How to Achieve High-Performance LDPE Blends?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Blend Evolution

The evolution of Low-Density Polyethylene (LDPE) blends has been a significant journey in the field of polymer science and engineering. Initially developed in the 1930s, LDPE quickly became a popular material due to its versatility and ease of processing. However, as industrial demands grew, so did the need for enhanced properties and performance.

In the 1950s and 1960s, researchers began experimenting with blending LDPE with other polymers to improve its mechanical and thermal properties. This marked the beginning of the LDPE blend evolution. Early attempts focused on combining LDPE with high-density polyethylene (HDPE) to create materials with a balance of flexibility and strength.

The 1970s saw a shift towards more complex blends, incorporating various polyolefins and elastomers. This era introduced the concept of compatibilizers, which helped to improve the miscibility of different polymers in the blend. The use of maleic anhydride-grafted polyethylene as a compatibilizer became a significant breakthrough, allowing for better dispersion and interfacial adhesion between blend components.

The 1980s and 1990s witnessed a surge in research on LDPE blends with engineering plastics. Blends of LDPE with polyamides, polyesters, and polycarbonates were developed, aiming to combine the processability of LDPE with the superior mechanical properties of these engineering plastics. This period also saw the introduction of nanocomposites, where nanoscale fillers were incorporated into LDPE blends to enhance properties such as barrier resistance and flame retardancy.

As environmental concerns grew in the late 1990s and early 2000s, the focus shifted towards developing sustainable LDPE blends. This led to increased research on blends incorporating biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). Simultaneously, efforts were made to improve the recyclability of LDPE blends, addressing the growing issue of plastic waste.

The past decade has seen a renewed interest in high-performance LDPE blends, driven by demands in sectors such as packaging, automotive, and electronics. Advanced characterization techniques and computational modeling have enabled a more precise understanding of blend morphology and property relationships. This has led to the development of tailored LDPE blends with specific property profiles for targeted applications.

Recent trends in LDPE blend evolution include the incorporation of functional additives for smart packaging applications, the development of self-healing LDPE blends, and the exploration of bio-based alternatives to traditional blend components. The ongoing research in this field continues to push the boundaries of what can be achieved with LDPE blends, promising exciting developments in the quest for high-performance, sustainable materials.

In the 1950s and 1960s, researchers began experimenting with blending LDPE with other polymers to improve its mechanical and thermal properties. This marked the beginning of the LDPE blend evolution. Early attempts focused on combining LDPE with high-density polyethylene (HDPE) to create materials with a balance of flexibility and strength.

The 1970s saw a shift towards more complex blends, incorporating various polyolefins and elastomers. This era introduced the concept of compatibilizers, which helped to improve the miscibility of different polymers in the blend. The use of maleic anhydride-grafted polyethylene as a compatibilizer became a significant breakthrough, allowing for better dispersion and interfacial adhesion between blend components.

The 1980s and 1990s witnessed a surge in research on LDPE blends with engineering plastics. Blends of LDPE with polyamides, polyesters, and polycarbonates were developed, aiming to combine the processability of LDPE with the superior mechanical properties of these engineering plastics. This period also saw the introduction of nanocomposites, where nanoscale fillers were incorporated into LDPE blends to enhance properties such as barrier resistance and flame retardancy.

As environmental concerns grew in the late 1990s and early 2000s, the focus shifted towards developing sustainable LDPE blends. This led to increased research on blends incorporating biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs). Simultaneously, efforts were made to improve the recyclability of LDPE blends, addressing the growing issue of plastic waste.

The past decade has seen a renewed interest in high-performance LDPE blends, driven by demands in sectors such as packaging, automotive, and electronics. Advanced characterization techniques and computational modeling have enabled a more precise understanding of blend morphology and property relationships. This has led to the development of tailored LDPE blends with specific property profiles for targeted applications.

Recent trends in LDPE blend evolution include the incorporation of functional additives for smart packaging applications, the development of self-healing LDPE blends, and the exploration of bio-based alternatives to traditional blend components. The ongoing research in this field continues to push the boundaries of what can be achieved with LDPE blends, promising exciting developments in the quest for high-performance, sustainable materials.

