Innovations in Biodegradable LDPE for Eco-Friendly Use

JUN 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Biodegradability: Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its invention in the 1930s. Its versatility, durability, and low cost have made it ubiquitous in packaging, consumer goods, and various industrial applications. However, the very properties that make LDPE so useful have also contributed to a global environmental crisis, as conventional LDPE can persist in the environment for hundreds of years.

The growing awareness of plastic pollution has led to increased pressure on industries and governments to find sustainable alternatives. This has sparked a surge of interest in biodegradable LDPE, which aims to maintain the beneficial properties of traditional LDPE while addressing its end-of-life environmental impact. The development of biodegradable LDPE represents a convergence of polymer science, microbiology, and environmental engineering.

The evolution of biodegradable LDPE technology can be traced through several key phases. Initially, efforts focused on blending LDPE with naturally biodegradable materials such as starch. While this approach showed promise, it often resulted in compromised material properties. Subsequent research shifted towards modifying the LDPE polymer structure itself to enhance biodegradability, including the incorporation of pro-oxidant additives to promote oxidative degradation.

Recent innovations have explored more sophisticated approaches, such as the development of enzyme-responsive LDPE and the use of novel microbial strains capable of metabolizing polyethylene. These advancements aim to create LDPE materials that can maintain their functional properties during use but degrade rapidly under specific environmental conditions.

The primary objective of current research in biodegradable LDPE is to develop materials that offer comparable performance to conventional LDPE in terms of mechanical properties, processability, and cost-effectiveness, while significantly reducing environmental persistence. This goal encompasses several specific targets, including achieving complete biodegradation within industrially relevant timeframes, ensuring the absence of harmful residues, and maintaining compatibility with existing LDPE processing and recycling infrastructure.

Furthermore, researchers are working towards understanding and optimizing the degradation mechanisms of biodegradable LDPE in various environments, from industrial composting facilities to marine ecosystems. This involves studying the interplay between material composition, environmental conditions, and microbial communities to engineer LDPE variants that can biodegrade efficiently across diverse scenarios.

As the field progresses, there is also a growing emphasis on life cycle assessment and circular economy principles. The aim is not only to create biodegradable materials but to ensure that their production, use, and disposal result in a net positive environmental impact compared to conventional LDPE. This holistic approach is driving interdisciplinary collaboration and pushing the boundaries of polymer science towards more sustainable and eco-friendly solutions.

The growing awareness of plastic pollution has led to increased pressure on industries and governments to find sustainable alternatives. This has sparked a surge of interest in biodegradable LDPE, which aims to maintain the beneficial properties of traditional LDPE while addressing its end-of-life environmental impact. The development of biodegradable LDPE represents a convergence of polymer science, microbiology, and environmental engineering.

The evolution of biodegradable LDPE technology can be traced through several key phases. Initially, efforts focused on blending LDPE with naturally biodegradable materials such as starch. While this approach showed promise, it often resulted in compromised material properties. Subsequent research shifted towards modifying the LDPE polymer structure itself to enhance biodegradability, including the incorporation of pro-oxidant additives to promote oxidative degradation.

Recent innovations have explored more sophisticated approaches, such as the development of enzyme-responsive LDPE and the use of novel microbial strains capable of metabolizing polyethylene. These advancements aim to create LDPE materials that can maintain their functional properties during use but degrade rapidly under specific environmental conditions.

The primary objective of current research in biodegradable LDPE is to develop materials that offer comparable performance to conventional LDPE in terms of mechanical properties, processability, and cost-effectiveness, while significantly reducing environmental persistence. This goal encompasses several specific targets, including achieving complete biodegradation within industrially relevant timeframes, ensuring the absence of harmful residues, and maintaining compatibility with existing LDPE processing and recycling infrastructure.

Furthermore, researchers are working towards understanding and optimizing the degradation mechanisms of biodegradable LDPE in various environments, from industrial composting facilities to marine ecosystems. This involves studying the interplay between material composition, environmental conditions, and microbial communities to engineer LDPE variants that can biodegrade efficiently across diverse scenarios.

As the field progresses, there is also a growing emphasis on life cycle assessment and circular economy principles. The aim is not only to create biodegradable materials but to ensure that their production, use, and disposal result in a net positive environmental impact compared to conventional LDPE. This holistic approach is driving interdisciplinary collaboration and pushing the boundaries of polymer science towards more sustainable and eco-friendly solutions.

