How to Create Biodegradable LDPE Composites?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Biodegradability Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its introduction in the 1930s. Its versatility, low cost, and excellent physical properties have made it ubiquitous in packaging, consumer goods, and various industrial applications. However, the persistence of LDPE in the environment has become a significant concern, contributing to plastic pollution and ecological damage.

The development of biodegradable LDPE composites represents a critical technological frontier in addressing these environmental challenges. This initiative aims to create materials that retain the desirable properties of LDPE while introducing biodegradability, thus mitigating its long-term environmental impact. The primary objective is to engineer LDPE composites that can degrade under natural conditions within a reasonable timeframe, without compromising the material's performance during its intended use.

The evolution of biodegradable LDPE composites is closely tied to advancements in polymer science and environmental technology. Early attempts focused on blending LDPE with naturally biodegradable polymers, such as starch or cellulose. However, these efforts often resulted in materials with compromised mechanical properties or limited biodegradability.

Recent technological trends have shifted towards more sophisticated approaches, including the incorporation of pro-oxidant additives, the development of oxo-biodegradable LDPE, and the exploration of novel biodegradable polymer blends. These advancements are driven by a growing understanding of polymer degradation mechanisms and the microbial processes involved in biodegradation.

The market demand for biodegradable LDPE composites is rapidly expanding, fueled by increasing environmental awareness, stringent regulations on plastic waste, and consumer preferences for sustainable products. This demand spans various sectors, including packaging, agriculture, and consumer goods, presenting significant opportunities for innovation and market growth.

Achieving true biodegradability in LDPE composites presents several technical challenges. These include maintaining the material's desirable properties, ensuring consistent and predictable degradation rates, and developing composites that can biodegrade in diverse environmental conditions. Additionally, the composites must be cost-effective and compatible with existing manufacturing processes to facilitate widespread adoption.

The successful development of biodegradable LDPE composites has the potential to revolutionize the plastics industry, offering a sustainable alternative to conventional LDPE without sacrificing performance. This technology could significantly reduce plastic pollution, contribute to circular economy initiatives, and meet the growing global demand for environmentally friendly materials.

The development of biodegradable LDPE composites represents a critical technological frontier in addressing these environmental challenges. This initiative aims to create materials that retain the desirable properties of LDPE while introducing biodegradability, thus mitigating its long-term environmental impact. The primary objective is to engineer LDPE composites that can degrade under natural conditions within a reasonable timeframe, without compromising the material's performance during its intended use.

The evolution of biodegradable LDPE composites is closely tied to advancements in polymer science and environmental technology. Early attempts focused on blending LDPE with naturally biodegradable polymers, such as starch or cellulose. However, these efforts often resulted in materials with compromised mechanical properties or limited biodegradability.

Recent technological trends have shifted towards more sophisticated approaches, including the incorporation of pro-oxidant additives, the development of oxo-biodegradable LDPE, and the exploration of novel biodegradable polymer blends. These advancements are driven by a growing understanding of polymer degradation mechanisms and the microbial processes involved in biodegradation.

The market demand for biodegradable LDPE composites is rapidly expanding, fueled by increasing environmental awareness, stringent regulations on plastic waste, and consumer preferences for sustainable products. This demand spans various sectors, including packaging, agriculture, and consumer goods, presenting significant opportunities for innovation and market growth.

Achieving true biodegradability in LDPE composites presents several technical challenges. These include maintaining the material's desirable properties, ensuring consistent and predictable degradation rates, and developing composites that can biodegrade in diverse environmental conditions. Additionally, the composites must be cost-effective and compatible with existing manufacturing processes to facilitate widespread adoption.

The successful development of biodegradable LDPE composites has the potential to revolutionize the plastics industry, offering a sustainable alternative to conventional LDPE without sacrificing performance. This technology could significantly reduce plastic pollution, contribute to circular economy initiatives, and meet the growing global demand for environmentally friendly materials.

Market Analysis for Eco-Friendly Plastics

The market for eco-friendly plastics, particularly biodegradable LDPE composites, has been experiencing significant growth in recent years. This surge is driven by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer awareness about sustainable products. The global biodegradable plastics market is projected to expand at a compound annual growth rate of 9.5% from 2021 to 2026, with biodegradable LDPE composites playing a crucial role in this growth.

Consumer packaged goods companies are increasingly adopting biodegradable LDPE composites for packaging applications, as they offer a balance between functionality and environmental sustainability. The food and beverage industry, in particular, has shown strong interest in these materials for single-use packaging items. Additionally, the agriculture sector is emerging as a significant market for biodegradable LDPE composites, especially in mulch films and greenhouse coverings.

