How Solenoid Valves Contribute to Wastewater Treatment Innovations

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Wastewater Treatment

The evolution of solenoid valves in wastewater treatment has been marked by significant technological advancements and innovations over the past few decades. Initially, solenoid valves were primarily used for basic on/off control in wastewater treatment systems, with limited functionality and reliability. However, as the demands for more efficient and precise water management grew, so did the capabilities of these valves.

In the early stages, solenoid valves faced challenges such as corrosion, clogging, and limited operational life in the harsh environments of wastewater treatment plants. This led to the development of more robust materials and designs, including the use of stainless steel bodies and corrosion-resistant coatings. The introduction of these improvements significantly extended the lifespan and reliability of solenoid valves in wastewater applications.

As automation became increasingly important in wastewater treatment processes, solenoid valves evolved to incorporate more sophisticated control mechanisms. The integration of electronic controls and sensors allowed for more precise regulation of water flow and pressure, enabling better management of treatment processes. This advancement was particularly crucial in optimizing the performance of membrane filtration systems and other critical treatment stages.

Another significant milestone in solenoid valve evolution was the development of energy-efficient designs. Early models were often power-hungry, leading to high operational costs. Newer generations of solenoid valves have been engineered to consume less energy while maintaining or even improving performance. This has not only reduced the carbon footprint of wastewater treatment facilities but also contributed to substantial cost savings in long-term operations.

The advent of smart technology has further revolutionized solenoid valves in wastewater treatment. Modern valves now often feature built-in diagnostics and communication capabilities, allowing for real-time monitoring and predictive maintenance. This has greatly enhanced the overall efficiency and reliability of wastewater treatment systems by minimizing downtime and optimizing maintenance schedules.

Recent innovations have also focused on improving the environmental impact of solenoid valves themselves. Manufacturers have been developing valves with eco-friendly materials and designs that minimize the use of harmful substances. Additionally, there has been a trend towards creating valves that can handle a wider range of wastewater compositions, including those with high solid content or aggressive chemicals, further expanding their applicability in diverse treatment scenarios.

Looking ahead, the evolution of solenoid valves in wastewater treatment is likely to continue with a focus on increased automation, improved energy efficiency, and enhanced integration with smart water management systems. As water scarcity becomes a growing global concern, the role of these valves in optimizing water usage and treatment processes is expected to become even more critical, driving further innovations in this field.

In the early stages, solenoid valves faced challenges such as corrosion, clogging, and limited operational life in the harsh environments of wastewater treatment plants. This led to the development of more robust materials and designs, including the use of stainless steel bodies and corrosion-resistant coatings. The introduction of these improvements significantly extended the lifespan and reliability of solenoid valves in wastewater applications.

As automation became increasingly important in wastewater treatment processes, solenoid valves evolved to incorporate more sophisticated control mechanisms. The integration of electronic controls and sensors allowed for more precise regulation of water flow and pressure, enabling better management of treatment processes. This advancement was particularly crucial in optimizing the performance of membrane filtration systems and other critical treatment stages.

Another significant milestone in solenoid valve evolution was the development of energy-efficient designs. Early models were often power-hungry, leading to high operational costs. Newer generations of solenoid valves have been engineered to consume less energy while maintaining or even improving performance. This has not only reduced the carbon footprint of wastewater treatment facilities but also contributed to substantial cost savings in long-term operations.

The advent of smart technology has further revolutionized solenoid valves in wastewater treatment. Modern valves now often feature built-in diagnostics and communication capabilities, allowing for real-time monitoring and predictive maintenance. This has greatly enhanced the overall efficiency and reliability of wastewater treatment systems by minimizing downtime and optimizing maintenance schedules.

Recent innovations have also focused on improving the environmental impact of solenoid valves themselves. Manufacturers have been developing valves with eco-friendly materials and designs that minimize the use of harmful substances. Additionally, there has been a trend towards creating valves that can handle a wider range of wastewater compositions, including those with high solid content or aggressive chemicals, further expanding their applicability in diverse treatment scenarios.

