How to Develop Bio-Based Alternatives to LDPE?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Alternatives: Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its development in the 1930s. Its versatility, durability, and low cost have made it ubiquitous in packaging, consumer goods, and industrial applications. However, the environmental impact of petroleum-based plastics has become a growing concern, driving the search for sustainable alternatives.

The development of bio-based alternatives to LDPE is rooted in the broader context of the circular economy and sustainable materials science. This initiative aims to address the environmental challenges posed by conventional plastics while maintaining the functional benefits that have made LDPE so widely used. The primary objective is to create materials that offer similar or superior performance characteristics to LDPE, but with a significantly reduced carbon footprint and improved end-of-life options.

Recent advancements in biotechnology and materials science have opened new avenues for the development of bio-based polymers. These innovations draw inspiration from nature's own polymers, such as cellulose, starch, and proteins, as well as from the ability to engineer microorganisms to produce novel biopolymers. The goal is to harness these biological processes and materials to create alternatives that can be sustainably sourced, manufactured with lower energy inputs, and biodegraded or recycled more effectively than traditional LDPE.

The technical evolution in this field has been marked by several key milestones. Early efforts focused on blending bio-based materials with conventional plastics to improve biodegradability. This approach has evolved towards the development of fully bio-based polymers that can match or exceed the performance of LDPE. Concurrently, there has been significant progress in optimizing production processes to make these alternatives economically viable at scale.

As the field progresses, researchers are exploring a diverse range of feedstocks and production methods. These include the use of agricultural waste, algae-based materials, and even carbon dioxide as raw materials for polymer synthesis. The ultimate aim is to develop a new generation of materials that can seamlessly integrate into existing manufacturing and recycling infrastructures while offering enhanced environmental benefits.

The pursuit of bio-based alternatives to LDPE is not without its challenges. Achieving the right balance of properties, such as tensile strength, barrier performance, and processability, while maintaining biodegradability or recyclability, remains a complex task. Additionally, scaling up production to meet global demand and ensuring cost-competitiveness with conventional LDPE are critical hurdles that must be overcome.

The development of bio-based alternatives to LDPE is rooted in the broader context of the circular economy and sustainable materials science. This initiative aims to address the environmental challenges posed by conventional plastics while maintaining the functional benefits that have made LDPE so widely used. The primary objective is to create materials that offer similar or superior performance characteristics to LDPE, but with a significantly reduced carbon footprint and improved end-of-life options.

Recent advancements in biotechnology and materials science have opened new avenues for the development of bio-based polymers. These innovations draw inspiration from nature's own polymers, such as cellulose, starch, and proteins, as well as from the ability to engineer microorganisms to produce novel biopolymers. The goal is to harness these biological processes and materials to create alternatives that can be sustainably sourced, manufactured with lower energy inputs, and biodegraded or recycled more effectively than traditional LDPE.

The technical evolution in this field has been marked by several key milestones. Early efforts focused on blending bio-based materials with conventional plastics to improve biodegradability. This approach has evolved towards the development of fully bio-based polymers that can match or exceed the performance of LDPE. Concurrently, there has been significant progress in optimizing production processes to make these alternatives economically viable at scale.

As the field progresses, researchers are exploring a diverse range of feedstocks and production methods. These include the use of agricultural waste, algae-based materials, and even carbon dioxide as raw materials for polymer synthesis. The ultimate aim is to develop a new generation of materials that can seamlessly integrate into existing manufacturing and recycling infrastructures while offering enhanced environmental benefits.

The pursuit of bio-based alternatives to LDPE is not without its challenges. Achieving the right balance of properties, such as tensile strength, barrier performance, and processability, while maintaining biodegradability or recyclability, remains a complex task. Additionally, scaling up production to meet global demand and ensuring cost-competitiveness with conventional LDPE are critical hurdles that must be overcome.

Market Analysis for Bio-Based Plastics

The market for bio-based plastics, particularly as alternatives to Low-Density Polyethylene (LDPE), has been experiencing significant growth and transformation in recent years. This surge is primarily driven by increasing environmental concerns, stringent regulations on conventional plastics, and a growing consumer preference for sustainable products.