Market Demand Analysis

The market demand for high-performance LDPE blends has been steadily increasing across various industries due to their unique properties and versatile applications. Low-density polyethylene (LDPE) blends offer a combination of flexibility, toughness, and chemical resistance, making them attractive for packaging, automotive, construction, and consumer goods sectors.

In the packaging industry, there is a growing need for materials that can provide enhanced barrier properties, improved strength, and better processability. High-performance LDPE blends are being sought after for their ability to meet these requirements while maintaining cost-effectiveness. The food packaging segment, in particular, has shown significant interest in LDPE blends that can offer extended shelf life and better protection against moisture and oxygen permeation.

The automotive sector has been driving demand for lightweight materials that can contribute to fuel efficiency and reduced emissions. High-performance LDPE blends are being explored for their potential in interior components, wire and cable insulation, and under-the-hood applications. The ability of these blends to withstand high temperatures and resist chemical degradation makes them particularly valuable in this industry.

In the construction industry, there is an increasing demand for durable and weather-resistant materials. High-performance LDPE blends are being utilized in geomembranes, roofing materials, and pipe systems due to their excellent weatherability and long-term performance. The growing focus on sustainable building practices has also led to increased interest in recyclable and environmentally friendly LDPE blends.

The consumer goods sector has been seeking materials that can offer improved aesthetics, durability, and functionality. High-performance LDPE blends are being used in household products, toys, and sporting goods due to their ability to be molded into complex shapes while maintaining desirable mechanical properties.

Market trends indicate a shift towards customized LDPE blends that can meet specific performance requirements for different applications. This has led to increased collaboration between material suppliers and end-users to develop tailored solutions. Additionally, there is a growing emphasis on sustainable LDPE blends that incorporate recycled content or bio-based materials, driven by increasing environmental regulations and consumer awareness.

The global market for high-performance LDPE blends is expected to experience steady growth in the coming years, with Asia-Pacific region showing the highest potential due to rapid industrialization and increasing consumer demand. North America and Europe are also significant markets, driven by technological advancements and stringent quality standards in various industries.

In the packaging industry, there is a growing need for materials that can provide enhanced barrier properties, improved strength, and better processability. High-performance LDPE blends are being sought after for their ability to meet these requirements while maintaining cost-effectiveness. The food packaging segment, in particular, has shown significant interest in LDPE blends that can offer extended shelf life and better protection against moisture and oxygen permeation.

The automotive sector has been driving demand for lightweight materials that can contribute to fuel efficiency and reduced emissions. High-performance LDPE blends are being explored for their potential in interior components, wire and cable insulation, and under-the-hood applications. The ability of these blends to withstand high temperatures and resist chemical degradation makes them particularly valuable in this industry.

In the construction industry, there is an increasing demand for durable and weather-resistant materials. High-performance LDPE blends are being utilized in geomembranes, roofing materials, and pipe systems due to their excellent weatherability and long-term performance. The growing focus on sustainable building practices has also led to increased interest in recyclable and environmentally friendly LDPE blends.

The consumer goods sector has been seeking materials that can offer improved aesthetics, durability, and functionality. High-performance LDPE blends are being used in household products, toys, and sporting goods due to their ability to be molded into complex shapes while maintaining desirable mechanical properties.

Market trends indicate a shift towards customized LDPE blends that can meet specific performance requirements for different applications. This has led to increased collaboration between material suppliers and end-users to develop tailored solutions. Additionally, there is a growing emphasis on sustainable LDPE blends that incorporate recycled content or bio-based materials, driven by increasing environmental regulations and consumer awareness.

The global market for high-performance LDPE blends is expected to experience steady growth in the coming years, with Asia-Pacific region showing the highest potential due to rapid industrialization and increasing consumer demand. North America and Europe are also significant markets, driven by technological advancements and stringent quality standards in various industries.

Technical Challenges

The development of high-performance Low-Density Polyethylene (LDPE) blends faces several significant technical challenges. One of the primary obstacles is achieving optimal compatibility between LDPE and other polymers or additives. The inherent chemical structure of LDPE, characterized by its long-chain branching, can lead to phase separation when blended with dissimilar materials, resulting in poor mechanical properties and inconsistent performance.