Looking ahead, the evolution of solenoid valves in wastewater treatment is likely to continue with a focus on increased automation, improved energy efficiency, and enhanced integration with smart water management systems. As water scarcity becomes a growing global concern, the role of these valves in optimizing water usage and treatment processes is expected to become even more critical, driving further innovations in this field.

Market Demand for Advanced Wastewater Solutions

The global wastewater treatment market is experiencing significant growth, driven by increasing urbanization, industrialization, and environmental concerns. Advanced wastewater solutions are in high demand as governments and industries seek to address water scarcity, pollution, and regulatory compliance. The market for innovative wastewater treatment technologies is expected to expand rapidly in the coming years, with a particular focus on energy-efficient and sustainable solutions.

Solenoid valves play a crucial role in this evolving landscape, contributing to the efficiency and effectiveness of wastewater treatment processes. These valves are essential components in controlling the flow of liquids and gases in treatment systems, offering precise and automated control over various stages of the treatment process. As a result, there is a growing demand for advanced solenoid valves that can withstand harsh environments, provide reliable operation, and integrate seamlessly with smart control systems.

The industrial sector, including chemical manufacturing, food and beverage processing, and pharmaceuticals, is a major driver of demand for advanced wastewater solutions. These industries require sophisticated treatment systems to meet stringent environmental regulations and reduce their water footprint. Solenoid valves are integral to these systems, enabling accurate dosing of chemicals, controlling backwash cycles, and managing the flow of wastewater through different treatment stages.

Municipal wastewater treatment plants are another significant market segment driving the demand for innovative solutions. As cities grow and water quality standards become more stringent, there is a pressing need to upgrade existing infrastructure and implement more efficient treatment technologies. Solenoid valves contribute to these advancements by enabling precise control of aeration systems, optimizing the distribution of wastewater across treatment tanks, and facilitating the implementation of advanced oxidation processes.

The agriculture sector is also emerging as a key market for advanced wastewater solutions, particularly in regions facing water scarcity. Solenoid valves are essential in irrigation systems that utilize treated wastewater, ensuring proper distribution and preventing contamination. Additionally, the growing adoption of decentralized wastewater treatment systems in rural and peri-urban areas is creating new opportunities for solenoid valve applications in small-scale treatment plants.

As the demand for water reuse and recycling grows, particularly in water-stressed regions, there is an increasing need for advanced treatment technologies that can produce high-quality reclaimed water. Solenoid valves are critical components in membrane filtration systems, reverse osmosis plants, and advanced oxidation processes, all of which are key technologies in producing water suitable for reuse in various applications.

Solenoid valves play a crucial role in this evolving landscape, contributing to the efficiency and effectiveness of wastewater treatment processes. These valves are essential components in controlling the flow of liquids and gases in treatment systems, offering precise and automated control over various stages of the treatment process. As a result, there is a growing demand for advanced solenoid valves that can withstand harsh environments, provide reliable operation, and integrate seamlessly with smart control systems.

The industrial sector, including chemical manufacturing, food and beverage processing, and pharmaceuticals, is a major driver of demand for advanced wastewater solutions. These industries require sophisticated treatment systems to meet stringent environmental regulations and reduce their water footprint. Solenoid valves are integral to these systems, enabling accurate dosing of chemicals, controlling backwash cycles, and managing the flow of wastewater through different treatment stages.

Municipal wastewater treatment plants are another significant market segment driving the demand for innovative solutions. As cities grow and water quality standards become more stringent, there is a pressing need to upgrade existing infrastructure and implement more efficient treatment technologies. Solenoid valves contribute to these advancements by enabling precise control of aeration systems, optimizing the distribution of wastewater across treatment tanks, and facilitating the implementation of advanced oxidation processes.

The agriculture sector is also emerging as a key market for advanced wastewater solutions, particularly in regions facing water scarcity. Solenoid valves are essential in irrigation systems that utilize treated wastewater, ensuring proper distribution and preventing contamination. Additionally, the growing adoption of decentralized wastewater treatment systems in rural and peri-urban areas is creating new opportunities for solenoid valve applications in small-scale treatment plants.

