How to Adjust K24 Engine Timing for Optimal Results?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Timing Background and Objectives

The K24 engine, developed by Honda, has been a cornerstone in the automotive industry since its introduction in the early 2000s. This 2.4-liter inline-four engine has gained popularity due to its reliability, performance potential, and versatility across various Honda and Acura models. The evolution of the K24 engine has seen several iterations, each improving upon its predecessor in terms of power output, fuel efficiency, and emissions compliance.

Engine timing, a critical aspect of internal combustion engine operation, plays a pivotal role in the K24's performance. Proper timing ensures optimal combustion, maximizing power output while maintaining fuel efficiency and minimizing emissions. As automotive technology has advanced, so too have the methods and precision of engine timing adjustment, moving from purely mechanical systems to more sophisticated electronic controls.

The primary objective in adjusting K24 engine timing is to achieve a balance between performance, efficiency, and longevity. This involves precise coordination of the engine's valvetrain with the piston's movement, ensuring that the intake and exhaust valves open and close at the ideal moments during the combustion cycle. Optimal timing can lead to increased horsepower, improved torque delivery, better fuel economy, and reduced emissions.

Recent technological advancements have introduced variable valve timing systems, such as Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control), which allows for dynamic adjustment of valve timing based on engine speed and load. This innovation has expanded the potential for timing optimization across a broader range of operating conditions, further enhancing the K24's versatility and performance envelope.

The pursuit of optimal K24 engine timing faces several challenges, including the need for precision in adjustment, the complexity of modern engine management systems, and the variability of operating conditions. Additionally, as emissions regulations become increasingly stringent, timing adjustments must be made with consideration for their impact on exhaust emissions and overall engine efficiency.

Looking forward, the goals for K24 engine timing optimization include further refinement of variable timing systems, integration with advanced engine management technologies, and exploration of timing strategies that can adapt to alternative fuels or hybrid powertrains. These objectives align with the broader automotive industry trends towards increased efficiency, reduced environmental impact, and enhanced performance across diverse driving scenarios.

Engine timing, a critical aspect of internal combustion engine operation, plays a pivotal role in the K24's performance. Proper timing ensures optimal combustion, maximizing power output while maintaining fuel efficiency and minimizing emissions. As automotive technology has advanced, so too have the methods and precision of engine timing adjustment, moving from purely mechanical systems to more sophisticated electronic controls.

The primary objective in adjusting K24 engine timing is to achieve a balance between performance, efficiency, and longevity. This involves precise coordination of the engine's valvetrain with the piston's movement, ensuring that the intake and exhaust valves open and close at the ideal moments during the combustion cycle. Optimal timing can lead to increased horsepower, improved torque delivery, better fuel economy, and reduced emissions.

Recent technological advancements have introduced variable valve timing systems, such as Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control), which allows for dynamic adjustment of valve timing based on engine speed and load. This innovation has expanded the potential for timing optimization across a broader range of operating conditions, further enhancing the K24's versatility and performance envelope.

The pursuit of optimal K24 engine timing faces several challenges, including the need for precision in adjustment, the complexity of modern engine management systems, and the variability of operating conditions. Additionally, as emissions regulations become increasingly stringent, timing adjustments must be made with consideration for their impact on exhaust emissions and overall engine efficiency.

Looking forward, the goals for K24 engine timing optimization include further refinement of variable timing systems, integration with advanced engine management technologies, and exploration of timing strategies that can adapt to alternative fuels or hybrid powertrains. These objectives align with the broader automotive industry trends towards increased efficiency, reduced environmental impact, and enhanced performance across diverse driving scenarios.

Market Demand for K24 Engine Performance

The market demand for K24 engine performance has been steadily growing over the past decade, driven by enthusiasts and performance-oriented consumers seeking to maximize the potential of their vehicles. This demand is particularly strong in the aftermarket sector, where owners of Honda and Acura models equipped with K24 engines are looking for ways to enhance power output, fuel efficiency, and overall engine responsiveness.

The K24 engine, known for its reliability and tuning potential, has become a popular choice for engine swaps and performance builds. This has created a significant market for aftermarket parts and services specifically tailored to K24 engine timing adjustments. Performance shops and tuning companies have reported an increase in requests for K24 engine timing optimization services, indicating a growing awareness among consumers about the benefits of proper engine timing.

In the racing and motorsport community, the demand for K24 engine performance enhancements is even more pronounced. Competitive drivers and teams are constantly seeking ways to extract maximum power and efficiency from their engines, with timing adjustments being a crucial aspect of their tuning strategies. This has led to the development of specialized timing components and advanced tuning software designed specifically for K24 engines.

