How to Balance Power and Efficiency in K24 Engine Mods?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Mod Background and Objectives

The K24 engine, developed by Honda, has become a popular choice for automotive enthusiasts seeking to enhance their vehicle's performance. This four-cylinder powerplant, initially designed for efficiency and reliability, has proven to be an excellent platform for modifications aimed at increasing power output. The challenge lies in striking a balance between power gains and maintaining the engine's efficiency and longevity.

The primary objective of K24 engine modifications is to optimize performance without compromising the engine's inherent reliability. This involves a careful consideration of various factors, including fuel efficiency, emissions, and overall drivability. As environmental concerns and fuel economy regulations become increasingly stringent, the need for balanced modifications that enhance power while maintaining or improving efficiency has become paramount.

The evolution of K24 engine modifications has been driven by advancements in automotive technology and a growing aftermarket industry. Early modifications focused primarily on increasing horsepower through basic upgrades such as cold air intakes and exhaust systems. However, as the platform matured, more sophisticated approaches emerged, incorporating engine management systems, forced induction, and internal engine modifications.

One of the key trends in K24 engine modifications is the integration of modern technologies to achieve both power and efficiency gains. This includes the use of direct injection systems, variable valve timing enhancements, and lightweight materials for internal components. These advancements allow for more precise control over the combustion process, resulting in improved power output and fuel economy.

The market demand for K24 engine modifications has grown significantly over the years, driven by enthusiasts seeking to personalize their vehicles and extract maximum performance. This demand has led to a robust aftermarket industry offering a wide range of products and services tailored to K24 engines. The challenge for both enthusiasts and aftermarket companies is to develop solutions that meet performance goals while adhering to increasingly strict emissions standards and fuel efficiency requirements.

As we look towards the future of K24 engine modifications, the focus is likely to shift towards more holistic approaches that consider the entire powertrain system. This may include the integration of hybrid technologies, advanced materials, and sophisticated engine management systems to push the boundaries of what is possible with this versatile engine platform. The ultimate goal remains to achieve a harmonious balance between power, efficiency, and reliability, ensuring that the K24 engine continues to be a favorite among performance enthusiasts for years to come.

The primary objective of K24 engine modifications is to optimize performance without compromising the engine's inherent reliability. This involves a careful consideration of various factors, including fuel efficiency, emissions, and overall drivability. As environmental concerns and fuel economy regulations become increasingly stringent, the need for balanced modifications that enhance power while maintaining or improving efficiency has become paramount.

The evolution of K24 engine modifications has been driven by advancements in automotive technology and a growing aftermarket industry. Early modifications focused primarily on increasing horsepower through basic upgrades such as cold air intakes and exhaust systems. However, as the platform matured, more sophisticated approaches emerged, incorporating engine management systems, forced induction, and internal engine modifications.

One of the key trends in K24 engine modifications is the integration of modern technologies to achieve both power and efficiency gains. This includes the use of direct injection systems, variable valve timing enhancements, and lightweight materials for internal components. These advancements allow for more precise control over the combustion process, resulting in improved power output and fuel economy.

The market demand for K24 engine modifications has grown significantly over the years, driven by enthusiasts seeking to personalize their vehicles and extract maximum performance. This demand has led to a robust aftermarket industry offering a wide range of products and services tailored to K24 engines. The challenge for both enthusiasts and aftermarket companies is to develop solutions that meet performance goals while adhering to increasingly strict emissions standards and fuel efficiency requirements.

As we look towards the future of K24 engine modifications, the focus is likely to shift towards more holistic approaches that consider the entire powertrain system. This may include the integration of hybrid technologies, advanced materials, and sophisticated engine management systems to push the boundaries of what is possible with this versatile engine platform. The ultimate goal remains to achieve a harmonious balance between power, efficiency, and reliability, ensuring that the K24 engine continues to be a favorite among performance enthusiasts for years to come.

Market Analysis for K24 Performance Upgrades

The market for K24 engine performance upgrades has shown significant growth in recent years, driven by enthusiasts seeking to enhance the power and efficiency of their Honda and Acura vehicles. The K24 engine, known for its reliability and tuning potential, has become a popular choice for modifications among car enthusiasts and racers alike.

The demand for K24 performance upgrades is primarily fueled by two main segments: street performance and motorsports. Street performance enthusiasts seek to improve their daily drivers' power output and responsiveness while maintaining fuel efficiency. On the other hand, motorsports participants require more substantial modifications to meet competitive racing standards.