As the demand for water reuse and recycling grows, particularly in water-stressed regions, there is an increasing need for advanced treatment technologies that can produce high-quality reclaimed water. Solenoid valves are critical components in membrane filtration systems, reverse osmosis plants, and advanced oxidation processes, all of which are key technologies in producing water suitable for reuse in various applications.

Current Challenges in Solenoid Valve Applications

Despite the widespread use of solenoid valves in wastewater treatment systems, several challenges persist in their application, hindering optimal performance and efficiency. One of the primary issues is the susceptibility of solenoid valves to clogging and fouling in the harsh environment of wastewater treatment plants. The presence of suspended solids, debris, and chemical precipitates in wastewater can accumulate within the valve, leading to reduced flow rates, inconsistent operation, and potential system failures.

Corrosion resistance remains a significant challenge for solenoid valves in wastewater applications. The aggressive nature of wastewater, often containing corrosive chemicals and varying pH levels, can rapidly degrade valve components, particularly those made from less resistant materials. This corrosion not only shortens the lifespan of the valves but also compromises their reliability and precision in controlling fluid flow.

Energy efficiency is another area of concern in solenoid valve applications for wastewater treatment. Traditional solenoid valves often require continuous power to maintain their open or closed state, resulting in higher energy consumption and operational costs. This inefficiency becomes particularly pronounced in large-scale treatment facilities where numerous valves are in constant operation.

The need for precise flow control presents an ongoing challenge in solenoid valve design. Wastewater treatment processes often require fine-tuned adjustments to flow rates to optimize treatment efficiency. However, many standard solenoid valves offer limited control over flow rates, operating primarily in binary open or closed states. This limitation can lead to suboptimal process control and reduced treatment effectiveness.

Maintenance and reliability issues also pose significant challenges in solenoid valve applications. The frequent cycling of valves in wastewater treatment systems can lead to wear and tear, necessitating regular maintenance and replacement. The difficulty in accessing valves installed in complex piping systems or submerged environments further complicates maintenance procedures, potentially leading to extended downtime and increased operational costs.

Scalability and adaptability of solenoid valve systems present challenges in meeting the evolving demands of wastewater treatment facilities. As treatment plants expand or upgrade their processes, existing valve systems may struggle to accommodate increased flow rates or new treatment technologies. The integration of smart technologies and automation into traditional solenoid valve systems also poses compatibility and implementation challenges.

Addressing these challenges requires innovative approaches in valve design, material selection, and system integration. Developing solenoid valves with enhanced resistance to clogging, improved corrosion-resistant materials, and more efficient power consumption mechanisms are critical areas for advancement. Furthermore, the incorporation of smart technologies for predictive maintenance and precise flow control could significantly improve the performance and reliability of solenoid valves in wastewater treatment applications.

Corrosion resistance remains a significant challenge for solenoid valves in wastewater applications. The aggressive nature of wastewater, often containing corrosive chemicals and varying pH levels, can rapidly degrade valve components, particularly those made from less resistant materials. This corrosion not only shortens the lifespan of the valves but also compromises their reliability and precision in controlling fluid flow.

Energy efficiency is another area of concern in solenoid valve applications for wastewater treatment. Traditional solenoid valves often require continuous power to maintain their open or closed state, resulting in higher energy consumption and operational costs. This inefficiency becomes particularly pronounced in large-scale treatment facilities where numerous valves are in constant operation.

The need for precise flow control presents an ongoing challenge in solenoid valve design. Wastewater treatment processes often require fine-tuned adjustments to flow rates to optimize treatment efficiency. However, many standard solenoid valves offer limited control over flow rates, operating primarily in binary open or closed states. This limitation can lead to suboptimal process control and reduced treatment effectiveness.

