How to Achieve Optimal Gel Polymerization for Electrophoresis?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gel Electrophoresis Background and Objectives

Gel electrophoresis has been a cornerstone technique in molecular biology and biochemistry for decades, serving as a powerful tool for separating and analyzing nucleic acids and proteins. The technique's origins can be traced back to the 1930s, with significant advancements occurring in the 1950s and 1960s. Over time, gel electrophoresis has evolved to encompass various forms, including agarose and polyacrylamide gel electrophoresis, each suited for different applications and biomolecule sizes.

The fundamental principle of gel electrophoresis relies on the migration of charged molecules through a porous gel matrix under the influence of an electric field. The rate of migration is determined by factors such as molecular size, shape, and charge. This principle has remained consistent throughout the technique's evolution, while improvements have focused on enhancing resolution, sensitivity, and applicability to diverse biomolecules.

In recent years, the field has witnessed a surge in technological advancements, particularly in the areas of high-resolution separation, miniaturization, and automation. These developments have expanded the technique's capabilities, enabling more precise analysis of complex biological samples and integration with other analytical methods.

The primary objective in achieving optimal gel polymerization for electrophoresis is to create a uniform and reproducible gel matrix that provides consistent and high-quality separation of biomolecules. This goal encompasses several key aspects, including improving gel stability, enhancing resolution, increasing sensitivity, and ensuring reproducibility across experiments.

Researchers aim to develop gel formulations and polymerization methods that minimize background noise, reduce gel artifacts, and allow for the separation of a wide range of molecular sizes. Additionally, there is a growing emphasis on creating environmentally friendly and safer alternatives to traditional gel components, addressing concerns related to toxicity and waste management.

Another crucial objective is to streamline the gel preparation process, making it more efficient and less time-consuming for researchers. This includes exploring rapid polymerization techniques, developing pre-cast gels with extended shelf lives, and creating user-friendly systems that require minimal expertise to operate.

As the field of molecular biology continues to advance, there is an increasing demand for gel electrophoresis techniques capable of separating and analyzing novel biomolecules, such as modified proteins, synthetic nucleic acids, and nanoparticles. Meeting this demand requires ongoing innovation in gel composition, polymerization methods, and detection systems.

The fundamental principle of gel electrophoresis relies on the migration of charged molecules through a porous gel matrix under the influence of an electric field. The rate of migration is determined by factors such as molecular size, shape, and charge. This principle has remained consistent throughout the technique's evolution, while improvements have focused on enhancing resolution, sensitivity, and applicability to diverse biomolecules.

In recent years, the field has witnessed a surge in technological advancements, particularly in the areas of high-resolution separation, miniaturization, and automation. These developments have expanded the technique's capabilities, enabling more precise analysis of complex biological samples and integration with other analytical methods.

The primary objective in achieving optimal gel polymerization for electrophoresis is to create a uniform and reproducible gel matrix that provides consistent and high-quality separation of biomolecules. This goal encompasses several key aspects, including improving gel stability, enhancing resolution, increasing sensitivity, and ensuring reproducibility across experiments.

Researchers aim to develop gel formulations and polymerization methods that minimize background noise, reduce gel artifacts, and allow for the separation of a wide range of molecular sizes. Additionally, there is a growing emphasis on creating environmentally friendly and safer alternatives to traditional gel components, addressing concerns related to toxicity and waste management.

Another crucial objective is to streamline the gel preparation process, making it more efficient and less time-consuming for researchers. This includes exploring rapid polymerization techniques, developing pre-cast gels with extended shelf lives, and creating user-friendly systems that require minimal expertise to operate.

As the field of molecular biology continues to advance, there is an increasing demand for gel electrophoresis techniques capable of separating and analyzing novel biomolecules, such as modified proteins, synthetic nucleic acids, and nanoparticles. Meeting this demand requires ongoing innovation in gel composition, polymerization methods, and detection systems.