Market Analysis for Eco-Friendly Plastics

The market for eco-friendly plastics, particularly biodegradable LDPE (Low-Density Polyethylene), has been experiencing significant growth in recent years. This surge is driven by increasing environmental concerns, stringent regulations on single-use plastics, and growing consumer awareness about sustainable packaging solutions. The global biodegradable plastics market, which includes biodegradable LDPE, is projected to reach substantial market value in the coming years, with a compound annual growth rate (CAGR) outpacing traditional plastics.

Consumer goods and packaging industries are the primary drivers of demand for biodegradable LDPE. These sectors are actively seeking alternatives to conventional plastics to reduce their environmental footprint and meet sustainability goals. The food and beverage industry, in particular, has shown a strong inclination towards adopting biodegradable LDPE for packaging applications, driven by consumer preferences for eco-friendly products.

Geographically, Europe leads the market for biodegradable plastics, including LDPE, due to stringent environmental regulations and high consumer awareness. North America and Asia-Pacific regions are also witnessing rapid growth, with countries like China and India emerging as key markets due to increasing urbanization and environmental concerns.

The agriculture sector presents another significant opportunity for biodegradable LDPE. Mulch films and other agricultural plastics made from biodegradable LDPE are gaining traction as they offer the dual benefit of soil protection and natural decomposition after use, reducing plastic pollution in farmlands.

However, the market faces challenges, primarily related to the higher cost of biodegradable LDPE compared to conventional LDPE. This cost differential is a significant barrier to widespread adoption, especially in price-sensitive markets. Additionally, there are concerns about the performance and durability of biodegradable LDPE in certain applications, which manufacturers are actively addressing through ongoing research and development efforts.

Despite these challenges, the long-term outlook for biodegradable LDPE remains positive. Technological advancements are expected to improve the cost-effectiveness and performance of biodegradable LDPE, making it more competitive with traditional plastics. Furthermore, the implementation of favorable government policies, such as bans on single-use plastics and incentives for eco-friendly alternatives, is likely to accelerate market growth.

In conclusion, the market for biodegradable LDPE is poised for substantial growth, driven by environmental concerns, regulatory pressures, and shifting consumer preferences. As technology advances and economies of scale are achieved, biodegradable LDPE is expected to capture a larger share of the overall plastics market, presenting significant opportunities for innovation and market expansion in the coming years.

Consumer goods and packaging industries are the primary drivers of demand for biodegradable LDPE. These sectors are actively seeking alternatives to conventional plastics to reduce their environmental footprint and meet sustainability goals. The food and beverage industry, in particular, has shown a strong inclination towards adopting biodegradable LDPE for packaging applications, driven by consumer preferences for eco-friendly products.

Geographically, Europe leads the market for biodegradable plastics, including LDPE, due to stringent environmental regulations and high consumer awareness. North America and Asia-Pacific regions are also witnessing rapid growth, with countries like China and India emerging as key markets due to increasing urbanization and environmental concerns.

The agriculture sector presents another significant opportunity for biodegradable LDPE. Mulch films and other agricultural plastics made from biodegradable LDPE are gaining traction as they offer the dual benefit of soil protection and natural decomposition after use, reducing plastic pollution in farmlands.

However, the market faces challenges, primarily related to the higher cost of biodegradable LDPE compared to conventional LDPE. This cost differential is a significant barrier to widespread adoption, especially in price-sensitive markets. Additionally, there are concerns about the performance and durability of biodegradable LDPE in certain applications, which manufacturers are actively addressing through ongoing research and development efforts.

Despite these challenges, the long-term outlook for biodegradable LDPE remains positive. Technological advancements are expected to improve the cost-effectiveness and performance of biodegradable LDPE, making it more competitive with traditional plastics. Furthermore, the implementation of favorable government policies, such as bans on single-use plastics and incentives for eco-friendly alternatives, is likely to accelerate market growth.

In conclusion, the market for biodegradable LDPE is poised for substantial growth, driven by environmental concerns, regulatory pressures, and shifting consumer preferences. As technology advances and economies of scale are achieved, biodegradable LDPE is expected to capture a larger share of the overall plastics market, presenting significant opportunities for innovation and market expansion in the coming years.

Current Challenges in LDPE Biodegradation

Low-density polyethylene (LDPE) has been widely used in various applications due to its versatility and cost-effectiveness. However, its persistence in the environment has become a significant concern, leading to increased efforts in developing biodegradable alternatives. Despite progress in this field, several challenges remain in achieving fully biodegradable LDPE that meets both performance and environmental requirements.