Market research indicates that the global automotive aftermarket for engine performance parts is expected to grow steadily over the next five years. Within this broader market, K24-specific upgrades have carved out a notable niche, with online retailers and specialty shops reporting increased sales of K24-related products.

Key factors driving the market include the widespread availability of K24 engines in popular Honda and Acura models, the engine's inherent durability, and its compatibility with a wide range of aftermarket parts. Additionally, the rise of online communities and social media platforms dedicated to K-series engine modifications has contributed to increased awareness and demand for performance upgrades.

The market for K24 performance upgrades encompasses a wide range of products, including intake systems, exhaust systems, turbocharger kits, engine management systems, and internal engine components. Among these, forced induction systems, particularly turbocharger kits, have seen the highest growth rate due to their ability to significantly boost power output.

Geographically, North America and Japan lead the market for K24 performance upgrades, with Europe and Australia showing increasing interest. The United States, in particular, has a robust aftermarket scene for Honda and Acura vehicles, supported by numerous performance shops and online retailers specializing in K-series engine modifications.

Consumer trends indicate a growing interest in balanced performance upgrades that offer power gains without sacrificing reliability or fuel efficiency. This has led to increased demand for ECU tuning solutions and bolt-on modifications that can be easily installed and reversed if necessary.

The competitive landscape of the K24 performance upgrade market is diverse, with a mix of established aftermarket brands and smaller, specialized manufacturers. Key players in this space include companies like Hondata, Skunk2 Racing, and AEM Electronics, which offer a range of products from simple bolt-on parts to complex engine management systems.

The demand for K24 performance upgrades is primarily fueled by two main segments: street performance and motorsports. Street performance enthusiasts seek to improve their daily drivers' power output and responsiveness while maintaining fuel efficiency. On the other hand, motorsports participants require more substantial modifications to meet competitive racing standards.

Market research indicates that the global automotive aftermarket for engine performance parts is expected to grow steadily over the next five years. Within this broader market, K24-specific upgrades have carved out a notable niche, with online retailers and specialty shops reporting increased sales of K24-related products.

Key factors driving the market include the widespread availability of K24 engines in popular Honda and Acura models, the engine's inherent durability, and its compatibility with a wide range of aftermarket parts. Additionally, the rise of online communities and social media platforms dedicated to K-series engine modifications has contributed to increased awareness and demand for performance upgrades.

The market for K24 performance upgrades encompasses a wide range of products, including intake systems, exhaust systems, turbocharger kits, engine management systems, and internal engine components. Among these, forced induction systems, particularly turbocharger kits, have seen the highest growth rate due to their ability to significantly boost power output.

Geographically, North America and Japan lead the market for K24 performance upgrades, with Europe and Australia showing increasing interest. The United States, in particular, has a robust aftermarket scene for Honda and Acura vehicles, supported by numerous performance shops and online retailers specializing in K-series engine modifications.

Consumer trends indicate a growing interest in balanced performance upgrades that offer power gains without sacrificing reliability or fuel efficiency. This has led to increased demand for ECU tuning solutions and bolt-on modifications that can be easily installed and reversed if necessary.

The competitive landscape of the K24 performance upgrade market is diverse, with a mix of established aftermarket brands and smaller, specialized manufacturers. Key players in this space include companies like Hondata, Skunk2 Racing, and AEM Electronics, which offer a range of products from simple bolt-on parts to complex engine management systems.

K24 Engine Modification Challenges

The K24 engine, renowned for its versatility and potential, presents several challenges when it comes to balancing power and efficiency through modifications. One of the primary hurdles is maintaining the engine's reliability while increasing its output. As enthusiasts push for higher horsepower, the stock components may struggle to withstand the increased stress, leading to premature wear or failure.

Another significant challenge lies in optimizing the air-fuel mixture across a wide range of operating conditions. Achieving the perfect balance between power and fuel efficiency often requires precise tuning of the engine management system, which can be complex and time-consuming. This is particularly true when introducing forced induction systems like turbochargers or superchargers, which dramatically alter the engine's breathing characteristics.

Heat management poses a considerable obstacle in K24 engine modifications. As power output increases, so does the thermal load on the engine. Inadequate cooling can lead to reduced performance, increased wear, and even catastrophic failure. Addressing this issue often necessitates upgrades to the cooling system, including larger radiators, oil coolers, and improved thermal management strategies.