Market Analysis for Gel Electrophoresis Products

The gel electrophoresis products market has experienced significant growth in recent years, driven by increasing applications in molecular biology, genetics, and biochemistry research. This market segment encompasses a wide range of products, including pre-cast gels, gel casting equipment, electrophoresis buffers, and related accessories.

Market demand for gel electrophoresis products is primarily fueled by the expanding biotechnology and pharmaceutical industries, as well as academic research institutions. The rising focus on personalized medicine and genomics has further boosted the adoption of gel electrophoresis techniques in various analytical processes.

The global gel electrophoresis market size was valued at approximately $1.6 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. North America currently holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the fastest growth due to increasing investments in life sciences research and development.

Key factors driving market growth include technological advancements in gel electrophoresis systems, growing funding for proteomics and genomics research, and the rising prevalence of infectious diseases and genetic disorders. The COVID-19 pandemic has also contributed to increased demand for gel electrophoresis products in diagnostic applications and vaccine development.

The market is segmented based on product type, with polyacrylamide gel electrophoresis (PAGE) holding the largest share due to its high resolution and versatility. Agarose gel electrophoresis is also widely used, particularly for DNA and RNA analysis. Emerging technologies, such as capillary electrophoresis and 2D gel electrophoresis, are gaining traction in specialized applications.

End-user segments include academic and research institutions, pharmaceutical and biotechnology companies, and diagnostic laboratories. Academic and research institutions currently dominate the market, but the pharmaceutical and biotechnology sector is expected to show the highest growth rate in the coming years.

Challenges facing the gel electrophoresis products market include the high cost of advanced systems and the emergence of alternative technologies such as next-generation sequencing. However, ongoing research and development efforts are focused on improving gel polymerization techniques to enhance resolution, reproducibility, and overall performance, which is expected to sustain market growth.

Market demand for gel electrophoresis products is primarily fueled by the expanding biotechnology and pharmaceutical industries, as well as academic research institutions. The rising focus on personalized medicine and genomics has further boosted the adoption of gel electrophoresis techniques in various analytical processes.

The global gel electrophoresis market size was valued at approximately $1.6 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 5% from 2021 to 2028. North America currently holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the fastest growth due to increasing investments in life sciences research and development.

Key factors driving market growth include technological advancements in gel electrophoresis systems, growing funding for proteomics and genomics research, and the rising prevalence of infectious diseases and genetic disorders. The COVID-19 pandemic has also contributed to increased demand for gel electrophoresis products in diagnostic applications and vaccine development.

The market is segmented based on product type, with polyacrylamide gel electrophoresis (PAGE) holding the largest share due to its high resolution and versatility. Agarose gel electrophoresis is also widely used, particularly for DNA and RNA analysis. Emerging technologies, such as capillary electrophoresis and 2D gel electrophoresis, are gaining traction in specialized applications.

End-user segments include academic and research institutions, pharmaceutical and biotechnology companies, and diagnostic laboratories. Academic and research institutions currently dominate the market, but the pharmaceutical and biotechnology sector is expected to show the highest growth rate in the coming years.

Challenges facing the gel electrophoresis products market include the high cost of advanced systems and the emergence of alternative technologies such as next-generation sequencing. However, ongoing research and development efforts are focused on improving gel polymerization techniques to enhance resolution, reproducibility, and overall performance, which is expected to sustain market growth.

Current Challenges in Gel Polymerization

Despite significant advancements in gel polymerization techniques for electrophoresis, several challenges persist in achieving optimal results. One of the primary issues is the inconsistency in gel uniformity, which can lead to irregular migration patterns and compromised resolution of separated molecules. This variability often stems from uneven polymerization rates across the gel matrix, resulting in regions of varying pore sizes and densities.

Another critical challenge is the control of polymerization kinetics. The rate of polymerization can significantly impact the final gel structure and its performance in electrophoretic separations. Rapid polymerization may lead to the formation of inhomogeneous gels with localized areas of high cross-linking, while slow polymerization can result in incomplete gel formation or excessive swelling.

