How to Approach K24 Engine Modifications for Racing Applications?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Racing Evolution

The K24 engine, originally developed by Honda for use in various passenger vehicles, has undergone significant evolution in racing applications. This transformation began in the early 2000s when enthusiasts recognized the engine's potential for high-performance modifications. The initial racing adaptations focused on basic bolt-on upgrades, such as cold air intakes, exhaust systems, and ECU tuning, which provided modest power gains while maintaining reliability.

As racing teams and aftermarket companies gained more experience with the K24, more advanced modification techniques emerged. The mid-2000s saw the introduction of forced induction systems specifically designed for the K24, including both turbocharging and supercharging options. These developments allowed for substantial increases in horsepower and torque, pushing the engine's capabilities far beyond its stock configuration.

Concurrent with forced induction advancements, internal engine modifications became more sophisticated. High-compression pistons, forged connecting rods, and strengthened crankshafts were developed to withstand the increased stresses of racing conditions. Cylinder head porting and polishing techniques were refined, and custom camshaft profiles were created to optimize valve timing for various racing disciplines.

The late 2000s and early 2010s marked a period of rapid innovation in K24 racing evolution. Engine management systems became more advanced, allowing for precise control over fuel and ignition timing. This era also saw the development of dry sump oiling systems for the K24, which improved oil control under high-G cornering and allowed for lower engine placement, enhancing vehicle dynamics.

In recent years, the focus has shifted towards maximizing efficiency and power density. The integration of direct fuel injection technology, originally absent from the K24, has been successfully implemented in some racing applications. Additionally, the use of exotic materials such as titanium for valves and connecting rods has become more prevalent in high-end racing builds, further pushing the performance envelope.

The evolution of K24 engine modifications for racing has also been influenced by advancements in manufacturing technologies. 3D printing and CNC machining have enabled the production of complex, lightweight components that were previously unfeasible. This has led to the development of bespoke intake manifolds, throttle bodies, and even entire engine blocks optimized for specific racing categories.

Throughout its racing evolution, the K24 engine has demonstrated remarkable versatility, finding success in various motorsport disciplines including circuit racing, drag racing, and time attack events. The continuous development of aftermarket parts and tuning strategies has ensured that the K24 remains a competitive choice for racers, even as newer engine designs have entered the market.

As racing teams and aftermarket companies gained more experience with the K24, more advanced modification techniques emerged. The mid-2000s saw the introduction of forced induction systems specifically designed for the K24, including both turbocharging and supercharging options. These developments allowed for substantial increases in horsepower and torque, pushing the engine's capabilities far beyond its stock configuration.

Concurrent with forced induction advancements, internal engine modifications became more sophisticated. High-compression pistons, forged connecting rods, and strengthened crankshafts were developed to withstand the increased stresses of racing conditions. Cylinder head porting and polishing techniques were refined, and custom camshaft profiles were created to optimize valve timing for various racing disciplines.

The late 2000s and early 2010s marked a period of rapid innovation in K24 racing evolution. Engine management systems became more advanced, allowing for precise control over fuel and ignition timing. This era also saw the development of dry sump oiling systems for the K24, which improved oil control under high-G cornering and allowed for lower engine placement, enhancing vehicle dynamics.

In recent years, the focus has shifted towards maximizing efficiency and power density. The integration of direct fuel injection technology, originally absent from the K24, has been successfully implemented in some racing applications. Additionally, the use of exotic materials such as titanium for valves and connecting rods has become more prevalent in high-end racing builds, further pushing the performance envelope.

The evolution of K24 engine modifications for racing has also been influenced by advancements in manufacturing technologies. 3D printing and CNC machining have enabled the production of complex, lightweight components that were previously unfeasible. This has led to the development of bespoke intake manifolds, throttle bodies, and even entire engine blocks optimized for specific racing categories.

Throughout its racing evolution, the K24 engine has demonstrated remarkable versatility, finding success in various motorsport disciplines including circuit racing, drag racing, and time attack events. The continuous development of aftermarket parts and tuning strategies has ensured that the K24 remains a competitive choice for racers, even as newer engine designs have entered the market.

Racing Market Demand Analysis

The racing market for K24 engine modifications has experienced significant growth in recent years, driven by the increasing popularity of motorsports and the desire for enhanced performance among automotive enthusiasts. This Honda engine, known for its reliability and potential for power gains, has become a favorite among racers and tuners alike.

