manufacturing approaches also incorporate buffer layers and stabilizing materials that contribute to reduced coupling losses between superconducting filaments.

- Magnetic field effects on REBCO AC losses: The interaction between external magnetic fields and REBCO superconductors significantly impacts AC loss characteristics. Research focuses on understanding how field orientation, amplitude, and frequency affect loss mechanisms in these materials. Studies examine the relationship between applied magnetic fields and hysteresis losses, as well as methods to shield or compensate for field effects. This knowledge is essential for designing REBCO applications in environments with varying magnetic field conditions, such as in motors, generators, and transformers.

- Cryogenic cooling systems for REBCO applications: Efficient cryogenic cooling systems are critical for managing AC losses in REBCO superconductors, as these losses generate heat that must be removed to maintain superconducting properties. Advanced cooling technologies include closed-loop helium or nitrogen systems, pulse tube cryocoolers, and thermosiphon-based approaches. These cooling systems are designed to handle the specific thermal loads associated with AC losses while maintaining stable operating temperatures, which is essential for reliable performance of REBCO-based devices.

- REBCO coil and magnet designs for loss reduction: Specialized coil and magnet designs using REBCO materials focus on minimizing AC losses in high-field applications. These designs incorporate innovative winding techniques, such as no-insulation or partial-insulation approaches, that reduce coupling losses between turns. Other strategies include using graded coil structures, optimizing aspect ratios, and implementing novel joint techniques that minimize resistance at connections. These design approaches are particularly important for applications requiring high current capacity and strong magnetic fields, such as in fusion reactors, MRI systems, and particle accelerators.

02 Composition modifications to minimize AC losses in REBCO materials

The chemical composition of REBCO materials can be modified to reduce AC losses. By adjusting the rare earth elements, barium content, copper oxide ratios, or introducing dopants, the superconducting properties can be enhanced while minimizing losses. These compositional modifications affect the pinning centers, flux dynamics, and overall current-carrying capacity of the superconductor, leading to improved performance under alternating current conditions. Optimized compositions show better stability and reduced energy dissipation during AC operation.Expand Specific Solutions03 Coating and interface engineering for AC loss reduction

Specialized coatings and interface engineering techniques can significantly reduce AC losses in REBCO superconductors. By applying specific buffer layers, stabilizing materials, or protective coatings, the electromagnetic behavior of the superconductor can be optimized. These surface treatments help manage flux penetration, reduce surface resistance, and improve thermal stability. Interface engineering between REBCO layers and substrates also plays a crucial role in minimizing energy dissipation during alternating current cycles.Expand Specific Solutions04 Cryogenic and cooling systems for AC loss management

Advanced cryogenic and cooling systems are essential for managing AC losses in REBCO superconductors. Efficient cooling designs help dissipate the heat generated by AC losses, maintaining the superconductor below its critical temperature. These systems may incorporate liquid nitrogen, helium, or cryocoolers with optimized flow patterns. Thermal stabilization techniques and temperature gradient management are also implemented to prevent localized heating that could lead to quenching and further energy losses during AC operation.Expand Specific Solutions05 Manufacturing processes to control AC loss characteristics

Specialized manufacturing processes can be employed to control and reduce AC losses in REBCO superconductors. These include precise deposition techniques, controlled heat treatments, laser patterning for creating artificial pinning centers, and advanced annealing processes. The microstructural control achieved through these manufacturing methods directly impacts the AC loss behavior by optimizing grain boundaries, crystal orientation, and defect distribution. Process innovations focus on creating more homogeneous superconducting properties throughout the material to minimize localized loss mechanisms.Expand Specific Solutions

Leading Organizations in REBCO Superconductor Development

The REBCO AC loss minimization in rotating machinery and SMES market is currently in its growth phase, with increasing adoption driven by advancements in superconducting technologies. The global market size is expanding as energy efficiency demands rise, particularly in power applications. Technical maturity varies across players, with research institutions like North China Electric Power University, Shanghai University, and Hefei Institutes of Physical Science leading fundamental research, while commercial entities such as Siemens AG, Mitsubishi Electric, and Shanghai Creative Superconductor Technologies focus on practical applications. Chinese companies like Zhongtian Group and Jiangsu Zhongtian Technology are rapidly advancing in REBCO implementation, while established industrial players like Toshiba and ABB Alstom Power bring manufacturing expertise to scale these technologies for commercial deployment.