Another critical challenge lies in maintaining the desirable properties of LDPE while enhancing its performance through blending. LDPE is valued for its flexibility, toughness, and chemical resistance, but these attributes can be compromised when introducing other components. Striking the right balance between improving certain characteristics (such as tensile strength or barrier properties) and preserving LDPE's inherent advantages requires precise formulation and processing techniques.

The processing of LDPE blends presents its own set of challenges. The low melting point and high melt flow index of LDPE can lead to processing difficulties when combined with higher-melting-point polymers. This disparity in thermal properties can result in uneven melting, poor dispersion, and potential degradation of the LDPE component during extrusion or molding processes.

Achieving consistent and uniform dispersion of additives or other polymers within the LDPE matrix is another significant hurdle. The high viscosity of molten LDPE can impede the even distribution of components, leading to localized concentrations and heterogeneous properties throughout the final product. This challenge is particularly pronounced when incorporating nanomaterials or high-performance fillers to enhance specific properties of the blend.

The long-term stability and durability of LDPE blends also pose technical challenges. Environmental factors such as UV radiation, temperature fluctuations, and chemical exposure can accelerate the degradation of the blend components, potentially leading to premature failure or loss of desired properties. Developing blends that maintain their performance characteristics over extended periods under various conditions remains a complex task.

Furthermore, the recyclability and environmental impact of LDPE blends present additional technical hurdles. As sustainability becomes increasingly important, creating high-performance blends that can be easily recycled without significant loss of properties is crucial. This challenge is compounded by the potential incompatibility of blend components in recycling streams and the difficulty in separating these components for individual recycling processes.

Lastly, scaling up the production of high-performance LDPE blends from laboratory to industrial levels introduces its own set of challenges. Maintaining consistent quality, optimizing process parameters, and ensuring cost-effectiveness at larger scales require significant engineering efforts and often necessitate the development of specialized equipment and techniques.

Another critical challenge lies in maintaining the desirable properties of LDPE while enhancing its performance through blending. LDPE is valued for its flexibility, toughness, and chemical resistance, but these attributes can be compromised when introducing other components. Striking the right balance between improving certain characteristics (such as tensile strength or barrier properties) and preserving LDPE's inherent advantages requires precise formulation and processing techniques.

The processing of LDPE blends presents its own set of challenges. The low melting point and high melt flow index of LDPE can lead to processing difficulties when combined with higher-melting-point polymers. This disparity in thermal properties can result in uneven melting, poor dispersion, and potential degradation of the LDPE component during extrusion or molding processes.

Achieving consistent and uniform dispersion of additives or other polymers within the LDPE matrix is another significant hurdle. The high viscosity of molten LDPE can impede the even distribution of components, leading to localized concentrations and heterogeneous properties throughout the final product. This challenge is particularly pronounced when incorporating nanomaterials or high-performance fillers to enhance specific properties of the blend.

The long-term stability and durability of LDPE blends also pose technical challenges. Environmental factors such as UV radiation, temperature fluctuations, and chemical exposure can accelerate the degradation of the blend components, potentially leading to premature failure or loss of desired properties. Developing blends that maintain their performance characteristics over extended periods under various conditions remains a complex task.

Furthermore, the recyclability and environmental impact of LDPE blends present additional technical hurdles. As sustainability becomes increasingly important, creating high-performance blends that can be easily recycled without significant loss of properties is crucial. This challenge is compounded by the potential incompatibility of blend components in recycling streams and the difficulty in separating these components for individual recycling processes.

Lastly, scaling up the production of high-performance LDPE blends from laboratory to industrial levels introduces its own set of challenges. Maintaining consistent quality, optimizing process parameters, and ensuring cost-effectiveness at larger scales require significant engineering efforts and often necessitate the development of specialized equipment and techniques.

Current LDPE Solutions

01 LDPE blend composition improvements

Various additives and polymers are blended with LDPE to enhance its performance characteristics. These blends can improve properties such as strength, flexibility, and processability. The specific composition of the blend is tailored to meet the requirements of different applications.- LDPE blends with other polymers: LDPE can be blended with other polymers to enhance its performance characteristics. These blends often result in improved mechanical properties, such as increased tensile strength and impact resistance. The choice of blending polymer depends on the desired end properties and application of the material.