The global bio-based plastics market has shown robust growth, with a compound annual growth rate (CAGR) exceeding 20% over the past five years. This trend is expected to continue, with projections indicating that the market could reach a value of several billion dollars by 2025. Specifically, bio-based alternatives to LDPE are gaining traction in various industries, including packaging, agriculture, and consumer goods.

One of the key drivers for this market growth is the increasing awareness of environmental issues associated with traditional petroleum-based plastics. Governments worldwide are implementing stricter regulations on single-use plastics, which is pushing manufacturers to seek sustainable alternatives. This regulatory pressure, combined with consumer demand for eco-friendly products, is creating a favorable environment for bio-based LDPE alternatives.

The packaging industry represents the largest market segment for bio-based plastics, accounting for over 50% of the total market share. Within this segment, food packaging is a particularly promising area for bio-based LDPE alternatives due to their biodegradability and compostability. The agriculture sector is another significant market, with bio-based mulch films and greenhouse covers showing increased adoption.

Geographically, Europe leads the market for bio-based plastics, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and high consumer awareness, have been at the forefront of adopting bio-based alternatives. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

Despite the positive outlook, the market for bio-based alternatives to LDPE faces several challenges. The higher production costs compared to conventional LDPE remain a significant barrier to widespread adoption. Additionally, there are concerns about the performance and durability of bio-based plastics in certain applications, which need to be addressed through continued research and development.

Looking ahead, technological advancements in bio-based plastic production, coupled with economies of scale, are expected to drive down costs and improve performance. This will likely lead to increased market penetration across various industries. Furthermore, the development of novel feedstocks and production processes for bio-based LDPE alternatives presents significant opportunities for innovation and market growth in the coming years.

The global bio-based plastics market has shown robust growth, with a compound annual growth rate (CAGR) exceeding 20% over the past five years. This trend is expected to continue, with projections indicating that the market could reach a value of several billion dollars by 2025. Specifically, bio-based alternatives to LDPE are gaining traction in various industries, including packaging, agriculture, and consumer goods.

One of the key drivers for this market growth is the increasing awareness of environmental issues associated with traditional petroleum-based plastics. Governments worldwide are implementing stricter regulations on single-use plastics, which is pushing manufacturers to seek sustainable alternatives. This regulatory pressure, combined with consumer demand for eco-friendly products, is creating a favorable environment for bio-based LDPE alternatives.

The packaging industry represents the largest market segment for bio-based plastics, accounting for over 50% of the total market share. Within this segment, food packaging is a particularly promising area for bio-based LDPE alternatives due to their biodegradability and compostability. The agriculture sector is another significant market, with bio-based mulch films and greenhouse covers showing increased adoption.

Geographically, Europe leads the market for bio-based plastics, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and high consumer awareness, have been at the forefront of adopting bio-based alternatives. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

Despite the positive outlook, the market for bio-based alternatives to LDPE faces several challenges. The higher production costs compared to conventional LDPE remain a significant barrier to widespread adoption. Additionally, there are concerns about the performance and durability of bio-based plastics in certain applications, which need to be addressed through continued research and development.

Looking ahead, technological advancements in bio-based plastic production, coupled with economies of scale, are expected to drive down costs and improve performance. This will likely lead to increased market penetration across various industries. Furthermore, the development of novel feedstocks and production processes for bio-based LDPE alternatives presents significant opportunities for innovation and market growth in the coming years.

Current Challenges in Bio-Based LDPE Development

The development of bio-based alternatives to Low-Density Polyethylene (LDPE) faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is achieving comparable mechanical properties to traditional LDPE. Bio-based polymers often struggle to match the flexibility, tensile strength, and barrier properties that make LDPE so versatile in packaging applications.

Cost-effectiveness remains a major hurdle in the production of bio-based LDPE alternatives. The raw materials and processing methods for bio-based polymers are generally more expensive than those for petroleum-based LDPE. This price disparity makes it difficult for bio-based alternatives to compete in the market, especially in price-sensitive industries.

Scalability presents another significant challenge. While many bio-based polymers show promise in laboratory settings, translating these successes to large-scale industrial production has proven difficult. Issues such as inconsistent feedstock quality, complex processing requirements, and the need for specialized equipment contribute to this scalability problem.

