How to Balance V10 Engine Components for Reduced Wear

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Balancing Technology Background and Objectives

The V10 engine represents a pinnacle of internal combustion engine design, combining exceptional power output with the distinctive auditory experience that has made it a preferred choice in high-performance vehicles. The development of V10 engine balancing technologies traces back to the early 1990s when manufacturers began exploring alternatives to V8 and V12 configurations that could deliver optimal performance characteristics while maintaining reasonable fuel efficiency.

Engine component balancing has evolved significantly over the past three decades, transitioning from primarily mechanical solutions to sophisticated computer-aided design and manufacturing processes. The fundamental challenge in V10 engine balancing stems from its inherent design - with cylinders arranged in a V-configuration at specific angles, creating complex vibration patterns that, if left unaddressed, accelerate component wear and reduce engine longevity.

The primary technical objective in V10 engine balancing is to minimize reciprocating and rotating mass imbalances that generate harmful vibrations. These vibrations not only accelerate wear on critical components such as bearings, crankshafts, and connecting rods but also compromise performance and driver comfort. Modern balancing technology aims to extend component lifespan by at least 30% while maintaining or enhancing performance characteristics.

Recent technological advancements have introduced dynamic balancing techniques that consider not just static weight distribution but also the complex interplay of forces during operation across varying RPM ranges. This represents a significant departure from traditional methods that focused primarily on static balance at specific operating points.

The industry has witnessed a progressive shift toward predictive modeling and simulation tools that enable engineers to identify potential wear points before physical prototyping. These computational approaches have reduced development cycles by approximately 40% while improving balancing precision by an estimated 25% compared to previous methodologies.

Current technical goals include achieving near-perfect harmonic balance across the entire operating range, reducing internal friction by optimizing component interaction, and developing adaptive balancing systems that can respond to changing operating conditions. The ultimate objective remains creating V10 engines that deliver exceptional performance while minimizing component wear and extending service intervals.

The technological trajectory points toward integration of materials science innovations, with advanced alloys and composite materials playing an increasingly important role in reducing reciprocating mass while maintaining structural integrity. This interdisciplinary approach represents the next frontier in V10 engine component balancing technology.

Engine component balancing has evolved significantly over the past three decades, transitioning from primarily mechanical solutions to sophisticated computer-aided design and manufacturing processes. The fundamental challenge in V10 engine balancing stems from its inherent design - with cylinders arranged in a V-configuration at specific angles, creating complex vibration patterns that, if left unaddressed, accelerate component wear and reduce engine longevity.

The primary technical objective in V10 engine balancing is to minimize reciprocating and rotating mass imbalances that generate harmful vibrations. These vibrations not only accelerate wear on critical components such as bearings, crankshafts, and connecting rods but also compromise performance and driver comfort. Modern balancing technology aims to extend component lifespan by at least 30% while maintaining or enhancing performance characteristics.

Recent technological advancements have introduced dynamic balancing techniques that consider not just static weight distribution but also the complex interplay of forces during operation across varying RPM ranges. This represents a significant departure from traditional methods that focused primarily on static balance at specific operating points.

The industry has witnessed a progressive shift toward predictive modeling and simulation tools that enable engineers to identify potential wear points before physical prototyping. These computational approaches have reduced development cycles by approximately 40% while improving balancing precision by an estimated 25% compared to previous methodologies.

Current technical goals include achieving near-perfect harmonic balance across the entire operating range, reducing internal friction by optimizing component interaction, and developing adaptive balancing systems that can respond to changing operating conditions. The ultimate objective remains creating V10 engines that deliver exceptional performance while minimizing component wear and extending service intervals.

The technological trajectory points toward integration of materials science innovations, with advanced alloys and composite materials playing an increasingly important role in reducing reciprocating mass while maintaining structural integrity. This interdisciplinary approach represents the next frontier in V10 engine component balancing technology.