One of the primary challenges is maintaining the desirable properties of LDPE while enhancing its biodegradability. Traditional LDPE offers excellent flexibility, durability, and moisture resistance, which are crucial for many applications. Introducing biodegradable elements often compromises these properties, resulting in materials that may not meet industry standards or consumer expectations.

The rate of biodegradation poses another significant challenge. While some biodegradable LDPE alternatives show promising results in laboratory conditions, their degradation in real-world environments is often much slower. Factors such as temperature, moisture, and microbial activity significantly influence the biodegradation process, making it difficult to predict and control the material's lifespan in various disposal scenarios.

Compatibility with existing recycling systems is a critical issue. As the recycling infrastructure is primarily designed for conventional plastics, introducing biodegradable LDPE can potentially disrupt established recycling processes. This incompatibility may lead to contamination of recycling streams and reduce the overall efficiency of plastic waste management systems.

The cost of production remains a significant barrier to widespread adoption of biodegradable LDPE. The incorporation of biodegradable additives or the development of entirely new polymer structures often results in higher production costs compared to conventional LDPE. This price differential makes it challenging for biodegradable alternatives to compete in price-sensitive markets.

Ensuring consistent and complete biodegradation across different environments is another hurdle. While a biodegradable LDPE product may degrade effectively in industrial composting facilities, it may not perform as well in home composting systems or marine environments. This variability in biodegradation performance complicates the development of universally applicable solutions.

Regulatory challenges and standardization issues also impede progress in biodegradable LDPE development. The lack of globally harmonized standards for biodegradability and compostability creates confusion in the market and hinders the adoption of new materials. Additionally, varying regulations across different regions complicate the commercialization and distribution of biodegradable LDPE products.

Addressing these challenges requires a multidisciplinary approach, combining advances in polymer science, microbiology, and environmental engineering. Innovations in material design, such as the development of hybrid materials or the incorporation of bio-based additives, show promise in overcoming some of these obstacles. However, significant research and development efforts are still needed to create truly sustainable and commercially viable biodegradable LDPE alternatives.

One of the primary challenges is maintaining the desirable properties of LDPE while enhancing its biodegradability. Traditional LDPE offers excellent flexibility, durability, and moisture resistance, which are crucial for many applications. Introducing biodegradable elements often compromises these properties, resulting in materials that may not meet industry standards or consumer expectations.

The rate of biodegradation poses another significant challenge. While some biodegradable LDPE alternatives show promising results in laboratory conditions, their degradation in real-world environments is often much slower. Factors such as temperature, moisture, and microbial activity significantly influence the biodegradation process, making it difficult to predict and control the material's lifespan in various disposal scenarios.

Compatibility with existing recycling systems is a critical issue. As the recycling infrastructure is primarily designed for conventional plastics, introducing biodegradable LDPE can potentially disrupt established recycling processes. This incompatibility may lead to contamination of recycling streams and reduce the overall efficiency of plastic waste management systems.

The cost of production remains a significant barrier to widespread adoption of biodegradable LDPE. The incorporation of biodegradable additives or the development of entirely new polymer structures often results in higher production costs compared to conventional LDPE. This price differential makes it challenging for biodegradable alternatives to compete in price-sensitive markets.

Ensuring consistent and complete biodegradation across different environments is another hurdle. While a biodegradable LDPE product may degrade effectively in industrial composting facilities, it may not perform as well in home composting systems or marine environments. This variability in biodegradation performance complicates the development of universally applicable solutions.

Regulatory challenges and standardization issues also impede progress in biodegradable LDPE development. The lack of globally harmonized standards for biodegradability and compostability creates confusion in the market and hinders the adoption of new materials. Additionally, varying regulations across different regions complicate the commercialization and distribution of biodegradable LDPE products.

Addressing these challenges requires a multidisciplinary approach, combining advances in polymer science, microbiology, and environmental engineering. Innovations in material design, such as the development of hybrid materials or the incorporation of bio-based additives, show promise in overcoming some of these obstacles. However, significant research and development efforts are still needed to create truly sustainable and commercially viable biodegradable LDPE alternatives.

Existing Biodegradable LDPE Solutions

01 Biodegradable LDPE compositions

Development of biodegradable LDPE compositions by incorporating biodegradable additives or modifying the polymer structure. These compositions aim to enhance the biodegradability of LDPE while maintaining its desirable properties for various applications.- Biodegradable LDPE compositions: Development of biodegradable LDPE compositions by incorporating additives or modifying the polymer structure. These compositions aim to enhance the biodegradability of LDPE while maintaining its desirable properties for various applications.