Market analysis indicates a steady increase in demand for K24 engine modifications, particularly in the amateur and semi-professional racing circuits. The versatility of the K24 engine allows it to be used in various racing applications, from drag racing to circuit racing and even off-road competitions. This wide range of applications has contributed to the expansion of the market for K24 engine modifications.

The target demographic for K24 engine modifications primarily consists of racing enthusiasts aged 18-45, with a strong presence in North America, Europe, and parts of Asia. These consumers are typically willing to invest substantial amounts in engine upgrades to gain a competitive edge on the track. The market also includes professional racing teams and engine builders who seek to maximize the potential of the K24 platform for high-level competitions.

A key factor driving the demand for K24 engine modifications is the engine's inherent strength and ability to handle significant power increases. Racers appreciate the K24's robust bottom end and its capacity to withstand high levels of boost, making it an ideal candidate for forced induction applications. This has led to a thriving aftermarket industry offering a wide range of performance parts and services specifically tailored to the K24 engine.

The racing market for K24 modifications can be segmented into several categories, including naturally aspirated builds, forced induction setups, and hybrid configurations that combine K-series components with other Honda engine families. Each segment caters to different racing disciplines and performance goals, further diversifying the market and creating opportunities for specialized products and services.

Competition in the K24 modification market is fierce, with numerous aftermarket companies vying for market share. This has resulted in continuous innovation and improvement in product offerings, benefiting consumers with higher quality parts and more advanced engineering solutions. The market has also seen an increase in turnkey engine packages and complete swap solutions, catering to racers who prefer a more comprehensive approach to engine upgrades.

As environmental concerns grow, there is an emerging trend towards more efficient and eco-friendly racing solutions. This has led to increased interest in alternative fuels and hybrid technologies, even in the realm of K24 engine modifications. Some racing series are beginning to explore regulations that promote cleaner technologies, which may influence future directions in engine modification strategies.

Market analysis indicates a steady increase in demand for K24 engine modifications, particularly in the amateur and semi-professional racing circuits. The versatility of the K24 engine allows it to be used in various racing applications, from drag racing to circuit racing and even off-road competitions. This wide range of applications has contributed to the expansion of the market for K24 engine modifications.

The target demographic for K24 engine modifications primarily consists of racing enthusiasts aged 18-45, with a strong presence in North America, Europe, and parts of Asia. These consumers are typically willing to invest substantial amounts in engine upgrades to gain a competitive edge on the track. The market also includes professional racing teams and engine builders who seek to maximize the potential of the K24 platform for high-level competitions.

A key factor driving the demand for K24 engine modifications is the engine's inherent strength and ability to handle significant power increases. Racers appreciate the K24's robust bottom end and its capacity to withstand high levels of boost, making it an ideal candidate for forced induction applications. This has led to a thriving aftermarket industry offering a wide range of performance parts and services specifically tailored to the K24 engine.

The racing market for K24 modifications can be segmented into several categories, including naturally aspirated builds, forced induction setups, and hybrid configurations that combine K-series components with other Honda engine families. Each segment caters to different racing disciplines and performance goals, further diversifying the market and creating opportunities for specialized products and services.

Competition in the K24 modification market is fierce, with numerous aftermarket companies vying for market share. This has resulted in continuous innovation and improvement in product offerings, benefiting consumers with higher quality parts and more advanced engineering solutions. The market has also seen an increase in turnkey engine packages and complete swap solutions, catering to racers who prefer a more comprehensive approach to engine upgrades.

As environmental concerns grow, there is an emerging trend towards more efficient and eco-friendly racing solutions. This has led to increased interest in alternative fuels and hybrid technologies, even in the realm of K24 engine modifications. Some racing series are beginning to explore regulations that promote cleaner technologies, which may influence future directions in engine modification strategies.

K24 Engine Limitations

The K24 engine, while renowned for its reliability and versatility, faces several limitations when adapted for racing applications. One of the primary constraints is its stock power output, which ranges from 160 to 205 horsepower depending on the specific variant. This baseline power is often insufficient for competitive racing scenarios, necessitating significant modifications to meet performance demands.

