Exploring Biodegradable LDPE to Cut Waste

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Biodegradation Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the packaging industry since its introduction in the 1930s. Its versatility, durability, and low cost have made it ubiquitous in modern life. However, the very properties that make LDPE so useful also contribute to its environmental persistence, leading to significant waste management challenges and ecological concerns.

The evolution of LDPE technology has been driven by the need for improved material properties and processing efficiency. Initially developed as a high-pressure polymerization process, LDPE production has seen advancements in catalyst technology and manufacturing techniques. These improvements have resulted in enhanced control over molecular weight distribution and branching, allowing for tailored material properties to suit various applications.

As global plastic waste has become an increasingly pressing issue, the focus has shifted towards developing biodegradable alternatives to conventional LDPE. This technological trajectory aims to maintain the beneficial properties of LDPE while addressing its end-of-life environmental impact. The goal is to create materials that can degrade naturally in various environments, reducing the accumulation of plastic waste in landfills and ecosystems.

The objectives of exploring biodegradable LDPE are multifaceted. Primarily, researchers aim to develop LDPE variants that can undergo complete biodegradation within a reasonable timeframe under diverse environmental conditions. This includes degradation in soil, marine environments, and industrial composting facilities. Additionally, there is a focus on ensuring that the degradation products are non-toxic and do not contribute to microplastic pollution.

Another critical objective is to maintain or improve the performance characteristics of biodegradable LDPE compared to its conventional counterparts. This includes preserving tensile strength, flexibility, and barrier properties while introducing biodegradability. The challenge lies in balancing these often conflicting requirements to create a material that is both functional and environmentally responsible.

From a manufacturing perspective, the goal is to develop biodegradable LDPE that can be produced using existing infrastructure with minimal modifications. This approach aims to facilitate a smoother transition for industry adoption, reducing the economic barriers to implementing more sustainable packaging solutions.

The pursuit of biodegradable LDPE also aligns with broader sustainability goals and circular economy principles. By creating materials that can be safely returned to natural cycles, the industry seeks to reduce its reliance on fossil fuel resources and minimize the long-term environmental impact of plastic products. This technological evolution represents a significant step towards more sustainable packaging solutions and waste reduction strategies.

The evolution of LDPE technology has been driven by the need for improved material properties and processing efficiency. Initially developed as a high-pressure polymerization process, LDPE production has seen advancements in catalyst technology and manufacturing techniques. These improvements have resulted in enhanced control over molecular weight distribution and branching, allowing for tailored material properties to suit various applications.

As global plastic waste has become an increasingly pressing issue, the focus has shifted towards developing biodegradable alternatives to conventional LDPE. This technological trajectory aims to maintain the beneficial properties of LDPE while addressing its end-of-life environmental impact. The goal is to create materials that can degrade naturally in various environments, reducing the accumulation of plastic waste in landfills and ecosystems.

The objectives of exploring biodegradable LDPE are multifaceted. Primarily, researchers aim to develop LDPE variants that can undergo complete biodegradation within a reasonable timeframe under diverse environmental conditions. This includes degradation in soil, marine environments, and industrial composting facilities. Additionally, there is a focus on ensuring that the degradation products are non-toxic and do not contribute to microplastic pollution.

Another critical objective is to maintain or improve the performance characteristics of biodegradable LDPE compared to its conventional counterparts. This includes preserving tensile strength, flexibility, and barrier properties while introducing biodegradability. The challenge lies in balancing these often conflicting requirements to create a material that is both functional and environmentally responsible.

From a manufacturing perspective, the goal is to develop biodegradable LDPE that can be produced using existing infrastructure with minimal modifications. This approach aims to facilitate a smoother transition for industry adoption, reducing the economic barriers to implementing more sustainable packaging solutions.

The pursuit of biodegradable LDPE also aligns with broader sustainability goals and circular economy principles. By creating materials that can be safely returned to natural cycles, the industry seeks to reduce its reliance on fossil fuel resources and minimize the long-term environmental impact of plastic products. This technological evolution represents a significant step towards more sustainable packaging solutions and waste reduction strategies.

Market Analysis for Eco-Friendly Packaging

The market for eco-friendly packaging has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce plastic waste. The global biodegradable packaging market is expected to reach $21.7 billion by 2025, growing at a CAGR of 17.4% from 2020 to 2025. This growth is primarily fueled by the rising demand for sustainable packaging solutions across various industries, including food and beverage, personal care, and healthcare.

