How to Increase Reusability in LDPE Products?

JUN 30, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Reusability Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its commercial introduction in the 1930s. Known for its flexibility, durability, and cost-effectiveness, LDPE has found widespread use in packaging, construction, and consumer goods. However, as environmental concerns have grown, the focus has shifted towards increasing the reusability of LDPE products to reduce waste and promote sustainability.

The evolution of LDPE technology has been marked by continuous improvements in production processes and material properties. Initially developed through high-pressure polymerization, LDPE manufacturing has seen advancements in catalyst technology and process control, leading to enhanced product quality and efficiency. These developments have paved the way for exploring reusability options that were previously unfeasible.

In recent years, the push for circular economy principles has intensified the need for reusable LDPE solutions. This shift is driven by increasing environmental awareness, stringent regulations on single-use plastics, and growing consumer demand for sustainable products. The technical objective now is to develop LDPE products that maintain their desirable properties through multiple use cycles while minimizing environmental impact.

Achieving increased reusability in LDPE products presents several technical challenges. These include enhancing material durability to withstand repeated use, improving resistance to degradation from environmental factors, and developing efficient cleaning and reconditioning processes. Additionally, there is a need to design LDPE products that are inherently reusable from the outset, rather than retrofitting existing single-use designs.

The current landscape of LDPE reusability research encompasses various approaches. These range from material modifications to enhance longevity, to the development of advanced recycling technologies that can restore used LDPE to near-virgin quality. Innovations in additive technologies and polymer blending are being explored to create LDPE formulations that retain their properties over extended lifecycles.

Looking ahead, the trajectory of LDPE reusability is likely to involve interdisciplinary collaborations, combining materials science, chemical engineering, and product design. The goal is to create a new generation of LDPE products that are not only reusable but also easily recyclable at the end of their extended life. This holistic approach aims to address the entire lifecycle of LDPE products, from production to multiple use phases and eventual recycling or biodegradation.

As we delve deeper into the technical aspects of increasing LDPE reusability, it is crucial to consider the balance between performance, cost-effectiveness, and environmental impact. The ultimate objective is to develop solutions that are technically feasible, economically viable, and environmentally sustainable, paving the way for a more circular and responsible use of LDPE in various applications.

The evolution of LDPE technology has been marked by continuous improvements in production processes and material properties. Initially developed through high-pressure polymerization, LDPE manufacturing has seen advancements in catalyst technology and process control, leading to enhanced product quality and efficiency. These developments have paved the way for exploring reusability options that were previously unfeasible.

In recent years, the push for circular economy principles has intensified the need for reusable LDPE solutions. This shift is driven by increasing environmental awareness, stringent regulations on single-use plastics, and growing consumer demand for sustainable products. The technical objective now is to develop LDPE products that maintain their desirable properties through multiple use cycles while minimizing environmental impact.

Achieving increased reusability in LDPE products presents several technical challenges. These include enhancing material durability to withstand repeated use, improving resistance to degradation from environmental factors, and developing efficient cleaning and reconditioning processes. Additionally, there is a need to design LDPE products that are inherently reusable from the outset, rather than retrofitting existing single-use designs.

The current landscape of LDPE reusability research encompasses various approaches. These range from material modifications to enhance longevity, to the development of advanced recycling technologies that can restore used LDPE to near-virgin quality. Innovations in additive technologies and polymer blending are being explored to create LDPE formulations that retain their properties over extended lifecycles.

Looking ahead, the trajectory of LDPE reusability is likely to involve interdisciplinary collaborations, combining materials science, chemical engineering, and product design. The goal is to create a new generation of LDPE products that are not only reusable but also easily recyclable at the end of their extended life. This holistic approach aims to address the entire lifecycle of LDPE products, from production to multiple use phases and eventual recycling or biodegradation.

As we delve deeper into the technical aspects of increasing LDPE reusability, it is crucial to consider the balance between performance, cost-effectiveness, and environmental impact. The ultimate objective is to develop solutions that are technically feasible, economically viable, and environmentally sustainable, paving the way for a more circular and responsible use of LDPE in various applications.

