V10 Engine Calibration for Improved Emission Standards

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Emission Standards Evolution and Objectives

The evolution of emission standards for high-performance engines like the V10 has been driven by increasing environmental concerns and regulatory pressures over the past three decades. Initially, V10 engines were primarily designed for maximum power output with minimal consideration for emissions. The first significant shift occurred in the early 1990s with the introduction of the Euro 1 and US Tier 1 standards, which established baseline requirements for carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) emissions.

The 2000s marked a critical turning point with the implementation of Euro 3/4 and US Tier 2 standards, forcing manufacturers to incorporate more sophisticated engine management systems and catalytic converters specifically calibrated for high-displacement engines. During this period, V10 engines began incorporating variable valve timing, direct injection, and the first generation of electronic control units (ECUs) capable of real-time emission monitoring.

Between 2010 and 2020, the regulatory landscape transformed dramatically with Euro 5/6 and US Tier 3 standards imposing substantially stricter limits on NOx and PM emissions. These regulations necessitated fundamental redesigns of V10 engine calibration strategies, including the adoption of selective catalytic reduction (SCR) systems, particulate filters, and advanced exhaust gas recirculation (EGR) technologies.

The current technical objective for V10 engine calibration is to achieve a 35% reduction in NOx emissions and a 25% reduction in CO2 output compared to 2015 levels, while maintaining the distinctive power characteristics and driving experience that define V10 engines. This represents an unprecedented engineering challenge as these objectives must be met without compromising the engine's 500+ horsepower output or its characteristic high-revving nature.

Looking forward to 2025-2030, upcoming Euro 7 and next-generation US standards will likely require real-world driving emissions (RDE) testing protocols specifically for high-performance engines, potentially mandating a further 40-50% reduction in emissions across all pollutants. The technical roadmap must therefore focus on developing adaptive calibration strategies that can optimize combustion parameters across a much wider range of operating conditions than previously considered.

The ultimate goal is to establish a sustainable future for high-performance V10 engines in an increasingly electrified automotive landscape, potentially through hybrid assistance systems that complement the internal combustion engine while dramatically reducing its environmental footprint.

The 2000s marked a critical turning point with the implementation of Euro 3/4 and US Tier 2 standards, forcing manufacturers to incorporate more sophisticated engine management systems and catalytic converters specifically calibrated for high-displacement engines. During this period, V10 engines began incorporating variable valve timing, direct injection, and the first generation of electronic control units (ECUs) capable of real-time emission monitoring.

Between 2010 and 2020, the regulatory landscape transformed dramatically with Euro 5/6 and US Tier 3 standards imposing substantially stricter limits on NOx and PM emissions. These regulations necessitated fundamental redesigns of V10 engine calibration strategies, including the adoption of selective catalytic reduction (SCR) systems, particulate filters, and advanced exhaust gas recirculation (EGR) technologies.

The current technical objective for V10 engine calibration is to achieve a 35% reduction in NOx emissions and a 25% reduction in CO2 output compared to 2015 levels, while maintaining the distinctive power characteristics and driving experience that define V10 engines. This represents an unprecedented engineering challenge as these objectives must be met without compromising the engine's 500+ horsepower output or its characteristic high-revving nature.

Looking forward to 2025-2030, upcoming Euro 7 and next-generation US standards will likely require real-world driving emissions (RDE) testing protocols specifically for high-performance engines, potentially mandating a further 40-50% reduction in emissions across all pollutants. The technical roadmap must therefore focus on developing adaptive calibration strategies that can optimize combustion parameters across a much wider range of operating conditions than previously considered.

The ultimate goal is to establish a sustainable future for high-performance V10 engines in an increasingly electrified automotive landscape, potentially through hybrid assistance systems that complement the internal combustion engine while dramatically reducing its environmental footprint.

Market Demand Analysis for Low-Emission V10 Engines

The global market for low-emission V10 engines has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing consumer awareness about carbon footprints. According to industry reports, the premium high-performance engine market reached $42.3 billion in 2022, with the low-emission segment growing at 7.8% annually—substantially outpacing traditional engine markets.