Consumer preferences are shifting towards environmentally responsible products, with a survey indicating that 74% of consumers are willing to pay more for sustainable packaging. This trend is particularly pronounced among younger generations, with millennials and Gen Z showing the highest preference for eco-friendly alternatives. As a result, major brands and retailers are increasingly adopting biodegradable packaging options to meet consumer demands and improve their environmental credentials.

The food and beverage industry represents the largest market segment for biodegradable packaging, accounting for approximately 45% of the total market share. This sector's dominance is attributed to the high volume of single-use packaging and the perishable nature of food products. The personal care and cosmetics industry is also emerging as a significant adopter of eco-friendly packaging, with a projected CAGR of 19.2% from 2020 to 2025.

Geographically, Europe leads the biodegradable packaging market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate, propelled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market drivers include government regulations, such as the EU Single-Use Plastics Directive, which aims to reduce plastic waste and promote sustainable alternatives. Additionally, technological advancements in biodegradable materials, including improvements in barrier properties and shelf life, are expanding the application scope of eco-friendly packaging.

However, challenges remain in the widespread adoption of biodegradable packaging. The higher cost of production compared to traditional plastics remains a significant barrier, particularly for small and medium-sized enterprises. Furthermore, the lack of standardized disposal and composting infrastructure in many regions hinders the effective end-of-life management of biodegradable packaging materials.

In conclusion, the market for eco-friendly packaging, particularly biodegradable options, shows strong growth potential driven by consumer demand, regulatory pressures, and technological advancements. As the industry continues to innovate and scale, it is expected to play a crucial role in addressing the global plastic waste crisis and moving towards a more sustainable packaging ecosystem.

Consumer preferences are shifting towards environmentally responsible products, with a survey indicating that 74% of consumers are willing to pay more for sustainable packaging. This trend is particularly pronounced among younger generations, with millennials and Gen Z showing the highest preference for eco-friendly alternatives. As a result, major brands and retailers are increasingly adopting biodegradable packaging options to meet consumer demands and improve their environmental credentials.

The food and beverage industry represents the largest market segment for biodegradable packaging, accounting for approximately 45% of the total market share. This sector's dominance is attributed to the high volume of single-use packaging and the perishable nature of food products. The personal care and cosmetics industry is also emerging as a significant adopter of eco-friendly packaging, with a projected CAGR of 19.2% from 2020 to 2025.

Geographically, Europe leads the biodegradable packaging market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate, propelled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Key market drivers include government regulations, such as the EU Single-Use Plastics Directive, which aims to reduce plastic waste and promote sustainable alternatives. Additionally, technological advancements in biodegradable materials, including improvements in barrier properties and shelf life, are expanding the application scope of eco-friendly packaging.

However, challenges remain in the widespread adoption of biodegradable packaging. The higher cost of production compared to traditional plastics remains a significant barrier, particularly for small and medium-sized enterprises. Furthermore, the lack of standardized disposal and composting infrastructure in many regions hinders the effective end-of-life management of biodegradable packaging materials.

In conclusion, the market for eco-friendly packaging, particularly biodegradable options, shows strong growth potential driven by consumer demand, regulatory pressures, and technological advancements. As the industry continues to innovate and scale, it is expected to play a crucial role in addressing the global plastic waste crisis and moving towards a more sustainable packaging ecosystem.

Current LDPE Biodegradation Challenges

Low-density polyethylene (LDPE) is widely used in packaging and consumer products due to its versatility and low cost. However, its persistence in the environment has become a significant concern. The current challenges in LDPE biodegradation stem from its chemical structure and physical properties, which make it resistant to natural degradation processes.

One of the primary obstacles is the high molecular weight and strong carbon-carbon bonds in LDPE. These characteristics make it difficult for microorganisms to break down the polymer chains effectively. The long, branched structure of LDPE also contributes to its resistance to biodegradation, as it prevents enzymes from accessing the internal portions of the material.

The hydrophobic nature of LDPE poses another challenge. This property inhibits the attachment and colonization of microorganisms on the polymer surface, which is crucial for initiating the biodegradation process. As a result, LDPE tends to persist in various environments, including soil and water, for extended periods.

The lack of functional groups in LDPE's structure further complicates biodegradation efforts. Unlike natural polymers, LDPE does not contain easily recognizable chemical groups that microorganisms can target for decomposition. This absence of biodegradation-friendly features makes it challenging for enzymes to catalyze the breakdown of the polymer.