Market Analysis for Reusable LDPE Products

The market for reusable LDPE (Low-Density Polyethylene) products has been experiencing significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce single-use plastics. This trend is expected to continue as consumers and businesses alike seek more sustainable alternatives to traditional disposable plastic items.

The global market for reusable LDPE products is diverse, encompassing various sectors such as packaging, consumer goods, and industrial applications. In the packaging industry, reusable LDPE bags and containers are gaining traction as alternatives to single-use plastic bags in retail and grocery settings. The food and beverage sector is also adopting reusable LDPE packaging solutions for transportation and storage purposes.

Consumer demand for eco-friendly products has led to an increase in reusable LDPE items such as water bottles, food storage containers, and household cleaning product containers. This shift in consumer behavior is driving manufacturers to innovate and develop more durable and attractive LDPE products that can withstand multiple uses.

In the industrial sector, reusable LDPE products are finding applications in logistics and supply chain management. Durable LDPE pallets, crates, and containers are being used to replace traditional wooden or single-use plastic alternatives, offering benefits such as reduced weight, improved hygiene, and longer lifespan.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the reusable LDPE products market, due to rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe are also significant markets, with established recycling infrastructure and strong consumer awareness driving demand for reusable alternatives.

Key market drivers include government regulations aimed at reducing plastic waste, corporate sustainability initiatives, and growing consumer preference for environmentally friendly products. However, challenges such as the higher initial cost of reusable LDPE products compared to single-use alternatives and the need for effective cleaning and maintenance systems may hinder market growth.

The COVID-19 pandemic has had a mixed impact on the market for reusable LDPE products. While concerns about hygiene initially led to increased use of single-use plastics, the long-term trend towards sustainability remains strong. As economies recover, there is potential for accelerated adoption of reusable LDPE products as part of broader efforts to build more resilient and environmentally friendly supply chains.

The global market for reusable LDPE products is diverse, encompassing various sectors such as packaging, consumer goods, and industrial applications. In the packaging industry, reusable LDPE bags and containers are gaining traction as alternatives to single-use plastic bags in retail and grocery settings. The food and beverage sector is also adopting reusable LDPE packaging solutions for transportation and storage purposes.

Consumer demand for eco-friendly products has led to an increase in reusable LDPE items such as water bottles, food storage containers, and household cleaning product containers. This shift in consumer behavior is driving manufacturers to innovate and develop more durable and attractive LDPE products that can withstand multiple uses.

In the industrial sector, reusable LDPE products are finding applications in logistics and supply chain management. Durable LDPE pallets, crates, and containers are being used to replace traditional wooden or single-use plastic alternatives, offering benefits such as reduced weight, improved hygiene, and longer lifespan.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the reusable LDPE products market, due to rapid industrialization, urbanization, and increasing environmental regulations. North America and Europe are also significant markets, with established recycling infrastructure and strong consumer awareness driving demand for reusable alternatives.

Key market drivers include government regulations aimed at reducing plastic waste, corporate sustainability initiatives, and growing consumer preference for environmentally friendly products. However, challenges such as the higher initial cost of reusable LDPE products compared to single-use alternatives and the need for effective cleaning and maintenance systems may hinder market growth.

The COVID-19 pandemic has had a mixed impact on the market for reusable LDPE products. While concerns about hygiene initially led to increased use of single-use plastics, the long-term trend towards sustainability remains strong. As economies recover, there is potential for accelerated adoption of reusable LDPE products as part of broader efforts to build more resilient and environmentally friendly supply chains.

Current Challenges in LDPE Recycling

The recycling of Low-Density Polyethylene (LDPE) products faces several significant challenges that hinder the widespread adoption of reusability practices. One of the primary obstacles is the contamination of LDPE waste streams. LDPE products often contain various additives, colorants, and labels that are difficult to separate during the recycling process. These contaminants can significantly degrade the quality of recycled LDPE, limiting its potential applications and reducing its market value.