The automotive industry's shift towards more fuel-efficient and environmentally friendly vehicles has also contributed to the demand for K24 engine performance optimization. Many consumers are looking for ways to improve their vehicle's fuel economy without sacrificing performance, and proper engine timing adjustment is seen as a cost-effective method to achieve this balance.

Online automotive forums and social media platforms have played a significant role in driving market demand for K24 engine performance. Enthusiasts share their experiences, tips, and results from timing adjustments, creating a community-driven knowledge base that encourages others to explore similar modifications. This peer-to-peer influence has been instrumental in expanding the market beyond traditional performance-oriented consumers.

The aftermarket parts industry has responded to this demand by developing a wide range of products designed to facilitate K24 engine timing adjustments. These include adjustable cam gears, high-performance timing chains, and advanced engine management systems that allow for precise timing control. The availability of these products has made it easier for both professional mechanics and DIY enthusiasts to optimize their K24 engine timing.

As vehicle manufacturers continue to phase out naturally aspirated engines in favor of turbocharged alternatives, the K24 engine has gained a nostalgic appeal among enthusiasts. This has further fueled the demand for performance enhancements, including timing adjustments, as owners seek to preserve and improve upon the unique characteristics of this beloved engine platform.

The K24 engine, known for its reliability and tuning potential, has become a popular choice for engine swaps and performance builds. This has created a significant market for aftermarket parts and services specifically tailored to K24 engine timing adjustments. Performance shops and tuning companies have reported an increase in requests for K24 engine timing optimization services, indicating a growing awareness among consumers about the benefits of proper engine timing.

In the racing and motorsport community, the demand for K24 engine performance enhancements is even more pronounced. Competitive drivers and teams are constantly seeking ways to extract maximum power and efficiency from their engines, with timing adjustments being a crucial aspect of their tuning strategies. This has led to the development of specialized timing components and advanced tuning software designed specifically for K24 engines.

The automotive industry's shift towards more fuel-efficient and environmentally friendly vehicles has also contributed to the demand for K24 engine performance optimization. Many consumers are looking for ways to improve their vehicle's fuel economy without sacrificing performance, and proper engine timing adjustment is seen as a cost-effective method to achieve this balance.

Online automotive forums and social media platforms have played a significant role in driving market demand for K24 engine performance. Enthusiasts share their experiences, tips, and results from timing adjustments, creating a community-driven knowledge base that encourages others to explore similar modifications. This peer-to-peer influence has been instrumental in expanding the market beyond traditional performance-oriented consumers.

The aftermarket parts industry has responded to this demand by developing a wide range of products designed to facilitate K24 engine timing adjustments. These include adjustable cam gears, high-performance timing chains, and advanced engine management systems that allow for precise timing control. The availability of these products has made it easier for both professional mechanics and DIY enthusiasts to optimize their K24 engine timing.

As vehicle manufacturers continue to phase out naturally aspirated engines in favor of turbocharged alternatives, the K24 engine has gained a nostalgic appeal among enthusiasts. This has further fueled the demand for performance enhancements, including timing adjustments, as owners seek to preserve and improve upon the unique characteristics of this beloved engine platform.

Current Challenges in K24 Engine Timing Adjustment

Adjusting the timing of the K24 engine presents several significant challenges that technicians and enthusiasts must navigate to achieve optimal performance. One of the primary difficulties lies in the precision required for accurate timing adjustments. The K24 engine, known for its high-revving capabilities and robust power output, demands exacting specifications to maintain its performance characteristics.

The complexity of the K24's variable valve timing (VTC) system adds another layer of difficulty to the timing adjustment process. This system, while providing improved engine efficiency and power across a broad RPM range, introduces additional variables that must be carefully considered during timing adjustments. Technicians must ensure that the VTC system is functioning correctly and that its operation is synchronized with the overall engine timing.

Another challenge is the potential for timing chain stretch over time, which can lead to timing inaccuracies. As the engine ages, the timing chain may elongate, causing a gradual shift in timing that can be difficult to detect without specialized tools. This subtle change can result in decreased performance and potentially lead to engine damage if left uncorrected.

The interdependence of various engine systems also complicates the timing adjustment process. Changes to the engine timing can affect fuel injection, ignition timing, and emissions control systems. Technicians must consider these relationships and make holistic adjustments to maintain optimal engine performance while adhering to emissions regulations.

