How to Address Challenges in LDPE Disposal?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Disposal Background and Objectives

Low-density polyethylene (LDPE) has been a ubiquitous material in packaging and consumer products since its introduction in the 1930s. Its versatility, low cost, and durability have led to widespread adoption across various industries. However, the very properties that make LDPE attractive for use also contribute to significant environmental challenges, particularly in terms of disposal and waste management.

The evolution of LDPE disposal methods has been closely tied to the growing awareness of environmental issues. Initially, LDPE waste was primarily sent to landfills or incinerated, practices that are now recognized as unsustainable due to their negative environmental impact. As global plastic waste has increased exponentially over the past decades, the urgency to develop effective LDPE disposal solutions has intensified.

Current trends in LDPE disposal focus on the principles of circular economy and sustainability. This shift has led to increased efforts in recycling, upcycling, and developing biodegradable alternatives. However, the recycling of LDPE presents unique challenges due to its chemical properties and the presence of contaminants in post-consumer waste streams.

The primary objective in addressing LDPE disposal challenges is to minimize environmental impact while maximizing resource efficiency. This involves developing technologies and systems that can effectively collect, sort, and process LDPE waste. Additionally, there is a growing emphasis on redesigning LDPE products to facilitate easier recycling or biodegradation at the end of their lifecycle.

Another critical goal is to reduce the overall consumption of LDPE by promoting alternative materials and encouraging reuse. This requires a multifaceted approach involving consumer education, policy interventions, and industry collaboration. The development of biodegradable plastics that can replace LDPE in certain applications is also a key area of research and innovation.

Addressing the challenges in LDPE disposal also necessitates improvements in waste management infrastructure, particularly in developing countries where informal waste collection systems often lead to environmental pollution. Enhancing the global capacity for proper LDPE disposal and recycling is crucial for mitigating its environmental impact on a worldwide scale.

As we move forward, the objectives for LDPE disposal are becoming increasingly ambitious. These include achieving higher recycling rates, developing more efficient sorting technologies, and creating closed-loop systems where LDPE products can be continuously recycled without loss of quality. The ultimate aim is to transition towards a circular economy model for LDPE, where waste is minimized, and materials are kept in use for as long as possible.

The evolution of LDPE disposal methods has been closely tied to the growing awareness of environmental issues. Initially, LDPE waste was primarily sent to landfills or incinerated, practices that are now recognized as unsustainable due to their negative environmental impact. As global plastic waste has increased exponentially over the past decades, the urgency to develop effective LDPE disposal solutions has intensified.

Current trends in LDPE disposal focus on the principles of circular economy and sustainability. This shift has led to increased efforts in recycling, upcycling, and developing biodegradable alternatives. However, the recycling of LDPE presents unique challenges due to its chemical properties and the presence of contaminants in post-consumer waste streams.

The primary objective in addressing LDPE disposal challenges is to minimize environmental impact while maximizing resource efficiency. This involves developing technologies and systems that can effectively collect, sort, and process LDPE waste. Additionally, there is a growing emphasis on redesigning LDPE products to facilitate easier recycling or biodegradation at the end of their lifecycle.

Another critical goal is to reduce the overall consumption of LDPE by promoting alternative materials and encouraging reuse. This requires a multifaceted approach involving consumer education, policy interventions, and industry collaboration. The development of biodegradable plastics that can replace LDPE in certain applications is also a key area of research and innovation.

Addressing the challenges in LDPE disposal also necessitates improvements in waste management infrastructure, particularly in developing countries where informal waste collection systems often lead to environmental pollution. Enhancing the global capacity for proper LDPE disposal and recycling is crucial for mitigating its environmental impact on a worldwide scale.

As we move forward, the objectives for LDPE disposal are becoming increasingly ambitious. These include achieving higher recycling rates, developing more efficient sorting technologies, and creating closed-loop systems where LDPE products can be continuously recycled without loss of quality. The ultimate aim is to transition towards a circular economy model for LDPE, where waste is minimized, and materials are kept in use for as long as possible.

Market Analysis for LDPE Recycling Solutions

The global market for LDPE recycling solutions is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. As one of the most widely used plastics, LDPE presents both challenges and opportunities in the recycling sector. The market demand for LDPE recycling solutions is primarily fueled by the packaging industry, which accounts for a substantial portion of LDPE consumption.

