How to Accelerate Innovations in LDPE Uses?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Innovation Landscape

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its discovery in 1933. This versatile material has found applications in numerous sectors, from packaging to construction, due to its unique properties such as flexibility, transparency, and moisture resistance. The LDPE innovation landscape has evolved significantly over the decades, driven by market demands, technological advancements, and environmental concerns.

In recent years, the focus of LDPE innovation has shifted towards sustainability and enhanced performance. Manufacturers are exploring bio-based alternatives to traditional petroleum-derived LDPE, aiming to reduce carbon footprint and dependence on fossil fuels. Simultaneously, efforts are being made to improve the recyclability of LDPE products, addressing the growing global concern over plastic waste.

The packaging industry remains the largest consumer of LDPE, continually pushing for innovations in film strength, barrier properties, and processability. Advanced multi-layer film technologies have emerged, allowing for thinner yet stronger packaging materials that maintain or even improve product protection while using less raw material.

In the agricultural sector, LDPE innovations are targeting improved crop yields and resource efficiency. Smart LDPE films with enhanced UV stability, temperature control properties, and even embedded sensors for monitoring soil conditions are being developed. These advancements promise to revolutionize greenhouse and mulch film applications.

The construction industry is another area where LDPE innovations are making significant strides. New formulations of LDPE are being engineered for improved insulation properties, moisture resistance, and durability in building materials. This includes developments in LDPE foams and composites that offer superior thermal and acoustic insulation.

Nanotechnology is playing an increasingly important role in LDPE innovation. The incorporation of nanoparticles into LDPE matrices is leading to enhanced mechanical properties, improved barrier characteristics, and even novel functionalities such as antimicrobial properties. This opens up new possibilities for LDPE in high-performance applications previously dominated by more expensive materials.

The automotive industry is also benefiting from LDPE innovations, particularly in lightweight components and fuel systems. Advanced LDPE composites are being developed to replace heavier materials, contributing to improved fuel efficiency and reduced emissions in vehicles.

As environmental regulations become more stringent, the LDPE innovation landscape is adapting to meet these challenges. Research into chemical recycling technologies for LDPE is gaining momentum, promising to close the loop on plastic waste and create a more circular economy for this ubiquitous material.

In recent years, the focus of LDPE innovation has shifted towards sustainability and enhanced performance. Manufacturers are exploring bio-based alternatives to traditional petroleum-derived LDPE, aiming to reduce carbon footprint and dependence on fossil fuels. Simultaneously, efforts are being made to improve the recyclability of LDPE products, addressing the growing global concern over plastic waste.

The packaging industry remains the largest consumer of LDPE, continually pushing for innovations in film strength, barrier properties, and processability. Advanced multi-layer film technologies have emerged, allowing for thinner yet stronger packaging materials that maintain or even improve product protection while using less raw material.

In the agricultural sector, LDPE innovations are targeting improved crop yields and resource efficiency. Smart LDPE films with enhanced UV stability, temperature control properties, and even embedded sensors for monitoring soil conditions are being developed. These advancements promise to revolutionize greenhouse and mulch film applications.

The construction industry is another area where LDPE innovations are making significant strides. New formulations of LDPE are being engineered for improved insulation properties, moisture resistance, and durability in building materials. This includes developments in LDPE foams and composites that offer superior thermal and acoustic insulation.

Nanotechnology is playing an increasingly important role in LDPE innovation. The incorporation of nanoparticles into LDPE matrices is leading to enhanced mechanical properties, improved barrier characteristics, and even novel functionalities such as antimicrobial properties. This opens up new possibilities for LDPE in high-performance applications previously dominated by more expensive materials.

The automotive industry is also benefiting from LDPE innovations, particularly in lightweight components and fuel systems. Advanced LDPE composites are being developed to replace heavier materials, contributing to improved fuel efficiency and reduced emissions in vehicles.

As environmental regulations become more stringent, the LDPE innovation landscape is adapting to meet these challenges. Research into chemical recycling technologies for LDPE is gaining momentum, promising to close the loop on plastic waste and create a more circular economy for this ubiquitous material.

Market Trends in LDPE Applications

The Low-Density Polyethylene (LDPE) market has been experiencing significant growth and transformation in recent years, driven by evolving consumer demands and technological advancements. The global LDPE market size was valued at approximately $33 billion in 2020 and is projected to reach $50 billion by 2027, growing at a CAGR of 5.8% during the forecast period.