Access to the timing components presents another challenge, particularly in cramped engine bays. The K24 engine's compact design can make it difficult to reach and manipulate timing-related parts without specialized tools or partial engine disassembly. This can increase the time and complexity of timing adjustments, especially for those without extensive experience with this specific engine.

Furthermore, the availability of accurate timing marks and reference points on the K24 engine can be limited, making precise adjustments challenging. Technicians often need to rely on advanced diagnostic equipment and timing lights to ensure accuracy, which may not be readily available to all who attempt these adjustments.

Lastly, the potential for catastrophic engine damage due to incorrect timing adjustments poses a significant risk. Even small errors in timing can lead to valve-to-piston contact, resulting in severe engine damage. This risk factor necessitates extreme caution and expertise when performing timing adjustments on the K24 engine, creating a barrier for less experienced individuals attempting to optimize their engine's performance.

The complexity of the K24's variable valve timing (VTC) system adds another layer of difficulty to the timing adjustment process. This system, while providing improved engine efficiency and power across a broad RPM range, introduces additional variables that must be carefully considered during timing adjustments. Technicians must ensure that the VTC system is functioning correctly and that its operation is synchronized with the overall engine timing.

Another challenge is the potential for timing chain stretch over time, which can lead to timing inaccuracies. As the engine ages, the timing chain may elongate, causing a gradual shift in timing that can be difficult to detect without specialized tools. This subtle change can result in decreased performance and potentially lead to engine damage if left uncorrected.

The interdependence of various engine systems also complicates the timing adjustment process. Changes to the engine timing can affect fuel injection, ignition timing, and emissions control systems. Technicians must consider these relationships and make holistic adjustments to maintain optimal engine performance while adhering to emissions regulations.

Access to the timing components presents another challenge, particularly in cramped engine bays. The K24 engine's compact design can make it difficult to reach and manipulate timing-related parts without specialized tools or partial engine disassembly. This can increase the time and complexity of timing adjustments, especially for those without extensive experience with this specific engine.

Furthermore, the availability of accurate timing marks and reference points on the K24 engine can be limited, making precise adjustments challenging. Technicians often need to rely on advanced diagnostic equipment and timing lights to ensure accuracy, which may not be readily available to all who attempt these adjustments.

Lastly, the potential for catastrophic engine damage due to incorrect timing adjustments poses a significant risk. Even small errors in timing can lead to valve-to-piston contact, resulting in severe engine damage. This risk factor necessitates extreme caution and expertise when performing timing adjustments on the K24 engine, creating a barrier for less experienced individuals attempting to optimize their engine's performance.

Existing K24 Timing Adjustment Methods

01 Variable valve timing systems for K24 engines

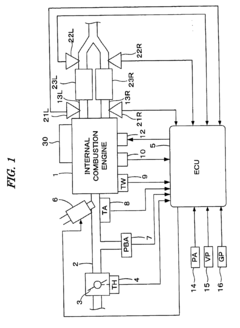

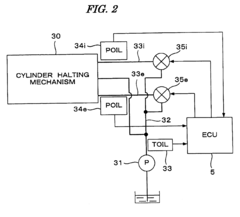

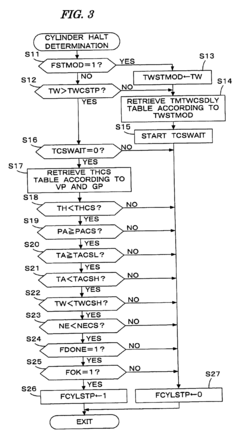

K24 engines often employ variable valve timing systems to optimize engine performance across different operating conditions. These systems can adjust the timing of valve opening and closing, improving fuel efficiency, power output, and emissions control. Advanced electronic control units manage the timing based on various engine parameters.- Variable valve timing systems for K24 engines: K24 engines often employ variable valve timing systems to optimize engine performance across different operating conditions. These systems can adjust the timing of valve opening and closing, improving fuel efficiency, power output, and emissions control. Advanced electronic control units manage the timing based on various engine parameters.

- Camshaft phasing mechanisms: Camshaft phasing mechanisms are crucial components in K24 engine timing systems. These mechanisms allow for the adjustment of camshaft rotation relative to the crankshaft, enabling variable valve timing. Hydraulic or electric actuators are commonly used to control the phasing, providing precise timing adjustments for improved engine performance.