The packaging sector, including food packaging, consumer goods, and industrial applications, continues to be the largest consumer of LDPE. This sector's demand for recycled LDPE is growing as companies seek to improve their sustainability profiles and meet consumer expectations for eco-friendly packaging. Additionally, the construction industry is emerging as a significant market for recycled LDPE, particularly in applications such as geomembranes and insulation materials.

Geographically, developed regions such as North America and Europe are leading the LDPE recycling market due to stringent regulations and advanced recycling infrastructure. However, developing economies in Asia-Pacific and Latin America are showing rapid growth potential as they address mounting plastic waste issues and implement more robust recycling policies.

The market for LDPE recycling solutions is characterized by technological advancements aimed at improving the quality and efficiency of recycled LDPE. Innovations in sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven systems, are enhancing the purity of recycled LDPE streams. This improvement in quality is crucial for expanding the applications of recycled LDPE and increasing its market value.

Chemical recycling technologies are gaining traction in the LDPE recycling market, offering the potential to break down LDPE into its chemical components for use in new plastic production. This approach addresses the limitations of mechanical recycling, particularly for contaminated or mixed plastic waste streams.

The circular economy concept is driving collaborations across the value chain, from plastic producers to recyclers and end-users. These partnerships are fostering innovation in product design for recyclability and creating closed-loop systems for LDPE recycling. Such initiatives are expected to significantly boost the demand for LDPE recycling solutions in the coming years.

Market analysts project steady growth for the LDPE recycling solutions market, with increasing adoption of recycled content in various industries. However, challenges such as collection inefficiencies, contamination issues, and the need for substantial infrastructure investments remain significant factors influencing market dynamics. Addressing these challenges through technological innovation and policy support will be crucial for realizing the full potential of the LDPE recycling market.

The packaging sector, including food packaging, consumer goods, and industrial applications, continues to be the largest consumer of LDPE. This sector's demand for recycled LDPE is growing as companies seek to improve their sustainability profiles and meet consumer expectations for eco-friendly packaging. Additionally, the construction industry is emerging as a significant market for recycled LDPE, particularly in applications such as geomembranes and insulation materials.

Geographically, developed regions such as North America and Europe are leading the LDPE recycling market due to stringent regulations and advanced recycling infrastructure. However, developing economies in Asia-Pacific and Latin America are showing rapid growth potential as they address mounting plastic waste issues and implement more robust recycling policies.

The market for LDPE recycling solutions is characterized by technological advancements aimed at improving the quality and efficiency of recycled LDPE. Innovations in sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven systems, are enhancing the purity of recycled LDPE streams. This improvement in quality is crucial for expanding the applications of recycled LDPE and increasing its market value.

Chemical recycling technologies are gaining traction in the LDPE recycling market, offering the potential to break down LDPE into its chemical components for use in new plastic production. This approach addresses the limitations of mechanical recycling, particularly for contaminated or mixed plastic waste streams.

The circular economy concept is driving collaborations across the value chain, from plastic producers to recyclers and end-users. These partnerships are fostering innovation in product design for recyclability and creating closed-loop systems for LDPE recycling. Such initiatives are expected to significantly boost the demand for LDPE recycling solutions in the coming years.

Market analysts project steady growth for the LDPE recycling solutions market, with increasing adoption of recycled content in various industries. However, challenges such as collection inefficiencies, contamination issues, and the need for substantial infrastructure investments remain significant factors influencing market dynamics. Addressing these challenges through technological innovation and policy support will be crucial for realizing the full potential of the LDPE recycling market.

Current LDPE Disposal Challenges

Low-density polyethylene (LDPE) disposal presents significant challenges in today's waste management landscape. As a widely used plastic material, LDPE's persistence in the environment and its low recycling rates have become major concerns for municipalities, industries, and environmental organizations worldwide.

One of the primary challenges in LDPE disposal is its resistance to degradation. LDPE can take hundreds of years to decompose naturally, leading to long-term environmental pollution. This durability, while beneficial for many applications, becomes problematic when LDPE products reach the end of their lifecycle. The accumulation of LDPE waste in landfills and natural environments has resulted in severe ecological impacts, including harm to wildlife and marine ecosystems.

The recycling of LDPE poses another significant challenge. Despite being technically recyclable, LDPE often ends up in landfills or incinerators due to various factors. The collection and sorting of LDPE waste are complicated by contamination issues, as LDPE products are frequently mixed with other materials or contain food residues. This contamination reduces the quality of recycled LDPE and increases the cost of recycling processes, making it economically less viable for many recycling facilities.