Geographically, Europe leads the market for eco-friendly plastics, including biodegradable LDPE composites, due to stringent environmental regulations and high consumer awareness. North America follows closely, with rapid adoption in the packaging and agricultural sectors. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth in the coming years, driven by increasing industrialization and government initiatives to reduce plastic waste.

Despite the positive outlook, several challenges persist in the market for biodegradable LDPE composites. The higher production costs compared to traditional LDPE remain a significant barrier to widespread adoption. Additionally, there are concerns about the performance and durability of these materials in certain applications, which may limit their use in specific industries.

The competitive landscape of the biodegradable LDPE composites market is characterized by a mix of established petrochemical companies and innovative start-ups. Major players are investing heavily in research and development to improve the properties and reduce the production costs of these materials. Collaborations between material scientists, polymer engineers, and biotechnology firms are becoming increasingly common, aiming to develop more efficient and cost-effective biodegradable LDPE composites.

Looking ahead, the market for biodegradable LDPE composites is expected to benefit from ongoing technological advancements and increasing regulatory pressure on conventional plastics. The development of novel biodegradable additives and the optimization of production processes are likely to drive down costs and improve material properties, further expanding the potential applications of these eco-friendly plastics across various industries.

Consumer packaged goods companies are increasingly adopting biodegradable LDPE composites for packaging applications, as they offer a balance between functionality and environmental sustainability. The food and beverage industry, in particular, has shown strong interest in these materials for single-use packaging items. Additionally, the agriculture sector is emerging as a significant market for biodegradable LDPE composites, especially in mulch films and greenhouse coverings.

Geographically, Europe leads the market for eco-friendly plastics, including biodegradable LDPE composites, due to stringent environmental regulations and high consumer awareness. North America follows closely, with rapid adoption in the packaging and agricultural sectors. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth in the coming years, driven by increasing industrialization and government initiatives to reduce plastic waste.

Despite the positive outlook, several challenges persist in the market for biodegradable LDPE composites. The higher production costs compared to traditional LDPE remain a significant barrier to widespread adoption. Additionally, there are concerns about the performance and durability of these materials in certain applications, which may limit their use in specific industries.

The competitive landscape of the biodegradable LDPE composites market is characterized by a mix of established petrochemical companies and innovative start-ups. Major players are investing heavily in research and development to improve the properties and reduce the production costs of these materials. Collaborations between material scientists, polymer engineers, and biotechnology firms are becoming increasingly common, aiming to develop more efficient and cost-effective biodegradable LDPE composites.

Looking ahead, the market for biodegradable LDPE composites is expected to benefit from ongoing technological advancements and increasing regulatory pressure on conventional plastics. The development of novel biodegradable additives and the optimization of production processes are likely to drive down costs and improve material properties, further expanding the potential applications of these eco-friendly plastics across various industries.

Current Challenges in LDPE Biodegradation

The biodegradation of Low-Density Polyethylene (LDPE) presents significant challenges due to its inherent chemical and physical properties. LDPE's high molecular weight, strong carbon-carbon bonds, and hydrophobic nature make it resistant to microbial attack and enzymatic degradation. This resistance is further compounded by the presence of antioxidants and stabilizers added during manufacturing, which inhibit oxidation and biodegradation processes.

One of the primary obstacles in LDPE biodegradation is the lack of naturally occurring microorganisms capable of efficiently breaking down the polymer structure. While some bacteria and fungi have shown limited ability to degrade LDPE, the process is extremely slow, often taking decades or even centuries for complete decomposition. This prolonged degradation time poses severe environmental concerns, as LDPE accumulates in ecosystems faster than it can be broken down.

The surface properties of LDPE also contribute to its recalcitrance towards biodegradation. The smooth, hydrophobic surface of LDPE films and particles prevents the adhesion of microorganisms and their enzymes, limiting their ability to initiate the degradation process. Additionally, the lack of functional groups on the LDPE surface further hinders microbial colonization and enzymatic attack.

Another challenge lies in the heterogeneity of LDPE waste. Different grades of LDPE with varying molecular weights, degrees of branching, and additive compositions are used in various applications. This diversity complicates the development of universal biodegradation strategies, as different LDPE formulations may require tailored approaches for effective breakdown.

