How to Mitigate LDPE Environmental Hazard Potential?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Hazards Overview

Low-density polyethylene (LDPE) is a widely used plastic material known for its versatility and low production costs. However, its widespread use has led to significant environmental concerns due to its persistence in ecosystems and potential hazards to wildlife and human health.

LDPE's primary environmental hazard stems from its non-biodegradable nature. When discarded, LDPE products can persist in the environment for hundreds of years, contributing to long-term pollution of land and water bodies. This persistence leads to the accumulation of plastic waste in ecosystems, causing physical harm to wildlife through entanglement or ingestion.

In marine environments, LDPE poses a particular threat. As it breaks down into smaller particles, known as microplastics, it can be ingested by marine organisms, leading to malnutrition, internal injuries, and potential death. These microplastics can also accumulate in the food chain, potentially affecting human health through the consumption of contaminated seafood.

LDPE's production process also contributes to environmental hazards. The manufacturing of LDPE involves the use of fossil fuels and releases greenhouse gases, contributing to climate change. Additionally, the additives used in LDPE production, such as plasticizers and stabilizers, can leach into the environment, potentially causing soil and water contamination.

The disposal of LDPE waste presents further challenges. Incineration of LDPE releases toxic chemicals into the atmosphere, including dioxins and furans, which are known carcinogens. Landfilling LDPE waste leads to soil degradation and potential groundwater contamination as chemicals leach from the plastic over time.

LDPE's low recycling rates exacerbate its environmental impact. Due to contamination issues and the low value of recycled LDPE, much of this plastic ends up in landfills or the environment rather than being recycled. This contributes to the growing global plastic waste crisis and the depletion of natural resources used in LDPE production.

The hazards associated with LDPE extend beyond direct environmental impacts. The production and disposal of LDPE contribute to energy consumption and greenhouse gas emissions, indirectly affecting global climate patterns and ecosystems. Furthermore, the aesthetic pollution caused by LDPE litter in natural environments can have negative impacts on tourism and local economies.

Addressing the environmental hazards of LDPE requires a multifaceted approach, including improved waste management systems, increased recycling efforts, development of biodegradable alternatives, and public education on responsible plastic use and disposal. As awareness of these hazards grows, there is an increasing push for regulations and innovations to mitigate the environmental impact of LDPE and other plastic materials.

LDPE's primary environmental hazard stems from its non-biodegradable nature. When discarded, LDPE products can persist in the environment for hundreds of years, contributing to long-term pollution of land and water bodies. This persistence leads to the accumulation of plastic waste in ecosystems, causing physical harm to wildlife through entanglement or ingestion.

In marine environments, LDPE poses a particular threat. As it breaks down into smaller particles, known as microplastics, it can be ingested by marine organisms, leading to malnutrition, internal injuries, and potential death. These microplastics can also accumulate in the food chain, potentially affecting human health through the consumption of contaminated seafood.

LDPE's production process also contributes to environmental hazards. The manufacturing of LDPE involves the use of fossil fuels and releases greenhouse gases, contributing to climate change. Additionally, the additives used in LDPE production, such as plasticizers and stabilizers, can leach into the environment, potentially causing soil and water contamination.

The disposal of LDPE waste presents further challenges. Incineration of LDPE releases toxic chemicals into the atmosphere, including dioxins and furans, which are known carcinogens. Landfilling LDPE waste leads to soil degradation and potential groundwater contamination as chemicals leach from the plastic over time.

LDPE's low recycling rates exacerbate its environmental impact. Due to contamination issues and the low value of recycled LDPE, much of this plastic ends up in landfills or the environment rather than being recycled. This contributes to the growing global plastic waste crisis and the depletion of natural resources used in LDPE production.

The hazards associated with LDPE extend beyond direct environmental impacts. The production and disposal of LDPE contribute to energy consumption and greenhouse gas emissions, indirectly affecting global climate patterns and ecosystems. Furthermore, the aesthetic pollution caused by LDPE litter in natural environments can have negative impacts on tourism and local economies.

Addressing the environmental hazards of LDPE requires a multifaceted approach, including improved waste management systems, increased recycling efforts, development of biodegradable alternatives, and public education on responsible plastic use and disposal. As awareness of these hazards grows, there is an increasing push for regulations and innovations to mitigate the environmental impact of LDPE and other plastic materials.

Market Demand Analysis

The market demand for solutions to mitigate LDPE (Low-Density Polyethylene) environmental hazards has been steadily increasing in recent years. This growth is primarily driven by heightened environmental awareness, stricter regulations, and the pressing need to address plastic pollution globally.