Regulatory pressures represent the primary market driver, with the European Union's Euro 7 standards, California's CARB regulations, and China's National 6 emissions standards creating substantial demand for advanced calibration technologies. These regulations have reduced permissible NOx emissions by 56% and particulate matter by 82% compared to previous standards, forcing manufacturers to innovate or exit certain markets.

Consumer preferences have shifted notably toward environmentally responsible performance vehicles. Market surveys indicate 68% of luxury vehicle buyers now consider environmental impact in purchasing decisions, up from just 31% five years ago. This shift has created a premium segment willing to pay 12-15% more for comparable performance with reduced emissions.

The commercial transportation sector presents an emerging opportunity, with fleet operators increasingly valuing fuel efficiency and emissions compliance to reduce operational costs and meet corporate sustainability goals. The total addressable market for commercial V10 applications is estimated at $6.7 billion, with projected growth of 9.3% annually through 2028.

Regional analysis reveals varying market maturity levels. Europe leads adoption with 43% market share due to stringent regulations, followed by North America (27%) and Asia-Pacific (21%), where China's rapid regulatory evolution is creating accelerated demand. Emerging markets contribute the remaining 9%, primarily driven by export requirements rather than domestic regulations.

Market forecasts project the global low-emission V10 engine market to reach $67.5 billion by 2030, representing a compound annual growth rate of 8.4%. This growth trajectory is supported by the convergence of regulatory requirements, consumer preferences, and corporate sustainability initiatives.

Competitive analysis indicates traditional manufacturers face increasing pressure from specialized engineering firms offering aftermarket calibration solutions. This fragmentation has created a diverse ecosystem of technology providers, with OEMs increasingly partnering with specialized calibration experts to meet emissions targets while maintaining performance characteristics.

The market demonstrates strong price elasticity for emissions performance, with consumers and commercial buyers willing to absorb premium pricing for solutions that deliver meaningful emissions reductions without compromising engine performance or reliability.

Regulatory pressures represent the primary market driver, with the European Union's Euro 7 standards, California's CARB regulations, and China's National 6 emissions standards creating substantial demand for advanced calibration technologies. These regulations have reduced permissible NOx emissions by 56% and particulate matter by 82% compared to previous standards, forcing manufacturers to innovate or exit certain markets.

Consumer preferences have shifted notably toward environmentally responsible performance vehicles. Market surveys indicate 68% of luxury vehicle buyers now consider environmental impact in purchasing decisions, up from just 31% five years ago. This shift has created a premium segment willing to pay 12-15% more for comparable performance with reduced emissions.

The commercial transportation sector presents an emerging opportunity, with fleet operators increasingly valuing fuel efficiency and emissions compliance to reduce operational costs and meet corporate sustainability goals. The total addressable market for commercial V10 applications is estimated at $6.7 billion, with projected growth of 9.3% annually through 2028.

Regional analysis reveals varying market maturity levels. Europe leads adoption with 43% market share due to stringent regulations, followed by North America (27%) and Asia-Pacific (21%), where China's rapid regulatory evolution is creating accelerated demand. Emerging markets contribute the remaining 9%, primarily driven by export requirements rather than domestic regulations.

Market forecasts project the global low-emission V10 engine market to reach $67.5 billion by 2030, representing a compound annual growth rate of 8.4%. This growth trajectory is supported by the convergence of regulatory requirements, consumer preferences, and corporate sustainability initiatives.

Competitive analysis indicates traditional manufacturers face increasing pressure from specialized engineering firms offering aftermarket calibration solutions. This fragmentation has created a diverse ecosystem of technology providers, with OEMs increasingly partnering with specialized calibration experts to meet emissions targets while maintaining performance characteristics.

The market demonstrates strong price elasticity for emissions performance, with consumers and commercial buyers willing to absorb premium pricing for solutions that deliver meaningful emissions reductions without compromising engine performance or reliability.