- Additives for LDPE blend performance enhancement: Various additives can be incorporated into LDPE blends to improve their performance. These may include stabilizers, antioxidants, processing aids, and compatibilizers. The additives help to enhance properties such as thermal stability, UV resistance, and processability of the LDPE blends.

- LDPE blend processing techniques: The performance of LDPE blends can be significantly influenced by the processing techniques used. Methods such as extrusion, injection molding, and blow molding can affect the final properties of the blend. Optimizing processing parameters like temperature, pressure, and cooling rate can lead to improved blend performance.

- LDPE blend applications in packaging: LDPE blends find extensive use in packaging applications due to their versatile properties. These blends can offer improved barrier properties, sealability, and flexibility compared to pure LDPE. The performance of LDPE blends in packaging can be tailored to meet specific requirements for food, medical, and industrial packaging.

- Environmental considerations for LDPE blends: The environmental impact of LDPE blends is an important consideration in their development and use. Research is focused on improving the recyclability and biodegradability of LDPE blends. This includes the development of blends with bio-based polymers or additives that enhance the material's end-of-life performance without compromising its functional properties.

02 Enhanced mechanical properties of LDPE blends

LDPE blends are formulated to improve mechanical properties such as tensile strength, impact resistance, and elongation at break. This is achieved through careful selection of blend components and optimization of processing conditions. The enhanced mechanical properties expand the range of applications for LDPE-based materials.Expand Specific Solutions03 Thermal stability and processing improvements

Blending LDPE with other polymers or additives can lead to improved thermal stability and processing characteristics. These enhancements allow for better performance during manufacturing and in high-temperature applications. The improved thermal properties also contribute to the overall durability of the final product.Expand Specific Solutions04 Environmental and sustainability aspects

LDPE blends are being developed with a focus on environmental sustainability. This includes the incorporation of biodegradable additives, recycled materials, or bio-based polymers. These environmentally friendly blends aim to reduce the carbon footprint and improve the overall lifecycle impact of LDPE-based products.Expand Specific Solutions05 Specialized LDPE blends for specific applications

LDPE is blended with various components to create specialized materials for specific applications. These can include improved barrier properties for packaging, enhanced electrical insulation for wire and cable applications, or modified surface properties for adhesion or printing. The tailored blends meet the unique requirements of different industries and end-uses.Expand Specific Solutions

Key Industry Players

The competition landscape for high-performance LDPE blends is characterized by a mature market with significant growth potential. Major players like Dow Global Technologies, ExxonMobil Chemical, and SABIC are at the forefront of innovation, leveraging their extensive R&D capabilities. The market is driven by increasing demand for advanced packaging materials and automotive applications. Technological maturity varies, with established companies like LyondellBasell and Chevron Phillips Chemical focusing on incremental improvements, while newer entrants like DL Chemical are exploring novel approaches. The global market size is substantial, with projections indicating steady growth due to the versatility and cost-effectiveness of LDPE blends in various industries.

Dow Global Technologies LLC

Technical Solution: Dow's approach to achieving high-performance LDPE blends involves advanced catalyst systems and process technologies. They utilize a combination of tubular and autoclave reactors to produce LDPE with tailored molecular structures[1]. Their ELITE™ Enhanced Polyethylene technology allows for the creation of LDPE blends with improved mechanical properties and processability[2]. Dow also employs controlled branching techniques to optimize melt strength and extensibility, which are crucial for applications like film extrusion and blow molding[3]. Additionally, they incorporate compatibilizers to enhance the miscibility of different polyethylene grades in blends, resulting in superior performance characteristics[4].

Strengths: Wide range of tailored solutions, advanced catalyst systems, and process control. Weaknesses: Potentially higher production costs due to complex technologies.

Borealis AG

Technical Solution: Borealis focuses on developing high-performance LDPE blends through their Borstar® bimodal technology. This process allows for the production of LDPE with a controlled bimodal molecular weight distribution, resulting in an excellent balance of processability and mechanical properties[5]. They also utilize their proprietary Borlink™ technology for crosslinkable polyethylene compounds, which enhances the performance of LDPE blends in high-stress applications such as power cables[6]. Borealis employs advanced nucleating agents and processing aids to improve the crystallization behavior and melt flow characteristics of their LDPE blends, leading to enhanced optical and mechanical properties[7].