Consumer awareness regarding the environmental impact of plastic waste has led to a significant shift in market dynamics. Many consumers now actively seek eco-friendly alternatives and support brands that demonstrate commitment to sustainability. This trend has created a substantial market for products and technologies that can effectively reduce the environmental footprint of LDPE.

In the packaging industry, which is a major consumer of LDPE, there is a growing demand for recyclable and biodegradable alternatives. Companies are investing in research and development to create packaging solutions that maintain the beneficial properties of LDPE while minimizing its environmental impact. This has opened up new market opportunities for innovative materials and recycling technologies.

The construction sector, another significant user of LDPE, is also experiencing increased demand for environmentally friendly options. As green building practices gain traction, there is a rising need for sustainable insulation and waterproofing materials that can replace traditional LDPE products.

Government regulations and policies aimed at reducing plastic waste have further stimulated market demand for LDPE mitigation solutions. Many countries have implemented or are considering bans on single-use plastics, creating a urgent need for alternative materials and improved recycling technologies. This regulatory landscape has spurred innovation and investment in the development of more sustainable plastic products and waste management systems.

The recycling industry has seen significant growth in response to the LDPE environmental challenge. There is an increasing demand for advanced sorting and recycling technologies that can efficiently process LDPE waste. Additionally, the market for recycled LDPE products is expanding as more industries seek to incorporate recycled materials into their supply chains.

In the agricultural sector, there is a growing market for biodegradable mulch films and other LDPE alternatives. Farmers are increasingly aware of the long-term environmental impacts of plastic use in agriculture and are seeking more sustainable options.

The textile industry is another area where demand for LDPE mitigation solutions is on the rise. As microplastic pollution from synthetic fibers becomes a growing concern, there is increased interest in developing textiles that shed fewer microfibers or in creating more effective filtration systems for washing machines.

Overall, the market for LDPE environmental hazard mitigation solutions is diverse and expanding. It encompasses a wide range of industries and technologies, from material science and chemical engineering to waste management and recycling. As environmental concerns continue to shape consumer behavior and regulatory landscapes, this market is expected to see sustained growth and innovation in the coming years.

Consumer awareness regarding the environmental impact of plastic waste has led to a significant shift in market dynamics. Many consumers now actively seek eco-friendly alternatives and support brands that demonstrate commitment to sustainability. This trend has created a substantial market for products and technologies that can effectively reduce the environmental footprint of LDPE.

In the packaging industry, which is a major consumer of LDPE, there is a growing demand for recyclable and biodegradable alternatives. Companies are investing in research and development to create packaging solutions that maintain the beneficial properties of LDPE while minimizing its environmental impact. This has opened up new market opportunities for innovative materials and recycling technologies.

The construction sector, another significant user of LDPE, is also experiencing increased demand for environmentally friendly options. As green building practices gain traction, there is a rising need for sustainable insulation and waterproofing materials that can replace traditional LDPE products.

Government regulations and policies aimed at reducing plastic waste have further stimulated market demand for LDPE mitigation solutions. Many countries have implemented or are considering bans on single-use plastics, creating a urgent need for alternative materials and improved recycling technologies. This regulatory landscape has spurred innovation and investment in the development of more sustainable plastic products and waste management systems.

The recycling industry has seen significant growth in response to the LDPE environmental challenge. There is an increasing demand for advanced sorting and recycling technologies that can efficiently process LDPE waste. Additionally, the market for recycled LDPE products is expanding as more industries seek to incorporate recycled materials into their supply chains.

In the agricultural sector, there is a growing market for biodegradable mulch films and other LDPE alternatives. Farmers are increasingly aware of the long-term environmental impacts of plastic use in agriculture and are seeking more sustainable options.

The textile industry is another area where demand for LDPE mitigation solutions is on the rise. As microplastic pollution from synthetic fibers becomes a growing concern, there is increased interest in developing textiles that shed fewer microfibers or in creating more effective filtration systems for washing machines.

Overall, the market for LDPE environmental hazard mitigation solutions is diverse and expanding. It encompasses a wide range of industries and technologies, from material science and chemical engineering to waste management and recycling. As environmental concerns continue to shape consumer behavior and regulatory landscapes, this market is expected to see sustained growth and innovation in the coming years.