The engine's compression ratio, typically around 9.7:1 to 10.5:1 in stock form, presents another limitation. While adequate for daily driving, these ratios are generally too low for high-performance racing applications, where higher compression ratios can yield substantial power gains. Increasing the compression ratio, however, requires careful consideration of fuel quality and engine management to prevent detonation.

Thermal management poses a significant challenge in racing conditions. The stock cooling system, designed for street use, may struggle to dissipate heat effectively under the sustained high-load conditions typical in racing. This can lead to reduced performance and potential engine damage if not addressed properly.

The K24's valvetrain, while robust for street use, may become a bottleneck at higher RPMs. The stock valve springs and camshafts are not optimized for the extreme conditions of racing, potentially limiting the engine's ability to breathe efficiently at high speeds and leading to valve float.

Fuel delivery is another area of concern. The stock fuel injectors and fuel pump are typically inadequate for the increased fuel demands of a highly modified racing engine. This limitation can result in lean conditions under high load, potentially causing engine damage.

The engine's stock internals, including connecting rods and pistons, may not withstand the increased stresses of high-performance racing applications. While the K24 block is generally strong, these components can become weak points when pushing the engine beyond its original design parameters.

Lastly, the stock engine management system is calibrated for emissions compliance and daily drivability, not for maximum performance. This limits the ability to fine-tune critical parameters such as fuel mapping, ignition timing, and VTEC engagement points, which are crucial for optimizing racing performance.

Addressing these limitations requires a comprehensive approach to engine modification, balancing performance gains with reliability considerations. Overcoming these constraints often involves significant investment in aftermarket components and expert tuning to unlock the K24's full racing potential.

The engine's compression ratio, typically around 9.7:1 to 10.5:1 in stock form, presents another limitation. While adequate for daily driving, these ratios are generally too low for high-performance racing applications, where higher compression ratios can yield substantial power gains. Increasing the compression ratio, however, requires careful consideration of fuel quality and engine management to prevent detonation.

Thermal management poses a significant challenge in racing conditions. The stock cooling system, designed for street use, may struggle to dissipate heat effectively under the sustained high-load conditions typical in racing. This can lead to reduced performance and potential engine damage if not addressed properly.

The K24's valvetrain, while robust for street use, may become a bottleneck at higher RPMs. The stock valve springs and camshafts are not optimized for the extreme conditions of racing, potentially limiting the engine's ability to breathe efficiently at high speeds and leading to valve float.

Fuel delivery is another area of concern. The stock fuel injectors and fuel pump are typically inadequate for the increased fuel demands of a highly modified racing engine. This limitation can result in lean conditions under high load, potentially causing engine damage.

The engine's stock internals, including connecting rods and pistons, may not withstand the increased stresses of high-performance racing applications. While the K24 block is generally strong, these components can become weak points when pushing the engine beyond its original design parameters.

Lastly, the stock engine management system is calibrated for emissions compliance and daily drivability, not for maximum performance. This limits the ability to fine-tune critical parameters such as fuel mapping, ignition timing, and VTEC engagement points, which are crucial for optimizing racing performance.

Addressing these limitations requires a comprehensive approach to engine modification, balancing performance gains with reliability considerations. Overcoming these constraints often involves significant investment in aftermarket components and expert tuning to unlock the K24's full racing potential.

Current K24 Racing Solutions

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. The engine control unit (ECU) plays a crucial role in managing these functions and adapting to different driving conditions.- Engine control and optimization: Advanced control systems and algorithms are used to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Real-time adjustments are made based on driving conditions and engine load to ensure optimal performance.

- Turbocharging and forced induction: Turbocharging technology is applied to the K24 engine to increase power output and improve overall performance. This involves using exhaust gases to drive a turbine, which in turn compresses the intake air, allowing more air and fuel to be forced into the combustion chamber. The result is increased horsepower and torque across a wide range of engine speeds.

- Variable valve timing and lift: The K24 engine incorporates variable valve timing and lift systems to optimize performance across different engine speeds and loads. These systems allow for precise control of valve opening and closing times, as well as the amount of valve lift, resulting in improved power output, fuel efficiency, and reduced emissions.

- Fuel injection and combustion optimization: Advanced fuel injection systems and combustion chamber designs are utilized to enhance the K24 engine's performance. Direct injection technology, coupled with optimized injector placement and spray patterns, ensures efficient fuel atomization and combustion. This leads to improved power output, fuel economy, and reduced emissions.