The stock K24 engine's compression ratio, while beneficial for efficiency, can become a limiting factor when pursuing significant power gains. Lowering the compression ratio to accommodate forced induction or high-boost applications can compromise the engine's efficiency at lower RPMs and during normal driving conditions. Striking the right balance between compression ratio and power potential is a delicate task that requires careful consideration.

Emissions compliance presents an ongoing challenge, especially for those seeking to use modified K24 engines in street-legal applications. Increasing power output often leads to higher emissions, which can conflict with increasingly stringent environmental regulations. Developing modifications that boost performance while maintaining acceptable emissions levels demands innovative solutions and often involves the use of advanced catalytic converters and exhaust systems.

Drivability is another crucial aspect that modifiers must address. While raw power gains are desirable, they must be delivered in a manner that doesn't compromise the engine's responsiveness or low-end torque. Achieving a broad, usable power band that enhances both performance and daily drivability requires careful selection and integration of aftermarket components.

Lastly, the cost-effectiveness of modifications presents a constant challenge. Balancing the desire for increased power and efficiency against budget constraints often requires prioritizing certain upgrades over others. This economic factor can significantly influence the approach taken in modifying K24 engines, pushing enthusiasts and tuners to seek innovative, cost-effective solutions that maximize performance gains without breaking the bank.

Another significant challenge lies in optimizing the air-fuel mixture across a wide range of operating conditions. Achieving the perfect balance between power and fuel efficiency often requires precise tuning of the engine management system, which can be complex and time-consuming. This is particularly true when introducing forced induction systems like turbochargers or superchargers, which dramatically alter the engine's breathing characteristics.

Heat management poses a considerable obstacle in K24 engine modifications. As power output increases, so does the thermal load on the engine. Inadequate cooling can lead to reduced performance, increased wear, and even catastrophic failure. Addressing this issue often necessitates upgrades to the cooling system, including larger radiators, oil coolers, and improved thermal management strategies.

The stock K24 engine's compression ratio, while beneficial for efficiency, can become a limiting factor when pursuing significant power gains. Lowering the compression ratio to accommodate forced induction or high-boost applications can compromise the engine's efficiency at lower RPMs and during normal driving conditions. Striking the right balance between compression ratio and power potential is a delicate task that requires careful consideration.

Emissions compliance presents an ongoing challenge, especially for those seeking to use modified K24 engines in street-legal applications. Increasing power output often leads to higher emissions, which can conflict with increasingly stringent environmental regulations. Developing modifications that boost performance while maintaining acceptable emissions levels demands innovative solutions and often involves the use of advanced catalytic converters and exhaust systems.

Drivability is another crucial aspect that modifiers must address. While raw power gains are desirable, they must be delivered in a manner that doesn't compromise the engine's responsiveness or low-end torque. Achieving a broad, usable power band that enhances both performance and daily drivability requires careful selection and integration of aftermarket components.

Lastly, the cost-effectiveness of modifications presents a constant challenge. Balancing the desire for increased power and efficiency against budget constraints often requires prioritizing certain upgrades over others. This economic factor can significantly influence the approach taken in modifying K24 engines, pushing enthusiasts and tuners to seek innovative, cost-effective solutions that maximize performance gains without breaking the bank.

Current K24 Power-Efficiency Balancing Techniques

01 Improved combustion efficiency

The K24 engine's power and efficiency are enhanced through optimized combustion processes. This includes advanced fuel injection systems, improved air intake designs, and refined combustion chamber geometries. These improvements lead to more complete fuel burning, reduced emissions, and increased overall engine performance.- Engine control systems for improved efficiency: Advanced control systems are implemented to optimize the K24 engine's performance and efficiency. These systems manage various engine parameters such as fuel injection, ignition timing, and valve timing to achieve better power output and fuel economy. By continuously adjusting these parameters based on real-time data, the engine can operate at its peak efficiency across different driving conditions.

- Turbocharging and supercharging technologies: Forced induction systems, including turbochargers and superchargers, are utilized to enhance the K24 engine's power output and efficiency. These systems compress the intake air, allowing more air and fuel to be combusted in each cycle. This results in increased power density and improved overall engine efficiency, especially at higher rpm ranges.

- Variable valve timing and lift mechanisms: Advanced valve control systems are implemented in the K24 engine to optimize airflow and combustion efficiency. These systems allow for dynamic adjustment of valve timing and lift based on engine speed and load, resulting in improved power output, fuel efficiency, and emissions performance across a wide range of operating conditions.