Current Mitigation Challenges

The mitigation of LDPE (Low-Density Polyethylene) environmental hazards faces several significant challenges in the current landscape. One of the primary obstacles is the widespread use and production of LDPE, which has become deeply ingrained in various industries and consumer products. This ubiquity makes it difficult to implement comprehensive mitigation strategies without causing substantial disruptions to existing supply chains and manufacturing processes.

Another major challenge is the lack of cost-effective and scalable recycling technologies for LDPE. While recycling methods exist, they often struggle to maintain the quality and properties of the recycled material, limiting its potential applications. This issue is compounded by the fact that LDPE is frequently contaminated with other materials or additives, making the recycling process more complex and less economically viable.

The persistence of LDPE in the environment poses a significant long-term challenge. Its slow degradation rate means that once it enters ecosystems, it can remain for hundreds of years, continuously contributing to pollution and potentially harming wildlife. This persistence makes it difficult to address the existing environmental burden of LDPE, even as efforts are made to reduce new inputs.

Consumer behavior and awareness present another hurdle in mitigating LDPE hazards. Despite growing environmental consciousness, many consumers still struggle to properly dispose of or recycle LDPE products. This is partly due to inconsistent recycling infrastructure and guidelines across different regions, as well as a general lack of understanding about the environmental impact of LDPE.

From a regulatory perspective, there is a lack of unified global standards and policies regarding LDPE production, use, and disposal. This inconsistency makes it challenging to implement effective, large-scale mitigation strategies that can address the issue on an international level. Additionally, the economic interests of industries heavily reliant on LDPE often conflict with environmental protection goals, leading to resistance against stringent regulations.

The development of biodegradable alternatives to LDPE is progressing, but faces its own set of challenges. Many current biodegradable plastics either do not fully break down in natural environments or require specific industrial composting conditions that are not widely available. Furthermore, the production costs and performance characteristics of these alternatives often fall short of traditional LDPE, limiting their adoption in various applications.

Lastly, the sheer volume of LDPE already in circulation and continuing to be produced presents a massive scale challenge. Addressing this requires not only technological innovations but also significant changes in industrial practices, consumer habits, and waste management systems. The complexity and interconnectedness of these challenges make the mitigation of LDPE environmental hazards a multifaceted problem requiring coordinated efforts across various sectors and stakeholders.

Another major challenge is the lack of cost-effective and scalable recycling technologies for LDPE. While recycling methods exist, they often struggle to maintain the quality and properties of the recycled material, limiting its potential applications. This issue is compounded by the fact that LDPE is frequently contaminated with other materials or additives, making the recycling process more complex and less economically viable.

The persistence of LDPE in the environment poses a significant long-term challenge. Its slow degradation rate means that once it enters ecosystems, it can remain for hundreds of years, continuously contributing to pollution and potentially harming wildlife. This persistence makes it difficult to address the existing environmental burden of LDPE, even as efforts are made to reduce new inputs.

Consumer behavior and awareness present another hurdle in mitigating LDPE hazards. Despite growing environmental consciousness, many consumers still struggle to properly dispose of or recycle LDPE products. This is partly due to inconsistent recycling infrastructure and guidelines across different regions, as well as a general lack of understanding about the environmental impact of LDPE.

From a regulatory perspective, there is a lack of unified global standards and policies regarding LDPE production, use, and disposal. This inconsistency makes it challenging to implement effective, large-scale mitigation strategies that can address the issue on an international level. Additionally, the economic interests of industries heavily reliant on LDPE often conflict with environmental protection goals, leading to resistance against stringent regulations.

The development of biodegradable alternatives to LDPE is progressing, but faces its own set of challenges. Many current biodegradable plastics either do not fully break down in natural environments or require specific industrial composting conditions that are not widely available. Furthermore, the production costs and performance characteristics of these alternatives often fall short of traditional LDPE, limiting their adoption in various applications.

Lastly, the sheer volume of LDPE already in circulation and continuing to be produced presents a massive scale challenge. Addressing this requires not only technological innovations but also significant changes in industrial practices, consumer habits, and waste management systems. The complexity and interconnectedness of these challenges make the mitigation of LDPE environmental hazards a multifaceted problem requiring coordinated efforts across various sectors and stakeholders.

Existing Mitigation Strategies

01 Biodegradable LDPE composites

Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's degradability while maintaining its useful properties. This approach aims to address the environmental concerns associated with traditional LDPE.- Biodegradable LDPE composites: Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's degradability while maintaining its useful properties.

- Recycling and upcycling of LDPE waste: Methods for recycling and upcycling LDPE waste to minimize environmental hazards. These processes involve collecting, sorting, and reprocessing LDPE materials into new products or raw materials for other applications.