- Biodegradation enhancement methods: Methods to improve the biodegradability of LDPE, including the use of pro-oxidants, UV sensitizers, or microbial inoculation. These techniques aim to accelerate the breakdown of LDPE in natural environments.

- Biodegradable LDPE blends: Creation of biodegradable blends by combining LDPE with other biodegradable polymers or natural materials. These blends aim to improve the overall biodegradability while maintaining the desired physical properties of the material.

- Testing and evaluation of LDPE biodegradability: Development of methods and standards for assessing the biodegradability of LDPE materials. These include laboratory tests, field trials, and long-term environmental impact studies to determine the rate and extent of biodegradation.

- Environmental impact and regulations: Studies on the environmental impact of biodegradable LDPE and the development of regulations and standards for its use and disposal. This includes life cycle assessments, eco-toxicity studies, and policy recommendations for sustainable plastic use.

02 Enzymatic degradation of LDPE

Utilization of specific enzymes or microbial strains to accelerate the biodegradation of LDPE. This approach focuses on developing enzymatic systems that can effectively break down the polymer chains of LDPE in natural environments.Expand Specific Solutions03 LDPE blends with biodegradable polymers

Creation of blends combining LDPE with biodegradable polymers to improve overall biodegradability. These blends aim to balance the performance characteristics of LDPE with enhanced environmental degradation properties.Expand Specific Solutions04 Oxo-biodegradable LDPE

Development of oxo-biodegradable LDPE materials that undergo initial oxidative degradation followed by biodegradation. This approach involves incorporating pro-oxidant additives to facilitate the breakdown of LDPE in the presence of oxygen and microorganisms.Expand Specific Solutions05 Environmental impact assessment of biodegradable LDPE

Studies and methodologies for evaluating the environmental impact and biodegradation rates of modified LDPE materials. This includes developing standardized testing protocols and analyzing the long-term effects of biodegradable LDPE in various ecosystems.Expand Specific Solutions

Key Players in Biodegradable LDPE Industry

The biodegradable LDPE market is in a growth phase, driven by increasing environmental concerns and regulations. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, biodegradable LDPE is advancing, but still faces challenges in matching the performance of traditional LDPE. Companies like Braskem, ExxonMobil Chemical, and Kingfa Sci. & Tech. are leading innovation efforts, developing new formulations and production processes. Academic institutions such as IIT Roorkee and Tsinghua University are contributing to research advancements. While progress is being made, full commercial viability and widespread adoption of biodegradable LDPE solutions are still evolving, indicating a market in transition towards maturity.

International Paper Co.

Technical Solution: International Paper Co., while primarily known for paper products, has been expanding its research into biodegradable alternatives for plastic packaging, including LDPE substitutes. The company has developed cellulose-based materials that can be used as coatings or barriers in packaging applications, potentially replacing or reducing the use of LDPE in certain products[12]. Their approach focuses on leveraging their expertise in fiber-based materials to create biodegradable and compostable packaging solutions. International Paper has also explored partnerships with bioplastic producers to develop hybrid materials that combine the strength of paper with the barrier properties of biodegradable plastics, aiming to create more sustainable packaging options[13].

Strengths: Expertise in renewable fiber-based materials, potential for integration with existing paper products, compostable solutions. Weaknesses: Limited experience with plastic polymers compared to chemical companies, may require significant R&D investment to compete in LDPE alternatives.

Braskem SA

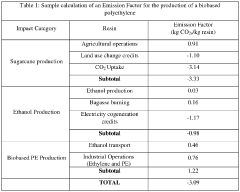

Technical Solution: Braskem SA has pioneered the development of bio-based polyethylene, including biodegradable LDPE alternatives. Their I'm green™ Polyethylene is derived from sugarcane ethanol, offering a renewable source for plastic production[4]. While not inherently biodegradable, Braskem has been working on enhancing the biodegradability of their bio-based PE through additives and blending techniques. The company has also developed oxo-biodegradable additives that can be incorporated into LDPE to accelerate its breakdown in the presence of oxygen and sunlight[5]. Braskem's research focuses on maintaining the desirable properties of LDPE while improving its end-of-life environmental impact.

Strengths: Renewable sourcing, reduced carbon footprint, compatible with existing PE processing equipment. Weaknesses: Not inherently biodegradable without additives, oxo-biodegradable solutions face regulatory challenges in some regions.