Strengths: Proprietary bimodal technology, specialized solutions for high-stress applications. Weaknesses: May have limitations in certain commodity markets due to focus on high-end applications.

Core LDPE Technologies

Lldpe-LDPE blown film blend

PatentInactiveUS20130245201A1

Innovation

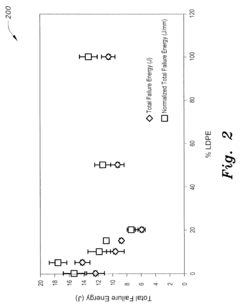

- A blown film blend of unimodal hexene-LLDPE and LDPE with a blend ratio of 2%-10% LDPE to 98%-90% h-LLDPE, which increases transverse direction tear resistance by 100%, impact failure energy by 20%, and toughness and yield strength in the machine direction, while reducing energy consumption in film production.

Novel LDPE enabling high output and good optics when blended with other polymers

PatentActiveEP2440588A1

Innovation

- Development of a new LDPE with specific molecular weight distribution, density, and branching characteristics, allowing for increased output when blended with LLDPE, while maintaining mechanical properties and reducing haze and bubble instability.

Environmental Impact

The environmental impact of high-performance LDPE blends is a critical consideration in their development and application. These blends, while offering enhanced properties, can have both positive and negative effects on the environment throughout their lifecycle. One of the primary environmental benefits of high-performance LDPE blends is their potential for improved durability and longevity. By creating more robust materials, these blends can extend the lifespan of products, reducing the need for frequent replacements and thereby decreasing overall waste generation.

However, the production process of high-performance LDPE blends often requires additional energy and resources compared to standard LDPE. This increased energy consumption can lead to higher greenhouse gas emissions during manufacturing. Additionally, the use of additives and compatibilizers to achieve desired properties may introduce new chemical compounds into the environment, potentially raising concerns about their long-term ecological effects.

Recycling presents both challenges and opportunities for high-performance LDPE blends. On one hand, the complex compositions of these blends can make them more difficult to recycle compared to pure LDPE. The presence of multiple polymers and additives may require more sophisticated sorting and recycling technologies. On the other hand, if properly managed, the recycling of these high-performance blends could lead to the recovery of valuable materials, reducing the demand for virgin plastics and minimizing waste.

The end-of-life disposal of products made from high-performance LDPE blends is another crucial environmental consideration. While these blends may offer improved resistance to degradation during use, this same property can lead to persistence in the environment if not properly disposed of or recycled. This persistence raises concerns about potential accumulation in ecosystems, particularly in marine environments where plastic pollution is already a significant issue.

To mitigate these environmental impacts, researchers and manufacturers are exploring various strategies. These include developing bio-based additives to enhance LDPE properties, improving the compatibility of different polymers in blends to facilitate recycling, and designing products with end-of-life considerations in mind. Additionally, efforts are being made to optimize production processes to reduce energy consumption and emissions.

As the demand for high-performance materials continues to grow, balancing performance enhancements with environmental sustainability remains a key challenge. Future developments in high-performance LDPE blends will likely focus on creating materials that not only offer superior properties but also minimize environmental impact throughout their lifecycle, from production to disposal or recycling.

However, the production process of high-performance LDPE blends often requires additional energy and resources compared to standard LDPE. This increased energy consumption can lead to higher greenhouse gas emissions during manufacturing. Additionally, the use of additives and compatibilizers to achieve desired properties may introduce new chemical compounds into the environment, potentially raising concerns about their long-term ecological effects.

Recycling presents both challenges and opportunities for high-performance LDPE blends. On one hand, the complex compositions of these blends can make them more difficult to recycle compared to pure LDPE. The presence of multiple polymers and additives may require more sophisticated sorting and recycling technologies. On the other hand, if properly managed, the recycling of these high-performance blends could lead to the recovery of valuable materials, reducing the demand for virgin plastics and minimizing waste.

The end-of-life disposal of products made from high-performance LDPE blends is another crucial environmental consideration. While these blends may offer improved resistance to degradation during use, this same property can lead to persistence in the environment if not properly disposed of or recycled. This persistence raises concerns about potential accumulation in ecosystems, particularly in marine environments where plastic pollution is already a significant issue.