Another major challenge is the lack of efficient sorting and separation technologies. LDPE products come in various forms, such as films, bags, and containers, which are often mixed with other plastic types in waste streams. The current sorting methods struggle to accurately identify and separate LDPE from other plastics, leading to lower-quality recycled materials and increased processing costs.

The degradation of LDPE during multiple recycling cycles poses a significant technical hurdle. Each time LDPE is recycled, its polymer chains break down, resulting in a loss of mechanical properties and overall quality. This degradation limits the number of times LDPE can be effectively recycled, reducing its long-term reusability potential.

Economic factors also play a crucial role in the challenges facing LDPE recycling. The cost of collecting, sorting, and processing LDPE waste often exceeds the value of the recycled material, especially when compared to virgin LDPE production. This economic imbalance discourages investment in recycling infrastructure and technology development, further impeding progress in LDPE reusability.

The lack of standardization in LDPE product design and composition presents another significant challenge. The wide variety of LDPE formulations used in different products makes it difficult to develop universal recycling processes. This diversity also complicates the creation of consistent, high-quality recycled LDPE materials that meet specific industry standards and consumer expectations.

Consumer behavior and awareness also contribute to the challenges in LDPE recycling. Many consumers are unaware of proper disposal methods for LDPE products or lack access to appropriate recycling facilities. This results in a significant portion of LDPE waste ending up in landfills or incineration plants, reducing the overall volume of material available for recycling and reuse.

Regulatory inconsistencies across different regions and countries further complicate LDPE recycling efforts. Varying waste management policies, recycling standards, and incentive structures create a fragmented landscape that hinders the development of large-scale, efficient recycling systems for LDPE products.

Another major challenge is the lack of efficient sorting and separation technologies. LDPE products come in various forms, such as films, bags, and containers, which are often mixed with other plastic types in waste streams. The current sorting methods struggle to accurately identify and separate LDPE from other plastics, leading to lower-quality recycled materials and increased processing costs.

The degradation of LDPE during multiple recycling cycles poses a significant technical hurdle. Each time LDPE is recycled, its polymer chains break down, resulting in a loss of mechanical properties and overall quality. This degradation limits the number of times LDPE can be effectively recycled, reducing its long-term reusability potential.

Economic factors also play a crucial role in the challenges facing LDPE recycling. The cost of collecting, sorting, and processing LDPE waste often exceeds the value of the recycled material, especially when compared to virgin LDPE production. This economic imbalance discourages investment in recycling infrastructure and technology development, further impeding progress in LDPE reusability.

The lack of standardization in LDPE product design and composition presents another significant challenge. The wide variety of LDPE formulations used in different products makes it difficult to develop universal recycling processes. This diversity also complicates the creation of consistent, high-quality recycled LDPE materials that meet specific industry standards and consumer expectations.

Consumer behavior and awareness also contribute to the challenges in LDPE recycling. Many consumers are unaware of proper disposal methods for LDPE products or lack access to appropriate recycling facilities. This results in a significant portion of LDPE waste ending up in landfills or incineration plants, reducing the overall volume of material available for recycling and reuse.

Regulatory inconsistencies across different regions and countries further complicate LDPE recycling efforts. Varying waste management policies, recycling standards, and incentive structures create a fragmented landscape that hinders the development of large-scale, efficient recycling systems for LDPE products.

Existing LDPE Reusability Solutions

01 Recycling and reprocessing of LDPE products

LDPE products can be recycled and reprocessed to create new materials. This process involves collecting, sorting, cleaning, and melting down LDPE items to form new products. The recycled LDPE can be used in various applications, reducing waste and promoting sustainability.- Recycling and reprocessing of LDPE products: LDPE products can be recycled and reprocessed to create new materials or products. This process involves collecting, sorting, cleaning, and melting down LDPE waste to form new pellets or raw materials. These recycled materials can then be used in the production of various items, reducing the need for virgin LDPE and promoting circular economy principles.