Institute of Electrical Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Electrical Engineering (IEE) at the Chinese Academy of Sciences has developed innovative REBCO-based solutions for minimizing AC losses in both rotating machinery and SMES applications. Their approach involves implementing a novel conductor architecture using REBCO tapes with striated structures. By dividing REBCO films into multiple filaments separated by resistive barriers, they effectively reduce eddy current paths. Their research demonstrates that filamentization through laser scribing can reduce AC losses by up to 70% compared to non-striated tapes. Additionally, IEE has pioneered the use of Roebel transposed conductors specifically designed for rotating machinery applications, where the transposition of REBCO tapes minimizes coupling losses between adjacent conductors. For SMES applications, they've developed pancake coils with optimized winding patterns that reduce the perpendicular magnetic field component, as perpendicular fields contribute significantly to AC losses in REBCO tapes. Their comprehensive approach also includes advanced cryogenic cooling systems that maintain operational stability while managing the heat generated from residual AC losses.

Strengths: Expertise in both filamentization techniques and transposed conductor designs provides comprehensive AC loss reduction. Their integrated approach addressing both material structure and coil geometry offers superior performance in real-world applications. Weaknesses: The laser scribing process for filamentization may introduce localized damage to superconducting properties, potentially reducing critical current capacity in some implementations.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a multi-faceted approach to minimize AC losses in REBCO applications for both rotating machinery and SMES systems. Their proprietary technology focuses on advanced conductor architecture utilizing artificially created pinning centers within the REBCO crystal structure to reduce flux movement during AC operation. For rotating machinery, they've implemented a segmented REBCO tape design with specialized metal alloy substrates that reduce eddy current paths while maintaining mechanical strength necessary for high-speed rotation. Their REBCO tapes feature precisely controlled thickness variations (typically 30-50μm) and incorporate nano-engineered buffer layers that optimize current distribution. In SMES applications, Mitsubishi employs a unique double-pancake coil configuration with optimized aspect ratios that minimize the perpendicular field component on the REBCO tapes. Their recent innovations include a hybrid winding technique that combines different tape widths and arrangements to create magnetic field profiles that inherently reduce AC losses by up to 40% compared to conventional designs. Additionally, they've developed advanced quench detection systems that prevent thermal runaway scenarios that could exacerbate AC losses during operational transients.

Strengths: Their integrated approach combining material science innovations with optimized coil geometries provides comprehensive AC loss reduction across different applications. Their manufacturing capabilities ensure consistent quality in large-scale production. Weaknesses: The complex tape architecture with specialized pinning centers increases production costs significantly compared to standard REBCO tapes, potentially limiting widespread adoption in cost-sensitive applications.

Critical Technologies for AC Loss Minimization in REBCO

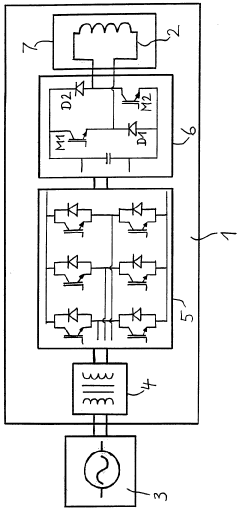

Device with a power electronics unit for low-temperature systems

PatentWO2000057530A1

Innovation

- The power electronics circuit is located in a low-temperature chamber, using high alternating voltage to transform energy to low voltage, reducing current intensities and employing low-static-loss power semiconductor components like MOSFETs, which allows for lower voltage handling in charging switches and reduced AC losses, thereby optimizing energy balance.