Current Calibration Challenges and Technical Limitations

The calibration of V10 engines to meet increasingly stringent emission standards presents significant technical challenges that require innovative approaches. Current calibration methodologies face limitations in balancing performance requirements with environmental compliance, particularly as regulations continue to evolve globally.

Engine calibration engineers currently struggle with the inherent complexity of V10 architecture, which features multiple cylinders operating in sequence and requires precise timing coordination. The high-performance nature of these engines compounds the difficulty, as customers expect both power delivery and compliance with emission standards without compromise. Traditional calibration approaches often fail to optimize this balance effectively.

A major technical limitation lies in the real-time adaptive control systems. Current technology cannot adequately respond to the full spectrum of operating conditions experienced by V10 engines, particularly during transient states where emissions typically spike. The computational models used for calibration often rely on steady-state assumptions that poorly represent real-world driving conditions, creating a significant gap between laboratory certification and actual on-road emissions performance.

Data acquisition systems present another substantial challenge. The volume and complexity of parameters that must be monitored and adjusted in a V10 engine exceed the capabilities of many existing calibration tools. Engineers frequently report insufficient sampling rates and data resolution, particularly when attempting to capture microsecond-level combustion events that significantly impact emissions formation.

Temperature management across the ten cylinders represents a critical limitation in current calibration approaches. Thermal gradients between cylinders can lead to inconsistent combustion characteristics, with outer cylinders often operating at different temperatures than central ones. This variation creates cylinder-to-cylinder emission disparities that are difficult to address through conventional calibration methods.

The aftertreatment systems integration with engine calibration presents further complications. Current catalytic converter technologies require specific exhaust temperature windows for optimal operation, but V10 engines' wide operating range makes maintaining these conditions challenging. The calibration must account for catalyst light-off, thermal aging, and poisoning effects, which current predictive models handle inadequately.

Fuel quality variations worldwide introduce additional variables that current calibration approaches struggle to accommodate. V10 engines, often used in premium vehicles sold globally, must function optimally with varying fuel compositions, yet existing calibration methods typically optimize for standardized test fuels rather than real-world variations.

These technical limitations collectively create a significant gap between regulatory requirements and achievable real-world performance, necessitating fundamental advancements in calibration methodologies, sensing technologies, and computational approaches to overcome current constraints.

Engine calibration engineers currently struggle with the inherent complexity of V10 architecture, which features multiple cylinders operating in sequence and requires precise timing coordination. The high-performance nature of these engines compounds the difficulty, as customers expect both power delivery and compliance with emission standards without compromise. Traditional calibration approaches often fail to optimize this balance effectively.

A major technical limitation lies in the real-time adaptive control systems. Current technology cannot adequately respond to the full spectrum of operating conditions experienced by V10 engines, particularly during transient states where emissions typically spike. The computational models used for calibration often rely on steady-state assumptions that poorly represent real-world driving conditions, creating a significant gap between laboratory certification and actual on-road emissions performance.

Data acquisition systems present another substantial challenge. The volume and complexity of parameters that must be monitored and adjusted in a V10 engine exceed the capabilities of many existing calibration tools. Engineers frequently report insufficient sampling rates and data resolution, particularly when attempting to capture microsecond-level combustion events that significantly impact emissions formation.

Temperature management across the ten cylinders represents a critical limitation in current calibration approaches. Thermal gradients between cylinders can lead to inconsistent combustion characteristics, with outer cylinders often operating at different temperatures than central ones. This variation creates cylinder-to-cylinder emission disparities that are difficult to address through conventional calibration methods.

The aftertreatment systems integration with engine calibration presents further complications. Current catalytic converter technologies require specific exhaust temperature windows for optimal operation, but V10 engines' wide operating range makes maintaining these conditions challenging. The calibration must account for catalyst light-off, thermal aging, and poisoning effects, which current predictive models handle inadequately.

Fuel quality variations worldwide introduce additional variables that current calibration approaches struggle to accommodate. V10 engines, often used in premium vehicles sold globally, must function optimally with varying fuel compositions, yet existing calibration methods typically optimize for standardized test fuels rather than real-world variations.