- Improving LDPE product durability for extended use: Techniques to enhance the durability of LDPE products can increase their lifespan and reusability. This may include adding stabilizers, reinforcing agents, or using advanced manufacturing processes to improve the material's resistance to degradation, UV radiation, and mechanical stress. Durable LDPE products can be used multiple times before requiring replacement or recycling.

- Development of biodegradable LDPE alternatives: Research into biodegradable alternatives to traditional LDPE can lead to more environmentally friendly products. These materials are designed to break down naturally in the environment while maintaining similar properties to LDPE during use. Biodegradable alternatives can reduce the environmental impact of single-use plastics and promote sustainable consumption patterns.

- LDPE product design for disassembly and reuse: Designing LDPE products with disassembly and reuse in mind can significantly increase their reusability. This approach involves creating products that can be easily taken apart, cleaned, and reassembled or repurposed. Such designs facilitate maintenance, repair, and eventual recycling, extending the product's useful life and reducing waste.

- Chemical recycling of LDPE products: Chemical recycling processes can break down LDPE products into their basic chemical components, which can then be used to create new plastics or other materials. This method allows for the recycling of contaminated or mixed plastic waste that may not be suitable for mechanical recycling, potentially increasing the overall reusability of LDPE products.

02 Improving LDPE properties for enhanced reusability

Techniques to enhance the properties of LDPE, such as increasing its durability, heat resistance, and chemical stability, can improve its reusability. This may involve adding specific additives or modifying the polymer structure to create more robust LDPE products that can withstand multiple use cycles.Expand Specific Solutions03 LDPE blends and composites for extended product life

Creating blends or composites of LDPE with other materials can result in products with improved characteristics and longer lifespans. These enhanced materials may offer better resistance to degradation, allowing for extended use and multiple recycling cycles.Expand Specific Solutions04 Design for disassembly and reuse of LDPE components

Developing LDPE products with a focus on easy disassembly can facilitate the separation of components for reuse or recycling. This approach involves designing products that can be easily taken apart, allowing for the replacement of worn parts or the recovery of LDPE materials for reprocessing.Expand Specific Solutions05 Chemical recycling of LDPE for feedstock recovery

Advanced chemical recycling techniques can break down LDPE products into their basic chemical components. This process allows for the recovery of valuable feedstock materials that can be used to create new LDPE products or other petrochemical-based items, effectively closing the loop in plastic production.Expand Specific Solutions

Key Players in LDPE Recycling Industry

The market for increasing reusability in LDPE products is in a growth phase, driven by rising environmental concerns and regulatory pressures. The global market size for recycled LDPE is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with major players like Dow Global Technologies, SABIC, and ExxonMobil leading innovation. These companies are developing improved recycling processes, enhancing material properties, and exploring new applications for recycled LDPE. While the technology is maturing, there's still room for significant advancements in areas like contamination removal, material quality, and process efficiency to fully realize the potential of LDPE reusability.

Dow Global Technologies LLC

Technical Solution: Dow has developed ELITE™ Enhanced Polyethylene (EPE) Resins, which offer improved mechanical properties and processability compared to traditional LDPE. These resins incorporate molecular architecture control to enhance reusability without compromising performance. Dow's AGILITY™ EC technology enables the production of LDPE with controlled long-chain branching, resulting in improved melt strength and easier recyclability[1]. The company has also introduced REVOLOOP™, a portfolio of mechanically recycled polyethylene, including LDPE, which can be used in various applications while maintaining product integrity[2].

Strengths: Advanced polymer science expertise, global scale, and extensive R&D capabilities. Weaknesses: Potential higher costs associated with specialized resins and recycling processes.

SABIC Global Technologies BV

Technical Solution: SABIC has developed SABIC® LDPE PCR compounds, incorporating post-consumer recycled (PCR) content into LDPE products. These compounds are designed to maintain key properties of virgin LDPE while increasing reusability. SABIC's TRUCIRCLE™ portfolio includes mechanically recycled LDPE for packaging applications, offering a circular solution[3]. The company has also invested in advanced recycling technologies, such as pyrolysis, to convert mixed plastic waste back into feedstock for new LDPE production, effectively increasing the reusability of LDPE products[4].