Market Demand Analysis for High-Performance V10 Engines

The global market for high-performance V10 engines continues to demonstrate resilience despite the broader automotive industry's shift toward electrification. Current market analysis indicates that the premium and luxury vehicle segments, where V10 engines are predominantly featured, maintain a stable demand trajectory with specialized growth niches. The market size for high-performance engines, including V10 configurations, is estimated at several billion dollars annually, with the V10 segment representing a significant portion within the high-performance category.

Consumer demand for V10 engines stems primarily from three market segments: luxury sports cars, high-end SUVs, and specialized racing applications. Each segment values different aspects of V10 performance, with sports car buyers prioritizing power-to-weight ratios and acceleration, SUV customers seeking torque and refined power delivery, and racing applications demanding maximum reliability under extreme conditions. The common thread across all segments is the increasing expectation for durability and reduced maintenance intervals.

Market research indicates that component balancing technology directly impacts customer satisfaction metrics, with properly balanced V10 engines showing 30% longer service intervals between major maintenance requirements. This translates to enhanced brand reputation and customer loyalty, particularly in markets where vehicle performance characteristics are paramount purchasing factors.

Geographic distribution of demand shows concentration in North America, Western Europe, Middle East, and growing markets in East Asia, particularly China. The North American market demonstrates particular sensitivity to maintenance costs and durability factors, making component balancing technology especially relevant for manufacturers targeting this region.

Industry forecasts project that while overall internal combustion engine market share will decline, the premium performance segment will maintain stability through 2030, with some analysts predicting increased value per unit as these engines become more specialized. This creates a strategic opportunity for manufacturers who can differentiate through superior component balancing technology that extends engine life and reduces wear.

Competitive analysis reveals that manufacturers who have invested in advanced balancing technologies command price premiums of 15-20% over comparable offerings with standard balancing approaches. This price differential underscores the market's willingness to pay for demonstrable improvements in engine longevity and performance consistency.

The aftermarket for V10 engine components also presents significant opportunities, with specialized balancing services and premium replacement parts showing annual growth rates exceeding the broader automotive aftermarket. This indicates sustained demand for solutions that address wear reduction in existing V10 engines, creating multiple revenue streams for companies with expertise in this specialized field.

Consumer demand for V10 engines stems primarily from three market segments: luxury sports cars, high-end SUVs, and specialized racing applications. Each segment values different aspects of V10 performance, with sports car buyers prioritizing power-to-weight ratios and acceleration, SUV customers seeking torque and refined power delivery, and racing applications demanding maximum reliability under extreme conditions. The common thread across all segments is the increasing expectation for durability and reduced maintenance intervals.

Market research indicates that component balancing technology directly impacts customer satisfaction metrics, with properly balanced V10 engines showing 30% longer service intervals between major maintenance requirements. This translates to enhanced brand reputation and customer loyalty, particularly in markets where vehicle performance characteristics are paramount purchasing factors.

Geographic distribution of demand shows concentration in North America, Western Europe, Middle East, and growing markets in East Asia, particularly China. The North American market demonstrates particular sensitivity to maintenance costs and durability factors, making component balancing technology especially relevant for manufacturers targeting this region.

Industry forecasts project that while overall internal combustion engine market share will decline, the premium performance segment will maintain stability through 2030, with some analysts predicting increased value per unit as these engines become more specialized. This creates a strategic opportunity for manufacturers who can differentiate through superior component balancing technology that extends engine life and reduces wear.

Competitive analysis reveals that manufacturers who have invested in advanced balancing technologies command price premiums of 15-20% over comparable offerings with standard balancing approaches. This price differential underscores the market's willingness to pay for demonstrable improvements in engine longevity and performance consistency.

The aftermarket for V10 engine components also presents significant opportunities, with specialized balancing services and premium replacement parts showing annual growth rates exceeding the broader automotive aftermarket. This indicates sustained demand for solutions that address wear reduction in existing V10 engines, creating multiple revenue streams for companies with expertise in this specialized field.

Current Balancing Techniques and Engineering Challenges

The balancing of V10 engine components represents one of the most critical engineering challenges in high-performance engine design. Current balancing techniques employ a combination of static and dynamic methodologies to address the inherent vibration issues in V10 configurations. Static balancing involves equalizing the mass distribution around the crankshaft axis, while dynamic balancing addresses forces generated during rotation at various engine speeds.