Temperature regulation during the polymerization process remains a persistent issue. Fluctuations in temperature can affect the rate of radical formation and propagation, leading to inconsistencies in the gel structure. Maintaining a uniform temperature throughout the gel solution during polymerization is particularly challenging for larger gel formats.

The presence of oxygen during polymerization poses another significant hurdle. Oxygen acts as a radical scavenger, inhibiting the polymerization process and potentially causing incomplete gel formation, especially near the gel surfaces exposed to air. This can result in poorly defined wells and inconsistent sample loading capacities.

Achieving the desired pore size distribution is also a complex challenge. The pore size directly influences the separation efficiency and resolution of different molecular weight species. Controlling factors such as monomer concentration, cross-linker ratio, and initiator levels to consistently produce gels with the optimal pore size range for specific applications remains difficult.

Furthermore, the incorporation of specialized monomers or additives for enhanced separation properties often introduces additional complexities in the polymerization process. These additives can affect polymerization kinetics, gel mechanical properties, and overall performance, requiring careful optimization of polymerization conditions.

Lastly, the reproducibility of gel polymerization across different batches and laboratories continues to be a significant challenge. Variations in reagent quality, environmental conditions, and subtle differences in preparation techniques can lead to inconsistencies in gel properties, affecting the reliability and comparability of electrophoretic results across experiments and research groups.

Another critical challenge is the control of polymerization kinetics. The rate of polymerization can significantly impact the final gel structure and its performance in electrophoretic separations. Rapid polymerization may lead to the formation of inhomogeneous gels with localized areas of high cross-linking, while slow polymerization can result in incomplete gel formation or excessive swelling.

Temperature regulation during the polymerization process remains a persistent issue. Fluctuations in temperature can affect the rate of radical formation and propagation, leading to inconsistencies in the gel structure. Maintaining a uniform temperature throughout the gel solution during polymerization is particularly challenging for larger gel formats.

The presence of oxygen during polymerization poses another significant hurdle. Oxygen acts as a radical scavenger, inhibiting the polymerization process and potentially causing incomplete gel formation, especially near the gel surfaces exposed to air. This can result in poorly defined wells and inconsistent sample loading capacities.

Achieving the desired pore size distribution is also a complex challenge. The pore size directly influences the separation efficiency and resolution of different molecular weight species. Controlling factors such as monomer concentration, cross-linker ratio, and initiator levels to consistently produce gels with the optimal pore size range for specific applications remains difficult.

Furthermore, the incorporation of specialized monomers or additives for enhanced separation properties often introduces additional complexities in the polymerization process. These additives can affect polymerization kinetics, gel mechanical properties, and overall performance, requiring careful optimization of polymerization conditions.

Lastly, the reproducibility of gel polymerization across different batches and laboratories continues to be a significant challenge. Variations in reagent quality, environmental conditions, and subtle differences in preparation techniques can lead to inconsistencies in gel properties, affecting the reliability and comparability of electrophoretic results across experiments and research groups.

Existing Gel Polymerization Methods

01 Optimal conditions for gel polymerization

Achieving optimal gel polymerization involves controlling various parameters such as temperature, initiator concentration, and monomer composition. These factors significantly influence the final properties of the gel, including its mechanical strength, porosity, and swelling behavior. Optimizing these conditions can lead to improved gel performance for specific applications.- Optimal conditions for gel polymerization: Achieving optimal gel polymerization involves controlling various parameters such as temperature, initiator concentration, and monomer composition. These factors significantly influence the final properties of the gel, including its mechanical strength, porosity, and swelling behavior. Optimizing these conditions can lead to improved gel performance for specific applications.