One of the key trends shaping the LDPE market is the increasing demand for flexible packaging solutions across various industries, particularly in food and beverage, pharmaceuticals, and personal care sectors. LDPE's excellent moisture barrier properties, flexibility, and cost-effectiveness make it an ideal choice for packaging applications. The rise of e-commerce and the need for sustainable packaging solutions have further boosted the demand for LDPE in the packaging industry.

Another significant trend is the growing adoption of LDPE in the agriculture sector. LDPE films are widely used in greenhouse coverings, mulching, and silage wraps due to their durability and weather resistance. The increasing focus on precision agriculture and crop yield optimization has led to a surge in demand for LDPE-based agricultural films.

The construction industry is also driving the LDPE market growth, with applications in insulation, vapor barriers, and geomembranes. The booming construction activities in emerging economies and the emphasis on energy-efficient buildings have contributed to the increased use of LDPE in construction materials.

In recent years, there has been a notable shift towards sustainable and recyclable LDPE products. Manufacturers are investing in research and development to produce bio-based LDPE and improve recycling technologies. This trend is driven by stringent environmental regulations and growing consumer awareness about plastic waste.

The automotive industry is another sector where LDPE applications are gaining traction. LDPE is used in various automotive components, including wire and cable insulation, fuel tanks, and interior trims. The lightweight properties of LDPE contribute to fuel efficiency, making it an attractive material for automotive manufacturers striving to meet stringent emission standards.

Geographically, Asia-Pacific dominates the LDPE market, accounting for the largest share of global consumption. The rapid industrialization, urbanization, and population growth in countries like China and India are driving the demand for LDPE across various end-use industries. North America and Europe follow, with steady growth in LDPE applications, particularly in packaging and agriculture sectors.

One of the key trends shaping the LDPE market is the increasing demand for flexible packaging solutions across various industries, particularly in food and beverage, pharmaceuticals, and personal care sectors. LDPE's excellent moisture barrier properties, flexibility, and cost-effectiveness make it an ideal choice for packaging applications. The rise of e-commerce and the need for sustainable packaging solutions have further boosted the demand for LDPE in the packaging industry.

Another significant trend is the growing adoption of LDPE in the agriculture sector. LDPE films are widely used in greenhouse coverings, mulching, and silage wraps due to their durability and weather resistance. The increasing focus on precision agriculture and crop yield optimization has led to a surge in demand for LDPE-based agricultural films.

The construction industry is also driving the LDPE market growth, with applications in insulation, vapor barriers, and geomembranes. The booming construction activities in emerging economies and the emphasis on energy-efficient buildings have contributed to the increased use of LDPE in construction materials.

In recent years, there has been a notable shift towards sustainable and recyclable LDPE products. Manufacturers are investing in research and development to produce bio-based LDPE and improve recycling technologies. This trend is driven by stringent environmental regulations and growing consumer awareness about plastic waste.

The automotive industry is another sector where LDPE applications are gaining traction. LDPE is used in various automotive components, including wire and cable insulation, fuel tanks, and interior trims. The lightweight properties of LDPE contribute to fuel efficiency, making it an attractive material for automotive manufacturers striving to meet stringent emission standards.

Geographically, Asia-Pacific dominates the LDPE market, accounting for the largest share of global consumption. The rapid industrialization, urbanization, and population growth in countries like China and India are driving the demand for LDPE across various end-use industries. North America and Europe follow, with steady growth in LDPE applications, particularly in packaging and agriculture sectors.

Technical Hurdles in LDPE Development

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry for decades, but its development faces several technical hurdles that impede innovation and broader application. One of the primary challenges is improving the material's mechanical properties without compromising its desirable characteristics, such as flexibility and transparency.

The molecular structure of LDPE, characterized by long chains with numerous short branches, contributes to its unique properties but also limits its strength and stiffness. Enhancing these attributes without altering the fundamental structure that gives LDPE its advantageous qualities remains a significant technical obstacle. Researchers are exploring various methods, including the incorporation of nanofillers and the development of novel catalysts, to address this issue.

Another major hurdle is the improvement of LDPE's barrier properties. While LDPE is widely used in packaging applications, its relatively high permeability to gases and moisture limits its use in certain high-performance packaging scenarios. Developing LDPE formulations with enhanced barrier properties without significantly increasing production costs or compromising recyclability is a complex challenge that requires innovative approaches in polymer science.