- Lightweight materials and design optimization: The use of lightweight materials and optimized component designs contributes to the K24 engine's power-to-weight ratio and overall efficiency. Advanced materials such as aluminum alloys and composite materials are employed in engine components to reduce weight while maintaining strength. Additionally, computer-aided design and simulation techniques are used to optimize the engine's internal geometry for improved combustion efficiency and reduced friction losses.

- Fuel injection and combustion optimization: Sophisticated fuel injection systems and combustion chamber designs are employed to enhance the K24 engine's power output and efficiency. Direct injection technology, coupled with precise fuel metering and spray patterns, allows for better fuel atomization and more complete combustion. Advanced combustion chamber designs, including optimized piston crown shapes and intake port configurations, further improve the engine's thermodynamic efficiency and power generation capabilities.

02 Variable valve timing and lift

Implementing variable valve timing and lift mechanisms in the K24 engine allows for better control over the engine's breathing. This technology optimizes valve operation based on engine speed and load, resulting in improved power output, fuel efficiency, and reduced emissions across a wide range of operating conditions.Expand Specific Solutions03 Turbocharging and supercharging

Forced induction systems, such as turbochargers or superchargers, can significantly boost the K24 engine's power output. These systems compress the intake air, allowing for more fuel to be burned and resulting in increased horsepower and torque. When properly implemented, they can also improve fuel efficiency under certain operating conditions.Expand Specific Solutions04 Engine management and control systems

Advanced engine control units (ECUs) and management systems play a crucial role in optimizing the K24 engine's performance. These systems continuously monitor and adjust various engine parameters, such as fuel injection timing, ignition timing, and air-fuel ratios, to maximize power output and efficiency while minimizing fuel consumption and emissions.Expand Specific Solutions05 Lightweight materials and design optimization

Utilizing lightweight materials, such as aluminum alloys or composite materials, in the engine's construction can reduce overall weight and improve power-to-weight ratio. Additionally, optimizing the engine's design through computer-aided engineering and simulation techniques can lead to better thermal management, reduced friction, and improved overall efficiency.Expand Specific Solutions

Key Players in K24 Aftermarket Industry

The K24 engine modification market is in a mature stage, with a well-established ecosystem of aftermarket parts and tuning solutions. The global automotive aftermarket industry, which includes engine modifications, is estimated to be worth over $400 billion. Technologically, K24 engine mods have reached a high level of sophistication, with companies like Honda, GM, and BYD leading innovation in power and efficiency optimization. Aftermarket specialists such as Pratt & Whitney Canada and Robert Bosch GmbH contribute advanced solutions for balancing performance and fuel economy. Academic institutions like Tsinghua University and Beijing Institute of Technology are also actively researching cutting-edge engine technologies, further driving the field's maturity and potential for future advancements.

GM Global Technology Operations LLC

Technical Solution: GM's approach to balancing power and efficiency in K24 engine mods focuses on advanced combustion technologies and precision engineering. They employ direct injection and variable valve timing systems to optimize fuel delivery and combustion timing[1]. GM has also developed a proprietary thermal management system that reduces friction and improves heat dissipation, allowing for higher compression ratios without sacrificing reliability[2]. Additionally, they utilize lightweight materials and advanced manufacturing techniques to reduce overall engine weight while maintaining structural integrity[3]. GM's engine control units (ECUs) are programmed with sophisticated algorithms that continuously adjust engine parameters based on driving conditions, further enhancing the balance between power output and fuel efficiency[4].

Strengths: Extensive R&D resources, cutting-edge technology integration, and a proven track record in engine development. Weaknesses: Potentially higher costs associated with advanced technologies and the need for specialized maintenance.

Robert Bosch GmbH

Technical Solution: Bosch's strategy for K24 engine mods centers on their innovative fuel injection systems and engine management solutions. They have developed high-precision piezoelectric injectors that allow for multiple injections per cycle, improving fuel atomization and combustion efficiency[5]. Bosch's engine control systems incorporate machine learning algorithms to adapt to individual driving styles and environmental conditions, optimizing the power-efficiency balance in real-time[6]. Their start-stop technology and regenerative braking systems further contribute to overall efficiency without compromising performance[7]. Bosch has also pioneered the use of 48V mild hybrid systems that can be integrated with K24 engines, providing electric boost during acceleration and enabling more aggressive engine downsizing[8].