The environmental conditions required for optimal LDPE biodegradation present another hurdle. Factors such as temperature, humidity, UV exposure, and oxygen availability significantly influence the rate of degradation. Achieving and maintaining these conditions in real-world scenarios, particularly in marine environments where much plastic waste accumulates, is challenging and often impractical.

Furthermore, the formation of microplastics during the partial degradation of LDPE poses additional environmental risks. As LDPE breaks down into smaller particles, it becomes more difficult to remove from the environment and can be ingested by various organisms, potentially entering the food chain and causing long-term ecological impacts.

The development of biodegradable LDPE composites faces its own set of challenges. Incorporating biodegradable additives or fillers into LDPE without compromising its desirable properties, such as flexibility, durability, and barrier properties, is a complex task. Achieving a balance between enhanced biodegradability and maintaining the functional characteristics of LDPE requires careful material selection and process optimization.

Lastly, the economic viability of biodegradable LDPE composites remains a significant hurdle. The additional costs associated with developing and producing these materials, coupled with the need for specialized waste management infrastructure, can make them less attractive to manufacturers and consumers compared to conventional LDPE products.

One of the primary obstacles in LDPE biodegradation is the lack of naturally occurring microorganisms capable of efficiently breaking down the polymer structure. While some bacteria and fungi have shown limited ability to degrade LDPE, the process is extremely slow, often taking decades or even centuries for complete decomposition. This prolonged degradation time poses severe environmental concerns, as LDPE accumulates in ecosystems faster than it can be broken down.

The surface properties of LDPE also contribute to its recalcitrance towards biodegradation. The smooth, hydrophobic surface of LDPE films and particles prevents the adhesion of microorganisms and their enzymes, limiting their ability to initiate the degradation process. Additionally, the lack of functional groups on the LDPE surface further hinders microbial colonization and enzymatic attack.

Another challenge lies in the heterogeneity of LDPE waste. Different grades of LDPE with varying molecular weights, degrees of branching, and additive compositions are used in various applications. This diversity complicates the development of universal biodegradation strategies, as different LDPE formulations may require tailored approaches for effective breakdown.

The environmental conditions required for optimal LDPE biodegradation present another hurdle. Factors such as temperature, humidity, UV exposure, and oxygen availability significantly influence the rate of degradation. Achieving and maintaining these conditions in real-world scenarios, particularly in marine environments where much plastic waste accumulates, is challenging and often impractical.

Furthermore, the formation of microplastics during the partial degradation of LDPE poses additional environmental risks. As LDPE breaks down into smaller particles, it becomes more difficult to remove from the environment and can be ingested by various organisms, potentially entering the food chain and causing long-term ecological impacts.

The development of biodegradable LDPE composites faces its own set of challenges. Incorporating biodegradable additives or fillers into LDPE without compromising its desirable properties, such as flexibility, durability, and barrier properties, is a complex task. Achieving a balance between enhanced biodegradability and maintaining the functional characteristics of LDPE requires careful material selection and process optimization.

Lastly, the economic viability of biodegradable LDPE composites remains a significant hurdle. The additional costs associated with developing and producing these materials, coupled with the need for specialized waste management infrastructure, can make them less attractive to manufacturers and consumers compared to conventional LDPE products.

Existing Biodegradable LDPE Composite Solutions

01 Biodegradable LDPE composites with natural additives

Incorporating natural additives such as starch, cellulose, or plant fibers into LDPE composites can enhance their biodegradability. These additives provide sites for microbial attack, accelerating the decomposition process of the otherwise non-biodegradable LDPE matrix.- Biodegradable LDPE composites with natural additives: Incorporating natural additives such as starch, cellulose, or other plant-based materials into LDPE composites can enhance their biodegradability. These additives provide sites for microbial attack, accelerating the decomposition process of the polymer matrix.

- Pro-oxidant additives for LDPE biodegradation: Adding pro-oxidant additives to LDPE composites can promote oxidation and subsequent biodegradation. These additives typically include transition metal compounds that catalyze the oxidation process, leading to chain scission and making the polymer more susceptible to microbial degradation.

- Blending LDPE with biodegradable polymers: Blending LDPE with biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA) can improve the overall biodegradability of the composite. The biodegradable component acts as an initiator for the degradation process, creating pathways for microbial access to the LDPE matrix.

- Surface modification of LDPE for enhanced biodegradability: Modifying the surface of LDPE through techniques such as plasma treatment, UV irradiation, or chemical etching can increase its susceptibility to biodegradation. These treatments create functional groups on the polymer surface, making it more hydrophilic and accessible to microbial enzymes.