The environmental impact of bio-based LDPE alternatives is not always straightforward. While these materials are derived from renewable resources, their production may involve energy-intensive processes or require large amounts of land and water. Additionally, the end-of-life management of these materials can be problematic, as many bio-based polymers are not compatible with existing recycling infrastructure.

Regulatory hurdles and certification processes pose additional challenges. The lack of standardized testing methods and certification criteria for bio-based materials can lead to confusion in the market and hesitation among potential adopters. Navigating the complex landscape of regulations across different regions adds another layer of difficulty for manufacturers.

Performance consistency is another area of concern. Bio-based polymers can exhibit variations in properties depending on the source and quality of the biomass feedstock. This inconsistency can be problematic for industries that require strict quality control, such as food packaging or medical applications.

Lastly, market acceptance and consumer perception present ongoing challenges. While there is growing interest in sustainable alternatives, many consumers and businesses are hesitant to switch from familiar LDPE products. Overcoming this inertia requires not only technical advancements but also effective education and marketing strategies to highlight the benefits of bio-based alternatives.

Cost-effectiveness remains a major hurdle in the production of bio-based LDPE alternatives. The raw materials and processing methods for bio-based polymers are generally more expensive than those for petroleum-based LDPE. This price disparity makes it difficult for bio-based alternatives to compete in the market, especially in price-sensitive industries.

Scalability presents another significant challenge. While many bio-based polymers show promise in laboratory settings, translating these successes to large-scale industrial production has proven difficult. Issues such as inconsistent feedstock quality, complex processing requirements, and the need for specialized equipment contribute to this scalability problem.

The environmental impact of bio-based LDPE alternatives is not always straightforward. While these materials are derived from renewable resources, their production may involve energy-intensive processes or require large amounts of land and water. Additionally, the end-of-life management of these materials can be problematic, as many bio-based polymers are not compatible with existing recycling infrastructure.

Regulatory hurdles and certification processes pose additional challenges. The lack of standardized testing methods and certification criteria for bio-based materials can lead to confusion in the market and hesitation among potential adopters. Navigating the complex landscape of regulations across different regions adds another layer of difficulty for manufacturers.

Performance consistency is another area of concern. Bio-based polymers can exhibit variations in properties depending on the source and quality of the biomass feedstock. This inconsistency can be problematic for industries that require strict quality control, such as food packaging or medical applications.

Lastly, market acceptance and consumer perception present ongoing challenges. While there is growing interest in sustainable alternatives, many consumers and businesses are hesitant to switch from familiar LDPE products. Overcoming this inertia requires not only technical advancements but also effective education and marketing strategies to highlight the benefits of bio-based alternatives.

Existing Bio-Based LDPE Alternatives

01 Biodegradable polymers as LDPE alternatives

Biodegradable polymers derived from renewable resources are being developed as eco-friendly alternatives to LDPE. These materials offer similar properties to traditional plastics while being more environmentally sustainable. They can be produced from various bio-based sources and are designed to decompose naturally, reducing environmental impact.- Biopolymer-based alternatives: Biopolymers derived from renewable resources are being developed as eco-friendly alternatives to LDPE. These materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), offer similar properties to LDPE while being biodegradable and compostable. Research focuses on improving their mechanical properties and processability to match or exceed LDPE performance.

- Starch-based blends and composites: Starch, a readily available and biodegradable polymer, is being used in blends and composites as an alternative to LDPE. These materials often incorporate other bio-based polymers or additives to enhance properties such as water resistance and mechanical strength. Ongoing research aims to optimize formulations for various applications while maintaining biodegradability.

- Cellulose-derived materials: Cellulose, the most abundant biopolymer on Earth, is being utilized to create bio-based alternatives to LDPE. Cellulose derivatives and nanocellulose composites are being developed to mimic LDPE properties while offering improved environmental sustainability. These materials show promise in packaging and other applications traditionally dominated by LDPE.

- Bio-based polyethylene: Researchers are developing methods to produce polyethylene from renewable resources, such as sugarcane or other plant-based feedstocks. This bio-based polyethylene has identical properties to conventional LDPE but with a reduced carbon footprint. The challenge lies in scaling up production and reducing costs to compete with fossil-fuel-derived LDPE.