Maintenance and reliability issues also pose significant challenges in solenoid valve applications. The frequent cycling of valves in wastewater treatment systems can lead to wear and tear, necessitating regular maintenance and replacement. The difficulty in accessing valves installed in complex piping systems or submerged environments further complicates maintenance procedures, potentially leading to extended downtime and increased operational costs.

Scalability and adaptability of solenoid valve systems present challenges in meeting the evolving demands of wastewater treatment facilities. As treatment plants expand or upgrade their processes, existing valve systems may struggle to accommodate increased flow rates or new treatment technologies. The integration of smart technologies and automation into traditional solenoid valve systems also poses compatibility and implementation challenges.

Addressing these challenges requires innovative approaches in valve design, material selection, and system integration. Developing solenoid valves with enhanced resistance to clogging, improved corrosion-resistant materials, and more efficient power consumption mechanisms are critical areas for advancement. Furthermore, the incorporation of smart technologies for predictive maintenance and precise flow control could significantly improve the performance and reliability of solenoid valves in wastewater treatment applications.

Innovative Solenoid Valve Designs for Wastewater

01 Solenoid valve design and structure

Solenoid valves are electromechanical devices that control the flow of fluids. They consist of a solenoid coil, plunger, and valve body. When energized, the coil creates a magnetic field that moves the plunger, opening or closing the valve. Various designs exist to optimize performance, including improvements in sealing, response time, and durability.- Design and structure of solenoid valves: Solenoid valves are designed with specific structures to control fluid flow. They typically consist of a coil, plunger, and valve body. The design may include features for improved performance, such as noise reduction, faster response times, or enhanced sealing capabilities. Various configurations are used for different applications, including direct-acting and pilot-operated valves.

- Control systems for solenoid valves: Control systems are crucial for the operation of solenoid valves. These systems may include electronic controllers, sensors, and feedback mechanisms to regulate valve operation. Advanced control systems can provide precise timing, variable flow control, and integration with larger automated systems. Some designs incorporate pulse-width modulation or other techniques for fine-tuned control.

- Applications of solenoid valves: Solenoid valves find applications in various industries and systems. They are used in automotive systems, industrial processes, irrigation systems, and household appliances. Specific applications include fuel injection systems, pneumatic control systems, water treatment plants, and HVAC systems. The versatility of solenoid valves makes them suitable for controlling the flow of liquids, gases, and slurries in different environments.

- Energy efficiency and power management: Improving energy efficiency is a key focus in solenoid valve design. This includes developing low-power consumption valves, implementing energy-saving modes, and optimizing the electromagnetic circuit. Some designs incorporate energy recovery systems or use alternative power sources. Power management strategies may involve intelligent control systems that adjust power consumption based on operational requirements.

- Maintenance and reliability of solenoid valves: Ensuring the reliability and ease of maintenance of solenoid valves is crucial for their long-term performance. Designs may incorporate features for easy disassembly, self-cleaning mechanisms, or wear-resistant materials. Some valves include diagnostic capabilities for predictive maintenance. Innovations in this area focus on extending valve lifespan, reducing downtime, and simplifying repair procedures.

02 Application in fuel injection systems

Solenoid valves play a crucial role in fuel injection systems for internal combustion engines. They control the precise timing and amount of fuel delivered to the engine, improving efficiency and reducing emissions. Advanced designs incorporate features like multiple injection events per cycle and high-speed operation.Expand Specific Solutions03 Integration with electronic control systems

Modern solenoid valves are often integrated with electronic control systems, allowing for precise and programmable operation. This integration enables features such as pulse-width modulation for fine control of fluid flow, diagnostics, and adaptive control based on various sensor inputs.Expand Specific Solutions04 Miniaturization and efficiency improvements

Ongoing research focuses on miniaturizing solenoid valves while improving their efficiency. This includes developing new materials for coils and plungers, optimizing magnetic circuit designs, and reducing power consumption. These advancements enable the use of solenoid valves in compact and portable applications.Expand Specific Solutions05 Specialized solenoid valves for harsh environments