Strengths: Diverse portfolio of recycling solutions, strong focus on circular economy. Weaknesses: Dependence on waste collection infrastructure and potential quality variations in recycled content.

Innovations in LDPE Reprocessing

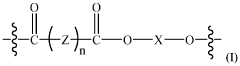

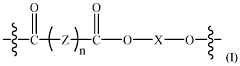

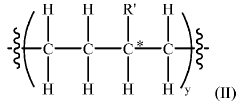

Repeatedly recyclable polymer mimics (RR-pm) of low-density polyethylene (LDPE) polymers

PatentWO2024133401A2

Innovation

- Development of repeatedly recyclable polymer mimics (RR-PM) of LDPE, which are created from a reaction product of difunctional oligomers and linkers obtained through depolymerization of used articles, allowing for repeated recycling with minimal loss of properties and reduced need for virgin materials.

Modified waste polyethylene special material for pipeline and preparation method of modified waste polyethylene special material

PatentInactiveCN105017612A

Innovation

- The composite toughening modifier is composed of waste tire rubber powder, ethylene-octene copolymer (POE) and low-density polyethylene resin (LLDPE), and is combined with anhydrite through blending micro-crosslinking technology and thermoplastic elastomer. Powder serves as an inorganic filler to optimize the mechanical properties and processing properties of the material.

Environmental Impact Assessment

The environmental impact assessment of increasing reusability in LDPE (Low-Density Polyethylene) products is a critical aspect of sustainable product development. LDPE, widely used in packaging and consumer goods, has significant environmental implications throughout its lifecycle. By enhancing the reusability of LDPE products, we can potentially mitigate these impacts.

Reusable LDPE products can substantially reduce the demand for virgin plastic production. This decrease in production leads to lower energy consumption and greenhouse gas emissions associated with the manufacturing process. Studies have shown that reusing LDPE items just a few times can cut their carbon footprint by up to 80% compared to single-use alternatives.

Water conservation is another key benefit of increased LDPE reusability. The production of virgin LDPE requires significant water resources, both for the manufacturing process and for cooling. By extending the life of LDPE products through reuse, we can reduce the overall water demand in the plastic industry, contributing to water conservation efforts.

Landfill waste reduction is a crucial environmental advantage of reusable LDPE products. Single-use LDPE items contribute significantly to plastic waste in landfills, where they can take hundreds of years to decompose. Increasing reusability directly addresses this issue by keeping products in circulation longer, thereby reducing the volume of plastic waste entering landfills and potentially ending up in natural ecosystems.

However, it's important to consider the environmental trade-offs of reusable LDPE products. The durability required for multiple uses often necessitates thicker plastic or additional materials, which could increase the initial environmental footprint. This emphasizes the need for life cycle assessments to ensure that the benefits of reuse outweigh the increased resource input in production.

The cleaning and maintenance of reusable LDPE products also have environmental implications. While reuse reduces waste, the energy and water consumed in cleaning processes must be factored into the overall environmental impact. Developing efficient cleaning methods and educating consumers on proper care can help minimize these secondary environmental effects.

Lastly, the end-of-life management of reusable LDPE products remains a crucial consideration. Even with extended use, these products will eventually require disposal or recycling. Implementing effective recycling systems and exploring innovative recycling technologies for LDPE can further enhance the environmental benefits of reusable products, creating a more circular economy for plastic materials.

Reusable LDPE products can substantially reduce the demand for virgin plastic production. This decrease in production leads to lower energy consumption and greenhouse gas emissions associated with the manufacturing process. Studies have shown that reusing LDPE items just a few times can cut their carbon footprint by up to 80% compared to single-use alternatives.

Water conservation is another key benefit of increased LDPE reusability. The production of virgin LDPE requires significant water resources, both for the manufacturing process and for cooling. By extending the life of LDPE products through reuse, we can reduce the overall water demand in the plastic industry, contributing to water conservation efforts.