Environmental factors also play a role in the difficulties surrounding LDPE biodegradation. The material's resistance to water absorption limits the effectiveness of hydrolysis, a key mechanism in the degradation of many polymers. Additionally, LDPE's stability under various temperature and pH conditions further contributes to its persistence in diverse ecosystems.

The slow rate of LDPE biodegradation presents a significant challenge for waste management. Even under optimal conditions, the process can take several decades to centuries, leading to the accumulation of plastic waste in landfills and natural environments. This prolonged degradation time exacerbates the environmental impact of LDPE products.

Current biodegradation techniques for LDPE often involve pre-treatments or additives to enhance the material's susceptibility to microbial attack. However, these methods can be costly, energy-intensive, or may introduce additional environmental concerns. Finding a balance between enhancing biodegradability and maintaining the desirable properties of LDPE remains a significant challenge.

The development of effective biodegradation strategies for LDPE is further complicated by the variability in environmental conditions across different disposal scenarios. What works in a controlled laboratory setting may not be as effective in real-world conditions, where factors such as temperature, moisture, and microbial populations can vary widely.

One of the primary obstacles is the high molecular weight and strong carbon-carbon bonds in LDPE. These characteristics make it difficult for microorganisms to break down the polymer chains effectively. The long, branched structure of LDPE also contributes to its resistance to biodegradation, as it prevents enzymes from accessing the internal portions of the material.

The hydrophobic nature of LDPE poses another challenge. This property inhibits the attachment and colonization of microorganisms on the polymer surface, which is crucial for initiating the biodegradation process. As a result, LDPE tends to persist in various environments, including soil and water, for extended periods.

The lack of functional groups in LDPE's structure further complicates biodegradation efforts. Unlike natural polymers, LDPE does not contain easily recognizable chemical groups that microorganisms can target for decomposition. This absence of biodegradation-friendly features makes it challenging for enzymes to catalyze the breakdown of the polymer.

Environmental factors also play a role in the difficulties surrounding LDPE biodegradation. The material's resistance to water absorption limits the effectiveness of hydrolysis, a key mechanism in the degradation of many polymers. Additionally, LDPE's stability under various temperature and pH conditions further contributes to its persistence in diverse ecosystems.

The slow rate of LDPE biodegradation presents a significant challenge for waste management. Even under optimal conditions, the process can take several decades to centuries, leading to the accumulation of plastic waste in landfills and natural environments. This prolonged degradation time exacerbates the environmental impact of LDPE products.

Current biodegradation techniques for LDPE often involve pre-treatments or additives to enhance the material's susceptibility to microbial attack. However, these methods can be costly, energy-intensive, or may introduce additional environmental concerns. Finding a balance between enhancing biodegradability and maintaining the desirable properties of LDPE remains a significant challenge.

The development of effective biodegradation strategies for LDPE is further complicated by the variability in environmental conditions across different disposal scenarios. What works in a controlled laboratory setting may not be as effective in real-world conditions, where factors such as temperature, moisture, and microbial populations can vary widely.

Existing Biodegradable LDPE Solutions

01 Biodegradable LDPE compositions

Development of biodegradable LDPE compositions by incorporating additives or modifying the polymer structure. These compositions aim to enhance the degradation of LDPE in natural environments, reducing its environmental impact and waste accumulation.- Biodegradable LDPE compositions: Development of biodegradable LDPE compositions that incorporate additives or blends to enhance degradation. These compositions aim to reduce the environmental impact of LDPE waste by promoting faster breakdown in natural conditions.

- Waste reduction through recycling technologies: Implementation of advanced recycling technologies to process LDPE waste, converting it into reusable materials or energy. These methods aim to reduce the amount of LDPE waste sent to landfills or incineration facilities.

- Enzymatic degradation of LDPE: Utilization of specific enzymes or microbial strains capable of breaking down LDPE. This approach focuses on accelerating the natural degradation process of LDPE waste in controlled environments.

- LDPE waste conversion to valuable products: Development of processes to convert LDPE waste into valuable products such as fuel, chemicals, or other materials. This approach aims to create economic incentives for LDPE waste collection and processing.

- Improved LDPE packaging design: Innovation in LDPE packaging design to reduce material usage, enhance recyclability, and promote reuse. This includes the development of thinner films, multi-layer structures with improved separability, and designs that facilitate easier recycling.