- Engine cooling and thermal management: Efficient cooling systems and thermal management strategies are employed to maintain optimal operating temperatures for the K24 engine. This includes advanced radiator designs, precision-controlled coolant flow, and intelligent fan control systems. Proper thermal management ensures consistent performance, reduces wear, and extends engine life.

02 Turbocharging and forced induction

Turbocharging technology is applied to the K24 engine to increase its power output and overall performance. This involves using exhaust gases to drive a turbine, which in turn compresses the intake air, allowing more air and fuel to be combusted in each cycle. The result is improved engine efficiency, increased torque, and better acceleration across a wide range of engine speeds.Expand Specific Solutions03 Variable valve timing and lift

The K24 engine incorporates variable valve timing and lift systems to optimize performance across different engine speeds and load conditions. These systems allow for precise control of valve opening and closing times, as well as the amount of valve lift, resulting in improved power output, fuel efficiency, and reduced emissions. This technology enables the engine to adapt to various driving scenarios effectively.Expand Specific Solutions04 Fuel injection and combustion optimization

Advanced fuel injection systems are employed in the K24 engine to enhance combustion efficiency and performance. These systems utilize precise fuel metering, multiple injection events per cycle, and optimized spray patterns to improve fuel atomization and mixture formation. The result is more complete combustion, increased power output, and reduced emissions across various operating conditions.Expand Specific Solutions05 Engine diagnostics and performance monitoring

Sophisticated diagnostic and monitoring systems are integrated into the K24 engine to ensure optimal performance and early detection of potential issues. These systems utilize various sensors and data analysis techniques to monitor engine parameters, detect anomalies, and provide real-time feedback on engine health and performance. This enables proactive maintenance and helps maintain the engine's performance over its lifetime.Expand Specific Solutions

Key Aftermarket Manufacturers

The K24 engine modification market for racing applications is in a mature stage, with a diverse range of established players and emerging companies. The market size is substantial, driven by the growing popularity of motorsports and performance tuning. Technologically, the field is advanced, with companies like Ford Global Technologies, GM Global Technology Operations, and Robert Bosch GmbH leading in innovation. Emerging players such as Guangdong Kadake Automobile Technology and Lantu Automobile Technology are also contributing to the competitive landscape. The technology's maturity is evident in the involvement of academic institutions like Jilin University and Southeast University, indicating a strong research foundation supporting ongoing advancements in engine modification techniques.

Ford Global Technologies LLC

Technical Solution: Ford's approach to K24 engine modifications for racing applications leverages their EcoBoost technology and racing heritage. They focus on enhancing the engine's breathing capabilities through advanced cylinder head designs with optimized port shapes and valve sizes[1]. Ford employs direct injection technology coupled with high-pressure fuel pumps to improve fuel atomization and combustion efficiency[2]. Their racing-specific engine control modules (ECMs) allow for precise tuning of fuel and ignition maps, as well as advanced features like launch control and anti-lag systems[3]. Ford also utilizes lightweight, high-strength materials such as forged pistons and connecting rods to increase the engine's rev limit and durability under high-stress conditions[4].

Strengths: Extensive racing experience, advanced fuel injection technology, and robust engine management systems. Weaknesses: May be more focused on their own engine platforms, potentially limiting direct K24-specific solutions.

GM Global Technology Operations LLC

Technical Solution: GM's approach to K24 engine modifications for racing applications draws from their extensive motorsport experience, particularly in NASCAR and IMSA. They focus on advanced combustion chamber designs to optimize flame propagation and increase thermal efficiency[1]. GM employs sophisticated CFD (Computational Fluid Dynamics) simulations to refine intake and exhaust port geometries, maximizing flow coefficients[2]. Their racing division has developed specialized camshaft profiles and variable valve timing systems to enhance power output across a wide RPM range[3]. GM also utilizes advanced materials such as titanium valves and sodium-filled exhaust valves to improve heat dissipation and reduce valve train mass[4]. Additionally, they have implemented race-specific engine control strategies that incorporate predictive algorithms for optimizing fuel mixture and ignition timing based on real-time sensor data[5].