The processing of LDPE also presents technical difficulties. Current manufacturing methods, while well-established, have limitations in terms of energy efficiency and production speed. Innovations in extrusion and molding technologies are needed to reduce energy consumption, increase throughput, and improve the overall quality of LDPE products. This includes developing more efficient cooling systems and exploring alternative processing techniques such as additive manufacturing for LDPE.

Recyclability and sustainability pose additional technical challenges. While LDPE is recyclable, the process is often hindered by contamination and the degradation of material properties after multiple recycling cycles. Developing more efficient sorting and cleaning technologies, as well as methods to maintain or restore the original properties of recycled LDPE, are crucial areas of research. Additionally, finding ways to incorporate bio-based or biodegradable components into LDPE without compromising its performance or recyclability is a complex but necessary endeavor.

Lastly, the development of specialized grades of LDPE for emerging applications presents its own set of technical hurdles. For instance, creating LDPE formulations suitable for 3D printing, conductive polymers for electronic applications, or materials with enhanced UV resistance for outdoor use requires overcoming specific technical challenges related to material properties and processing conditions.

The molecular structure of LDPE, characterized by long chains with numerous short branches, contributes to its unique properties but also limits its strength and stiffness. Enhancing these attributes without altering the fundamental structure that gives LDPE its advantageous qualities remains a significant technical obstacle. Researchers are exploring various methods, including the incorporation of nanofillers and the development of novel catalysts, to address this issue.

Another major hurdle is the improvement of LDPE's barrier properties. While LDPE is widely used in packaging applications, its relatively high permeability to gases and moisture limits its use in certain high-performance packaging scenarios. Developing LDPE formulations with enhanced barrier properties without significantly increasing production costs or compromising recyclability is a complex challenge that requires innovative approaches in polymer science.

The processing of LDPE also presents technical difficulties. Current manufacturing methods, while well-established, have limitations in terms of energy efficiency and production speed. Innovations in extrusion and molding technologies are needed to reduce energy consumption, increase throughput, and improve the overall quality of LDPE products. This includes developing more efficient cooling systems and exploring alternative processing techniques such as additive manufacturing for LDPE.

Recyclability and sustainability pose additional technical challenges. While LDPE is recyclable, the process is often hindered by contamination and the degradation of material properties after multiple recycling cycles. Developing more efficient sorting and cleaning technologies, as well as methods to maintain or restore the original properties of recycled LDPE, are crucial areas of research. Additionally, finding ways to incorporate bio-based or biodegradable components into LDPE without compromising its performance or recyclability is a complex but necessary endeavor.

Lastly, the development of specialized grades of LDPE for emerging applications presents its own set of technical hurdles. For instance, creating LDPE formulations suitable for 3D printing, conductive polymers for electronic applications, or materials with enhanced UV resistance for outdoor use requires overcoming specific technical challenges related to material properties and processing conditions.

Current LDPE Innovation Strategies

01 Composition and properties of LDPE

Low-Density Polyethylene (LDPE) is a thermoplastic polymer with a low density and high flexibility. It is characterized by its branched structure, which results in lower crystallinity and density compared to other polyethylene types. LDPE exhibits good chemical resistance, electrical insulation properties, and processability, making it suitable for various applications.- Composition and properties of LDPE: Low-Density Polyethylene (LDPE) is a thermoplastic polymer with a low density and high flexibility. It is characterized by its branched structure, which results in lower crystallinity and density compared to other polyethylene types. LDPE exhibits good chemical resistance, electrical insulation properties, and processability, making it suitable for various applications.

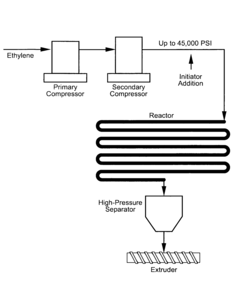

- Manufacturing processes for LDPE: LDPE is primarily produced through high-pressure polymerization of ethylene using free-radical initiators. Various manufacturing techniques have been developed to improve the production efficiency and control the properties of LDPE. These include modifications to reactor designs, catalyst systems, and process conditions to achieve desired molecular weight distributions and branching characteristics.