Strengths: World-class expertise in fuel injection and engine management systems, extensive supplier network. Weaknesses: Reliance on OEM partnerships for full implementation, potential complexity in aftermarket applications.

Innovative K24 Modification Technologies

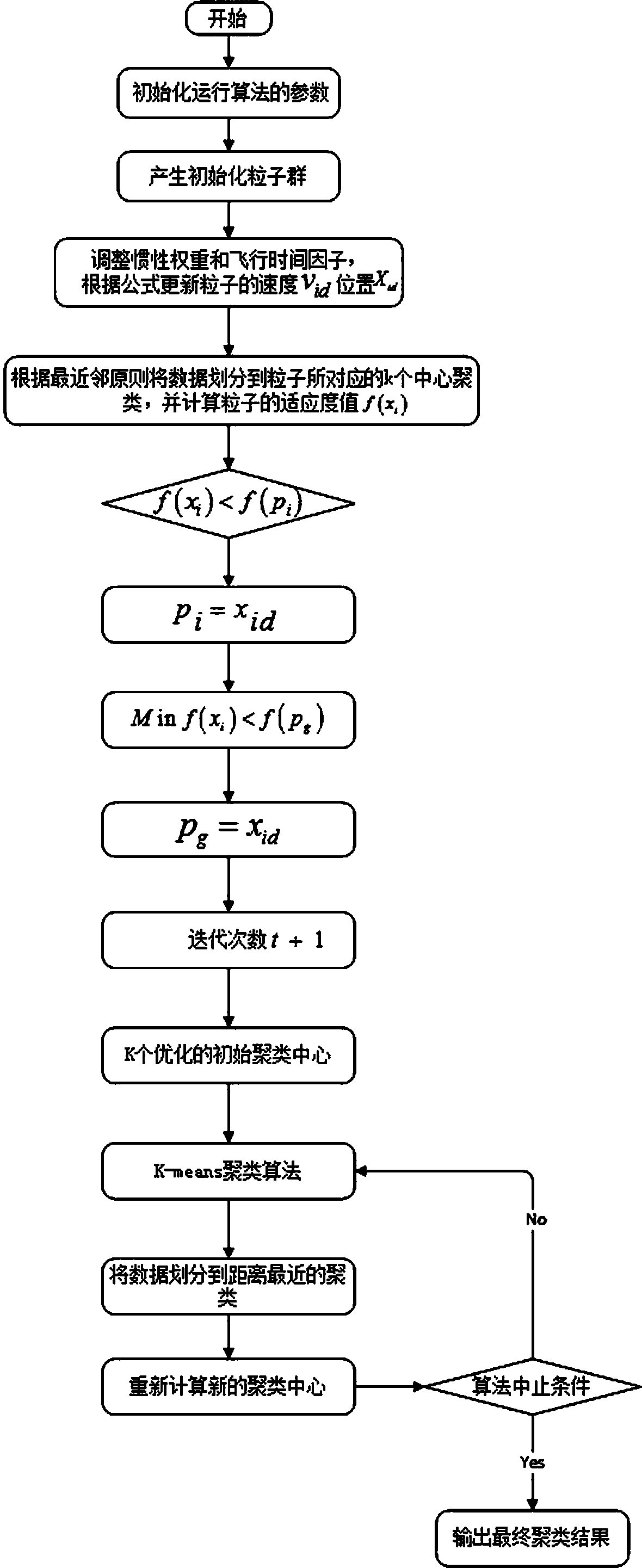

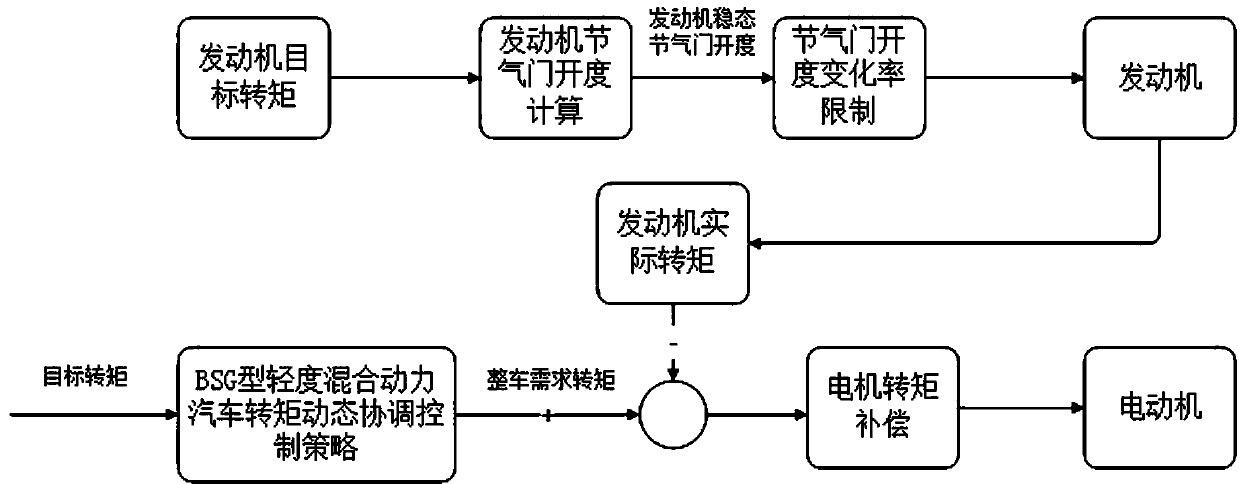

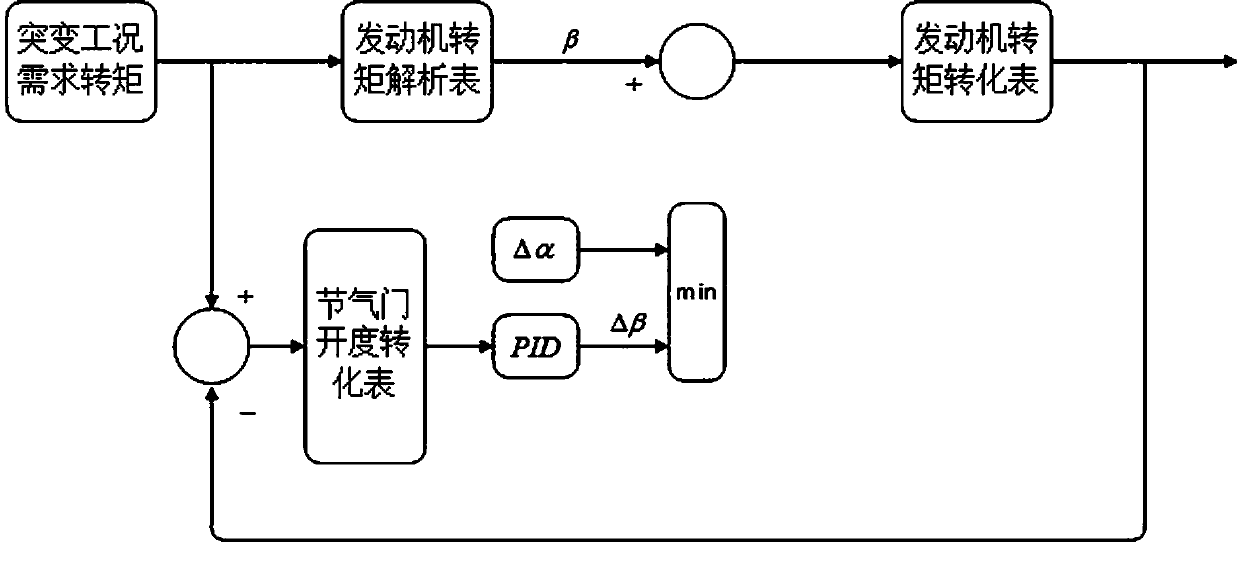

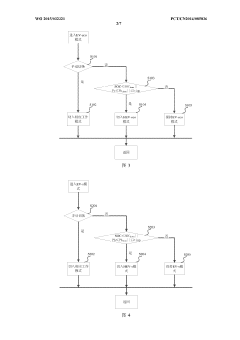

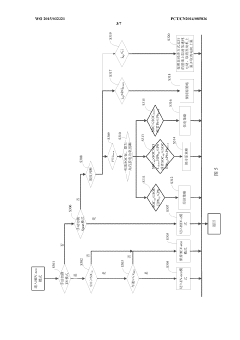

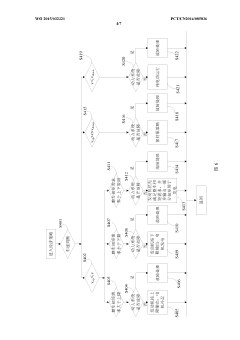

Dynamic coordination hybrid electric vehicle energy management method based on working condition classification

PatentInactiveCN110696816A

Innovation

- The particle swarm algorithm and K-means algorithm are used to build a working condition division model, and the throttle dynamic coordination program is used to reasonably allocate the torque between the engine and the motor, limit the change rate of the engine throttle opening, and achieve real-time control.