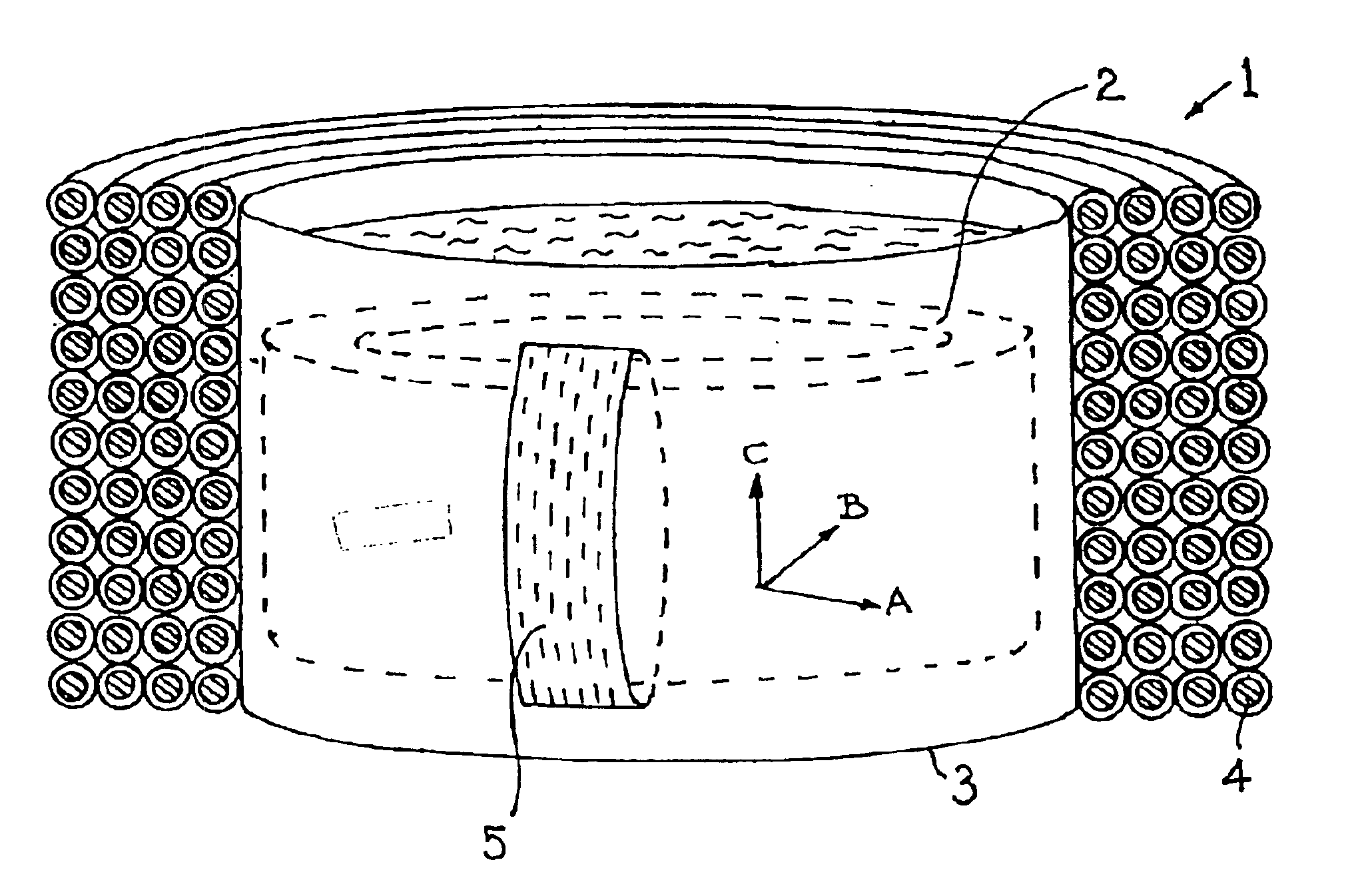

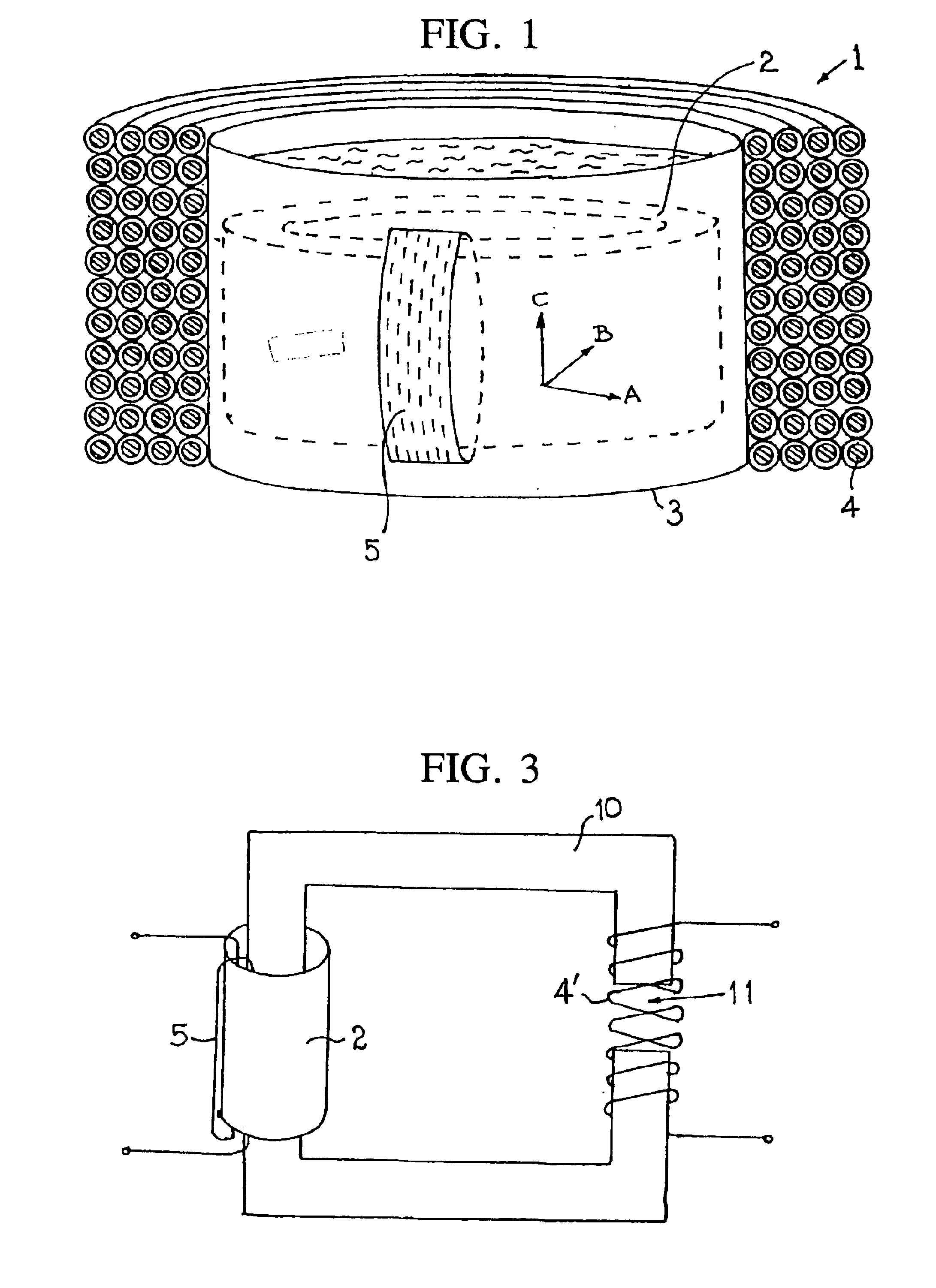

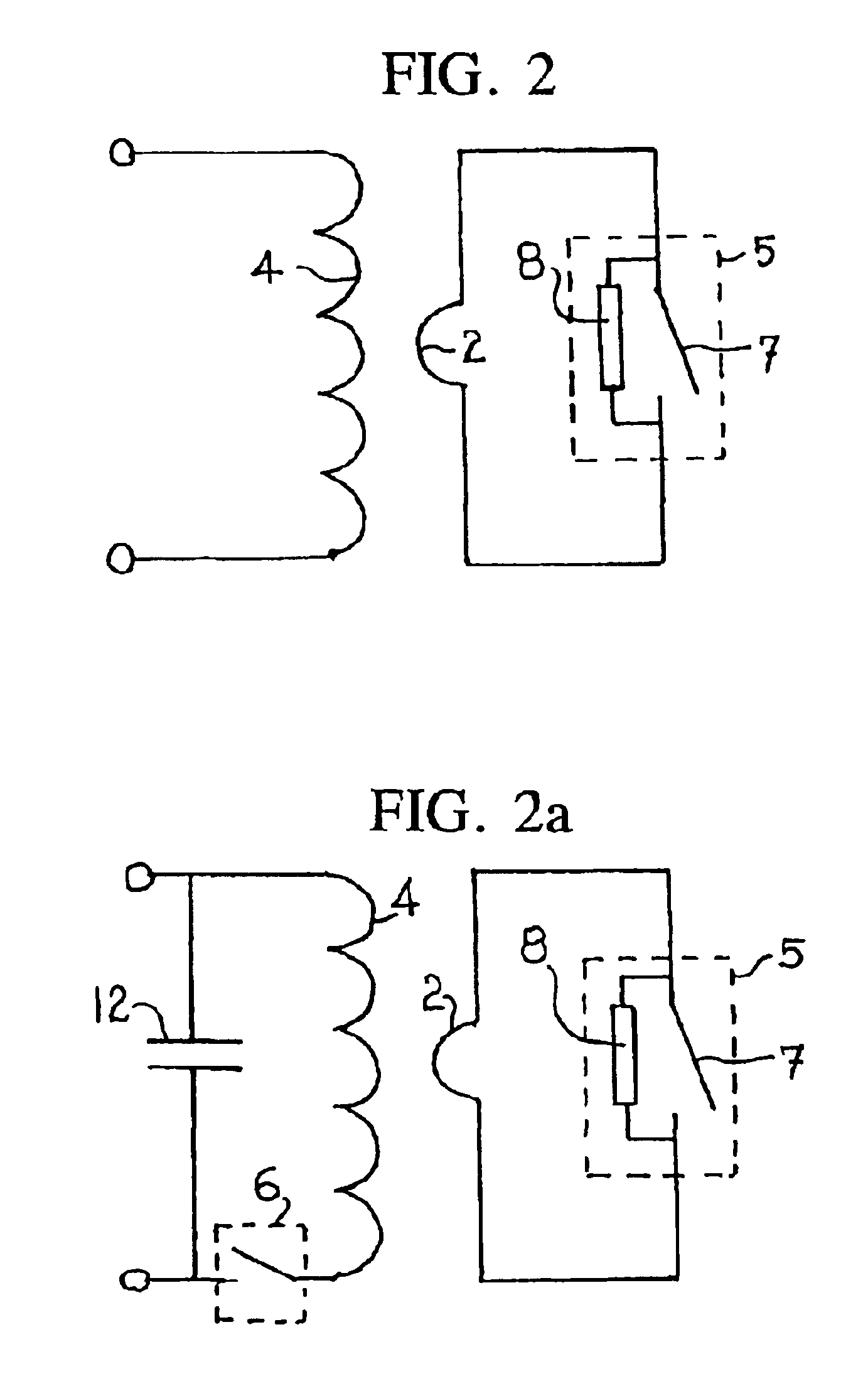

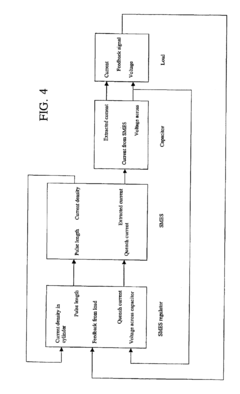

Magnetic energy storage device

PatentInactiveUS6897749B2

Innovation

- A SMES device with a closed-loop superconducting coil and a third coil for applying a magnetic field to switch between superconducting and non-superconducting states, allowing energy transfer without mechanical connections and minimizing heat leakage by using inductive coupling at elevated temperatures, eliminating the need for oscillating circuits and reducing resistive losses.