- Initiator systems for gel polymerization: The choice of initiator system plays a crucial role in gel polymerization. Different types of initiators, such as thermal, redox, or photo-initiators, can be used depending on the desired polymerization kinetics and final gel properties. The concentration and type of initiator can affect the polymerization rate, gel formation time, and network structure.

- Monomer selection and composition: The selection of monomers and their composition significantly impact the properties of the resulting gel. Factors such as monomer functionality, hydrophilicity, and reactivity influence the crosslinking density, swelling behavior, and mechanical properties of the gel. Optimizing the monomer composition can lead to gels with tailored characteristics for specific applications.

- Crosslinking strategies for gel formation: Various crosslinking strategies can be employed to optimize gel formation and properties. These include chemical crosslinking, physical crosslinking, and hybrid approaches. The choice of crosslinking method and the degree of crosslinking can significantly affect the gel's mechanical strength, degradation rate, and response to external stimuli.

- Characterization and analysis of gel properties: Proper characterization and analysis of gel properties are essential for optimizing the polymerization process. Techniques such as rheology, spectroscopy, and microscopy can be used to evaluate gel formation kinetics, network structure, and mechanical properties. These analyses help in fine-tuning the polymerization conditions and understanding structure-property relationships in gel systems.

02 Initiator systems for gel polymerization

The choice of initiator system plays a crucial role in gel polymerization. Different types of initiators, such as thermal, redox, or photo-initiators, can be used to trigger the polymerization process. The selection of an appropriate initiator system depends on the desired gel properties and the specific application requirements.Expand Specific Solutions03 Crosslinking strategies in gel polymerization

Crosslinking is essential for the formation of three-dimensional gel networks. Various crosslinking strategies can be employed, including chemical crosslinking, physical crosslinking, and radiation-induced crosslinking. The choice of crosslinking method and the degree of crosslinking significantly impact the gel's mechanical properties and swelling behavior.Expand Specific Solutions04 Controlled polymerization techniques for gel synthesis

Controlled polymerization techniques, such as atom transfer radical polymerization (ATRP) and reversible addition-fragmentation chain transfer (RAFT) polymerization, can be used to synthesize gels with well-defined structures and properties. These techniques allow for precise control over molecular weight, polydispersity, and architecture of the polymer chains within the gel network.Expand Specific Solutions05 Characterization methods for optimized gel polymerization

Various characterization techniques are employed to evaluate the success of gel polymerization and optimize the process. These methods include rheological measurements, spectroscopic analysis, microscopy, and swelling studies. By utilizing these characterization tools, researchers can fine-tune the polymerization conditions and achieve gels with desired properties for specific applications.Expand Specific Solutions

Key Players in Electrophoresis Industry

The field of gel polymerization for electrophoresis is in a mature stage, with established techniques and a significant market presence. The global electrophoresis market size is estimated to be around $2-3 billion, driven by applications in research, diagnostics, and quality control. Key players like Bio-Rad Laboratories, Life Technologies, and Agilent Technologies dominate the market with advanced products and solutions. These companies, along with emerging players such as Sage Science and Expedeon, are continuously innovating to improve gel polymerization techniques, focusing on enhancing resolution, speed, and reproducibility. The technology's maturity is evident in its widespread adoption across academic, pharmaceutical, and biotechnology sectors, with ongoing research aimed at further optimizing performance and expanding applications.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad has developed a proprietary acrylamide formulation called TGX (Tris-Glycine eXtended) for optimal gel polymerization in electrophoresis. This formulation allows for rapid polymerization and extended shelf life of precast gels. The TGX gels incorporate a unique buffer system that enables faster run times and sharper band resolution[1]. Bio-Rad also utilizes a patented gel casting technology that ensures uniform pore size distribution, resulting in consistent and reproducible protein separation[2]. Additionally, they have introduced stain-free technology, which allows for instant visualization of proteins without the need for staining steps, significantly reducing the overall electrophoresis workflow time[3].