Hybrid electrical vehicle control system and method

PatentWO2015032321A1

Innovation

- The parallel-connected engine power subsystem and motor power subsystem are used to switch between pure electric economic mode and hybrid economic mode through the controller, which improves energy utilization, reduces fuel consumption and emissions, and avoids frequent engine starts and stops.

Emissions Regulations Impact on K24 Mods

Emissions regulations have become increasingly stringent in recent years, significantly impacting the landscape of K24 engine modifications. These regulations aim to reduce harmful emissions and improve air quality, posing challenges for enthusiasts and tuners seeking to balance power and efficiency in their K24 engine builds.

The implementation of stricter emissions standards has led to the development of more advanced catalytic converters and exhaust systems. These components are designed to reduce pollutants such as carbon monoxide, nitrogen oxides, and hydrocarbons. As a result, K24 engine modifications must now consider the integration of these emission control devices without compromising performance gains.

One of the primary challenges faced by K24 engine modifiers is maintaining compliance with emissions regulations while pursuing increased power output. Traditional methods of boosting performance, such as aggressive camshaft profiles or high-flow exhaust systems, may no longer be viable options due to their potential to increase emissions beyond acceptable limits. This has necessitated a shift towards more sophisticated tuning approaches and the adoption of cleaner technologies.

The use of advanced engine management systems has become crucial in addressing emissions concerns. These systems allow for precise control over fuel injection, ignition timing, and other parameters, enabling tuners to optimize engine performance while staying within emissions limits. Additionally, the integration of variable valve timing and lift technologies has proven effective in balancing power and efficiency while meeting regulatory requirements.

Forced induction modifications, such as turbocharging and supercharging, have also been impacted by emissions regulations. Tuners must now carefully consider the selection and sizing of these systems to ensure they do not overwhelm the engine's ability to maintain clean combustion. This has led to the development of more efficient turbocharger and supercharger designs that can deliver power gains without significantly increasing emissions.

The aftermarket industry has responded to these challenges by developing emissions-compliant performance parts specifically designed for K24 engines. These components, including high-flow catalytic converters and low-restriction mufflers, aim to maintain or improve upon factory emissions levels while still offering performance benefits. However, the cost and complexity of these parts have increased, potentially limiting accessibility for some enthusiasts.

As emissions regulations continue to evolve, the future of K24 engine modifications will likely see a greater emphasis on hybrid and electric assist technologies. These systems can provide power boosts while simultaneously reducing overall emissions, offering a potential pathway for enthusiasts to achieve their performance goals within regulatory constraints.

The implementation of stricter emissions standards has led to the development of more advanced catalytic converters and exhaust systems. These components are designed to reduce pollutants such as carbon monoxide, nitrogen oxides, and hydrocarbons. As a result, K24 engine modifications must now consider the integration of these emission control devices without compromising performance gains.

One of the primary challenges faced by K24 engine modifiers is maintaining compliance with emissions regulations while pursuing increased power output. Traditional methods of boosting performance, such as aggressive camshaft profiles or high-flow exhaust systems, may no longer be viable options due to their potential to increase emissions beyond acceptable limits. This has necessitated a shift towards more sophisticated tuning approaches and the adoption of cleaner technologies.

The use of advanced engine management systems has become crucial in addressing emissions concerns. These systems allow for precise control over fuel injection, ignition timing, and other parameters, enabling tuners to optimize engine performance while staying within emissions limits. Additionally, the integration of variable valve timing and lift technologies has proven effective in balancing power and efficiency while meeting regulatory requirements.

Forced induction modifications, such as turbocharging and supercharging, have also been impacted by emissions regulations. Tuners must now carefully consider the selection and sizing of these systems to ensure they do not overwhelm the engine's ability to maintain clean combustion. This has led to the development of more efficient turbocharger and supercharger designs that can deliver power gains without significantly increasing emissions.

The aftermarket industry has responded to these challenges by developing emissions-compliant performance parts specifically designed for K24 engines. These components, including high-flow catalytic converters and low-restriction mufflers, aim to maintain or improve upon factory emissions levels while still offering performance benefits. However, the cost and complexity of these parts have increased, potentially limiting accessibility for some enthusiasts.