Cryogenic System Integration Considerations

The integration of cryogenic systems with REBCO-based rotating machinery and Superconducting Magnetic Energy Storage (SMES) systems presents unique challenges that must be addressed to ensure optimal performance and AC loss minimization. Effective cryogenic system design requires careful consideration of thermal management, mechanical interfaces, and operational stability across varying load conditions.

Temperature stability is paramount in REBCO applications, as fluctuations can significantly impact AC losses. Modern cryogenic systems for REBCO implementations typically operate in the 20-77K range, with precision temperature control systems maintaining variations within ±0.5K during operation. This stability is achieved through sophisticated feedback control mechanisms that continuously monitor and adjust cooling parameters based on real-time thermal load data.

Heat transfer efficiency between the REBCO components and the cryogenic medium represents another critical consideration. Advanced cooling techniques, including conduction cooling with high-purity metals and direct immersion in subcooled liquid nitrogen, have demonstrated superior performance in managing heat loads generated during AC operation. Recent developments in nanofluid-enhanced cryogens show promising results, with heat transfer coefficients improved by up to 30% compared to conventional cooling media.

Mechanical integration aspects must account for differential thermal contraction between room temperature and cryogenic operating conditions. Specialized flexible cryogenic couplings and thermally compensated mounting systems have been developed to accommodate these dimensional changes while maintaining precise alignment of rotating components. These systems typically incorporate low-thermal-conductivity materials at strategic interface points to minimize parasitic heat leaks.

Cryocooler selection and sizing must balance cooling capacity against power consumption and reliability requirements. For rotating machinery applications, Gifford-McMahon and pulse tube cryocoolers have emerged as preferred solutions due to their low vibration characteristics and maintenance intervals exceeding 20,000 hours. Hybrid cooling approaches, combining cryocoolers with liquid nitrogen precooling stages, offer optimized efficiency for varying load profiles typical in SMES applications.

Vacuum insulation systems surrounding REBCO components require careful design to minimize radiative heat transfer while accommodating necessary electrical and mechanical penetrations. Multi-layer insulation (MLI) configurations with 30-50 layers have demonstrated effective thermal isolation, reducing radiative heat loads to below 1 W/m² in properly designed systems. Vacuum maintenance strategies must also be considered, with modern systems incorporating getter materials to maintain high vacuum levels over extended operational periods.

Temperature stability is paramount in REBCO applications, as fluctuations can significantly impact AC losses. Modern cryogenic systems for REBCO implementations typically operate in the 20-77K range, with precision temperature control systems maintaining variations within ±0.5K during operation. This stability is achieved through sophisticated feedback control mechanisms that continuously monitor and adjust cooling parameters based on real-time thermal load data.

Heat transfer efficiency between the REBCO components and the cryogenic medium represents another critical consideration. Advanced cooling techniques, including conduction cooling with high-purity metals and direct immersion in subcooled liquid nitrogen, have demonstrated superior performance in managing heat loads generated during AC operation. Recent developments in nanofluid-enhanced cryogens show promising results, with heat transfer coefficients improved by up to 30% compared to conventional cooling media.

Mechanical integration aspects must account for differential thermal contraction between room temperature and cryogenic operating conditions. Specialized flexible cryogenic couplings and thermally compensated mounting systems have been developed to accommodate these dimensional changes while maintaining precise alignment of rotating components. These systems typically incorporate low-thermal-conductivity materials at strategic interface points to minimize parasitic heat leaks.

Cryocooler selection and sizing must balance cooling capacity against power consumption and reliability requirements. For rotating machinery applications, Gifford-McMahon and pulse tube cryocoolers have emerged as preferred solutions due to their low vibration characteristics and maintenance intervals exceeding 20,000 hours. Hybrid cooling approaches, combining cryocoolers with liquid nitrogen precooling stages, offer optimized efficiency for varying load profiles typical in SMES applications.