02 Recycling and upcycling of LDPE waste

Methods for recycling and upcycling LDPE waste into new products or materials. This approach focuses on reducing waste by reprocessing LDPE into valuable resources, thereby extending its lifecycle and minimizing environmental impact.Expand Specific Solutions03 Enzymatic degradation of LDPE

Utilization of specific enzymes or microorganisms to accelerate the biodegradation of LDPE. This biological approach aims to break down LDPE into environmentally friendly components, reducing its persistence in ecosystems.Expand Specific Solutions04 LDPE waste reduction in packaging

Innovative packaging designs and materials that reduce the use of LDPE or replace it with more environmentally friendly alternatives. This approach focuses on minimizing LDPE waste at the source by developing sustainable packaging solutions.Expand Specific Solutions05 Chemical treatment for LDPE degradation

Application of chemical treatments to promote the degradation of LDPE. This method involves using specific chemical agents or processes to break down LDPE molecules, facilitating faster decomposition and reducing environmental persistence.Expand Specific Solutions

Key Players in Biodegradable Plastics

The biodegradable LDPE market is in a growth phase, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The global market size for biodegradable plastics is projected to reach $7.8 billion by 2025, with a CAGR of 9.5%. While the technology is advancing, it is still maturing, with companies like SABIC, Braskem, and LG Chem leading innovation. These firms are investing heavily in R&D to improve the performance and cost-effectiveness of biodegradable LDPE. Smaller players like Northern Technologies International and Kingfa Sci. & Tech. are also contributing to technological advancements. The competitive landscape is characterized by a mix of large petrochemical companies and specialized bioplastics firms, with increasing collaborations between industry and academic institutions to accelerate progress.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of biodegradable LDPE solutions, including their TRUCIRCLE™ portfolio. This includes certified circular polymers, certified renewable polymers, and mechanically recycled polymers. Their biodegradable LDPE is designed to break down in industrial composting facilities, typically within 3-6 months[1]. The material maintains the desirable properties of traditional LDPE, such as flexibility and moisture resistance, while being environmentally friendly. SABIC's approach involves incorporating organic additives that accelerate the biodegradation process when exposed to microbial activity in compost environments[2]. The company has also invested in chemical recycling technologies to convert mixed plastic waste back into feedstock for new plastics production[3].

Strengths: Wide range of biodegradable solutions, maintains LDPE properties, accelerated biodegradation. Weaknesses: Requires industrial composting facilities, potentially higher production costs compared to traditional LDPE.

Braskem SA

Technical Solution: Braskem has pioneered the development of bio-based polyethylene, including biodegradable LDPE, derived from sugarcane ethanol. Their I'm green™ Polyethylene captures and fixes CO2 from the atmosphere during its production, helping to reduce greenhouse gas emissions[4]. The company has developed a proprietary technology that allows for the production of LDPE with varying degrees of biodegradability, tailored to specific applications. Braskem's biodegradable LDPE maintains the same properties and processability as fossil-based polyethylene while offering improved end-of-life options. The material can be designed to biodegrade in specific environments such as soil, freshwater, or marine conditions[5]. Braskem has also invested in partnerships to develop composting infrastructure and educate consumers about proper disposal of biodegradable plastics[6].

Strengths: Bio-based feedstock, carbon-negative production, tailored biodegradability. Weaknesses: Potential competition with food crops for agricultural land, limited availability of industrial composting facilities.

Core Innovations in LDPE Biodegradation

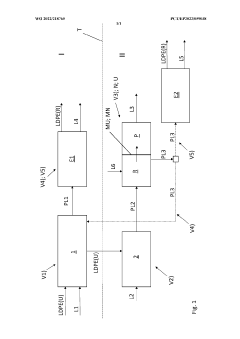

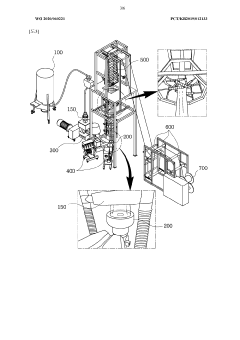

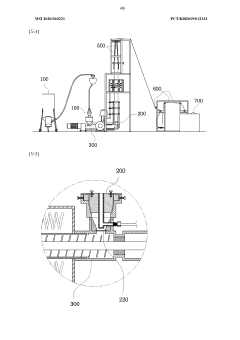

Method and apparatus for the recycling of low-density polyethylene (LDPE)

PatentWO2022218765A1

Innovation

- A method involving selective dissolution of LDPE in an organic solvent at a temperature where HDPE and PP do not dissolve, followed by ultrafiltration or nanofiltration to concentrate LDPE, allowing for its efficient recovery through evaporation, eliminating the need for additional separation steps and reducing energy consumption.