- Incorporation of biodegradation-promoting microorganisms: Adding specific microorganisms or enzymes known to degrade polyethylene into LDPE composites can accelerate the biodegradation process. These biological agents can be encapsulated or immobilized within the composite to maintain their viability and effectiveness over time.

02 Pro-oxidant additives for LDPE biodegradation

Adding pro-oxidant additives to LDPE composites can promote oxidation and fragmentation of the polymer chains, making them more susceptible to microbial degradation. These additives typically include transition metal compounds that catalyze the oxidation process.Expand Specific Solutions03 Biodegradable polymer blends with LDPE

Blending LDPE with biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA) can improve the overall biodegradability of the composite. The biodegradable component acts as a weak link, allowing for faster disintegration of the material.Expand Specific Solutions04 Enzymatic degradation of LDPE composites

Incorporating enzymes or enzyme-producing microorganisms into LDPE composites can facilitate their biodegradation. These biological catalysts can break down the polymer chains, making them more accessible to microbial degradation.Expand Specific Solutions05 Surface modification for enhanced biodegradability

Modifying the surface of LDPE composites through techniques such as plasma treatment or chemical functionalization can increase their hydrophilicity and susceptibility to microbial attack, thereby improving biodegradability.Expand Specific Solutions

Key Players in Biodegradable LDPE Research

The biodegradable LDPE composites market is in its growth stage, driven by increasing environmental concerns and regulatory pressures. The global market size for biodegradable plastics is projected to reach $6.12 billion by 2023, with LDPE composites playing a significant role. Technologically, the field is advancing rapidly, with companies like PetroChina, SABIC, and Braskem leading in research and development. These industry giants are investing heavily in sustainable solutions, while smaller players like Orinko Advanced Plastics and Nanjing Aidobo Environmental Protection Technology are focusing on niche applications. The technology's maturity varies, with some biodegradable LDPE composites already commercialized, while others are still in the experimental stage. Collaboration between industry and academia, such as partnerships with Hunan University of Technology and Cornell University, is accelerating innovation in this field.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of biodegradable LDPE composites using their proprietary d2w technology. This additive-based approach allows for the production of oxo-biodegradable plastics that break down in the presence of oxygen, light, and heat[1]. The company has successfully incorporated natural fibers such as wood flour and agricultural waste into LDPE matrices, enhancing biodegradability while maintaining desirable mechanical properties[2]. SABIC's process involves careful selection of compatibilizers to improve the interfacial adhesion between the hydrophilic natural fibers and hydrophobic LDPE, resulting in composites with improved tensile strength and elongation at break[3]. The company has also explored the use of nanofillers like nanoclay to further enhance the mechanical and barrier properties of their biodegradable LDPE composites[4].

Strengths: Established technology with proven biodegradability, versatile application across various products, maintains good mechanical properties. Weaknesses: Requires specific environmental conditions for biodegradation, potential for microplastic formation during breakdown process.

Braskem SA

Technical Solution: Braskem has pioneered the development of bio-based LDPE composites derived from sugarcane ethanol, marketed under the I'm green™ brand. This innovative approach produces LDPE with identical properties to fossil-based LDPE but with a significantly reduced carbon footprint[1]. The company has further enhanced the biodegradability of these bio-based LDPE composites by incorporating natural fibers such as cellulose and lignin residues from the sugarcane industry[2]. Braskem's technology involves optimizing the processing conditions to achieve a homogeneous dispersion of natural fibers within the LDPE matrix, resulting in improved mechanical properties and accelerated biodegradation rates[3]. The company has also developed compatibilization techniques using maleic anhydride-grafted polyethylene to enhance the interfacial adhesion between the biobased LDPE and natural fibers, leading to superior mechanical performance and biodegradability[4].

Strengths: Renewable feedstock source, reduced carbon footprint, potential for closed-loop recycling within the sugarcane industry. Weaknesses: Limited availability of bio-based feedstock, potential competition with food crops, higher production costs compared to conventional LDPE.

Innovative Approaches to LDPE Biodegradation

Biodegradable composites

PatentPendingUS20250059348A1

Innovation

- A biodegradable composite is developed by combining a biodegradable polymer, such as 2-hydroxyethyl cellulose (HEC) or agar, with bio-crystals like L-tyrosine crystals, in concentrations ranging from 1 wt% to 50 wt%, resulting in enhanced mechanical properties.