Specialized solenoid valves are designed for operation in harsh environments, such as high-temperature, high-pressure, or corrosive conditions. These valves incorporate advanced sealing technologies, corrosion-resistant materials, and robust construction to ensure reliable operation in challenging industrial and automotive applications.Expand Specific Solutions

Key Players in Wastewater Treatment Industry

The wastewater treatment industry is experiencing significant innovations driven by solenoid valve technology. This sector is in a growth phase, with increasing market size due to rising environmental concerns and stringent regulations. The technology's maturity is advancing rapidly, with key players like Eaton Corp., RPE Srl, and Buschjost GmbH leading the way in solenoid valve applications for wastewater treatment. Companies such as Siemens Water Technologies Corp. and Baxter International, Inc. are integrating these valves into comprehensive water treatment solutions, demonstrating the technology's versatility and importance in the field. The competitive landscape is diverse, with both specialized valve manufacturers and larger conglomerates contributing to advancements in wastewater treatment efficiency and effectiveness.

Eaton Corp.

Technical Solution: Eaton Corporation has developed advanced solenoid valve solutions for wastewater treatment innovations. Their technology focuses on precision flow control and energy efficiency. Eaton's solenoid valves utilize a patented dual-stage design that allows for more accurate fluid regulation in treatment processes[1]. The valves incorporate smart sensors and actuators for real-time monitoring and adjustment of flow rates, pressure, and chemical dosing[3]. This enables optimized treatment performance and reduced energy consumption. Eaton has also implemented corrosion-resistant materials and coatings to enhance valve durability in harsh wastewater environments[5].

Strengths: Precise flow control, energy efficiency, smart monitoring capabilities. Weaknesses: Potentially higher initial cost, may require specialized maintenance.

Robert Bosch GmbH

Technical Solution: Bosch has innovated in solenoid valve technology for wastewater treatment through their Rexroth division. Their approach focuses on integrating solenoid valves into comprehensive automation systems for treatment plants. Bosch's valves feature high-speed switching capabilities, allowing for rapid adjustments in treatment processes[2]. They have developed specialized valve designs for handling aggressive media and particulate-laden wastewater[4]. Bosch's solenoid valves are also equipped with advanced diagnostics and predictive maintenance features, enhancing overall system reliability[6]. The company has invested in miniaturization techniques to create compact valve assemblies that reduce footprint in treatment facilities.

Strengths: Integrated automation solutions, robust design for harsh environments, advanced diagnostics. Weaknesses: May be complex to implement in existing systems, potentially higher cost for full integration.

Breakthrough Patents in Valve Technology

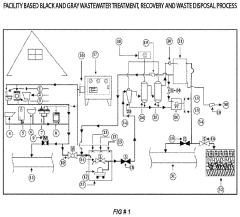

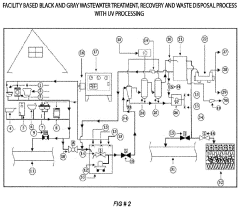

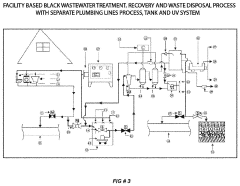

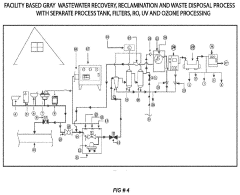

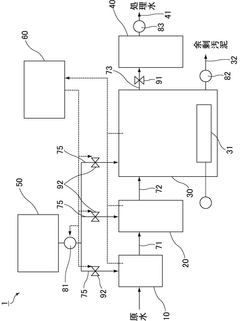

Facility-based wastewater treatment, reuse,waste disposal process.

PatentInactiveUS20220356090A1

Innovation

- A facility-based chemical neutralization system using modified toilets with motor-driven cutting blades, Hypochlorous Acid Chemical Producing Machines, and advanced filtration systems to treat and reuse domestic wastewater, reducing pathogens and energy consumption, and returning treated water to the soil for groundwater replenishment.