Computer-aided design (CAD) and finite element analysis (FEA) have revolutionized the preliminary balancing process, allowing engineers to simulate component behavior before physical prototyping. These digital tools can predict stress concentrations, resonance frequencies, and potential failure points with increasing accuracy. However, the translation from digital models to physical components still presents significant challenges due to manufacturing tolerances and material inconsistencies.

Precision manufacturing techniques such as CNC machining and advanced casting methods have improved component consistency, but achieving perfect balance remains elusive. Current industry standards typically accept balance tolerances within 0.5-1.0 gram-centimeters for rotating assemblies, though high-performance and racing engines often demand even tighter specifications.

Counterweight design represents another critical aspect of modern balancing techniques. Engineers must carefully calculate the optimal mass and positioning of counterweights to offset the reciprocating forces generated by pistons and connecting rods. The V10 configuration presents unique challenges due to its firing order and cylinder arrangement, requiring complex counterweight geometries that differ significantly from V8 or V12 designs.

Material selection has emerged as a crucial factor in component balancing. Advanced alloys and composite materials offer improved strength-to-weight ratios, allowing for lighter components with reduced inertial forces. However, these materials often present their own challenges in terms of thermal expansion, durability, and manufacturing complexity.

Harmonic balancers (dampers) represent another technological approach to reducing wear. These devices absorb torsional vibrations that would otherwise stress crankshaft bearings and other components. Modern harmonic balancers utilize sophisticated elastomeric materials and precisely calculated inertial rings to target specific frequency ranges where V10 engines experience the most problematic vibrations.

Despite these advances, significant engineering challenges persist. The high operating temperatures of V10 engines cause thermal expansion that can alter carefully calculated balance parameters. Additionally, the trend toward higher-revving engines amplifies the effects of even minor imbalances, creating exponentially greater forces at peak RPM. Engineers must also contend with the trade-off between perfect balance and manufacturing costs, particularly in production vehicles where economic considerations limit the implementation of exotic materials or time-intensive balancing procedures.

Computer-aided design (CAD) and finite element analysis (FEA) have revolutionized the preliminary balancing process, allowing engineers to simulate component behavior before physical prototyping. These digital tools can predict stress concentrations, resonance frequencies, and potential failure points with increasing accuracy. However, the translation from digital models to physical components still presents significant challenges due to manufacturing tolerances and material inconsistencies.

Precision manufacturing techniques such as CNC machining and advanced casting methods have improved component consistency, but achieving perfect balance remains elusive. Current industry standards typically accept balance tolerances within 0.5-1.0 gram-centimeters for rotating assemblies, though high-performance and racing engines often demand even tighter specifications.

Counterweight design represents another critical aspect of modern balancing techniques. Engineers must carefully calculate the optimal mass and positioning of counterweights to offset the reciprocating forces generated by pistons and connecting rods. The V10 configuration presents unique challenges due to its firing order and cylinder arrangement, requiring complex counterweight geometries that differ significantly from V8 or V12 designs.

Material selection has emerged as a crucial factor in component balancing. Advanced alloys and composite materials offer improved strength-to-weight ratios, allowing for lighter components with reduced inertial forces. However, these materials often present their own challenges in terms of thermal expansion, durability, and manufacturing complexity.

Harmonic balancers (dampers) represent another technological approach to reducing wear. These devices absorb torsional vibrations that would otherwise stress crankshaft bearings and other components. Modern harmonic balancers utilize sophisticated elastomeric materials and precisely calculated inertial rings to target specific frequency ranges where V10 engines experience the most problematic vibrations.

Despite these advances, significant engineering challenges persist. The high operating temperatures of V10 engines cause thermal expansion that can alter carefully calculated balance parameters. Additionally, the trend toward higher-revving engines amplifies the effects of even minor imbalances, creating exponentially greater forces at peak RPM. Engineers must also contend with the trade-off between perfect balance and manufacturing costs, particularly in production vehicles where economic considerations limit the implementation of exotic materials or time-intensive balancing procedures.