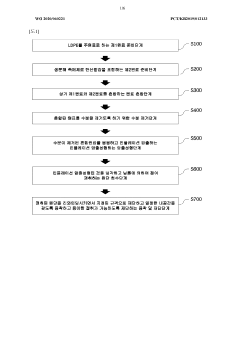

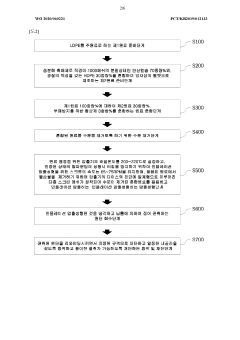

Method for manufacturing biodegradable packaging vinyl sheet

PatentWO2020060221A1

Innovation

- A method involving the use of low-density polyethylene (LDPE) as the main raw material, calcium carbonate as a biodegradation catalyst, and high-density polyethylene (HDPE) to maintain strength, combined with an antibacterial agent, and a multi-layer screen mesh to filter impurities, ensuring consistent extrusion speed and density during inflation extrusion molding.

Environmental Impact Assessment

The environmental impact assessment of biodegradable Low-Density Polyethylene (LDPE) is crucial in evaluating its potential to reduce waste and mitigate environmental harm. Biodegradable LDPE offers a promising solution to the persistent plastic pollution problem, as it can decompose naturally under specific conditions, unlike conventional LDPE.

One of the primary environmental benefits of biodegradable LDPE is its reduced persistence in ecosystems. While traditional LDPE can take hundreds of years to degrade, biodegradable variants can break down within months to a few years, depending on environmental conditions. This shorter lifespan significantly reduces the accumulation of plastic waste in landfills, oceans, and terrestrial environments.

However, the environmental impact of biodegradable LDPE is not entirely positive. The production process of biodegradable LDPE may require more energy and resources compared to conventional LDPE, potentially leading to higher greenhouse gas emissions during manufacturing. This trade-off between end-of-life benefits and production-phase impacts necessitates a comprehensive life cycle assessment to determine the overall environmental footprint.

The degradation process of biodegradable LDPE also warrants careful consideration. While it breaks down more rapidly than conventional plastics, the byproducts of this degradation process must be thoroughly studied. Some biodegradable plastics may fragment into microplastics before fully decomposing, potentially causing harm to marine life and ecosystems. Additionally, the conditions required for optimal biodegradation may not always be present in natural environments, potentially limiting the effectiveness of these materials in real-world scenarios.

Another critical aspect of the environmental impact assessment is the effect on waste management systems. Biodegradable LDPE could potentially disrupt existing recycling streams if not properly sorted and managed. Mixing biodegradable and non-biodegradable plastics in recycling processes can compromise the quality of recycled materials, potentially leading to increased waste and reduced efficiency in recycling operations.

The land use implications of shifting to biodegradable LDPE production must also be evaluated. If bio-based materials are used in the production of biodegradable LDPE, there may be concerns about competition with food crops for agricultural land. This could have cascading effects on food security and land use patterns, requiring careful consideration in the overall environmental impact assessment.

In conclusion, while biodegradable LDPE presents a promising avenue for reducing plastic waste, its environmental impact is complex and multifaceted. A thorough assessment must consider the entire life cycle of the material, from production to disposal, to ensure that the benefits of reduced persistence in the environment outweigh any potential negative impacts associated with its production and degradation processes.

One of the primary environmental benefits of biodegradable LDPE is its reduced persistence in ecosystems. While traditional LDPE can take hundreds of years to degrade, biodegradable variants can break down within months to a few years, depending on environmental conditions. This shorter lifespan significantly reduces the accumulation of plastic waste in landfills, oceans, and terrestrial environments.

However, the environmental impact of biodegradable LDPE is not entirely positive. The production process of biodegradable LDPE may require more energy and resources compared to conventional LDPE, potentially leading to higher greenhouse gas emissions during manufacturing. This trade-off between end-of-life benefits and production-phase impacts necessitates a comprehensive life cycle assessment to determine the overall environmental footprint.

The degradation process of biodegradable LDPE also warrants careful consideration. While it breaks down more rapidly than conventional plastics, the byproducts of this degradation process must be thoroughly studied. Some biodegradable plastics may fragment into microplastics before fully decomposing, potentially causing harm to marine life and ecosystems. Additionally, the conditions required for optimal biodegradation may not always be present in natural environments, potentially limiting the effectiveness of these materials in real-world scenarios.