These technical limitations collectively create a significant gap between regulatory requirements and achievable real-world performance, necessitating fundamental advancements in calibration methodologies, sensing technologies, and computational approaches to overcome current constraints.

Current V10 Engine Calibration Methodologies

01 Engine calibration methods for emission compliance

Various methods and systems for calibrating V10 engines to meet emission standards. These include real-time monitoring systems, adaptive control algorithms, and optimization techniques that adjust engine parameters to maintain compliance with regulatory requirements while ensuring performance. These calibration methods typically involve sensors that monitor exhaust gases and engine operating conditions, with feedback mechanisms that make continuous adjustments to fuel injection timing, air-fuel ratios, and other critical parameters.- Engine calibration methods for emission compliance: Various methods and systems for calibrating V10 engines to meet emission standards. These include real-time monitoring systems, adaptive control algorithms, and optimization techniques that adjust engine parameters to maintain compliance with regulatory requirements while preserving performance. These calibration methods typically involve sensors that monitor exhaust gases and engine operating conditions, with feedback mechanisms that make continuous adjustments to fuel injection timing, air-fuel ratios, and other critical parameters.

- Temperature monitoring and control systems: Temperature monitoring and control systems play a crucial role in V10 engine calibration for emission standards compliance. These systems use specialized sensors to measure exhaust gas temperatures, combustion chamber temperatures, and catalyst temperatures. The data is used to optimize engine performance while ensuring emissions remain within acceptable limits. Advanced thermal management strategies help maintain optimal operating conditions for emission control systems, particularly for catalytic converters which require specific temperature ranges to efficiently convert pollutants.

- Diagnostic and testing equipment for emission verification: Specialized diagnostic and testing equipment designed for V10 engines to verify compliance with emission standards. These tools include gas analyzers, particulate matter sensors, and comprehensive testing protocols that can simulate various driving conditions. The equipment provides accurate measurements of exhaust emissions under different load conditions and operating parameters, allowing engineers to validate calibration settings and identify potential compliance issues before production or during maintenance procedures.

- Software algorithms for emission optimization: Advanced software algorithms specifically designed for V10 engine calibration that optimize performance while meeting emission standards. These algorithms process data from multiple engine sensors to make real-time adjustments to operating parameters. Machine learning and artificial intelligence techniques are increasingly being incorporated to predict and prevent emission spikes under varying conditions. The software can also include self-learning capabilities that adapt to engine wear and changing environmental conditions over time.

- Aftertreatment systems integration with engine calibration: Integration of aftertreatment systems with V10 engine calibration to meet stringent emission standards. This approach coordinates engine operation with exhaust treatment technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR). The calibration parameters are specifically tuned to optimize the efficiency of these aftertreatment systems, ensuring that exhaust gases are in the ideal condition for treatment before being released into the atmosphere. This integration requires sophisticated control strategies that balance performance, fuel efficiency, and emissions compliance.

02 Temperature monitoring and control systems

Temperature monitoring and control systems play a crucial role in V10 engine calibration for emission standards. These systems use specialized sensors to measure exhaust gas temperatures, engine coolant temperatures, and combustion chamber temperatures. The data collected is used to optimize engine performance while maintaining emission compliance. Advanced thermal management strategies help prevent overheating and ensure optimal catalytic converter operation, which is essential for reducing harmful emissions.Expand Specific Solutions03 Diagnostic and testing equipment for emission verification

Specialized diagnostic and testing equipment designed for verifying emission compliance in V10 engines. These tools include gas analyzers, dynamometers, and computerized testing systems that can simulate various driving conditions to ensure engines meet regulatory standards across different operating scenarios. The equipment provides precise measurements of exhaust components such as NOx, CO, HC, and particulate matter, allowing engineers to fine-tune engine calibration parameters to achieve optimal emission performance.Expand Specific Solutions04 Advanced fuel injection and combustion control