- Applications of LDPE in packaging: LDPE is widely used in the packaging industry due to its flexibility, transparency, and moisture resistance. It is commonly employed in the production of plastic bags, food packaging films, and shrink wraps. Recent developments focus on improving the barrier properties and sustainability of LDPE packaging materials, including the incorporation of additives and the development of recyclable or biodegradable variants.

- LDPE blends and composites: Research in LDPE technology includes the development of blends and composites to enhance its properties or create materials with unique characteristics. This involves combining LDPE with other polymers, fillers, or additives to improve mechanical strength, thermal stability, or introduce specific functionalities. Such developments expand the application range of LDPE-based materials in various industries.

- Recycling and sustainability of LDPE: With increasing environmental concerns, significant efforts are directed towards improving the recyclability and sustainability of LDPE products. This includes developing more efficient recycling processes, designing easily recyclable LDPE products, and exploring bio-based alternatives. Research also focuses on reducing the environmental impact of LDPE production and enhancing its biodegradability without compromising performance.

02 Manufacturing processes for LDPE

LDPE is typically produced through high-pressure polymerization of ethylene using free-radical initiators. Various manufacturing techniques have been developed to improve the production efficiency and control the properties of LDPE. These processes may involve different reactor designs, catalysts, and process conditions to achieve desired molecular weight distributions and branching characteristics.Expand Specific Solutions03 Applications of LDPE

LDPE finds widespread use in numerous applications due to its unique properties. It is commonly used in packaging materials, such as plastic bags, films, and containers. LDPE is also utilized in the production of wire and cable insulation, toys, and various household items. Its flexibility and chemical resistance make it suitable for agricultural applications and as a component in composite materials.Expand Specific Solutions04 Modifications and blends of LDPE

To enhance the performance of LDPE, various modifications and blending techniques have been developed. These include the incorporation of additives, crosslinking, and blending with other polymers. Such modifications can improve properties like strength, barrier characteristics, and heat resistance, expanding the range of applications for LDPE-based materials.Expand Specific Solutions05 Recycling and sustainability of LDPE

As environmental concerns grow, there is an increasing focus on the recycling and sustainability of LDPE products. Research efforts are directed towards developing efficient recycling processes, improving the recyclability of LDPE-based materials, and exploring bio-based alternatives. These initiatives aim to reduce the environmental impact of LDPE and promote a circular economy approach in its use and disposal.Expand Specific Solutions

Key LDPE Industry Players

The market for LDPE innovations is in a mature stage, with a global market size expected to reach $33 billion by 2027. The technology's maturity is evident from the involvement of major petrochemical companies like Dow Global Technologies, SABIC, and LyondellBasell. However, there's ongoing research to improve LDPE properties and production efficiency. Companies such as Sinopec and PetroChina are investing in R&D to enhance LDPE performance, while universities like Zhejiang University and Beijing University of Chemical Technology are contributing to academic research. The competitive landscape is characterized by established players and emerging innovators, with a focus on sustainable and high-performance LDPE applications.

Dow Global Technologies LLC

Technical Solution: Dow has developed innovative LDPE technologies focusing on enhancing material properties and sustainability. Their approach includes the development of ELITE™ Enhanced Polyethylene resins, which offer improved toughness, stiffness, and processability[1]. They have also introduced AGILITY™ EC, a performance LDPE resin designed for extrusion coating applications, providing excellent adhesion and low neck-in properties[2]. Dow's research extends to incorporating bio-based feedstocks and developing recycling-friendly LDPE formulations to address circular economy challenges[3]. Their innovations aim to reduce material usage while maintaining or improving performance, thus contributing to sustainability goals in packaging and other applications.

Strengths: Strong R&D capabilities, wide product portfolio, focus on sustainability. Weaknesses: Potential higher costs associated with advanced technologies, market competition from other major players.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been actively innovating in LDPE technologies to meet the growing demand in the Asian market. Their research focuses on developing high-performance LDPE grades for film and coating applications, with an emphasis on improving optical properties and processability[8]. Sinopec has invested in advanced catalysts and process technologies to enhance LDPE production efficiency and product quality. They have also been exploring the integration of recycled content into their LDPE products to address sustainability concerns. Sinopec's innovations aim to provide cost-effective LDPE solutions that meet the stringent requirements of packaging and agricultural film applications while reducing environmental impact.