Strengths: Extensive racing pedigree, advanced simulation capabilities, and innovative materials technology. Weaknesses: May be more focused on their own engine platforms, potentially limiting direct K24-specific solutions.

Core K24 Racing Innovations

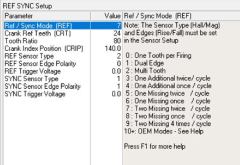

Method for judging ignition of camshaft of CF650 engine based on MoTeC M800 ECU

PatentInactiveCN117345453A

Innovation

- The MoTeC M800 ECU is used to determine the ignition method of the CF650 engine camshaft. By installing the cam sensor and connecting to the MoTeC M800 ECU, GT-power software is used for engine modeling and virtual calibration, and the fuel injection pulse width and ignition advance angle are adjusted to obtain the optimal Optimal parameters and environmental and voltage corrections are made to ensure the optimization of ignition and fuel injection systems.

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Performance Testing Methods

Performance testing methods are crucial for evaluating the effectiveness of K24 engine modifications in racing applications. Dynamometer testing is a primary method used to measure power output and torque curves. This involves mounting the engine on a dynamometer and running it through various RPM ranges to collect data on horsepower and torque production. The results provide valuable insights into the engine's performance characteristics and help identify areas for further improvement.

Track testing is another essential method for assessing K24 engine modifications. This involves installing the modified engine in a race car and conducting timed laps on a race track. Lap times, top speeds, and acceleration data are recorded and compared to baseline performance metrics. Track testing allows for real-world evaluation of the engine's performance under actual racing conditions, including factors such as heat management and fuel efficiency.

Engine data logging is a critical component of performance testing. Advanced data acquisition systems are used to monitor and record various engine parameters during both dynamometer and track testing. These parameters include air/fuel ratios, exhaust gas temperatures, boost pressure (if applicable), and engine temperatures. Analyzing this data helps identify potential issues and fine-tune the engine's performance.

Acceleration testing is often conducted to measure the engine's ability to propel the vehicle from a standing start. This typically involves timed runs from 0-60 mph or quarter-mile acceleration tests. These measurements provide valuable data on the engine's low-end torque and overall power delivery characteristics.

Thermal imaging is employed to assess heat distribution and identify potential hot spots in the modified K24 engine. This method helps engineers optimize cooling systems and ensure that the engine can maintain peak performance under sustained high-load conditions typical in racing environments.

Fuel consumption testing is another important aspect of performance evaluation. This involves measuring fuel flow rates and calculating fuel efficiency under various operating conditions. Optimizing fuel consumption while maintaining high performance is crucial for endurance racing applications.

Durability testing is essential to ensure that the modified K24 engine can withstand the rigors of racing. This may involve extended running periods on a dynamometer or prolonged track sessions to simulate race conditions. Engineers monitor wear patterns, oil analysis, and component integrity to assess the engine's long-term reliability.

Track testing is another essential method for assessing K24 engine modifications. This involves installing the modified engine in a race car and conducting timed laps on a race track. Lap times, top speeds, and acceleration data are recorded and compared to baseline performance metrics. Track testing allows for real-world evaluation of the engine's performance under actual racing conditions, including factors such as heat management and fuel efficiency.

Engine data logging is a critical component of performance testing. Advanced data acquisition systems are used to monitor and record various engine parameters during both dynamometer and track testing. These parameters include air/fuel ratios, exhaust gas temperatures, boost pressure (if applicable), and engine temperatures. Analyzing this data helps identify potential issues and fine-tune the engine's performance.

Acceleration testing is often conducted to measure the engine's ability to propel the vehicle from a standing start. This typically involves timed runs from 0-60 mph or quarter-mile acceleration tests. These measurements provide valuable data on the engine's low-end torque and overall power delivery characteristics.

Thermal imaging is employed to assess heat distribution and identify potential hot spots in the modified K24 engine. This method helps engineers optimize cooling systems and ensure that the engine can maintain peak performance under sustained high-load conditions typical in racing environments.

Fuel consumption testing is another important aspect of performance evaluation. This involves measuring fuel flow rates and calculating fuel efficiency under various operating conditions. Optimizing fuel consumption while maintaining high performance is crucial for endurance racing applications.

Durability testing is essential to ensure that the modified K24 engine can withstand the rigors of racing. This may involve extended running periods on a dynamometer or prolonged track sessions to simulate race conditions. Engineers monitor wear patterns, oil analysis, and component integrity to assess the engine's long-term reliability.