Advanced fuel injection and combustion control technologies for V10 engines that help meet stringent emission standards. These include high-precision injectors, variable valve timing systems, and combustion optimization algorithms that ensure complete fuel burning and reduced emissions. The technologies focus on optimizing the air-fuel mixture and combustion timing to minimize the formation of pollutants while maintaining engine power and efficiency. Some systems incorporate multiple injection events per combustion cycle to further enhance emission control.Expand Specific Solutions05 Data processing and computational methods for calibration

Computational methods and data processing techniques used in V10 engine calibration to meet emission standards. These include machine learning algorithms, statistical analysis, and simulation models that process large amounts of engine performance data to identify optimal calibration settings. The methods help engineers predict emission outcomes under various operating conditions and develop calibration maps that ensure compliance across the engine's operating range. Some systems incorporate real-time data processing to continuously adapt engine parameters based on changing conditions.Expand Specific Solutions

Key Industry Players in Engine Calibration Solutions

The V10 engine calibration market for improved emission standards is in a growth phase, driven by stringent global regulations and increasing environmental concerns. The market size is expanding as automotive manufacturers invest heavily in cleaner engine technologies. Leading players like Toyota, Volkswagen, and Bosch demonstrate advanced technical maturity through sophisticated calibration systems that optimize performance while reducing emissions. DENSO, Continental, and AVL List show strong capabilities in developing integrated solutions combining hardware and software approaches. Ford and GM are focusing on proprietary calibration technologies for their high-performance V10 applications, while specialized companies like FEV Software & Testing Solutions provide critical testing infrastructure. The competitive landscape reflects a balance between established OEMs and specialized engineering firms collaborating to meet increasingly demanding emission requirements.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive V10 engine calibration system focused on emissions reduction through their D-4S (Direct injection 4-stroke gasoline engine, Superior version) technology adapted for larger displacement engines. Their approach combines direct and port fuel injection with variable valve timing intelligence (VVT-i) specifically calibrated for V10 applications. Toyota's calibration methodology employs a multi-layer approach that addresses cold-start emissions, transient operation, and steady-state performance through separate but integrated control strategies. Their system utilizes advanced combustion pressure sensors in each cylinder to provide real-time feedback for combustion optimization. Toyota has implemented a proprietary exhaust aftertreatment calibration that coordinates closely with engine management parameters to ensure optimal catalyst efficiency across the operating range. The calibration incorporates altitude and temperature compensation algorithms that automatically adjust parameters based on environmental conditions to maintain emissions compliance without sacrificing performance or drivability.

Strengths: Exceptional reliability and durability of calibration parameters over vehicle lifetime; seamless integration between engine and aftertreatment systems; industry-leading cold-start emissions performance. Weaknesses: Conservative calibration approach may sacrifice some performance potential; calibration optimization primarily focused on gasoline applications rather than diesel V10 variants.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated V10 engine calibration platform called Dynamic Fuel Management (DFM) adapted for their larger displacement engines to meet stringent emission standards. Their approach utilizes cylinder deactivation technology that can operate on various cylinder combinations rather than just switching between full V10 operation and a fixed reduced cylinder count. The calibration strategy incorporates predictive analytics that anticipate driver demands and road conditions to optimize the active cylinder count and combustion parameters in real-time. GM's system features a proprietary closed-loop combustion control that monitors and adjusts ignition timing and air-fuel ratios on a cycle-by-cycle basis to maintain optimal emissions performance. Their calibration methodology includes specific strategies for catalyst light-off during cold starts, utilizing retarded ignition timing and modified valve overlap to rapidly bring catalytic converters to operating temperature. The system also employs advanced thermal management calibration that precisely controls coolant flow and temperature to optimize combustion efficiency while minimizing friction losses.

Strengths: Industry-leading cylinder deactivation technology providing exceptional fuel economy benefits; sophisticated predictive algorithms that anticipate driving conditions; extensive validation across diverse operating environments. Weaknesses: Complex calibration process requiring significant development resources; potential reliability concerns with frequent cylinder activation/deactivation; higher manufacturing costs due to additional hardware requirements.