To mitigate these environmental impacts, researchers and manufacturers are exploring various strategies. These include developing bio-based additives to enhance LDPE properties, improving the compatibility of different polymers in blends to facilitate recycling, and designing products with end-of-life considerations in mind. Additionally, efforts are being made to optimize production processes to reduce energy consumption and emissions.

As the demand for high-performance materials continues to grow, balancing performance enhancements with environmental sustainability remains a key challenge. Future developments in high-performance LDPE blends will likely focus on creating materials that not only offer superior properties but also minimize environmental impact throughout their lifecycle, from production to disposal or recycling.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and commercialization of high-performance LDPE blends. As these materials are widely used in various industries, including food packaging, medical devices, and consumer goods, adherence to stringent regulations is essential to ensure product safety and environmental sustainability.

In the United States, the Food and Drug Administration (FDA) regulates the use of LDPE blends in food contact applications. Manufacturers must comply with the Code of Federal Regulations Title 21, specifically parts 174-179, which outline the requirements for food contact substances. These regulations stipulate the permissible additives, processing aids, and monomers that can be used in LDPE blends intended for food packaging.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of LDPE blends. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide detailed information on the properties, hazards, and safe use of their materials. Additionally, the EU Plastics Regulation (EU) No 10/2011 sets specific migration limits for substances used in plastic food contact materials, including LDPE blends.

Environmental regulations also impact the development of high-performance LDPE blends. Many countries have implemented restrictions on single-use plastics and are promoting the use of recyclable and biodegradable materials. As a result, manufacturers are increasingly focusing on developing LDPE blends that are more easily recyclable or incorporate bio-based components to meet these evolving regulatory requirements.

To achieve regulatory compliance for high-performance LDPE blends, manufacturers must implement robust quality control systems and maintain detailed documentation of their production processes. This includes conducting regular testing to ensure that the final products meet the specified regulatory limits for chemical migration, mechanical properties, and overall safety.

Furthermore, as global regulations continue to evolve, companies must stay informed about changes in regulatory requirements across different markets. This may involve engaging with regulatory bodies, participating in industry associations, and investing in ongoing research and development to adapt their LDPE blend formulations to meet new standards.

In conclusion, achieving regulatory compliance for high-performance LDPE blends requires a comprehensive approach that encompasses material selection, production processes, quality control, and ongoing monitoring of regulatory developments. By prioritizing compliance, manufacturers can ensure the safety and marketability of their products while contributing to the sustainable development of the plastics industry.

In the United States, the Food and Drug Administration (FDA) regulates the use of LDPE blends in food contact applications. Manufacturers must comply with the Code of Federal Regulations Title 21, specifically parts 174-179, which outline the requirements for food contact substances. These regulations stipulate the permissible additives, processing aids, and monomers that can be used in LDPE blends intended for food packaging.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects the production and use of LDPE blends. Manufacturers must register their substances with the European Chemicals Agency (ECHA) and provide detailed information on the properties, hazards, and safe use of their materials. Additionally, the EU Plastics Regulation (EU) No 10/2011 sets specific migration limits for substances used in plastic food contact materials, including LDPE blends.

Environmental regulations also impact the development of high-performance LDPE blends. Many countries have implemented restrictions on single-use plastics and are promoting the use of recyclable and biodegradable materials. As a result, manufacturers are increasingly focusing on developing LDPE blends that are more easily recyclable or incorporate bio-based components to meet these evolving regulatory requirements.

To achieve regulatory compliance for high-performance LDPE blends, manufacturers must implement robust quality control systems and maintain detailed documentation of their production processes. This includes conducting regular testing to ensure that the final products meet the specified regulatory limits for chemical migration, mechanical properties, and overall safety.

Furthermore, as global regulations continue to evolve, companies must stay informed about changes in regulatory requirements across different markets. This may involve engaging with regulatory bodies, participating in industry associations, and investing in ongoing research and development to adapt their LDPE blend formulations to meet new standards.

In conclusion, achieving regulatory compliance for high-performance LDPE blends requires a comprehensive approach that encompasses material selection, production processes, quality control, and ongoing monitoring of regulatory developments. By prioritizing compliance, manufacturers can ensure the safety and marketability of their products while contributing to the sustainable development of the plastics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!