Strengths: Rapid polymerization, extended shelf life, faster run times, and improved band resolution. The stain-free technology offers a significant advantage in workflow efficiency. Weaknesses: Proprietary formulations may be more expensive than standard acrylamide gels and may require specific equipment compatibility.

Amersham Biosciences AB

Technical Solution: Amersham Biosciences (now part of GE Healthcare Life Sciences) has developed the PhastSystem for automated electrophoresis, which utilizes pre-cast polyacrylamide gels with optimized polymerization conditions. Their approach involves a proprietary gel matrix composition that allows for rapid electrophoresis and high-resolution protein separation[12]. The company has also introduced the Ettan DIGE system for 2D electrophoresis, which incorporates a specialized gel polymerization process to ensure compatibility with fluorescent labeling techniques[13]. Amersham's gel formulations include optimized ratios of acrylamide/bis-acrylamide and catalysts to achieve consistent pore sizes and mechanical stability across batches[14].

Strengths: Automated systems for rapid electrophoresis, high-resolution protein separation, and compatibility with fluorescent labeling techniques. The pre-cast gels offer consistency and convenience. Weaknesses: Reliance on proprietary systems may limit flexibility in experimental design. The specialized nature of the gels may result in higher costs compared to traditional hand-cast gels.

Innovative Approaches to Optimal Polymerization

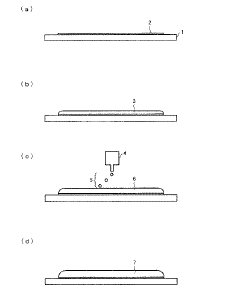

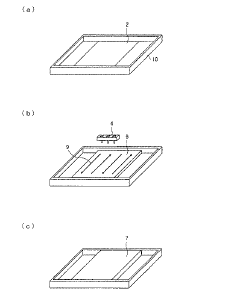

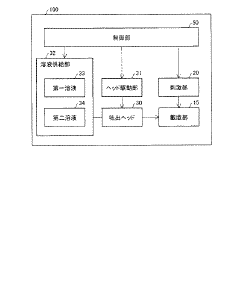

Electrophoresis gel manufacturing method and electrophoresis gel manufacturing apparatus

PatentInactiveJPWO2013133083A1

Innovation

- A method involving external energy, such as light or heat, is used to initiate polymerization of gel-forming monomers, with controlled addition and dispersion of initiators, and surface treatments to form gradients, allowing for precise and efficient gel formation on a substrate.

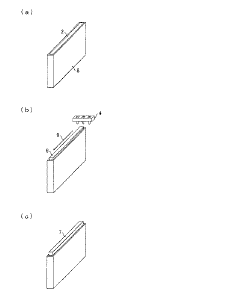

Low-concentration gel for electrophoresis, and method of manufacturing the same

PatentInactiveJP2010060510A

Innovation

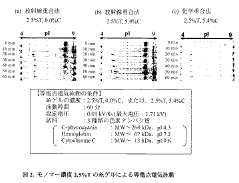

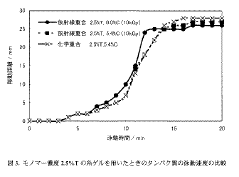

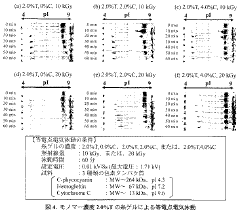

- A low-concentration electrophoresis gel is produced by radiation polymerization, combining monomer concentrations of 1.5%T to 3.0%T and cross-linking agent concentrations of 0 to 8.0%C, eliminating the need for chemical polymerization initiators and catalysts, and incorporating a filamentous body to enhance physical strength and pore size.

Quality Control in Gel Electrophoresis

Quality control is a critical aspect of gel electrophoresis, ensuring the reliability and reproducibility of results. Effective quality control measures begin with the gel preparation process, particularly focusing on optimal gel polymerization. Consistent and uniform gel polymerization is essential for achieving accurate and reproducible separation of biomolecules.