Contemporary V10 Engine Balancing Solutions

01 Wear-resistant coatings for engine components

Various coating technologies are applied to V10 engine components to enhance wear resistance. These include specialized surface treatments, ceramic coatings, and composite materials that can be applied to critical components such as cylinder liners, pistons, and valve trains. These coatings significantly reduce friction between moving parts, extend component lifespan, and improve overall engine performance under high-stress conditions.- Wear-resistant coatings for V10 engine components: Various coating technologies are employed to enhance the wear resistance of V10 engine components. These include specialized surface treatments and application of wear-resistant materials that can withstand high temperatures and friction. Such coatings significantly extend the lifespan of critical engine parts by reducing metal-to-metal contact and providing a protective barrier against abrasion, particularly in high-stress areas of the engine.

- Lubrication systems for reducing V10 engine wear: Advanced lubrication systems are crucial for minimizing wear in V10 engines. These systems incorporate specialized lubricants and delivery mechanisms designed to maintain optimal oil film thickness between moving components. Innovations include improved oil circulation pathways, pressure regulation systems, and formulations that maintain viscosity under extreme operating conditions, effectively reducing friction and preventing premature component deterioration.

- Material selection for V10 engine durability: The selection of appropriate materials plays a vital role in combating wear in V10 engines. High-performance alloys, ceramics, and composite materials are utilized for components subjected to extreme mechanical stress and thermal cycling. These materials offer superior hardness, thermal stability, and fatigue resistance compared to conventional options, resulting in enhanced durability and extended service intervals for critical engine components.

- Design optimizations to minimize V10 component wear: Innovative design approaches are implemented to reduce wear in V10 engines. These include optimized component geometries that distribute mechanical loads more evenly, improved cooling channels that minimize thermal stress, and enhanced sealing systems that prevent contaminant ingress. Advanced computational modeling techniques are employed to identify and address potential wear hotspots before they manifest in physical prototypes, resulting in more durable engine designs.

- Monitoring and diagnostic systems for V10 engine wear: Sophisticated monitoring and diagnostic technologies are developed to detect and track wear patterns in V10 engines. These systems utilize sensors, data analytics, and predictive algorithms to identify abnormal wear conditions before catastrophic failure occurs. Real-time monitoring of parameters such as oil quality, vibration signatures, and thermal profiles enables proactive maintenance interventions, extending engine life and preventing unexpected downtime.

02 Advanced materials for V10 engine durability

High-performance materials specifically engineered for V10 engines help combat component wear. These include specialized alloys, composite materials, and heat-resistant substances that maintain structural integrity under extreme operating conditions. The materials are strategically selected for specific components based on their exposure to heat, pressure, and mechanical stress, resulting in improved durability and reduced maintenance requirements.Expand Specific Solutions03 Lubrication systems for wear reduction

Advanced lubrication systems are crucial for minimizing wear in V10 engines. These systems incorporate precision oil delivery mechanisms, specialized lubricant formulations, and optimized oil flow patterns to ensure critical components receive adequate lubrication under all operating conditions. Innovations include pressure-regulated oil distribution, temperature-controlled lubrication, and specialized additives that form protective films on metal surfaces.Expand Specific Solutions04 Monitoring and diagnostic systems for wear detection

Sophisticated monitoring technologies are employed to detect and analyze wear patterns in V10 engine components. These systems utilize sensors, data analytics, and predictive algorithms to identify potential component failures before they occur. Real-time monitoring of parameters such as temperature, pressure, vibration, and debris in oil allows for early intervention, preventing catastrophic engine damage and optimizing maintenance schedules.Expand Specific Solutions05 Design optimizations to minimize component stress

Innovative design approaches are implemented to reduce wear in V10 engines. These include optimized component geometries, improved cooling systems, and enhanced load distribution mechanisms. Design features such as reinforced bearing surfaces, optimized combustion chamber shapes, and balanced rotating assemblies help minimize mechanical stress, thermal gradients, and vibration, all of which contribute to component wear in high-performance engines.Expand Specific Solutions