As emissions regulations continue to evolve, the future of K24 engine modifications will likely see a greater emphasis on hybrid and electric assist technologies. These systems can provide power boosts while simultaneously reducing overall emissions, offering a potential pathway for enthusiasts to achieve their performance goals within regulatory constraints.

Cost-Benefit Analysis of K24 Engine Upgrades

When considering K24 engine modifications, a thorough cost-benefit analysis is crucial for enthusiasts and professionals alike. The K24 engine, known for its reliability and potential, offers various upgrade options that can significantly enhance performance. However, these modifications come with associated costs that must be carefully weighed against the potential gains.

One of the primary considerations is the cost of parts and labor for different upgrade paths. Basic modifications such as cold air intakes, exhaust systems, and ECU tuning offer moderate power gains at relatively low costs. These upgrades typically provide a good balance of performance improvement and financial investment, making them popular among entry-level enthusiasts.

More advanced modifications, such as camshaft upgrades, high-compression pistons, and forced induction systems, offer substantial power increases but at significantly higher costs. These upgrades often require additional supporting modifications, further increasing the overall investment. For example, a turbocharger kit can dramatically boost horsepower but may necessitate upgrades to the fuel system, intercooler, and engine internals to handle the increased power output.

The longevity and reliability of the engine post-modification are crucial factors in the cost-benefit equation. While some upgrades can enhance engine durability, others may reduce the engine's lifespan or increase maintenance requirements. This potential for increased wear and tear should be factored into the long-term cost analysis.

Performance gains from modifications can be quantified through dyno testing and real-world performance metrics. However, the subjective value of these improvements varies among individuals. Some may prioritize raw horsepower, while others may value improved throttle response or a broader powerband. Understanding personal goals and preferences is essential in determining the value proposition of each modification.

Fuel efficiency is another important consideration. Some modifications can improve fuel economy, particularly those that optimize engine breathing and combustion efficiency. However, more aggressive performance upgrades often lead to increased fuel consumption, which should be factored into the ongoing costs of operation.

Resale value is an often-overlooked aspect of the cost-benefit analysis. While some modifications can increase a vehicle's value in niche markets, extensive modifications may limit the pool of potential buyers and potentially decrease resale value in the broader market. This factor is particularly relevant for those who view their vehicle as a long-term investment.

In conclusion, balancing the costs and benefits of K24 engine modifications requires careful consideration of initial investment, long-term reliability, performance gains, fuel efficiency, and resale value. By thoroughly analyzing these factors, enthusiasts can make informed decisions that align with their performance goals and budget constraints.

One of the primary considerations is the cost of parts and labor for different upgrade paths. Basic modifications such as cold air intakes, exhaust systems, and ECU tuning offer moderate power gains at relatively low costs. These upgrades typically provide a good balance of performance improvement and financial investment, making them popular among entry-level enthusiasts.

More advanced modifications, such as camshaft upgrades, high-compression pistons, and forced induction systems, offer substantial power increases but at significantly higher costs. These upgrades often require additional supporting modifications, further increasing the overall investment. For example, a turbocharger kit can dramatically boost horsepower but may necessitate upgrades to the fuel system, intercooler, and engine internals to handle the increased power output.

The longevity and reliability of the engine post-modification are crucial factors in the cost-benefit equation. While some upgrades can enhance engine durability, others may reduce the engine's lifespan or increase maintenance requirements. This potential for increased wear and tear should be factored into the long-term cost analysis.

Performance gains from modifications can be quantified through dyno testing and real-world performance metrics. However, the subjective value of these improvements varies among individuals. Some may prioritize raw horsepower, while others may value improved throttle response or a broader powerband. Understanding personal goals and preferences is essential in determining the value proposition of each modification.

Fuel efficiency is another important consideration. Some modifications can improve fuel economy, particularly those that optimize engine breathing and combustion efficiency. However, more aggressive performance upgrades often lead to increased fuel consumption, which should be factored into the ongoing costs of operation.

Resale value is an often-overlooked aspect of the cost-benefit analysis. While some modifications can increase a vehicle's value in niche markets, extensive modifications may limit the pool of potential buyers and potentially decrease resale value in the broader market. This factor is particularly relevant for those who view their vehicle as a long-term investment.

In conclusion, balancing the costs and benefits of K24 engine modifications requires careful consideration of initial investment, long-term reliability, performance gains, fuel efficiency, and resale value. By thoroughly analyzing these factors, enthusiasts can make informed decisions that align with their performance goals and budget constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!