- Novel bio-based polymer blends: Innovative blends of various bio-based polymers and natural fibers are being explored as alternatives to LDPE. These blends aim to combine the strengths of different bio-based materials to create composites with properties similar to or superior to LDPE. Research focuses on optimizing blend ratios, improving compatibility between components, and enhancing overall performance for specific applications.

02 Starch-based composites

Starch-based composites are being explored as potential replacements for LDPE. These materials combine starch with other biodegradable polymers or natural fibers to improve mechanical properties and processability. The resulting composites can be tailored for various applications while maintaining biodegradability.Expand Specific Solutions03 Cellulose-derived materials

Cellulose, a naturally abundant polymer, is being utilized to create bio-based alternatives to LDPE. Various cellulose derivatives and composites are being developed to mimic the properties of LDPE while offering improved environmental characteristics. These materials can be sourced from agricultural waste or sustainable forestry practices.Expand Specific Solutions04 Bio-based polyethylene

Researchers are developing methods to produce polyethylene from renewable resources, creating a bio-based alternative that is chemically identical to traditional LDPE. This approach allows for the production of a familiar material with established recycling infrastructure while reducing reliance on fossil fuels.Expand Specific Solutions05 Protein-based polymers

Proteins from various sources, such as plant proteins or waste products from food processing, are being investigated as potential LDPE alternatives. These protein-based materials can be modified and blended to achieve properties similar to LDPE while offering biodegradability and sustainability advantages.Expand Specific Solutions

Key Players in Bio-Based Plastics Industry

The development of bio-based alternatives to LDPE is in an early growth stage, with increasing market potential driven by sustainability trends. The global market for bio-based plastics is expanding, though still relatively small compared to conventional plastics. Technologically, progress is being made but challenges remain in achieving cost-competitiveness and performance parity with petroleum-based LDPE. Companies like Archer-Daniels-Midland, Novamont, and Gevo are at the forefront of developing bio-based polymer technologies. Academic institutions such as the University of Massachusetts and South China University of Technology are also contributing significant research. Collaboration between industry and academia is accelerating innovation in this field.

Archer-Daniels-Midland Co.

Technical Solution: ADM has developed a bio-based alternative to LDPE through its collaboration with Metabolix, focusing on the production of polyhydroxyalkanoates (PHAs). Their technology involves the fermentation of corn sugar using genetically engineered microorganisms to produce PHA biopolymers[13]. These PHAs can be blended with other bio-based materials to create flexible films with properties similar to LDPE. ADM's approach leverages their expertise in agricultural processing and fermentation technology to produce renewable, biodegradable alternatives to traditional plastics[14]. The company has invested in large-scale fermentation facilities to support the commercial production of PHA-based materials[15].

Strengths: Fully bio-based and biodegradable, leverages existing agricultural infrastructure. Weaknesses: Higher production costs, potential limitations in certain high-performance applications compared to traditional LDPE.

Novamont SpA

Technical Solution: Novamont has developed a bio-based and biodegradable alternative to LDPE called Mater-Bi. This material is produced from renewable resources such as corn starch and vegetable oils. Mater-Bi can be processed using conventional plastic processing equipment and offers similar properties to traditional LDPE in terms of flexibility, durability, and barrier properties[1]. The company has also developed a range of grades suitable for different applications, including film extrusion, injection molding, and thermoforming[2]. Novamont's technology involves the use of proprietary catalysts and processes to create biodegradable polyesters and starch-based blends that can replace LDPE in various applications[3].

Strengths: Renewable sourcing, biodegradability, versatility in applications. Weaknesses: Potentially higher production costs, limited high-temperature resistance compared to traditional LDPE.

Innovative Bio-Polymer Technologies

Plastic starch material and preparation method thereof

PatentInactiveCN117050388A

Innovation

- Using starch as the main material, combined with plasticizers such as polyhydroxymethylated rosin glyceryl ester, polyglyceryl citrate, and polyglyceryl tartrate, a plastic starch material is prepared through high mixer mixing and ultra-fine grinding. , lower the glass transition temperature of starch molecules and improve its plasticizing processing performance.