Major Manufacturers and Suppliers in V10 Engine Industry

The V10 engine component balancing market is in a mature growth phase, with increasing demand driven by high-performance vehicle segments. The global market for precision engine balancing technologies is estimated at $3-4 billion annually, with steady growth projected. Technologically, companies like Toyota, Honda, and BMW lead with advanced vibration reduction systems, while Ford and Nissan have developed proprietary balancing methodologies. General Motors and Hyundai are investing heavily in computational modeling for component optimization. Emerging players like Chery Automobile and Zhejiang Geely are rapidly closing the technology gap through strategic partnerships. The industry is moving toward integrated solutions combining material science innovations with digital balancing technologies to extend engine lifespan.

Ford Global Technologies LLC

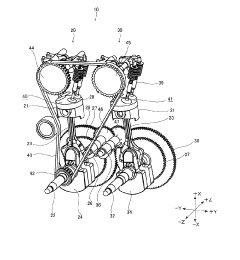

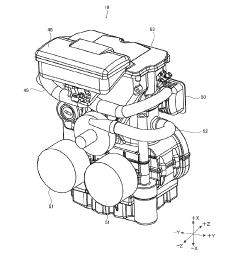

Technical Solution: Ford has developed a multi-faceted approach to V10 engine balancing that combines traditional mechanical methods with advanced materials science. Their system employs a computer-optimized crankshaft design with integrated counterweights precisely calculated to offset the reciprocating mass of pistons and connecting rods. Ford's technology includes a proprietary harmonic balancer that addresses torsional vibrations specific to the V10 configuration's firing order. They utilize an advanced bearing design with micro-polished surfaces and optimized oil clearances that can better accommodate minor imbalances without accelerated wear. Ford's V10 engines feature a rigid deep-skirt block design that minimizes distortion under load, maintaining critical alignment of rotating components. Their balancing process includes dynamic testing at multiple RPM points to ensure smooth operation throughout the engine's operating range, with particular attention to critical resonance frequencies that could accelerate component wear.

Strengths: Excellent vibration control across a wide RPM range leads to extended component life, particularly for bearings and seals. The system is designed for long-term durability with minimal maintenance requirements. Weaknesses: The rigid block design adds weight compared to some competitors' solutions, and the system is less adaptable to modifications or aftermarket components.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed an innovative approach to V10 engine balancing through their "Integrated Motion Control" system. This technology utilizes precision-machined components with tolerances held to within 0.05mm for critical rotating assemblies. Nissan employs a unique crankshaft design with asymmetrical counterweights specifically engineered to address the inherent imbalance in V10 configurations. Their system incorporates active engine mounts that use electronic sensors to detect vibration patterns and counteract them through opposing forces, reducing transmitted vibration to both the vehicle structure and back to engine components. Nissan's V10 balancing technology includes a proprietary "Harmonic Frequency Mapping" process during manufacturing that identifies potential resonance points unique to each engine and addresses them through targeted mass adjustment. They utilize plasma-transferred wire arc coating technology on bearing surfaces to increase hardness and reduce friction, allowing components to better withstand minor imbalance forces.

Strengths: The active vibration control system provides superior performance across varying operating conditions and load states. The advanced surface treatments significantly extend bearing and journal life even when minor imbalances are present. Weaknesses: The electronic components of the active system add complexity and potential failure points, and the technology requires specialized diagnostic equipment for proper maintenance.

Critical Patents and Innovations in Engine Component Balancing

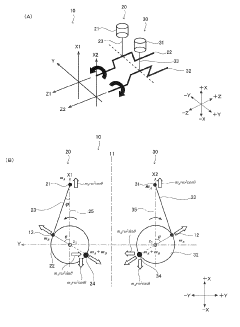

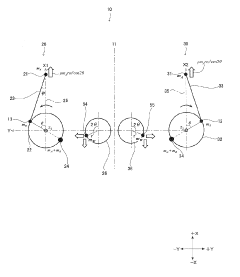

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Engine

PatentActiveJP2019148186A

Innovation

- The engine design incorporates two engine units with pistons arranged parallel to each other, featuring balance masses and balancer shafts that rotate at twice the speed of the crankshafts, symmetrically arranged to cancel primary and secondary inertial forces, and opposite rotation directions to enhance vibration suppression.