Vacuum insulation systems surrounding REBCO components require careful design to minimize radiative heat transfer while accommodating necessary electrical and mechanical penetrations. Multi-layer insulation (MLI) configurations with 30-50 layers have demonstrated effective thermal isolation, reducing radiative heat loads to below 1 W/m² in properly designed systems. Vacuum maintenance strategies must also be considered, with modern systems incorporating getter materials to maintain high vacuum levels over extended operational periods.

Economic Viability of REBCO in Commercial Applications

The economic viability of REBCO (Rare-Earth Barium Copper Oxide) superconductors in commercial applications represents a critical factor in determining their widespread adoption. While REBCO demonstrates superior technical performance in minimizing AC losses in rotating machinery and Superconducting Magnetic Energy Storage (SMES) systems, its commercial implementation faces significant economic hurdles.

Current manufacturing costs for REBCO tapes remain prohibitively high, ranging from $100-400 per meter depending on performance specifications and production volume. This represents a substantial premium compared to conventional copper conductors, creating a significant barrier to entry for many potential applications. However, production costs have decreased by approximately 60% over the past decade, suggesting a positive trajectory toward economic feasibility.

The total cost of ownership (TCO) analysis reveals more promising prospects. REBCO-based systems offer substantial operational savings through reduced energy losses, smaller footprint requirements, and higher power density. For SMES applications, REBCO enables energy storage efficiencies exceeding 95%, compared to 70-85% for conventional alternatives, translating to significant lifetime cost advantages despite higher initial investment.

In rotating machinery applications such as motors and generators, REBCO enables size and weight reductions of 40-60% while improving efficiency by 2-3 percentage points. For high-power industrial motors and generators (>5MW), these efficiency gains can offset the initial cost premium within 3-7 years of operation, depending on usage patterns and energy prices.

Market segmentation analysis indicates that early commercial viability will emerge in high-value applications where performance advantages outweigh cost considerations. These include military systems, medical imaging equipment, and specialized industrial applications where space and weight constraints are critical factors. The utility-scale energy storage market represents a secondary adoption phase, contingent upon further cost reductions.

Manufacturing scale economies present the most promising path to economic viability. Current REBCO production remains relatively small-scale, but industry projections suggest that a tenfold increase in production volume could reduce costs by 50-70%, potentially bringing REBCO into competitive range for broader commercial applications by 2030. Recent investments by major industrial players including Sumitomo Electric, SuperPower, and several Chinese manufacturers indicate growing confidence in this economic trajectory.

Current manufacturing costs for REBCO tapes remain prohibitively high, ranging from $100-400 per meter depending on performance specifications and production volume. This represents a substantial premium compared to conventional copper conductors, creating a significant barrier to entry for many potential applications. However, production costs have decreased by approximately 60% over the past decade, suggesting a positive trajectory toward economic feasibility.

The total cost of ownership (TCO) analysis reveals more promising prospects. REBCO-based systems offer substantial operational savings through reduced energy losses, smaller footprint requirements, and higher power density. For SMES applications, REBCO enables energy storage efficiencies exceeding 95%, compared to 70-85% for conventional alternatives, translating to significant lifetime cost advantages despite higher initial investment.

In rotating machinery applications such as motors and generators, REBCO enables size and weight reductions of 40-60% while improving efficiency by 2-3 percentage points. For high-power industrial motors and generators (>5MW), these efficiency gains can offset the initial cost premium within 3-7 years of operation, depending on usage patterns and energy prices.

Market segmentation analysis indicates that early commercial viability will emerge in high-value applications where performance advantages outweigh cost considerations. These include military systems, medical imaging equipment, and specialized industrial applications where space and weight constraints are critical factors. The utility-scale energy storage market represents a secondary adoption phase, contingent upon further cost reductions.

Manufacturing scale economies present the most promising path to economic viability. Current REBCO production remains relatively small-scale, but industry projections suggest that a tenfold increase in production volume could reduce costs by 50-70%, potentially bringing REBCO into competitive range for broader commercial applications by 2030. Recent investments by major industrial players including Sumitomo Electric, SuperPower, and several Chinese manufacturers indicate growing confidence in this economic trajectory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!