Strengths: Large-scale production capabilities, strong presence in the Asian market. Weaknesses: Potential challenges in competing with global players on advanced technologies.

Breakthrough LDPE Technologies

Modifying tubular LDPE with free radical initiator

PatentActiveUS8207277B2

Innovation

- Modifying tubular LDPE with a free radical initiator, such as peroxides or azo compounds, to increase its long chain branching index, measured by gel permeation chromatography branching index (gpcBR), to a level similar to autoclave LDPE, by reacting the LDPE with the initiator after discharge from the reactor or during extrusion.

Novel LDPE enabling high output and good optics when blended with other polymers

PatentWO2010144784A1

Innovation

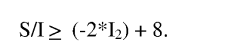

- Development of a new LDPE with specific molecular weight distribution, density, and branching characteristics, allowing for increased output when blended with LLDPE, while maintaining mechanical properties and improving optical quality through controlled tubular reactor technology and catalyst systems.

Environmental Impact of LDPE

The environmental impact of Low-Density Polyethylene (LDPE) is a critical concern in the context of accelerating innovations in LDPE uses. LDPE, a widely used plastic material, has significant implications for ecosystems and human health throughout its lifecycle. The production of LDPE involves the use of non-renewable fossil fuels, contributing to greenhouse gas emissions and climate change. The manufacturing process also releases various pollutants, including volatile organic compounds and particulate matter, which can negatively affect air quality and human health in surrounding areas.

One of the most pressing environmental issues associated with LDPE is its persistence in the environment. LDPE products, such as plastic bags and packaging materials, can take hundreds of years to decompose naturally. This longevity leads to the accumulation of plastic waste in landfills, oceans, and other ecosystems. Marine environments are particularly vulnerable, with LDPE contributing to the formation of large garbage patches in oceans and posing threats to marine life through ingestion and entanglement.

The disposal of LDPE products presents additional environmental challenges. Incineration of LDPE waste releases toxic emissions, including dioxins and furans, which are harmful to both human health and the environment. Recycling LDPE, while beneficial, is often hindered by contamination issues and the lack of efficient sorting and processing technologies. This results in a significant portion of LDPE waste ending up in landfills or the environment.

Microplastic pollution is another growing concern related to LDPE. As LDPE products break down into smaller particles, they form microplastics that can enter food chains and water systems. These microplastics have been found in various organisms, including humans, with potential long-term health effects that are still being studied.

However, innovations in LDPE uses are addressing some of these environmental concerns. Biodegradable and compostable alternatives to traditional LDPE are being developed, aiming to reduce the persistence of plastic waste in the environment. Advanced recycling technologies, such as chemical recycling, are emerging to improve the recyclability of LDPE products and create a more circular economy for plastics.

Efforts to reduce the environmental footprint of LDPE also include the development of more sustainable production methods. This includes the use of renewable energy sources in manufacturing processes and the exploration of bio-based feedstocks to replace fossil fuel-derived raw materials. Additionally, innovations in product design are focusing on reducing the amount of LDPE used in packaging and improving its reusability, thus minimizing waste generation.

One of the most pressing environmental issues associated with LDPE is its persistence in the environment. LDPE products, such as plastic bags and packaging materials, can take hundreds of years to decompose naturally. This longevity leads to the accumulation of plastic waste in landfills, oceans, and other ecosystems. Marine environments are particularly vulnerable, with LDPE contributing to the formation of large garbage patches in oceans and posing threats to marine life through ingestion and entanglement.

The disposal of LDPE products presents additional environmental challenges. Incineration of LDPE waste releases toxic emissions, including dioxins and furans, which are harmful to both human health and the environment. Recycling LDPE, while beneficial, is often hindered by contamination issues and the lack of efficient sorting and processing technologies. This results in a significant portion of LDPE waste ending up in landfills or the environment.

Microplastic pollution is another growing concern related to LDPE. As LDPE products break down into smaller particles, they form microplastics that can enter food chains and water systems. These microplastics have been found in various organisms, including humans, with potential long-term health effects that are still being studied.

However, innovations in LDPE uses are addressing some of these environmental concerns. Biodegradable and compostable alternatives to traditional LDPE are being developed, aiming to reduce the persistence of plastic waste in the environment. Advanced recycling technologies, such as chemical recycling, are emerging to improve the recyclability of LDPE products and create a more circular economy for plastics.