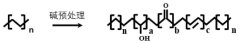

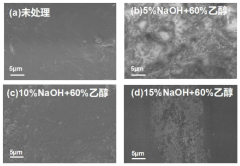

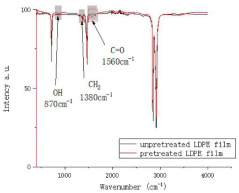

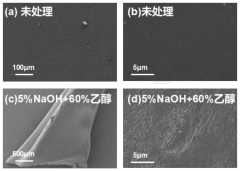

Application of overexpression of alkane hydroxylase and laccase genes in LDPE degradation

PatentActiveCN116650898B

Innovation

- Transform Yarrowia lipolytica through synthetic biology methods, express alkane hydroxylase and laccase genes, use Yarrowia lipolytica with excellent extracellular enzyme secretion ability to degrade LDPE, and combine it with ethanol solution pretreatment with sodium hydroxide Improve biodegradation efficiency.

Environmental Impact Assessment

The environmental impact assessment of developing bio-based alternatives to LDPE is crucial for understanding the potential benefits and drawbacks of these new materials. Bio-based alternatives, derived from renewable resources, offer promising opportunities to reduce the environmental footprint associated with traditional LDPE production and use.

One of the primary advantages of bio-based alternatives is their potential to reduce greenhouse gas emissions. Unlike conventional LDPE, which is derived from fossil fuels, bio-based materials can be produced from renewable sources such as plant-based feedstocks. This shift can lead to a significant reduction in carbon dioxide emissions throughout the product lifecycle, from raw material extraction to end-of-life disposal.

Water consumption is another critical factor to consider. While bio-based alternatives may require water for crop cultivation, advanced agricultural practices and efficient processing techniques can help minimize water usage. In contrast, traditional LDPE production often involves water-intensive processes in petrochemical refineries.

Land use changes associated with bio-based alternatives must be carefully evaluated. The cultivation of crops for bio-based plastics could potentially compete with food production or lead to deforestation if not managed sustainably. However, the use of agricultural waste or non-food crops can mitigate these concerns and provide additional value to existing agricultural systems.

Biodegradability is a key environmental advantage of many bio-based alternatives. Unlike conventional LDPE, which persists in the environment for hundreds of years, some bio-based plastics can decompose naturally under specific conditions. This property can significantly reduce the accumulation of plastic waste in landfills and marine environments, addressing one of the most pressing environmental issues associated with traditional plastics.

The production of bio-based alternatives may also lead to reduced toxicity and pollution. Many bio-based materials can be processed using less harmful chemicals compared to petrochemical-based LDPE, potentially decreasing the release of toxic substances into the environment during manufacturing and disposal.

Energy consumption in the production of bio-based alternatives is an important consideration. While some bio-based processes may require more energy initially, ongoing research and technological advancements are improving energy efficiency. Additionally, the use of renewable energy sources in production can further enhance the environmental benefits of these materials.

In conclusion, the environmental impact assessment of bio-based alternatives to LDPE reveals significant potential for reducing the ecological footprint of plastic production and use. However, careful consideration of factors such as land use, water consumption, and energy requirements is essential to ensure that these alternatives truly offer a more sustainable solution compared to traditional LDPE.

One of the primary advantages of bio-based alternatives is their potential to reduce greenhouse gas emissions. Unlike conventional LDPE, which is derived from fossil fuels, bio-based materials can be produced from renewable sources such as plant-based feedstocks. This shift can lead to a significant reduction in carbon dioxide emissions throughout the product lifecycle, from raw material extraction to end-of-life disposal.

Water consumption is another critical factor to consider. While bio-based alternatives may require water for crop cultivation, advanced agricultural practices and efficient processing techniques can help minimize water usage. In contrast, traditional LDPE production often involves water-intensive processes in petrochemical refineries.

Land use changes associated with bio-based alternatives must be carefully evaluated. The cultivation of crops for bio-based plastics could potentially compete with food production or lead to deforestation if not managed sustainably. However, the use of agricultural waste or non-food crops can mitigate these concerns and provide additional value to existing agricultural systems.

Biodegradability is a key environmental advantage of many bio-based alternatives. Unlike conventional LDPE, which persists in the environment for hundreds of years, some bio-based plastics can decompose naturally under specific conditions. This property can significantly reduce the accumulation of plastic waste in landfills and marine environments, addressing one of the most pressing environmental issues associated with traditional plastics.