- LDPE alternatives with reduced environmental impact: Development of alternative materials to replace LDPE with reduced environmental hazard potential. These alternatives may include bio-based polymers or other synthetic materials with improved biodegradability or recyclability.

- Additives to enhance LDPE degradation: Incorporation of additives into LDPE to enhance its degradation in the environment. These additives may include pro-oxidants, photocatalysts, or microbial agents that accelerate the breakdown of LDPE under various environmental conditions.

- LDPE waste management and disposal techniques: Development of improved waste management and disposal techniques for LDPE to minimize its environmental impact. These techniques may include advanced sorting systems, controlled landfill designs, or thermal treatment methods that reduce the release of harmful substances.

02 LDPE recycling technologies

Advancements in LDPE recycling technologies to mitigate environmental hazards. These include improved sorting methods, chemical recycling processes, and the development of upcycling techniques to convert LDPE waste into higher-value products. Such innovations aim to reduce the accumulation of LDPE in landfills and oceans.Expand Specific Solutions03 Eco-friendly LDPE alternatives

Research and development of eco-friendly alternatives to LDPE. This includes bio-based polyethylene, compostable plastics, and other sustainable materials that can replace LDPE in various applications. These alternatives aim to reduce the environmental impact associated with traditional LDPE production and disposal.Expand Specific Solutions04 LDPE waste management strategies

Implementation of improved LDPE waste management strategies to minimize environmental hazards. This includes the development of more efficient collection systems, the creation of circular economy models for LDPE, and the establishment of extended producer responsibility programs. These strategies aim to reduce LDPE pollution and promote responsible use and disposal.Expand Specific Solutions05 LDPE environmental impact assessment

Development of comprehensive environmental impact assessment methods for LDPE. These assessments consider the entire lifecycle of LDPE products, from production to disposal, and evaluate factors such as carbon footprint, marine pollution, and ecosystem effects. The goal is to better understand and mitigate the environmental hazards associated with LDPE use.Expand Specific Solutions

Key Industry Stakeholders

The mitigation of LDPE environmental hazards is a critical issue in the plastics industry, currently in a mature stage but facing increasing scrutiny. The global market for LDPE is substantial, with a growing focus on sustainable alternatives. Technologically, the field is evolving, with companies like Dow Global Technologies, Braskem SA, and ExxonMobil Technology & Engineering Co. leading innovation in biodegradable and recyclable LDPE alternatives. Research institutions such as Zhejiang University and Beijing University of Chemical Technology are contributing to advancements in eco-friendly polymer science. The competitive landscape is characterized by a mix of established petrochemical giants and emerging specialized materials firms, all striving to address environmental concerns while maintaining LDPE's versatility and economic viability.

Dow Global Technologies LLC

Technical Solution: Dow has developed a novel approach to mitigate LDPE environmental hazards through advanced recycling technologies. Their process involves chemical recycling of LDPE waste, breaking it down into its molecular components, which can then be used as feedstock for new plastics production[1]. This circular economy approach significantly reduces the environmental impact of LDPE. Additionally, Dow has introduced additives that enhance the biodegradability of LDPE products, allowing them to decompose more rapidly in specific environmental conditions[3]. The company is also investing in the development of bio-based LDPE alternatives, using renewable resources to create more sustainable plastic products[5].

Strengths: Comprehensive approach combining recycling, biodegradability enhancement, and bio-based alternatives. Weaknesses: Chemical recycling can be energy-intensive, and biodegradable additives may affect material properties.

Equistar Chemicals LP

Technical Solution: Equistar Chemicals, a subsidiary of LyondellBasell, has implemented a multi-faceted strategy to address LDPE environmental concerns. Their approach includes the development of advanced catalyst systems that allow for the production of LDPE with improved mechanical properties, enabling the use of thinner films and thus reducing overall plastic consumption[2]. They have also pioneered a solvent-based recycling process that can effectively separate LDPE from multi-layer packaging, significantly increasing the recyclability of complex plastic products[4]. Furthermore, Equistar is investing in the integration of post-consumer recycled (PCR) content into new LDPE products, creating a closed-loop system that reduces reliance on virgin materials[6].

Strengths: Innovative catalyst technology and recycling processes that address complex waste streams. Weaknesses: Solvent-based recycling may have its own environmental implications and scaling challenges.