- Timing chain and belt systems: K24 engines utilize timing chains or belts to synchronize the rotation of the crankshaft and camshafts. These systems ensure proper valve timing and piston movement. Timing chains are often preferred for their durability and longevity, while timing belts may offer quieter operation. Regular maintenance and replacement of these components are crucial for optimal engine performance.

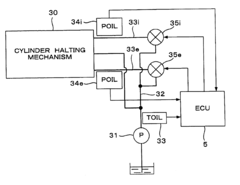

- Electronic timing control and sensors: Advanced electronic control systems and sensors play a vital role in K24 engine timing. These systems monitor various engine parameters such as crankshaft position, camshaft position, and engine load to precisely control valve timing. Sensors provide real-time data to the engine control unit, allowing for dynamic adjustments to optimize performance and efficiency.

- Timing adjustment mechanisms for performance tuning: K24 engines often incorporate timing adjustment mechanisms that allow for performance tuning. These mechanisms can include adjustable cam gears, variable valve lift systems, and programmable engine control units. By fine-tuning the engine timing, enthusiasts and tuners can optimize power output, torque delivery, and overall engine characteristics to suit specific performance goals.

02 Camshaft phasing mechanisms

Camshaft phasing mechanisms are crucial components in K24 engine timing systems. These mechanisms allow for the adjustment of camshaft rotation relative to the crankshaft, enabling variable valve timing. Hydraulic or electric actuators are commonly used to control the phasing, providing precise timing adjustments for improved engine performance.Expand Specific Solutions03 Timing chain and belt systems

K24 engines typically use timing chains or belts to synchronize the rotation of the crankshaft and camshafts. These systems ensure proper valve timing and piston movement. Timing chains are often preferred for their durability and longevity, while timing belts may offer quieter operation. Regular maintenance and replacement intervals are crucial for optimal engine performance.Expand Specific Solutions04 Engine control unit (ECU) timing management

The engine control unit plays a vital role in managing K24 engine timing. It processes data from various sensors to determine optimal valve timing and ignition timing. The ECU can make real-time adjustments to accommodate changes in engine load, speed, and environmental conditions, ensuring efficient combustion and power delivery across different operating scenarios.Expand Specific Solutions05 Timing sensor and feedback systems

K24 engines incorporate various sensors to monitor and control engine timing. These may include crankshaft position sensors, camshaft position sensors, and knock sensors. The feedback from these sensors allows the engine control unit to make precise timing adjustments, ensuring optimal engine performance, fuel efficiency, and emissions control under varying operating conditions.Expand Specific Solutions

Key Players in K24 Engine Aftermarket

The K24 engine timing adjustment market is in a mature phase, with established players dominating the landscape. The global automotive engine market, which includes K24 engines, is projected to reach $86 billion by 2025. Major automakers like Toyota, Honda, and Nissan have significant market share and technological expertise in engine timing systems. Aftermarket companies such as MSD LLC also play a role in providing performance-oriented timing solutions. The technology is well-developed, with companies like DENSO Corp. and Aisin KK supplying advanced engine management systems. However, ongoing research at institutions like Jilin University and Northwestern Polytechnical University suggests potential for further optimization and efficiency gains in engine timing technology.

Toyota Motor Corp.

Technical Solution: Toyota's approach to optimizing K24 engine timing involves their VVT-i (Variable Valve Timing with intelligence) system. This technology allows for continuous adjustment of the intake valve timing relative to crankshaft position, optimizing engine performance across various operating conditions[1]. Toyota has also implemented Dual VVT-i in some variants, which controls both intake and exhaust valve timing[2]. The company's engine control unit (ECU) uses advanced algorithms to analyze multiple parameters such as engine load, speed, and temperature to determine the optimal valve timing[3]. Toyota has further enhanced this system with the addition of VVT-iE, which uses an electric motor to control the intake camshaft, allowing for more precise and responsive timing adjustments, especially at low engine speeds and cold starts[4].

Strengths: Improved fuel efficiency and emissions control. Enhanced low-end torque and high-end power. Weaknesses: Increased system complexity may result in higher production costs. Potential for oil-related issues if maintenance is neglected.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced Variable Valve Timing and Lift Electronic Control (VTEC) system for the K24 engine. This system optimizes valve timing and lift across different engine speeds, improving both performance and fuel efficiency. Honda's approach involves using two cam profiles - one for low RPM and another for high RPM - with a hydraulic system to switch between them[1]. The company has also implemented i-VTEC (intelligent VTEC) which combines VTEC with Variable Timing Control (VTC) to continuously adjust intake camshaft phase, further enhancing engine performance across a broader RPM range[2]. Additionally, Honda has integrated a drive-by-wire throttle system to fine-tune air intake based on engine timing adjustments[3].