Furthermore, the low market value of recycled LDPE compared to virgin material discourages widespread recycling efforts. The fluctuating oil prices, which directly affect the cost of producing new LDPE, often make recycled LDPE less competitive in the market. This economic challenge has led to a lack of investment in LDPE recycling infrastructure and technologies.

The diversity of LDPE products also complicates disposal and recycling efforts. LDPE is used in a wide range of applications, from packaging films to agricultural mulch, each with different additives and properties. This variety makes it difficult to implement standardized recycling processes, as different LDPE products may require different treatment methods.

Another challenge lies in consumer behavior and awareness. Many consumers are unaware of proper LDPE disposal methods or lack access to appropriate recycling facilities. This knowledge gap leads to improper disposal, with LDPE often ending up in general waste streams or, worse, as litter in the environment.

The regulatory landscape surrounding LDPE disposal varies significantly across regions, creating inconsistencies in management approaches. While some countries have implemented strict regulations on plastic waste, others lag behind, leading to disparities in LDPE disposal practices globally. This lack of uniformity hampers the development of comprehensive, large-scale solutions to LDPE waste management.

Addressing these challenges requires a multifaceted approach involving technological innovation, policy reform, and public education. Developing more efficient recycling technologies, improving waste collection systems, and creating stronger markets for recycled LDPE are crucial steps. Additionally, promoting alternatives to LDPE and encouraging the design of more easily recyclable LDPE products are essential for long-term sustainability in plastic waste management.

One of the primary challenges in LDPE disposal is its resistance to degradation. LDPE can take hundreds of years to decompose naturally, leading to long-term environmental pollution. This durability, while beneficial for many applications, becomes problematic when LDPE products reach the end of their lifecycle. The accumulation of LDPE waste in landfills and natural environments has resulted in severe ecological impacts, including harm to wildlife and marine ecosystems.

The recycling of LDPE poses another significant challenge. Despite being technically recyclable, LDPE often ends up in landfills or incinerators due to various factors. The collection and sorting of LDPE waste are complicated by contamination issues, as LDPE products are frequently mixed with other materials or contain food residues. This contamination reduces the quality of recycled LDPE and increases the cost of recycling processes, making it economically less viable for many recycling facilities.

Furthermore, the low market value of recycled LDPE compared to virgin material discourages widespread recycling efforts. The fluctuating oil prices, which directly affect the cost of producing new LDPE, often make recycled LDPE less competitive in the market. This economic challenge has led to a lack of investment in LDPE recycling infrastructure and technologies.

The diversity of LDPE products also complicates disposal and recycling efforts. LDPE is used in a wide range of applications, from packaging films to agricultural mulch, each with different additives and properties. This variety makes it difficult to implement standardized recycling processes, as different LDPE products may require different treatment methods.

Another challenge lies in consumer behavior and awareness. Many consumers are unaware of proper LDPE disposal methods or lack access to appropriate recycling facilities. This knowledge gap leads to improper disposal, with LDPE often ending up in general waste streams or, worse, as litter in the environment.

The regulatory landscape surrounding LDPE disposal varies significantly across regions, creating inconsistencies in management approaches. While some countries have implemented strict regulations on plastic waste, others lag behind, leading to disparities in LDPE disposal practices globally. This lack of uniformity hampers the development of comprehensive, large-scale solutions to LDPE waste management.

Addressing these challenges requires a multifaceted approach involving technological innovation, policy reform, and public education. Developing more efficient recycling technologies, improving waste collection systems, and creating stronger markets for recycled LDPE are crucial steps. Additionally, promoting alternatives to LDPE and encouraging the design of more easily recyclable LDPE products are essential for long-term sustainability in plastic waste management.

Existing LDPE Disposal Technologies

01 Recycling and reprocessing of LDPE

LDPE can be recycled and reprocessed into new products. This involves collecting, sorting, cleaning, and melting the plastic before reforming it into new items. The process helps reduce waste and conserve resources by giving the material a second life.- Recycling and reprocessing of LDPE: LDPE can be recycled and reprocessed into new products. This involves collecting, sorting, cleaning, and melting the plastic before reforming it into new items. The process helps reduce waste and conserve resources by giving the material a second life.

- Chemical decomposition of LDPE: Chemical methods can be used to break down LDPE into its constituent molecules or other useful chemicals. This process, known as depolymerization, can involve the use of catalysts or solvents to convert the plastic into valuable raw materials for new products.