One key factor in quality control is the precise measurement and mixing of gel components. The concentration of acrylamide and bis-acrylamide must be carefully controlled to achieve the desired pore size and separation range. Deviations in these concentrations can lead to inconsistent gel structures and affect the migration of molecules. Additionally, the use of high-quality, purified reagents is crucial to prevent contamination that could interfere with polymerization or subsequent electrophoresis.

Temperature control during gel polymerization is another critical quality control parameter. Polymerization rates are temperature-dependent, and fluctuations can lead to uneven gel formation. Maintaining a consistent temperature throughout the polymerization process, typically around room temperature (20-25°C), helps ensure uniform gel structure. Some laboratories employ temperature-controlled chambers or water baths to maintain stable conditions during polymerization.

The timing of polymerization initiation and completion is also crucial for quality control. Proper mixing and rapid pouring of the gel solution after adding polymerization catalysts (such as ammonium persulfate and TEMED) help prevent premature polymerization and ensure even distribution of the catalysts. Allowing sufficient time for complete polymerization before use is essential to avoid gel instability during electrophoresis.

Visual inspection of the polymerized gel is an important quality control step. Checking for uniformity, absence of bubbles, and proper gel thickness helps identify potential issues before sample loading. Some laboratories employ standardized checklists or imaging techniques to document gel quality consistently.

Implementing regular calibration and maintenance of equipment used in gel preparation and electrophoresis is another crucial aspect of quality control. This includes calibrating pipettes for accurate reagent measurements, maintaining pH meters for buffer preparation, and ensuring proper functioning of gel casting apparatus and electrophoresis units.

Lastly, establishing standard operating procedures (SOPs) for gel preparation and electrophoresis, along with proper training of personnel, contributes significantly to consistent quality control. These SOPs should include detailed protocols for reagent preparation, gel casting, polymerization conditions, and troubleshooting guidelines. Regular proficiency testing and inter-laboratory comparisons can further enhance the reliability and reproducibility of gel electrophoresis results across different settings.

One key factor in quality control is the precise measurement and mixing of gel components. The concentration of acrylamide and bis-acrylamide must be carefully controlled to achieve the desired pore size and separation range. Deviations in these concentrations can lead to inconsistent gel structures and affect the migration of molecules. Additionally, the use of high-quality, purified reagents is crucial to prevent contamination that could interfere with polymerization or subsequent electrophoresis.

Temperature control during gel polymerization is another critical quality control parameter. Polymerization rates are temperature-dependent, and fluctuations can lead to uneven gel formation. Maintaining a consistent temperature throughout the polymerization process, typically around room temperature (20-25°C), helps ensure uniform gel structure. Some laboratories employ temperature-controlled chambers or water baths to maintain stable conditions during polymerization.

The timing of polymerization initiation and completion is also crucial for quality control. Proper mixing and rapid pouring of the gel solution after adding polymerization catalysts (such as ammonium persulfate and TEMED) help prevent premature polymerization and ensure even distribution of the catalysts. Allowing sufficient time for complete polymerization before use is essential to avoid gel instability during electrophoresis.

Visual inspection of the polymerized gel is an important quality control step. Checking for uniformity, absence of bubbles, and proper gel thickness helps identify potential issues before sample loading. Some laboratories employ standardized checklists or imaging techniques to document gel quality consistently.

Implementing regular calibration and maintenance of equipment used in gel preparation and electrophoresis is another crucial aspect of quality control. This includes calibrating pipettes for accurate reagent measurements, maintaining pH meters for buffer preparation, and ensuring proper functioning of gel casting apparatus and electrophoresis units.

Lastly, establishing standard operating procedures (SOPs) for gel preparation and electrophoresis, along with proper training of personnel, contributes significantly to consistent quality control. These SOPs should include detailed protocols for reagent preparation, gel casting, polymerization conditions, and troubleshooting guidelines. Regular proficiency testing and inter-laboratory comparisons can further enhance the reliability and reproducibility of gel electrophoresis results across different settings.