Wastewater treatment method and wastewater treatment apparatus

PatentWO2021132304A1

Innovation

- A method involving the culture of microorganisms that produce protein A in a surfactant-containing culture solution, which is then added to the wastewater treatment process to enhance organic matter decomposition and improve treatment efficiency, using a wastewater treatment device that includes a culture tank and supply means for adding the culture solution to the biological treatment tank.

Environmental Impact of Valve Innovations

The integration of innovative solenoid valve technologies in wastewater treatment processes has led to significant environmental benefits. These advancements have contributed to more efficient and sustainable water management practices, reducing the overall ecological footprint of treatment facilities.

One of the primary environmental impacts of valve innovations is the improvement in energy efficiency. Modern solenoid valves are designed to operate with minimal power consumption, resulting in reduced electricity usage across treatment plants. This energy conservation translates directly into lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

Water conservation is another crucial area where valve innovations have made a substantial impact. Precision control offered by advanced solenoid valves allows for more accurate regulation of water flow throughout the treatment process. This enhanced control minimizes water waste and enables the implementation of water recycling systems, effectively reducing the strain on freshwater resources.

The durability and longevity of modern valve materials have also contributed to waste reduction. Corrosion-resistant alloys and advanced polymers used in valve construction extend the operational lifespan of these components, reducing the frequency of replacements and associated material waste. This durability not only minimizes environmental impact but also reduces the need for maintenance-related chemical usage.

Improved chemical dosing accuracy, facilitated by precise valve control, has led to a reduction in the overall use of treatment chemicals. This decrease in chemical consumption not only lowers the environmental impact of chemical production and transportation but also minimizes the potential for harmful chemical residues in treated water discharged into natural water bodies.

The integration of smart valve technologies has enabled real-time monitoring and adjustment of treatment processes. This capability allows for rapid response to changing water quality conditions, preventing potential environmental incidents such as the release of undertreated water. The ability to fine-tune treatment processes also contributes to the overall efficiency of resource utilization within the facility.

Noise pollution, often an overlooked environmental concern in industrial settings, has been addressed through valve innovations. Modern solenoid valves are designed to operate more quietly, reducing the overall noise levels in treatment plants. This improvement not only enhances the working environment for plant operators but also minimizes disturbance to surrounding ecosystems, particularly in facilities located near sensitive habitats.

In conclusion, the environmental impact of valve innovations in wastewater treatment extends far beyond the immediate process improvements. These advancements contribute to a more sustainable and environmentally responsible approach to water management, aligning with global sustainability goals and setting new standards for eco-friendly industrial practices.

One of the primary environmental impacts of valve innovations is the improvement in energy efficiency. Modern solenoid valves are designed to operate with minimal power consumption, resulting in reduced electricity usage across treatment plants. This energy conservation translates directly into lower greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

Water conservation is another crucial area where valve innovations have made a substantial impact. Precision control offered by advanced solenoid valves allows for more accurate regulation of water flow throughout the treatment process. This enhanced control minimizes water waste and enables the implementation of water recycling systems, effectively reducing the strain on freshwater resources.

The durability and longevity of modern valve materials have also contributed to waste reduction. Corrosion-resistant alloys and advanced polymers used in valve construction extend the operational lifespan of these components, reducing the frequency of replacements and associated material waste. This durability not only minimizes environmental impact but also reduces the need for maintenance-related chemical usage.

Improved chemical dosing accuracy, facilitated by precise valve control, has led to a reduction in the overall use of treatment chemicals. This decrease in chemical consumption not only lowers the environmental impact of chemical production and transportation but also minimizes the potential for harmful chemical residues in treated water discharged into natural water bodies.

The integration of smart valve technologies has enabled real-time monitoring and adjustment of treatment processes. This capability allows for rapid response to changing water quality conditions, preventing potential environmental incidents such as the release of undertreated water. The ability to fine-tune treatment processes also contributes to the overall efficiency of resource utilization within the facility.