Efforts to reduce the environmental footprint of LDPE also include the development of more sustainable production methods. This includes the use of renewable energy sources in manufacturing processes and the exploration of bio-based feedstocks to replace fossil fuel-derived raw materials. Additionally, innovations in product design are focusing on reducing the amount of LDPE used in packaging and improving its reusability, thus minimizing waste generation.

LDPE Recycling Advancements

Recent advancements in LDPE recycling have significantly contributed to accelerating innovations in LDPE uses. The development of advanced sorting technologies has greatly improved the efficiency and quality of LDPE recycling processes. Optical sorting systems, utilizing near-infrared spectroscopy, can now accurately identify and separate different types of plastics, including LDPE, at high speeds. This has led to purer recycled LDPE streams, enabling the production of higher-quality recycled materials suitable for a wider range of applications.

Chemical recycling techniques have also emerged as a promising solution for LDPE recycling. Pyrolysis and depolymerization processes can break down LDPE into its constituent monomers or other valuable chemical feedstocks. These technologies offer the potential to create a circular economy for LDPE, where the material can be infinitely recycled without loss of quality. This breakthrough has opened up new possibilities for LDPE use in high-value applications, previously limited by the degradation of mechanical recycling processes.

Innovations in compatibilizers and additives have further enhanced the recyclability of LDPE. These additives can improve the compatibility between different types of plastics in mixed waste streams, allowing for more efficient recycling of LDPE-containing products. Additionally, new stabilizers have been developed to maintain the properties of recycled LDPE during multiple recycling cycles, extending its useful life and expanding its potential applications.

The development of multi-layer film recycling technologies has addressed one of the most challenging aspects of LDPE recycling. Advanced delamination processes can now separate LDPE from other materials in multi-layer packaging, allowing for the recovery of high-quality LDPE from previously unrecyclable products. This breakthrough has not only increased the recyclability of LDPE but also encouraged innovations in packaging design that prioritize recyclability without compromising functionality.

Advancements in recycling infrastructure and collection systems have also played a crucial role in improving LDPE recycling rates. The implementation of smart collection bins and improved sorting facilities has increased the efficiency of LDPE collection and processing. Furthermore, the development of blockchain-based tracking systems has enhanced transparency in the recycling supply chain, ensuring the quality and traceability of recycled LDPE materials.

These recycling advancements have collectively contributed to accelerating innovations in LDPE uses by providing a more sustainable and circular approach to LDPE production and consumption. As recycling technologies continue to evolve, they are expected to further drive innovations in LDPE applications, promoting the development of more sustainable and environmentally friendly products across various industries.

Chemical recycling techniques have also emerged as a promising solution for LDPE recycling. Pyrolysis and depolymerization processes can break down LDPE into its constituent monomers or other valuable chemical feedstocks. These technologies offer the potential to create a circular economy for LDPE, where the material can be infinitely recycled without loss of quality. This breakthrough has opened up new possibilities for LDPE use in high-value applications, previously limited by the degradation of mechanical recycling processes.

Innovations in compatibilizers and additives have further enhanced the recyclability of LDPE. These additives can improve the compatibility between different types of plastics in mixed waste streams, allowing for more efficient recycling of LDPE-containing products. Additionally, new stabilizers have been developed to maintain the properties of recycled LDPE during multiple recycling cycles, extending its useful life and expanding its potential applications.

The development of multi-layer film recycling technologies has addressed one of the most challenging aspects of LDPE recycling. Advanced delamination processes can now separate LDPE from other materials in multi-layer packaging, allowing for the recovery of high-quality LDPE from previously unrecyclable products. This breakthrough has not only increased the recyclability of LDPE but also encouraged innovations in packaging design that prioritize recyclability without compromising functionality.

Advancements in recycling infrastructure and collection systems have also played a crucial role in improving LDPE recycling rates. The implementation of smart collection bins and improved sorting facilities has increased the efficiency of LDPE collection and processing. Furthermore, the development of blockchain-based tracking systems has enhanced transparency in the recycling supply chain, ensuring the quality and traceability of recycled LDPE materials.

These recycling advancements have collectively contributed to accelerating innovations in LDPE uses by providing a more sustainable and circular approach to LDPE production and consumption. As recycling technologies continue to evolve, they are expected to further drive innovations in LDPE applications, promoting the development of more sustainable and environmentally friendly products across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!