Landfill waste reduction is a crucial environmental advantage of reusable LDPE products. Single-use LDPE items contribute significantly to plastic waste in landfills, where they can take hundreds of years to decompose. Increasing reusability directly addresses this issue by keeping products in circulation longer, thereby reducing the volume of plastic waste entering landfills and potentially ending up in natural ecosystems.

However, it's important to consider the environmental trade-offs of reusable LDPE products. The durability required for multiple uses often necessitates thicker plastic or additional materials, which could increase the initial environmental footprint. This emphasizes the need for life cycle assessments to ensure that the benefits of reuse outweigh the increased resource input in production.

The cleaning and maintenance of reusable LDPE products also have environmental implications. While reuse reduces waste, the energy and water consumed in cleaning processes must be factored into the overall environmental impact. Developing efficient cleaning methods and educating consumers on proper care can help minimize these secondary environmental effects.

Lastly, the end-of-life management of reusable LDPE products remains a crucial consideration. Even with extended use, these products will eventually require disposal or recycling. Implementing effective recycling systems and exploring innovative recycling technologies for LDPE can further enhance the environmental benefits of reusable products, creating a more circular economy for plastic materials.

Regulatory Framework for Plastic Recycling

The regulatory framework for plastic recycling plays a crucial role in increasing the reusability of LDPE products. Governments worldwide are implementing stricter regulations to promote circular economy principles and reduce plastic waste. In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling and reuse, aiming to ensure all plastic packaging is recyclable or reusable by 2030.

Many countries have introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize companies to design LDPE products with reusability in mind, encouraging the use of recycled content and easily recyclable materials.

Deposit-return systems have been implemented in several regions to encourage the return and reuse of plastic containers. While primarily focused on PET bottles, these systems could potentially be expanded to include LDPE products, promoting their reuse and reducing waste.

Labeling requirements are becoming more stringent, with many jurisdictions mandating clear recycling instructions on plastic products. This helps consumers properly dispose of LDPE items, increasing the likelihood of successful recycling and reuse.

Bans on single-use plastics are becoming more common, indirectly promoting the development of reusable LDPE alternatives. These regulations push manufacturers to innovate and create more durable, multi-use LDPE products that can replace disposable items.

Tax incentives and subsidies are being introduced in some countries to support businesses that invest in recycling infrastructure or incorporate recycled LDPE into their products. These financial measures aim to make recycling and reuse more economically viable for companies.

Standards and certifications for recycled plastics are being developed to ensure the quality and safety of recycled LDPE materials. These standards help build trust in recycled products and encourage their use in various applications, thereby increasing reusability.

Research and development grants are being offered by governments to support innovation in plastic recycling technologies. These initiatives aim to improve the efficiency and effectiveness of LDPE recycling processes, making it easier to reuse these materials in new products.

Many countries have introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize companies to design LDPE products with reusability in mind, encouraging the use of recycled content and easily recyclable materials.

Deposit-return systems have been implemented in several regions to encourage the return and reuse of plastic containers. While primarily focused on PET bottles, these systems could potentially be expanded to include LDPE products, promoting their reuse and reducing waste.

Labeling requirements are becoming more stringent, with many jurisdictions mandating clear recycling instructions on plastic products. This helps consumers properly dispose of LDPE items, increasing the likelihood of successful recycling and reuse.

Bans on single-use plastics are becoming more common, indirectly promoting the development of reusable LDPE alternatives. These regulations push manufacturers to innovate and create more durable, multi-use LDPE products that can replace disposable items.

Tax incentives and subsidies are being introduced in some countries to support businesses that invest in recycling infrastructure or incorporate recycled LDPE into their products. These financial measures aim to make recycling and reuse more economically viable for companies.

Standards and certifications for recycled plastics are being developed to ensure the quality and safety of recycled LDPE materials. These standards help build trust in recycled products and encourage their use in various applications, thereby increasing reusability.

Research and development grants are being offered by governments to support innovation in plastic recycling technologies. These initiatives aim to improve the efficiency and effectiveness of LDPE recycling processes, making it easier to reuse these materials in new products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!