Core Innovations in LDPE Biodegradation

A biodegradable and water repellent polypropylene based coating material for packaging applications and its method of preparation

PatentActiveIN202211066668A

Innovation

- A biodegradable aqueous dispersion of polypropylene graft copolymer is developed, comprising propylene copolymer, acrylamide, vinyl acetate, methyl acrylate, acrylic acid, and styrene, which is stable and exhibits excellent water-repellent capacity and adhesive properties.

Biocompatible low impact co2 emission polymer compositions, pharmaceutical articles and methods of preparing same

PatentWO2022112848A1

Innovation

- A biobased low density polyethylene polymer composition is developed, where at least a portion of ethylene is sourced from renewable carbon, reducing emissions and ensuring biocompatibility for pharmaceutical packaging, produced through methods like extrusion blow molding and injection blow molding.

Environmental Impact Assessment

The environmental impact assessment of biodegradable LDPE innovations is crucial for understanding their potential benefits and drawbacks in eco-friendly applications. These innovations aim to address the persistent plastic pollution problem caused by conventional LDPE, which can take hundreds of years to decompose in natural environments.

Biodegradable LDPE alternatives offer significant potential for reducing plastic waste accumulation in landfills, oceans, and terrestrial ecosystems. When properly disposed of, these materials can break down into harmless components within months to a few years, depending on the specific formulation and environmental conditions. This rapid degradation process can help mitigate the long-term ecological damage associated with traditional plastic waste.

However, the environmental impact of biodegradable LDPE is not uniformly positive. The production process of these materials often requires additional energy and resources compared to conventional LDPE manufacturing. This increased resource consumption may partially offset the environmental benefits gained from improved end-of-life degradability. Additionally, the use of certain additives or blending agents to enhance biodegradability may introduce new environmental concerns, such as potential toxicity or microplastic formation during degradation.

The disposal and management of biodegradable LDPE products also present challenges. While these materials can decompose in industrial composting facilities, they may not degrade effectively in home composting systems or natural environments. Improper disposal or mixing with conventional plastic recycling streams can complicate existing waste management processes and potentially contaminate recycled plastic products.

Life cycle assessments (LCAs) of biodegradable LDPE innovations have shown mixed results. Some studies indicate a net positive environmental impact when considering factors such as reduced plastic pollution and greenhouse gas emissions from waste incineration. However, other analyses suggest that the benefits may be outweighed by increased production-related emissions and resource consumption.

The environmental impact of biodegradable LDPE also depends on consumer behavior and waste management infrastructure. Proper education and labeling are essential to ensure that these products are disposed of correctly and do not contribute to littering or contamination of recycling streams. Furthermore, the development of appropriate composting and waste management facilities is crucial for realizing the full environmental benefits of biodegradable LDPE innovations.

In conclusion, while biodegradable LDPE innovations offer promising solutions for reducing plastic pollution, their overall environmental impact is complex and multifaceted. Continued research and development are necessary to optimize these materials' performance, production efficiency, and end-of-life management to maximize their positive environmental contributions while minimizing potential drawbacks.

Biodegradable LDPE alternatives offer significant potential for reducing plastic waste accumulation in landfills, oceans, and terrestrial ecosystems. When properly disposed of, these materials can break down into harmless components within months to a few years, depending on the specific formulation and environmental conditions. This rapid degradation process can help mitigate the long-term ecological damage associated with traditional plastic waste.

However, the environmental impact of biodegradable LDPE is not uniformly positive. The production process of these materials often requires additional energy and resources compared to conventional LDPE manufacturing. This increased resource consumption may partially offset the environmental benefits gained from improved end-of-life degradability. Additionally, the use of certain additives or blending agents to enhance biodegradability may introduce new environmental concerns, such as potential toxicity or microplastic formation during degradation.

The disposal and management of biodegradable LDPE products also present challenges. While these materials can decompose in industrial composting facilities, they may not degrade effectively in home composting systems or natural environments. Improper disposal or mixing with conventional plastic recycling streams can complicate existing waste management processes and potentially contaminate recycled plastic products.

Life cycle assessments (LCAs) of biodegradable LDPE innovations have shown mixed results. Some studies indicate a net positive environmental impact when considering factors such as reduced plastic pollution and greenhouse gas emissions from waste incineration. However, other analyses suggest that the benefits may be outweighed by increased production-related emissions and resource consumption.