Method for manufacturing biodegradable packaging vinyl sheet

PatentWO2020060221A1

Innovation

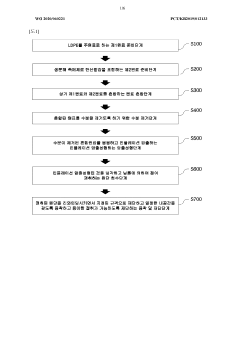

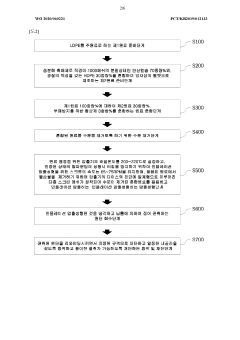

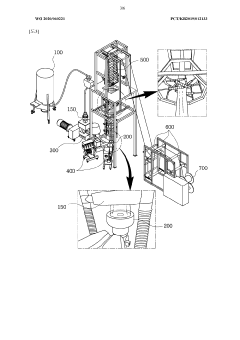

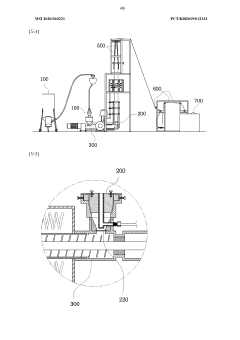

- A method involving the use of low-density polyethylene (LDPE) as the main raw material, calcium carbonate as a biodegradation catalyst, and high-density polyethylene (HDPE) to maintain strength, combined with an antibacterial agent, and a multi-layer screen mesh to filter impurities, ensuring consistent extrusion speed and density during inflation extrusion molding.

Environmental Impact Assessment

The environmental impact assessment of biodegradable LDPE composites is a critical aspect of their development and implementation. These composites offer potential solutions to the persistent plastic pollution problem, but their overall environmental footprint must be carefully evaluated.

Biodegradable LDPE composites are designed to break down more rapidly than traditional LDPE, reducing long-term environmental accumulation. However, the production process and additives used in these composites may have their own environmental implications. The assessment must consider the entire lifecycle of the product, from raw material extraction to disposal.

One key factor is the energy consumption and greenhouse gas emissions associated with the production of biodegradable LDPE composites. While they may offer benefits at the end-of-life stage, the manufacturing process could potentially be more energy-intensive than traditional LDPE production. This trade-off needs to be quantified and weighed against the environmental benefits of biodegradability.

The sourcing of raw materials for biodegradable additives is another important consideration. If these additives are derived from renewable resources, such as plant-based materials, they may contribute to reduced fossil fuel dependency. However, the land use and agricultural practices associated with growing these crops must be evaluated for their environmental impact, including effects on biodiversity and water resources.

Water consumption and pollution during the production process should also be assessed. The creation of biodegradable LDPE composites may require additional processing steps or chemicals that could increase water usage or potentially introduce new pollutants into wastewater streams.

The end-of-life scenario for biodegradable LDPE composites is a crucial aspect of their environmental impact. While they are designed to degrade more quickly than traditional LDPE, the actual rate and completeness of biodegradation in various environments (e.g., soil, marine, landfill) must be thoroughly studied. The byproducts of degradation and their potential effects on ecosystems need to be carefully examined.

Additionally, the impact on existing recycling systems should be considered. If biodegradable LDPE composites are not easily distinguishable from traditional LDPE, they could potentially contaminate recycling streams and reduce the quality of recycled plastics.

Lastly, the potential for these composites to reduce microplastic pollution should be evaluated. If they degrade more rapidly and completely, they may contribute less to the growing problem of microplastics in the environment. However, the interim stages of degradation and the potential release of smaller plastic particles before complete biodegradation must be investigated.

In conclusion, while biodegradable LDPE composites hold promise for reducing plastic pollution, a comprehensive environmental impact assessment is essential to ensure that their overall effect is indeed positive and that unintended consequences are minimized or avoided.

Biodegradable LDPE composites are designed to break down more rapidly than traditional LDPE, reducing long-term environmental accumulation. However, the production process and additives used in these composites may have their own environmental implications. The assessment must consider the entire lifecycle of the product, from raw material extraction to disposal.

One key factor is the energy consumption and greenhouse gas emissions associated with the production of biodegradable LDPE composites. While they may offer benefits at the end-of-life stage, the manufacturing process could potentially be more energy-intensive than traditional LDPE production. This trade-off needs to be quantified and weighed against the environmental benefits of biodegradability.