- Thermal treatment of LDPE waste: LDPE can be disposed of through thermal treatments such as incineration or pyrolysis. These processes involve heating the plastic to high temperatures, either with or without oxygen, to break it down into simpler compounds or energy. This can reduce waste volume and potentially recover energy.

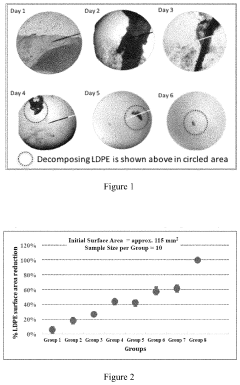

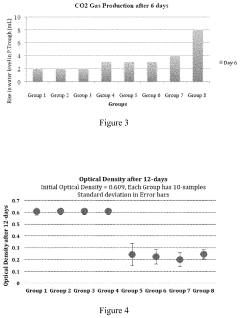

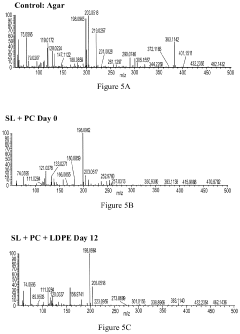

- Biodegradation of LDPE: Research is ongoing into methods to enhance the biodegradability of LDPE. This includes the development of additives or treatments that can make the plastic more susceptible to breakdown by microorganisms in the environment, potentially reducing its long-term environmental impact.

- Upcycling and repurposing of LDPE products: Instead of traditional disposal, LDPE products can be upcycled or repurposed. This involves creatively transforming waste LDPE items into new products with higher value or different applications, extending their useful life and reducing waste.

02 Chemical decomposition of LDPE

Chemical methods can be used to break down LDPE into its constituent molecules or other useful chemicals. This process, known as depolymerization, can involve the use of catalysts or other reactive substances to convert the plastic into valuable raw materials for new products.Expand Specific Solutions03 Biodegradation of LDPE

Research is ongoing into methods to enhance the biodegradability of LDPE. This includes the development of additives or treatments that can make the plastic more susceptible to breakdown by microorganisms in the environment, potentially reducing its long-term environmental impact.Expand Specific Solutions04 Energy recovery from LDPE waste

LDPE that cannot be recycled or reprocessed can be used for energy recovery through incineration. This process involves burning the plastic waste in controlled conditions to generate heat or electricity, while ensuring proper emission control measures are in place.Expand Specific Solutions05 Upcycling LDPE into value-added products

Innovative approaches are being developed to transform LDPE waste into higher-value products. This can include using the material in composite materials, construction applications, or as a feedstock for producing other chemicals, thereby finding new uses for the plastic waste.Expand Specific Solutions

Key Players in LDPE Recycling Industry

The LDPE disposal market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for plastic waste management is expanding, with a projected CAGR of 3.5% from 2021 to 2028. Technologically, LDPE disposal solutions are evolving, with companies like Dow Global Technologies LLC and SABIC Global Technologies BV leading innovation in recycling processes. China Petroleum & Chemical Corp. and PetroChina Co., Ltd. are investing in advanced chemical recycling technologies, while Equistar Chemicals LP and ExxonMobil Chemical Patents, Inc. focus on improving mechanical recycling methods. Collaboration between industry leaders and research institutions like Zhejiang University and Qingdao University is accelerating the development of more efficient and sustainable LDPE disposal techniques.

Dow Global Technologies LLC

Technical Solution: Dow has developed a breakthrough recycling technology called REVOLOOP™ for LDPE disposal. This process involves mechanical recycling combined with advanced sorting and cleaning techniques. The technology can recycle post-consumer plastic waste into high-quality recycled plastics suitable for various applications, including food packaging[1]. Dow's approach focuses on creating a circular economy for plastics by transforming waste into valuable resources. The company has also invested in chemical recycling technologies that can break down LDPE into its molecular components, allowing for the creation of new plastic products with virgin-like quality[2].

Strengths: Advanced recycling technology, circular economy approach, high-quality output. Weaknesses: Potential high implementation costs, reliance on efficient waste collection systems.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed an advanced recycling process called Exxtend™ technology for plastic waste, including LDPE. This technology uses a proprietary catalyst system to break down plastic waste into molecular building blocks. These can then be used to create new plastic products with the same performance as those made from virgin materials[3]. The process can handle mixed plastic waste streams, addressing the challenge of sorting different types of plastics. ExxonMobil has also invested in mechanical recycling facilities to complement its chemical recycling efforts, aiming to recycle up to 500,000 metric tons of plastic waste annually by 2026[4].