Racing Regulations Impact

Racing regulations play a crucial role in shaping the approach to K24 engine modifications for racing applications. These regulations, set by various motorsport governing bodies, define the parameters within which engine modifications can be made, ensuring fair competition and maintaining safety standards.

The impact of racing regulations on K24 engine modifications is multifaceted. Firstly, they often dictate the maximum engine displacement allowed in specific racing classes. This directly influences the extent to which the K24 engine can be bored or stroked, limiting the potential for increased power through volumetric efficiency.

Additionally, regulations frequently impose restrictions on the types of modifications permitted. For instance, some classes may allow only minor alterations to the stock engine, while others might permit more extensive modifications. This variance in rules across different racing series necessitates a tailored approach to K24 engine modifications, ensuring compliance while maximizing performance within the given constraints.

Fuel regulations also significantly impact K24 engine modifications. Many racing series mandate the use of specific fuel types or impose limitations on fuel octane ratings. These restrictions influence the compression ratios that can be safely achieved and the timing adjustments that can be made, directly affecting the engine's power output and efficiency.

Turbocharging and supercharging regulations are another critical factor. Some racing classes prohibit forced induction entirely, while others may allow it with specific restrictions on boost pressure or intercooler designs. These rules fundamentally shape the strategy for extracting maximum performance from the K24 engine, potentially steering modifications towards naturally aspirated solutions or carefully regulated forced induction setups.

Weight regulations indirectly impact K24 engine modifications by influencing the balance between power output and overall vehicle weight. This may necessitate compromises in engine design, such as using lighter materials or optimizing the engine's physical dimensions to meet weight requirements while maintaining performance.

Emissions regulations, particularly in endurance racing or certain road-legal racing series, can also affect K24 engine modifications. These rules may require the use of catalytic converters or impose limits on exhaust emissions, potentially constraining the engine's breathing capabilities and necessitating innovative solutions to maintain performance while meeting environmental standards.

In conclusion, racing regulations significantly shape the approach to K24 engine modifications, requiring a deep understanding of the specific rules governing each racing class. Successful modification strategies must navigate these regulatory constraints while maximizing performance, often leading to innovative engineering solutions and pushing the boundaries of engine technology within the permitted framework.

The impact of racing regulations on K24 engine modifications is multifaceted. Firstly, they often dictate the maximum engine displacement allowed in specific racing classes. This directly influences the extent to which the K24 engine can be bored or stroked, limiting the potential for increased power through volumetric efficiency.

Additionally, regulations frequently impose restrictions on the types of modifications permitted. For instance, some classes may allow only minor alterations to the stock engine, while others might permit more extensive modifications. This variance in rules across different racing series necessitates a tailored approach to K24 engine modifications, ensuring compliance while maximizing performance within the given constraints.

Fuel regulations also significantly impact K24 engine modifications. Many racing series mandate the use of specific fuel types or impose limitations on fuel octane ratings. These restrictions influence the compression ratios that can be safely achieved and the timing adjustments that can be made, directly affecting the engine's power output and efficiency.

Turbocharging and supercharging regulations are another critical factor. Some racing classes prohibit forced induction entirely, while others may allow it with specific restrictions on boost pressure or intercooler designs. These rules fundamentally shape the strategy for extracting maximum performance from the K24 engine, potentially steering modifications towards naturally aspirated solutions or carefully regulated forced induction setups.

Weight regulations indirectly impact K24 engine modifications by influencing the balance between power output and overall vehicle weight. This may necessitate compromises in engine design, such as using lighter materials or optimizing the engine's physical dimensions to meet weight requirements while maintaining performance.

Emissions regulations, particularly in endurance racing or certain road-legal racing series, can also affect K24 engine modifications. These rules may require the use of catalytic converters or impose limits on exhaust emissions, potentially constraining the engine's breathing capabilities and necessitating innovative solutions to maintain performance while meeting environmental standards.

In conclusion, racing regulations significantly shape the approach to K24 engine modifications, requiring a deep understanding of the specific rules governing each racing class. Successful modification strategies must navigate these regulatory constraints while maximizing performance, often leading to innovative engineering solutions and pushing the boundaries of engine technology within the permitted framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!