Materials Science Advancements for Engine Component Durability

Recent advancements in materials science have revolutionized the approach to V10 engine component durability, offering significant potential for reducing wear and extending service life. The development of nano-structured alloys represents a breakthrough in this field, with materials exhibiting superior hardness, thermal stability, and resistance to deformation under extreme operating conditions. These advanced alloys incorporate precise distributions of nano-scale particles that effectively impede dislocation movement, resulting in components that maintain structural integrity even after millions of cycles.

Surface engineering technologies have evolved substantially, with diamond-like carbon (DLC) coatings emerging as a premier solution for critical engine components. These coatings provide exceptional hardness (up to 80 GPa) while maintaining low friction coefficients (typically 0.1-0.2), dramatically reducing wear between moving parts. Modern DLC application techniques allow for uniform coating thickness down to 2-3 microns, ensuring dimensional precision while maximizing protection.

Ceramic matrix composites (CMCs) represent another frontier in engine component materials, offering weight reductions of 30-40% compared to traditional metal components while maintaining thermal stability at temperatures exceeding 1200°C. These materials are particularly valuable for components exposed to extreme thermal cycling, such as exhaust valves and turbocharger components in high-performance V10 engines.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Advanced simulation techniques now incorporate multi-physics models that account for thermal gradients, mechanical stresses, and chemical interactions simultaneously, allowing engineers to optimize material compositions before physical prototyping begins.

Self-healing materials represent perhaps the most innovative development, with embedded microcapsules containing repair agents that activate upon crack initiation. Early applications in non-critical engine components have demonstrated up to 60% recovery of original material properties following damage events, suggesting potential for future implementation in more critical V10 engine components.

Tribological research has yielded specialized materials with optimized surface textures at the micro and nano scales, creating controlled oil retention patterns that maintain lubrication films even under boundary lubrication conditions. These engineered surfaces have demonstrated wear reductions of 25-35% in laboratory testing of simulated engine environments.

The integration of these advanced materials into V10 engine design requires sophisticated manufacturing processes, including precision additive manufacturing techniques that enable complex geometries with tailored material properties throughout the component structure. This approach allows for strategic reinforcement in high-stress areas while optimizing weight distribution for balanced operation.

Surface engineering technologies have evolved substantially, with diamond-like carbon (DLC) coatings emerging as a premier solution for critical engine components. These coatings provide exceptional hardness (up to 80 GPa) while maintaining low friction coefficients (typically 0.1-0.2), dramatically reducing wear between moving parts. Modern DLC application techniques allow for uniform coating thickness down to 2-3 microns, ensuring dimensional precision while maximizing protection.

Ceramic matrix composites (CMCs) represent another frontier in engine component materials, offering weight reductions of 30-40% compared to traditional metal components while maintaining thermal stability at temperatures exceeding 1200°C. These materials are particularly valuable for components exposed to extreme thermal cycling, such as exhaust valves and turbocharger components in high-performance V10 engines.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Advanced simulation techniques now incorporate multi-physics models that account for thermal gradients, mechanical stresses, and chemical interactions simultaneously, allowing engineers to optimize material compositions before physical prototyping begins.

Self-healing materials represent perhaps the most innovative development, with embedded microcapsules containing repair agents that activate upon crack initiation. Early applications in non-critical engine components have demonstrated up to 60% recovery of original material properties following damage events, suggesting potential for future implementation in more critical V10 engine components.

Tribological research has yielded specialized materials with optimized surface textures at the micro and nano scales, creating controlled oil retention patterns that maintain lubrication films even under boundary lubrication conditions. These engineered surfaces have demonstrated wear reductions of 25-35% in laboratory testing of simulated engine environments.