Strengths: Versatile technology handling mixed plastics, high-quality output comparable to virgin materials. Weaknesses: Energy-intensive process, potential high capital investment required.

Innovative LDPE Recycling Methods

Method and apparatus for the recycling of low-density polyethylene (LDPE)

PatentWO2022218765A1

Innovation

- A method involving selective dissolution of LDPE in an organic solvent at a temperature where HDPE and PP do not dissolve, followed by ultrafiltration or nanofiltration to concentrate LDPE, allowing for its efficient recovery through evaporation, eliminating the need for additional separation steps and reducing energy consumption.

Methods for degrading low density polyethylene (LDPE) and remediating leachate

PatentActiveUS20200406320A1

Innovation

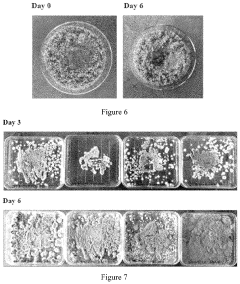

- Contacting pretreated LDPE with white-rot fungi, such as Phanerochaete chrysosporium, at elevated temperatures and potentially etching the LDPE, within the activated sludge infrastructure of landfills to achieve near 100% degradation and leachate remediation without toxic byproducts.

Environmental Impact Assessment

The environmental impact of LDPE disposal is a critical concern that requires comprehensive assessment. LDPE, or Low-Density Polyethylene, is widely used in packaging and consumer products, contributing significantly to plastic waste. When improperly disposed of, LDPE can persist in the environment for hundreds of years, causing long-term ecological damage.

In terrestrial ecosystems, LDPE waste can lead to soil degradation and reduced fertility. As it breaks down into smaller particles, it can interfere with soil structure, water retention, and nutrient cycling. This microplastic contamination affects plant growth and soil-dwelling organisms, potentially disrupting entire food chains.

Aquatic environments are particularly vulnerable to LDPE pollution. Rivers and oceans become repositories for plastic waste, where LDPE can fragment into microplastics. These tiny particles are ingested by marine life, leading to malnutrition, internal injuries, and bioaccumulation of toxins throughout the food web. The presence of LDPE in water bodies also alters habitat structures and can transport invasive species across ecosystems.

The atmospheric impact of LDPE disposal is often overlooked but significant. Improper incineration of LDPE releases harmful chemicals and greenhouse gases, contributing to air pollution and climate change. Even in landfills, LDPE degradation can result in the emission of methane, a potent greenhouse gas.

Wildlife is severely affected by LDPE waste. Animals can become entangled in larger pieces of plastic or mistake smaller fragments for food. Ingestion of LDPE can lead to blockages in digestive systems, malnutrition, and the transfer of toxic chemicals up the food chain, ultimately affecting human health through consumption of contaminated seafood.

The aesthetic impact of LDPE litter in natural and urban environments should not be underestimated. It diminishes the visual quality of landscapes, potentially affecting tourism and recreational activities. This visual pollution can also have psychological effects on human well-being and connection to nature.

Addressing the environmental impact of LDPE disposal requires a multifaceted approach. Improved waste management systems, increased recycling efforts, and the development of biodegradable alternatives are crucial steps. Public education on proper disposal methods and the consequences of plastic pollution is essential for behavioral change. Additionally, policy measures such as extended producer responsibility and plastic bag bans can help mitigate the environmental burden of LDPE waste.

In terrestrial ecosystems, LDPE waste can lead to soil degradation and reduced fertility. As it breaks down into smaller particles, it can interfere with soil structure, water retention, and nutrient cycling. This microplastic contamination affects plant growth and soil-dwelling organisms, potentially disrupting entire food chains.

Aquatic environments are particularly vulnerable to LDPE pollution. Rivers and oceans become repositories for plastic waste, where LDPE can fragment into microplastics. These tiny particles are ingested by marine life, leading to malnutrition, internal injuries, and bioaccumulation of toxins throughout the food web. The presence of LDPE in water bodies also alters habitat structures and can transport invasive species across ecosystems.

The atmospheric impact of LDPE disposal is often overlooked but significant. Improper incineration of LDPE releases harmful chemicals and greenhouse gases, contributing to air pollution and climate change. Even in landfills, LDPE degradation can result in the emission of methane, a potent greenhouse gas.

Wildlife is severely affected by LDPE waste. Animals can become entangled in larger pieces of plastic or mistake smaller fragments for food. Ingestion of LDPE can lead to blockages in digestive systems, malnutrition, and the transfer of toxic chemicals up the food chain, ultimately affecting human health through consumption of contaminated seafood.