Innovative LDPE Alternatives

Methods for degrading low density polyethylene (LDPE) and remediating leachate

PatentActiveUS20200406320A1

Innovation

- Contacting pretreated LDPE with white-rot fungi, such as Phanerochaete chrysosporium, at elevated temperatures and potentially etching the LDPE, within the activated sludge infrastructure of landfills to achieve near 100% degradation and leachate remediation without toxic byproducts.

Hydrophobic aerogel for oil spill remediation and its method of preparation thereof

PatentPendingIN202311066682A

Innovation

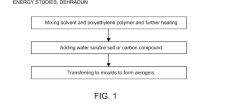

- A hydrophobic polyethylene-based aerogel is developed, utilizing low-density polyethylene (LDPE) from waste plastics and optionally water-soluble salts or carbon compounds, which is prepared by dissolving LDPE in a solvent, adding optional additives, and drying to create a porous, lightweight, and mechanically strong material for efficient oil-water separation.

Regulatory Framework

The regulatory framework surrounding Low-Density Polyethylene (LDPE) environmental hazard mitigation is complex and multifaceted, involving various levels of governance and international cooperation. At the global level, the United Nations Environment Programme (UNEP) has been instrumental in setting the agenda for plastic waste reduction through initiatives such as the Global Partnership on Marine Litter and the Clean Seas campaign. These programs aim to raise awareness and promote action to address plastic pollution, including LDPE waste.

In the European Union, the Plastic Strategy and the Single-Use Plastics Directive have established ambitious targets for plastic recycling and reduction of single-use plastics. These regulations directly impact LDPE production and disposal, encouraging manufacturers to adopt more sustainable practices and consumers to reduce their plastic consumption. The EU has also implemented Extended Producer Responsibility (EPR) schemes, which hold producers accountable for the entire lifecycle of their plastic products, including LDPE.

The United States has a more fragmented approach, with regulations varying at the state and local levels. However, the Environmental Protection Agency (EPA) provides guidelines and enforces regulations under the Resource Conservation and Recovery Act (RCRA) for the management of solid waste, including LDPE. Some states, like California, have implemented more stringent regulations, such as bans on single-use plastic bags, which often contain LDPE.

In developing countries, regulatory frameworks for LDPE mitigation are often less comprehensive but are evolving rapidly. Many nations are implementing bans on single-use plastics and imposing taxes on plastic bags. For instance, Kenya has introduced one of the world's strictest plastic bag bans, with severe penalties for production, sale, and even possession of plastic bags.

International agreements also play a crucial role in shaping the regulatory landscape. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal was amended in 2019 to include plastic waste, affecting the global trade of LDPE waste and encouraging countries to manage their plastic waste domestically.

Emerging regulatory trends focus on circular economy principles, emphasizing the need for LDPE products to be designed for recyclability and reuse. This shift is reflected in policies such as the EU's Circular Economy Action Plan, which aims to make sustainable products the norm and reduce waste generation.

As awareness of the environmental impacts of LDPE grows, regulatory frameworks are likely to become more stringent and comprehensive. Future regulations may include mandatory recycled content requirements, extended producer responsibility programs, and more aggressive recycling targets specifically for LDPE products. These evolving regulations will continue to shape the landscape of LDPE production, use, and disposal, driving innovation in mitigation strategies and sustainable alternatives.

In the European Union, the Plastic Strategy and the Single-Use Plastics Directive have established ambitious targets for plastic recycling and reduction of single-use plastics. These regulations directly impact LDPE production and disposal, encouraging manufacturers to adopt more sustainable practices and consumers to reduce their plastic consumption. The EU has also implemented Extended Producer Responsibility (EPR) schemes, which hold producers accountable for the entire lifecycle of their plastic products, including LDPE.

The United States has a more fragmented approach, with regulations varying at the state and local levels. However, the Environmental Protection Agency (EPA) provides guidelines and enforces regulations under the Resource Conservation and Recovery Act (RCRA) for the management of solid waste, including LDPE. Some states, like California, have implemented more stringent regulations, such as bans on single-use plastic bags, which often contain LDPE.

In developing countries, regulatory frameworks for LDPE mitigation are often less comprehensive but are evolving rapidly. Many nations are implementing bans on single-use plastics and imposing taxes on plastic bags. For instance, Kenya has introduced one of the world's strictest plastic bag bans, with severe penalties for production, sale, and even possession of plastic bags.

International agreements also play a crucial role in shaping the regulatory landscape. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal was amended in 2019 to include plastic waste, affecting the global trade of LDPE waste and encouraging countries to manage their plastic waste domestically.