The integration of these advanced materials into V10 engine design requires sophisticated manufacturing processes, including precision additive manufacturing techniques that enable complex geometries with tailored material properties throughout the component structure. This approach allows for strategic reinforcement in high-stress areas while optimizing weight distribution for balanced operation.

Environmental Impact and Emissions Considerations for V10 Engines

The environmental impact of V10 engines extends beyond performance considerations, particularly when examining component balancing for wear reduction. V10 engines, known for their power and distinctive sound profile, face increasing scrutiny regarding their emissions output and environmental footprint. The balancing techniques employed to reduce component wear directly influence exhaust emissions through improved combustion efficiency and reduced friction losses.

Modern emissions regulations worldwide have become increasingly stringent, forcing manufacturers to implement advanced balancing technologies that not only extend engine life but also optimize combustion processes. Properly balanced engine components contribute to more complete fuel combustion, reducing unburned hydrocarbon emissions and particulate matter. This relationship between mechanical balance and emissions performance represents a critical engineering consideration in V10 development.

The materials selected for V10 engine components also carry significant environmental implications. Traditional high-performance alloys often contain rare earth elements with environmentally intensive mining processes. Advanced balancing techniques allow for the use of alternative, more sustainable materials without compromising durability or performance characteristics. This materials evolution represents an important frontier in reducing the lifecycle environmental impact of high-performance engines.

Friction reduction through precision balancing directly correlates with decreased fuel consumption. Studies indicate that optimally balanced V10 engines can achieve 3-7% improvements in fuel efficiency compared to engines with standard balancing protocols. This efficiency gain translates to proportional reductions in carbon dioxide emissions over the operational lifespan of the engine, presenting a compelling environmental case for advanced balancing technologies.

The manufacturing processes for precision-balanced components typically require additional energy and resources, creating a complex environmental trade-off. However, lifecycle analyses demonstrate that these initial environmental investments are generally offset by the extended service life and improved operational efficiency of well-balanced engines. The reduced frequency of replacement parts manufacturing and decreased waste from premature component failure further enhance the environmental case for precision balancing.

Noise pollution, often overlooked in emissions discussions, represents another environmental consideration affected by component balancing. Properly balanced V10 engines generate less vibration-induced noise, potentially reducing their contribution to urban sound pollution. This aspect becomes increasingly relevant as environmental regulations expand beyond chemical emissions to include noise standards in many jurisdictions.

Modern emissions regulations worldwide have become increasingly stringent, forcing manufacturers to implement advanced balancing technologies that not only extend engine life but also optimize combustion processes. Properly balanced engine components contribute to more complete fuel combustion, reducing unburned hydrocarbon emissions and particulate matter. This relationship between mechanical balance and emissions performance represents a critical engineering consideration in V10 development.

The materials selected for V10 engine components also carry significant environmental implications. Traditional high-performance alloys often contain rare earth elements with environmentally intensive mining processes. Advanced balancing techniques allow for the use of alternative, more sustainable materials without compromising durability or performance characteristics. This materials evolution represents an important frontier in reducing the lifecycle environmental impact of high-performance engines.

Friction reduction through precision balancing directly correlates with decreased fuel consumption. Studies indicate that optimally balanced V10 engines can achieve 3-7% improvements in fuel efficiency compared to engines with standard balancing protocols. This efficiency gain translates to proportional reductions in carbon dioxide emissions over the operational lifespan of the engine, presenting a compelling environmental case for advanced balancing technologies.

The manufacturing processes for precision-balanced components typically require additional energy and resources, creating a complex environmental trade-off. However, lifecycle analyses demonstrate that these initial environmental investments are generally offset by the extended service life and improved operational efficiency of well-balanced engines. The reduced frequency of replacement parts manufacturing and decreased waste from premature component failure further enhance the environmental case for precision balancing.

Noise pollution, often overlooked in emissions discussions, represents another environmental consideration affected by component balancing. Properly balanced V10 engines generate less vibration-induced noise, potentially reducing their contribution to urban sound pollution. This aspect becomes increasingly relevant as environmental regulations expand beyond chemical emissions to include noise standards in many jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!