The environmental impact of biodegradable LDPE also depends on consumer behavior and waste management infrastructure. Proper education and labeling are essential to ensure that these products are disposed of correctly and do not contribute to littering or contamination of recycling streams. Furthermore, the development of appropriate composting and waste management facilities is crucial for realizing the full environmental benefits of biodegradable LDPE innovations.

In conclusion, while biodegradable LDPE innovations offer promising solutions for reducing plastic pollution, their overall environmental impact is complex and multifaceted. Continued research and development are necessary to optimize these materials' performance, production efficiency, and end-of-life management to maximize their positive environmental contributions while minimizing potential drawbacks.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics is a complex and evolving landscape that plays a crucial role in shaping the development and adoption of eco-friendly alternatives to traditional LDPE. As innovations in biodegradable LDPE continue to emerge, governments and international organizations are working to establish comprehensive guidelines and standards to ensure the effectiveness and environmental safety of these materials.

At the forefront of this regulatory framework are certification systems and standards that define what constitutes a truly biodegradable plastic. Organizations such as the European Committee for Standardization (CEN) and the American Society for Testing and Materials (ASTM) have developed specific standards for biodegradable plastics, including EN 13432 and ASTM D6400, respectively. These standards outline the requirements for packaging to be considered compostable and biodegradable, including criteria for biodegradation rates, ecotoxicity, and the absence of harmful residues.

Many countries have implemented or are in the process of implementing regulations that promote the use of biodegradable plastics while setting strict guidelines for their production and disposal. For instance, the European Union's Single-Use Plastics Directive, which came into effect in 2021, aims to reduce the environmental impact of certain plastic products and encourages the use of sustainable alternatives, including biodegradable options. Similarly, countries like Italy and France have introduced bans on single-use plastic bags, with exceptions made for certified compostable and biodegradable alternatives.

In the United States, regulations vary by state, with some states like California implementing comprehensive plastic bag bans and setting standards for reusable bags, including those made from biodegradable materials. The Federal Trade Commission (FTC) has also issued guidelines on environmental marketing claims, including those related to biodegradability, to prevent greenwashing and ensure accurate consumer information.

As the field of biodegradable LDPE advances, regulatory bodies are faced with the challenge of keeping pace with technological innovations. This has led to ongoing discussions and revisions of existing standards to accommodate new materials and biodegradation processes. For example, there is growing recognition of the need to develop standards for marine biodegradation, as many biodegradable plastics designed for terrestrial environments may not degrade effectively in aquatic ecosystems.

The regulatory framework also extends to waste management and recycling systems. Many countries are implementing extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This approach incentivizes the development of more sustainable packaging solutions, including biodegradable LDPE alternatives.

At the forefront of this regulatory framework are certification systems and standards that define what constitutes a truly biodegradable plastic. Organizations such as the European Committee for Standardization (CEN) and the American Society for Testing and Materials (ASTM) have developed specific standards for biodegradable plastics, including EN 13432 and ASTM D6400, respectively. These standards outline the requirements for packaging to be considered compostable and biodegradable, including criteria for biodegradation rates, ecotoxicity, and the absence of harmful residues.

Many countries have implemented or are in the process of implementing regulations that promote the use of biodegradable plastics while setting strict guidelines for their production and disposal. For instance, the European Union's Single-Use Plastics Directive, which came into effect in 2021, aims to reduce the environmental impact of certain plastic products and encourages the use of sustainable alternatives, including biodegradable options. Similarly, countries like Italy and France have introduced bans on single-use plastic bags, with exceptions made for certified compostable and biodegradable alternatives.

In the United States, regulations vary by state, with some states like California implementing comprehensive plastic bag bans and setting standards for reusable bags, including those made from biodegradable materials. The Federal Trade Commission (FTC) has also issued guidelines on environmental marketing claims, including those related to biodegradability, to prevent greenwashing and ensure accurate consumer information.

As the field of biodegradable LDPE advances, regulatory bodies are faced with the challenge of keeping pace with technological innovations. This has led to ongoing discussions and revisions of existing standards to accommodate new materials and biodegradation processes. For example, there is growing recognition of the need to develop standards for marine biodegradation, as many biodegradable plastics designed for terrestrial environments may not degrade effectively in aquatic ecosystems.

The regulatory framework also extends to waste management and recycling systems. Many countries are implementing extended producer responsibility (EPR) schemes, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This approach incentivizes the development of more sustainable packaging solutions, including biodegradable LDPE alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!