The production of bio-based alternatives may also lead to reduced toxicity and pollution. Many bio-based materials can be processed using less harmful chemicals compared to petrochemical-based LDPE, potentially decreasing the release of toxic substances into the environment during manufacturing and disposal.

Energy consumption in the production of bio-based alternatives is an important consideration. While some bio-based processes may require more energy initially, ongoing research and technological advancements are improving energy efficiency. Additionally, the use of renewable energy sources in production can further enhance the environmental benefits of these materials.

In conclusion, the environmental impact assessment of bio-based alternatives to LDPE reveals significant potential for reducing the ecological footprint of plastic production and use. However, careful consideration of factors such as land use, water consumption, and energy requirements is essential to ensure that these alternatives truly offer a more sustainable solution compared to traditional LDPE.

Regulatory Framework for Bio-Based Plastics

The regulatory framework for bio-based plastics is a complex and evolving landscape that plays a crucial role in the development and adoption of alternatives to traditional LDPE. As governments and international organizations increasingly recognize the environmental impact of conventional plastics, they are implementing policies and regulations to promote the use of bio-based materials.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for the recycling and recovery of packaging materials, including plastics. The directive encourages the use of bio-based materials as a means to reduce environmental impact. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of bio-based plastics in achieving sustainability goals.

The United States has implemented the Farm Bill, which includes provisions for the development and use of bio-based products. The USDA BioPreferred Program, established under this bill, promotes the purchase and use of bio-based products through federal procurement and voluntary labeling initiatives.

Many countries have introduced regulations on single-use plastics, which indirectly benefit bio-based alternatives. For instance, France has banned single-use plastic bags, encouraging the use of bio-based and compostable alternatives. Similarly, India has implemented a nationwide ban on single-use plastics, creating opportunities for bio-based LDPE alternatives.

Certification and labeling schemes play a significant role in the regulatory framework. The European Committee for Standardization (CEN) has developed standards for bio-based products, including EN 16785 for bio-based content determination. These standards provide a common language and methodology for assessing bio-based materials, facilitating trade and consumer confidence.

However, the regulatory landscape also presents challenges. The lack of harmonized global standards for bio-based plastics can create barriers to international trade and market expansion. Additionally, regulations regarding end-of-life management for bio-based plastics vary widely, with some regions lacking clear guidelines for composting or recycling these materials.

As the bio-based plastics industry continues to grow, regulatory bodies are working to address these challenges. The development of life cycle assessment (LCA) methodologies specific to bio-based materials is underway, which will help in creating more comprehensive and fair regulations. Furthermore, efforts are being made to align regulations across different regions to create a more cohesive global framework for bio-based plastics.

In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for the recycling and recovery of packaging materials, including plastics. The directive encourages the use of bio-based materials as a means to reduce environmental impact. Additionally, the EU's Circular Economy Action Plan emphasizes the importance of bio-based plastics in achieving sustainability goals.

The United States has implemented the Farm Bill, which includes provisions for the development and use of bio-based products. The USDA BioPreferred Program, established under this bill, promotes the purchase and use of bio-based products through federal procurement and voluntary labeling initiatives.

Many countries have introduced regulations on single-use plastics, which indirectly benefit bio-based alternatives. For instance, France has banned single-use plastic bags, encouraging the use of bio-based and compostable alternatives. Similarly, India has implemented a nationwide ban on single-use plastics, creating opportunities for bio-based LDPE alternatives.

Certification and labeling schemes play a significant role in the regulatory framework. The European Committee for Standardization (CEN) has developed standards for bio-based products, including EN 16785 for bio-based content determination. These standards provide a common language and methodology for assessing bio-based materials, facilitating trade and consumer confidence.

However, the regulatory landscape also presents challenges. The lack of harmonized global standards for bio-based plastics can create barriers to international trade and market expansion. Additionally, regulations regarding end-of-life management for bio-based plastics vary widely, with some regions lacking clear guidelines for composting or recycling these materials.

As the bio-based plastics industry continues to grow, regulatory bodies are working to address these challenges. The development of life cycle assessment (LCA) methodologies specific to bio-based materials is underway, which will help in creating more comprehensive and fair regulations. Furthermore, efforts are being made to align regulations across different regions to create a more cohesive global framework for bio-based plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!