Noise pollution, often an overlooked environmental concern in industrial settings, has been addressed through valve innovations. Modern solenoid valves are designed to operate more quietly, reducing the overall noise levels in treatment plants. This improvement not only enhances the working environment for plant operators but also minimizes disturbance to surrounding ecosystems, particularly in facilities located near sensitive habitats.

In conclusion, the environmental impact of valve innovations in wastewater treatment extends far beyond the immediate process improvements. These advancements contribute to a more sustainable and environmentally responsible approach to water management, aligning with global sustainability goals and setting new standards for eco-friendly industrial practices.

Regulatory Framework for Water Treatment Technologies

The regulatory framework for water treatment technologies plays a crucial role in shaping the adoption and implementation of innovative solutions in wastewater treatment, including the use of solenoid valves. These regulations are designed to ensure the safety, efficiency, and environmental sustainability of water treatment processes.

At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) provide guidelines and standards for water quality and treatment. These serve as a foundation for many national and regional regulatory bodies to develop their own specific regulations.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing water treatment technologies. The Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA) form the cornerstone of the regulatory framework. These acts establish water quality standards, effluent limitations, and treatment requirements that wastewater treatment facilities must adhere to.

The European Union has implemented the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive (UWWTD), which set comprehensive standards for water quality and treatment across member states. These directives encourage the adoption of innovative technologies, including advanced control systems that often incorporate solenoid valves.

Many countries have established their own regulatory bodies and frameworks. For instance, in China, the Ministry of Ecology and Environment oversees water treatment regulations, while in Australia, the National Water Quality Management Strategy provides a framework for water quality protection.

Regulatory frameworks often include specific provisions for the use of equipment and components in water treatment systems. Solenoid valves, as critical components in many treatment processes, must meet certain standards for materials, durability, and performance. For example, regulations may require the use of corrosion-resistant materials or specify minimum cycle life for valves used in critical applications.

Furthermore, regulations increasingly focus on energy efficiency and sustainability in water treatment. This has led to the development of standards that encourage the use of smart control systems and energy-efficient components, including advanced solenoid valves that can optimize water and energy usage.

As wastewater treatment innovations continue to emerge, regulatory frameworks are evolving to keep pace. Many jurisdictions are adopting performance-based standards rather than prescriptive requirements, allowing for greater flexibility in the implementation of new technologies. This approach can facilitate the integration of innovative solutions, such as those utilizing solenoid valves for precise control and automation in treatment processes.

At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) provide guidelines and standards for water quality and treatment. These serve as a foundation for many national and regional regulatory bodies to develop their own specific regulations.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing water treatment technologies. The Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA) form the cornerstone of the regulatory framework. These acts establish water quality standards, effluent limitations, and treatment requirements that wastewater treatment facilities must adhere to.

The European Union has implemented the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive (UWWTD), which set comprehensive standards for water quality and treatment across member states. These directives encourage the adoption of innovative technologies, including advanced control systems that often incorporate solenoid valves.

Many countries have established their own regulatory bodies and frameworks. For instance, in China, the Ministry of Ecology and Environment oversees water treatment regulations, while in Australia, the National Water Quality Management Strategy provides a framework for water quality protection.

Regulatory frameworks often include specific provisions for the use of equipment and components in water treatment systems. Solenoid valves, as critical components in many treatment processes, must meet certain standards for materials, durability, and performance. For example, regulations may require the use of corrosion-resistant materials or specify minimum cycle life for valves used in critical applications.

Furthermore, regulations increasingly focus on energy efficiency and sustainability in water treatment. This has led to the development of standards that encourage the use of smart control systems and energy-efficient components, including advanced solenoid valves that can optimize water and energy usage.

As wastewater treatment innovations continue to emerge, regulatory frameworks are evolving to keep pace. Many jurisdictions are adopting performance-based standards rather than prescriptive requirements, allowing for greater flexibility in the implementation of new technologies. This approach can facilitate the integration of innovative solutions, such as those utilizing solenoid valves for precise control and automation in treatment processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!