Strengths: Improved power output and fuel efficiency across a wide RPM range. Smooth transition between low and high-speed cam profiles. Weaknesses: Complexity of the system may lead to higher maintenance costs. Potential for increased oil consumption in some cases.

Innovative K24 Timing Solutions Analysis

Control system for internal combustion engine

PatentInactiveUS6830027B1

Innovation

- A control system that includes operating parameter detection, switching means, an oxygen concentration sensor, diagnosing means, and permitting means, which performs failure diagnosis during all-cylinder operation and permits partial-cylinder operation only after completing the diagnosis, ensuring accurate diagnosis of the oxygen concentration sensor.

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Environmental Impact of Engine Tuning

Engine tuning, while primarily focused on performance enhancement, has significant environmental implications that cannot be overlooked. The adjustment of engine timing, particularly in the K24 engine, can have both positive and negative effects on the environment. When optimizing engine timing for performance, there is often a trade-off between power output and emissions.

Properly adjusted engine timing can lead to more efficient fuel combustion, potentially reducing overall fuel consumption and, consequently, lowering carbon dioxide emissions. This is particularly relevant for the K24 engine, known for its balance of performance and efficiency. However, aggressive timing adjustments aimed at maximizing power output may result in increased nitrogen oxide (NOx) emissions, a major contributor to air pollution and smog formation.

The environmental impact of engine tuning extends beyond emissions. Improved engine efficiency can lead to reduced wear on engine components, potentially extending the lifespan of the vehicle and decreasing the demand for replacement parts. This, in turn, can reduce the environmental footprint associated with manufacturing and disposing of automotive components.

However, it's crucial to consider the broader implications of performance-oriented engine tuning. Increased power output often encourages more aggressive driving behaviors, which can negate any potential fuel efficiency gains and lead to higher overall emissions. Additionally, the pursuit of higher performance may lead to the use of higher-octane fuels, which typically have a greater environmental impact in terms of production and refining processes.

The K24 engine's versatility allows for a range of tuning options, each with its own environmental considerations. Mild tuning focused on optimizing efficiency can yield positive environmental outcomes, while extreme performance tuning may have detrimental effects. It's essential for tuners and vehicle owners to strike a balance between performance goals and environmental responsibility.

Regulatory bodies worldwide are increasingly scrutinizing vehicle emissions and fuel efficiency. Engine tuning practices must evolve to meet these stringent standards while still satisfying performance demands. This has led to the development of more sophisticated engine management systems and tuning techniques that aim to optimize both performance and environmental impact simultaneously.

In conclusion, the environmental impact of engine tuning, particularly for the K24 engine, is a complex issue that requires careful consideration. While there are potential benefits in terms of efficiency and reduced emissions, these must be weighed against the risks of increased pollutants and the broader implications of performance-oriented modifications. As environmental concerns continue to shape the automotive industry, the future of engine tuning will likely see an increased focus on balancing performance enhancements with ecological responsibility.

Properly adjusted engine timing can lead to more efficient fuel combustion, potentially reducing overall fuel consumption and, consequently, lowering carbon dioxide emissions. This is particularly relevant for the K24 engine, known for its balance of performance and efficiency. However, aggressive timing adjustments aimed at maximizing power output may result in increased nitrogen oxide (NOx) emissions, a major contributor to air pollution and smog formation.

The environmental impact of engine tuning extends beyond emissions. Improved engine efficiency can lead to reduced wear on engine components, potentially extending the lifespan of the vehicle and decreasing the demand for replacement parts. This, in turn, can reduce the environmental footprint associated with manufacturing and disposing of automotive components.

However, it's crucial to consider the broader implications of performance-oriented engine tuning. Increased power output often encourages more aggressive driving behaviors, which can negate any potential fuel efficiency gains and lead to higher overall emissions. Additionally, the pursuit of higher performance may lead to the use of higher-octane fuels, which typically have a greater environmental impact in terms of production and refining processes.

The K24 engine's versatility allows for a range of tuning options, each with its own environmental considerations. Mild tuning focused on optimizing efficiency can yield positive environmental outcomes, while extreme performance tuning may have detrimental effects. It's essential for tuners and vehicle owners to strike a balance between performance goals and environmental responsibility.