The aesthetic impact of LDPE litter in natural and urban environments should not be underestimated. It diminishes the visual quality of landscapes, potentially affecting tourism and recreational activities. This visual pollution can also have psychological effects on human well-being and connection to nature.

Addressing the environmental impact of LDPE disposal requires a multifaceted approach. Improved waste management systems, increased recycling efforts, and the development of biodegradable alternatives are crucial steps. Public education on proper disposal methods and the consequences of plastic pollution is essential for behavioral change. Additionally, policy measures such as extended producer responsibility and plastic bag bans can help mitigate the environmental burden of LDPE waste.

Regulatory Framework for Plastic Waste Management

The regulatory framework for plastic waste management plays a crucial role in addressing the challenges associated with LDPE disposal. Governments worldwide have implemented various policies and regulations to mitigate the environmental impact of plastic waste, including LDPE. These regulations typically encompass the entire lifecycle of plastic products, from production to disposal.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste. This amendment aims to reduce the export of plastic waste to countries with limited capacity for environmentally sound management.

Many countries have introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their plastic products. These schemes incentivize producers to design more sustainable products and improve recycling infrastructure. For instance, the European Union's Packaging and Packaging Waste Directive sets targets for recycling and recovery of packaging materials, including LDPE.

Plastic bag bans and taxes have been implemented in numerous jurisdictions to reduce the consumption of single-use plastics. These measures have shown varying degrees of success in reducing plastic waste and encouraging the use of reusable alternatives. Some countries have also introduced regulations on the thickness of plastic bags, promoting the use of more durable and recyclable options.

Recycling regulations play a significant role in LDPE waste management. Many countries have established recycling targets and implemented sorting requirements to improve the quality and quantity of recycled plastics. For example, China's National Sword policy, which banned the import of certain types of plastic waste, has led to increased domestic recycling efforts and stricter quality standards for recyclable materials.

Landfill regulations have also evolved to address plastic waste challenges. Some countries have implemented landfill taxes or bans on certain types of plastic waste to encourage recycling and alternative disposal methods. Additionally, regulations on waste-to-energy facilities have been developed to ensure the safe and efficient conversion of non-recyclable plastics into energy.

Emerging regulations are focusing on promoting a circular economy for plastics. The European Union's Circular Economy Action Plan, for instance, includes measures to increase the recyclability of plastics and boost the market for recycled plastics. This includes setting targets for recycled content in new products and improving the design of plastic items for easier recycling.

As the challenges of LDPE disposal continue to evolve, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on innovative approaches such as chemical recycling, biodegradable plastics, and alternative materials to further address the environmental impact of plastic waste.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste. This amendment aims to reduce the export of plastic waste to countries with limited capacity for environmentally sound management.

Many countries have introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their plastic products. These schemes incentivize producers to design more sustainable products and improve recycling infrastructure. For instance, the European Union's Packaging and Packaging Waste Directive sets targets for recycling and recovery of packaging materials, including LDPE.

Plastic bag bans and taxes have been implemented in numerous jurisdictions to reduce the consumption of single-use plastics. These measures have shown varying degrees of success in reducing plastic waste and encouraging the use of reusable alternatives. Some countries have also introduced regulations on the thickness of plastic bags, promoting the use of more durable and recyclable options.

Recycling regulations play a significant role in LDPE waste management. Many countries have established recycling targets and implemented sorting requirements to improve the quality and quantity of recycled plastics. For example, China's National Sword policy, which banned the import of certain types of plastic waste, has led to increased domestic recycling efforts and stricter quality standards for recyclable materials.

Landfill regulations have also evolved to address plastic waste challenges. Some countries have implemented landfill taxes or bans on certain types of plastic waste to encourage recycling and alternative disposal methods. Additionally, regulations on waste-to-energy facilities have been developed to ensure the safe and efficient conversion of non-recyclable plastics into energy.

Emerging regulations are focusing on promoting a circular economy for plastics. The European Union's Circular Economy Action Plan, for instance, includes measures to increase the recyclability of plastics and boost the market for recycled plastics. This includes setting targets for recycled content in new products and improving the design of plastic items for easier recycling.

As the challenges of LDPE disposal continue to evolve, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on innovative approaches such as chemical recycling, biodegradable plastics, and alternative materials to further address the environmental impact of plastic waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!