Another critical aspect of the environmental impact assessment is the effect on waste management systems. Biodegradable LDPE could potentially disrupt existing recycling streams if not properly sorted and managed. Mixing biodegradable and non-biodegradable plastics in recycling processes can compromise the quality of recycled materials, potentially leading to increased waste and reduced efficiency in recycling operations.

The land use implications of shifting to biodegradable LDPE production must also be evaluated. If bio-based materials are used in the production of biodegradable LDPE, there may be concerns about competition with food crops for agricultural land. This could have cascading effects on food security and land use patterns, requiring careful consideration in the overall environmental impact assessment.

In conclusion, while biodegradable LDPE presents a promising avenue for reducing plastic waste, its environmental impact is complex and multifaceted. A thorough assessment must consider the entire life cycle of the material, from production to disposal, to ensure that the benefits of reduced persistence in the environment outweigh any potential negative impacts associated with its production and degradation processes.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics, particularly biodegradable LDPE, is evolving rapidly as governments and international organizations recognize the need to address plastic waste. In the European Union, the Single-Use Plastics Directive (EU) 2019/904 sets ambitious targets for reducing plastic waste and promoting the use of sustainable alternatives. This directive specifically addresses biodegradable plastics, requiring them to meet certain standards for compostability and biodegradation.

In the United States, regulations vary by state, but there is a growing trend towards stricter controls on plastic waste. California, for instance, has implemented the SB 270 Plastic Bag Ban, which encourages the use of reusable bags and compostable alternatives. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability and compostability.

Internationally, the United Nations Environment Programme (UNEP) has been instrumental in developing global strategies to combat plastic pollution. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal now includes plastic waste, affecting the international trade and disposal of biodegradable plastics.

Certification systems play a crucial role in the regulatory landscape. Standards such as ASTM D6400 and EN 13432 provide specifications for compostable plastics. These standards are often referenced in regulations and are essential for manufacturers to demonstrate compliance with biodegradability requirements.

The regulatory framework also extends to labeling and consumer information. Many jurisdictions require clear and accurate labeling of biodegradable products to prevent greenwashing and ensure proper disposal. The ISO 14021 standard provides guidelines for environmental claims, including those related to biodegradability and compostability.

As research into biodegradable LDPE advances, regulators are working to keep pace with technological developments. There is an increasing focus on life cycle assessments to ensure that biodegradable alternatives truly offer environmental benefits over traditional plastics. This has led to more nuanced regulations that consider not just end-of-life disposal but also the production and use phases of bioplastics.

The regulatory landscape for bioplastics is complex and dynamic, with ongoing debates about the most effective approaches to reduce plastic waste. As the technology for biodegradable LDPE continues to evolve, it is likely that regulations will become more sophisticated, potentially including incentives for research and development, as well as stricter controls on production and disposal.

In the United States, regulations vary by state, but there is a growing trend towards stricter controls on plastic waste. California, for instance, has implemented the SB 270 Plastic Bag Ban, which encourages the use of reusable bags and compostable alternatives. The Federal Trade Commission's Green Guides provide guidelines for environmental marketing claims, including those related to biodegradability and compostability.

Internationally, the United Nations Environment Programme (UNEP) has been instrumental in developing global strategies to combat plastic pollution. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal now includes plastic waste, affecting the international trade and disposal of biodegradable plastics.

Certification systems play a crucial role in the regulatory landscape. Standards such as ASTM D6400 and EN 13432 provide specifications for compostable plastics. These standards are often referenced in regulations and are essential for manufacturers to demonstrate compliance with biodegradability requirements.

The regulatory framework also extends to labeling and consumer information. Many jurisdictions require clear and accurate labeling of biodegradable products to prevent greenwashing and ensure proper disposal. The ISO 14021 standard provides guidelines for environmental claims, including those related to biodegradability and compostability.

As research into biodegradable LDPE advances, regulators are working to keep pace with technological developments. There is an increasing focus on life cycle assessments to ensure that biodegradable alternatives truly offer environmental benefits over traditional plastics. This has led to more nuanced regulations that consider not just end-of-life disposal but also the production and use phases of bioplastics.

The regulatory landscape for bioplastics is complex and dynamic, with ongoing debates about the most effective approaches to reduce plastic waste. As the technology for biodegradable LDPE continues to evolve, it is likely that regulations will become more sophisticated, potentially including incentives for research and development, as well as stricter controls on production and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!