Environmental Impact of Gel Materials

The environmental impact of gel materials used in electrophoresis is a critical consideration in the pursuit of optimal gel polymerization. Acrylamide, the primary component in polyacrylamide gels, poses significant environmental and health risks. When improperly disposed of, acrylamide can contaminate soil and water systems, potentially harming aquatic life and entering the food chain. The neurotoxic and carcinogenic properties of acrylamide make its environmental presence particularly concerning.

Agarose gels, while generally considered less toxic than polyacrylamide, still contribute to environmental issues. The production of agarose involves the extraction of agar from seaweed, which can lead to overexploitation of marine resources if not managed sustainably. Additionally, the disposal of used agarose gels contributes to plastic waste, as they are often discarded after a single use.

The chemicals used in gel preparation and running buffers, such as Tris, EDTA, and boric acid, can also have environmental implications. These compounds, when released into the environment, may alter soil and water pH levels, affecting local ecosystems. Furthermore, the energy consumption associated with gel electrophoresis equipment contributes to the overall carbon footprint of laboratory operations.

To mitigate these environmental impacts, researchers are exploring more sustainable alternatives. Bio-based hydrogels derived from natural polymers like cellulose or chitosan show promise as environmentally friendly substitutes. These materials are biodegradable and can be sourced from renewable resources, reducing the reliance on petrochemical-based products.

Efforts to minimize waste generation in electrophoresis processes are also gaining traction. Techniques such as microfluidic electrophoresis and capillary electrophoresis require significantly smaller sample volumes and generate less waste compared to traditional slab gel methods. Additionally, the development of reusable gel systems and improved recycling protocols for gel materials can help reduce the environmental burden of electrophoresis techniques.

The scientific community is increasingly recognizing the importance of green chemistry principles in laboratory practices. This shift is driving innovation in gel formulations that are not only optimized for performance but also designed with environmental sustainability in mind. As research progresses, it is likely that we will see the emergence of new gel materials and electrophoresis techniques that balance analytical efficiency with reduced environmental impact, paving the way for more sustainable scientific practices in the field of molecular biology and biochemistry.

Agarose gels, while generally considered less toxic than polyacrylamide, still contribute to environmental issues. The production of agarose involves the extraction of agar from seaweed, which can lead to overexploitation of marine resources if not managed sustainably. Additionally, the disposal of used agarose gels contributes to plastic waste, as they are often discarded after a single use.

The chemicals used in gel preparation and running buffers, such as Tris, EDTA, and boric acid, can also have environmental implications. These compounds, when released into the environment, may alter soil and water pH levels, affecting local ecosystems. Furthermore, the energy consumption associated with gel electrophoresis equipment contributes to the overall carbon footprint of laboratory operations.

To mitigate these environmental impacts, researchers are exploring more sustainable alternatives. Bio-based hydrogels derived from natural polymers like cellulose or chitosan show promise as environmentally friendly substitutes. These materials are biodegradable and can be sourced from renewable resources, reducing the reliance on petrochemical-based products.

Efforts to minimize waste generation in electrophoresis processes are also gaining traction. Techniques such as microfluidic electrophoresis and capillary electrophoresis require significantly smaller sample volumes and generate less waste compared to traditional slab gel methods. Additionally, the development of reusable gel systems and improved recycling protocols for gel materials can help reduce the environmental burden of electrophoresis techniques.

The scientific community is increasingly recognizing the importance of green chemistry principles in laboratory practices. This shift is driving innovation in gel formulations that are not only optimized for performance but also designed with environmental sustainability in mind. As research progresses, it is likely that we will see the emergence of new gel materials and electrophoresis techniques that balance analytical efficiency with reduced environmental impact, paving the way for more sustainable scientific practices in the field of molecular biology and biochemistry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!