Regulatory bodies worldwide are increasingly scrutinizing vehicle emissions and fuel efficiency. Engine tuning practices must evolve to meet these stringent standards while still satisfying performance demands. This has led to the development of more sophisticated engine management systems and tuning techniques that aim to optimize both performance and environmental impact simultaneously.

In conclusion, the environmental impact of engine tuning, particularly for the K24 engine, is a complex issue that requires careful consideration. While there are potential benefits in terms of efficiency and reduced emissions, these must be weighed against the risks of increased pollutants and the broader implications of performance-oriented modifications. As environmental concerns continue to shape the automotive industry, the future of engine tuning will likely see an increased focus on balancing performance enhancements with ecological responsibility.

Safety Considerations in Engine Modification

When adjusting the K24 engine timing for optimal results, safety considerations in engine modification are paramount. The process involves working with high-precision components and potentially dangerous mechanical systems, necessitating a comprehensive approach to safety.

Firstly, proper protective equipment is essential. This includes safety glasses to protect against debris or fluids, gloves to guard against hot surfaces and sharp edges, and appropriate clothing to prevent entanglement in moving parts. A well-ventilated workspace is crucial to mitigate the risk of inhaling harmful fumes or gases.

Before beginning any modifications, it's imperative to ensure the engine is cool and disconnected from the power source. This prevents accidental starts and reduces the risk of burns. All tools should be in good condition and appropriate for the task to avoid slippage or damage to components.

Understanding the engine's specific timing requirements is critical. Incorrect timing can lead to severe engine damage, reduced performance, or even catastrophic failure. Consulting the manufacturer's specifications and using precise timing tools, such as a timing light or computerized diagnostic equipment, is essential for accurate adjustments.

Pressure within the engine system must be carefully managed. Releasing tension on timing belts or chains should be done gradually to prevent sudden movements that could cause injury or damage. Similarly, when retensioning, care must be taken to achieve the correct tension without over-stressing components.

Cleanliness is another crucial safety aspect. Ensuring all components are free from debris, oil, or other contaminants reduces the risk of contamination-induced failures and improves the accuracy of adjustments. Using clean, lint-free cloths and appropriate solvents for cleaning is recommended.

Documentation of all modifications and adjustments is vital for safety and future reference. This includes noting initial settings, changes made, and final configurations. Such records can be invaluable for troubleshooting or reverting changes if necessary.

Lastly, post-modification testing should be conducted in a controlled environment. This allows for the detection of any issues before the vehicle is used on public roads. Gradual increases in engine load and speed during testing help identify potential problems early, reducing the risk of damage or injury.

By adhering to these safety considerations, the process of adjusting K24 engine timing can be conducted effectively while minimizing risks to both the mechanic and the engine itself.

Firstly, proper protective equipment is essential. This includes safety glasses to protect against debris or fluids, gloves to guard against hot surfaces and sharp edges, and appropriate clothing to prevent entanglement in moving parts. A well-ventilated workspace is crucial to mitigate the risk of inhaling harmful fumes or gases.

Before beginning any modifications, it's imperative to ensure the engine is cool and disconnected from the power source. This prevents accidental starts and reduces the risk of burns. All tools should be in good condition and appropriate for the task to avoid slippage or damage to components.

Understanding the engine's specific timing requirements is critical. Incorrect timing can lead to severe engine damage, reduced performance, or even catastrophic failure. Consulting the manufacturer's specifications and using precise timing tools, such as a timing light or computerized diagnostic equipment, is essential for accurate adjustments.

Pressure within the engine system must be carefully managed. Releasing tension on timing belts or chains should be done gradually to prevent sudden movements that could cause injury or damage. Similarly, when retensioning, care must be taken to achieve the correct tension without over-stressing components.

Cleanliness is another crucial safety aspect. Ensuring all components are free from debris, oil, or other contaminants reduces the risk of contamination-induced failures and improves the accuracy of adjustments. Using clean, lint-free cloths and appropriate solvents for cleaning is recommended.

Documentation of all modifications and adjustments is vital for safety and future reference. This includes noting initial settings, changes made, and final configurations. Such records can be invaluable for troubleshooting or reverting changes if necessary.

Lastly, post-modification testing should be conducted in a controlled environment. This allows for the detection of any issues before the vehicle is used on public roads. Gradual increases in engine load and speed during testing help identify potential problems early, reducing the risk of damage or injury.

By adhering to these safety considerations, the process of adjusting K24 engine timing can be conducted effectively while minimizing risks to both the mechanic and the engine itself.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!