The sourcing of raw materials for biodegradable additives is another important consideration. If these additives are derived from renewable resources, such as plant-based materials, they may contribute to reduced fossil fuel dependency. However, the land use and agricultural practices associated with growing these crops must be evaluated for their environmental impact, including effects on biodiversity and water resources.

Water consumption and pollution during the production process should also be assessed. The creation of biodegradable LDPE composites may require additional processing steps or chemicals that could increase water usage or potentially introduce new pollutants into wastewater streams.

The end-of-life scenario for biodegradable LDPE composites is a crucial aspect of their environmental impact. While they are designed to degrade more quickly than traditional LDPE, the actual rate and completeness of biodegradation in various environments (e.g., soil, marine, landfill) must be thoroughly studied. The byproducts of degradation and their potential effects on ecosystems need to be carefully examined.

Additionally, the impact on existing recycling systems should be considered. If biodegradable LDPE composites are not easily distinguishable from traditional LDPE, they could potentially contaminate recycling streams and reduce the quality of recycled plastics.

Lastly, the potential for these composites to reduce microplastic pollution should be evaluated. If they degrade more rapidly and completely, they may contribute less to the growing problem of microplastics in the environment. However, the interim stages of degradation and the potential release of smaller plastic particles before complete biodegradation must be investigated.

In conclusion, while biodegradable LDPE composites hold promise for reducing plastic pollution, a comprehensive environmental impact assessment is essential to ensure that their overall effect is indeed positive and that unintended consequences are minimized or avoided.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development and adoption of biodegradable LDPE composites. As environmental concerns continue to grow, governments and international organizations have been implementing policies and standards to address plastic pollution and promote sustainable alternatives.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) have been working to establish guidelines and standards for biodegradable plastics. The ISO 17088 standard, for instance, provides specifications for compostable plastics, including biodegradable LDPE composites.

In the European Union, the European Committee for Standardization (CEN) has developed the EN 13432 standard, which outlines requirements for packaging recoverable through composting and biodegradation. This standard has been widely adopted and serves as a benchmark for biodegradable plastic certification in many countries.

The United States has also been active in developing regulations for biodegradable plastics. The Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability. Additionally, several states have implemented their own regulations, such as California's SB 567, which sets strict requirements for labeling products as "biodegradable" or "compostable."

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and certifying biodegradable materials, including LDPE composites.

These regulatory frameworks often include requirements for biodegradation rates, ecotoxicity testing, and compostability assessments. They also address labeling and marketing claims to prevent greenwashing and ensure consumer transparency.

For manufacturers developing biodegradable LDPE composites, compliance with these regulations is essential. This involves conducting extensive testing to demonstrate biodegradability under various environmental conditions, assessing the material's impact on ecosystems, and ensuring proper disposal methods are available.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the integration of biodegradable plastics into circular economy models.

Researchers and manufacturers working on biodegradable LDPE composites must stay informed about these regulatory developments and adapt their strategies accordingly. This may involve collaborating with policymakers, participating in standard-setting processes, and investing in innovative technologies to meet increasingly demanding environmental criteria.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) have been working to establish guidelines and standards for biodegradable plastics. The ISO 17088 standard, for instance, provides specifications for compostable plastics, including biodegradable LDPE composites.

In the European Union, the European Committee for Standardization (CEN) has developed the EN 13432 standard, which outlines requirements for packaging recoverable through composting and biodegradation. This standard has been widely adopted and serves as a benchmark for biodegradable plastic certification in many countries.

The United States has also been active in developing regulations for biodegradable plastics. The Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability. Additionally, several states have implemented their own regulations, such as California's SB 567, which sets strict requirements for labeling products as "biodegradable" or "compostable."

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and certifying biodegradable materials, including LDPE composites.

These regulatory frameworks often include requirements for biodegradation rates, ecotoxicity testing, and compostability assessments. They also address labeling and marketing claims to prevent greenwashing and ensure consumer transparency.

For manufacturers developing biodegradable LDPE composites, compliance with these regulations is essential. This involves conducting extensive testing to demonstrate biodegradability under various environmental conditions, assessing the material's impact on ecosystems, and ensuring proper disposal methods are available.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the integration of biodegradable plastics into circular economy models.

Researchers and manufacturers working on biodegradable LDPE composites must stay informed about these regulatory developments and adapt their strategies accordingly. This may involve collaborating with policymakers, participating in standard-setting processes, and investing in innovative technologies to meet increasingly demanding environmental criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!