Emerging regulatory trends focus on circular economy principles, emphasizing the need for LDPE products to be designed for recyclability and reuse. This shift is reflected in policies such as the EU's Circular Economy Action Plan, which aims to make sustainable products the norm and reduce waste generation.

As awareness of the environmental impacts of LDPE grows, regulatory frameworks are likely to become more stringent and comprehensive. Future regulations may include mandatory recycled content requirements, extended producer responsibility programs, and more aggressive recycling targets specifically for LDPE products. These evolving regulations will continue to shape the landscape of LDPE production, use, and disposal, driving innovation in mitigation strategies and sustainable alternatives.

Circular Economy Integration

Integrating circular economy principles into LDPE (Low-Density Polyethylene) management is crucial for mitigating its environmental hazard potential. This approach focuses on creating a closed-loop system where LDPE products are designed, produced, used, and recycled in a way that minimizes waste and maximizes resource efficiency.

One key aspect of circular economy integration for LDPE is the implementation of extended producer responsibility (EPR) programs. These initiatives hold manufacturers accountable for the entire lifecycle of their products, including collection and recycling after use. By incentivizing producers to design more recyclable LDPE products and invest in recycling infrastructure, EPR programs can significantly reduce the environmental impact of LDPE waste.

Another important strategy is the development of innovative recycling technologies specifically tailored for LDPE. Advanced mechanical recycling methods, such as improved sorting and cleaning processes, can enhance the quality of recycled LDPE, making it more suitable for reuse in various applications. Chemical recycling techniques, like pyrolysis and depolymerization, offer promising solutions for converting LDPE waste back into its basic chemical components, which can then be used to produce new plastics or other valuable materials.

The promotion of LDPE upcycling initiatives is also essential in a circular economy framework. This involves transforming LDPE waste into higher-value products, such as durable construction materials or artistic creations. By finding new and innovative uses for recycled LDPE, these initiatives can help create demand for recycled materials and reduce the reliance on virgin LDPE production.

Implementing deposit-return schemes for LDPE products can significantly increase collection rates and ensure a steady supply of recyclable materials. These systems incentivize consumers to return used LDPE items by offering a small refund, effectively closing the loop between consumption and recycling.

Collaboration between industry stakeholders, including manufacturers, retailers, recyclers, and policymakers, is crucial for successful circular economy integration. By fostering partnerships and knowledge sharing, the LDPE value chain can be optimized to reduce waste, improve recycling efficiency, and develop more sustainable product designs.

Education and awareness campaigns play a vital role in promoting circular economy principles for LDPE management. By informing consumers about proper disposal methods, the importance of recycling, and the environmental impact of LDPE waste, these initiatives can drive behavioral changes that support a more circular approach to LDPE use and disposal.

One key aspect of circular economy integration for LDPE is the implementation of extended producer responsibility (EPR) programs. These initiatives hold manufacturers accountable for the entire lifecycle of their products, including collection and recycling after use. By incentivizing producers to design more recyclable LDPE products and invest in recycling infrastructure, EPR programs can significantly reduce the environmental impact of LDPE waste.

Another important strategy is the development of innovative recycling technologies specifically tailored for LDPE. Advanced mechanical recycling methods, such as improved sorting and cleaning processes, can enhance the quality of recycled LDPE, making it more suitable for reuse in various applications. Chemical recycling techniques, like pyrolysis and depolymerization, offer promising solutions for converting LDPE waste back into its basic chemical components, which can then be used to produce new plastics or other valuable materials.

The promotion of LDPE upcycling initiatives is also essential in a circular economy framework. This involves transforming LDPE waste into higher-value products, such as durable construction materials or artistic creations. By finding new and innovative uses for recycled LDPE, these initiatives can help create demand for recycled materials and reduce the reliance on virgin LDPE production.

Implementing deposit-return schemes for LDPE products can significantly increase collection rates and ensure a steady supply of recyclable materials. These systems incentivize consumers to return used LDPE items by offering a small refund, effectively closing the loop between consumption and recycling.

Collaboration between industry stakeholders, including manufacturers, retailers, recyclers, and policymakers, is crucial for successful circular economy integration. By fostering partnerships and knowledge sharing, the LDPE value chain can be optimized to reduce waste, improve recycling efficiency, and develop more sustainable product designs.

Education and awareness campaigns play a vital role in promoting circular economy principles for LDPE management. By informing consumers about proper disposal methods, the importance of recycling, and the environmental impact of LDPE waste, these initiatives can drive behavioral changes that support a more circular approach to LDPE use and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!