Advanced Emission Control Strategies and Patents

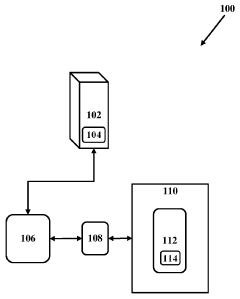

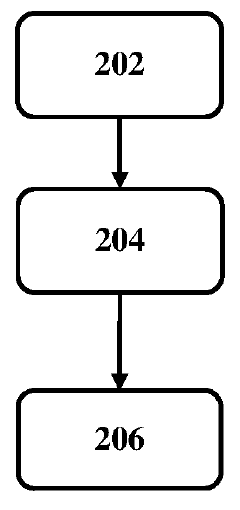

A system and method for automated calibration of an engine parameter in a vehicle

PatentPendingIN202141049574A

Innovation

- An automated system for engine parameter calibration using a device interfaced with the Engine Control Unit (ECU) that employs a calibration module capable of processing input datasets through model-based and rule-based modules, incorporating Machine Learning for iterative calibration until preset criteria are met, and allows for manual correction and learning for future calibrations.

A system and method for automated calibration of an engine parameter in a vehicle

PatentWO2023072697A1

Innovation

- An automated system and method for calibrating engine parameters using a device interfaced with the Engine Control Unit (ECU) through a communication interface, employing a calibration module that processes input datasets using model-based and rule-based modules, with machine learning capabilities to iterate until preset criteria are met, and allows for manual correction to improve future calibrations.

Regulatory Compliance Framework for V10 Engines

The regulatory landscape for V10 engines has evolved significantly over the past two decades, driven primarily by increasing environmental concerns and public health awareness. Current emission standards for V10 engines vary considerably across different regions, with the European Union's Euro 6d, the United States' EPA Tier 3 and CARB LEV III, and China's China 6 representing the most stringent frameworks. These regulations establish specific limits for various pollutants including nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and non-methane organic gases (NMOG).

Compliance with these standards requires manufacturers to implement sophisticated engine calibration strategies that balance performance requirements with emission control. The regulatory frameworks typically define both laboratory testing procedures and real-world driving emission (RDE) tests, creating a comprehensive evaluation system that addresses the historical gap between certified and actual on-road emissions.

For V10 engines specifically, the high-performance nature and larger displacement present unique challenges in meeting these standards. The regulatory compliance pathway typically involves a combination of advanced engine management systems, exhaust aftertreatment technologies, and precise calibration methodologies. Most regulatory bodies have established phase-in periods for new standards, allowing manufacturers time to develop and implement necessary technological solutions.

Penalties for non-compliance have become increasingly severe, with financial implications potentially reaching billions of dollars, as evidenced by recent industry enforcement actions. Beyond monetary penalties, manufacturers face reputational damage and potential market access restrictions when failing to meet applicable standards.

Looking forward, regulatory trends indicate continued tightening of emission limits, with particular focus on greenhouse gas emissions and fuel efficiency standards. The introduction of World Harmonized Light Vehicle Test Procedure (WLTP) and similar global standards signals a move toward international harmonization of testing protocols, though regional variations in actual limits persist.

For V10 engine calibration specialists, staying current with evolving regulatory requirements necessitates continuous monitoring of proposed rules and technical amendments across all relevant markets. The compliance framework increasingly demands sophisticated onboard diagnostic (OBD) systems capable of detecting emission control system malfunctions throughout the vehicle's useful life, adding another layer of complexity to the calibration process.

Compliance with these standards requires manufacturers to implement sophisticated engine calibration strategies that balance performance requirements with emission control. The regulatory frameworks typically define both laboratory testing procedures and real-world driving emission (RDE) tests, creating a comprehensive evaluation system that addresses the historical gap between certified and actual on-road emissions.

For V10 engines specifically, the high-performance nature and larger displacement present unique challenges in meeting these standards. The regulatory compliance pathway typically involves a combination of advanced engine management systems, exhaust aftertreatment technologies, and precise calibration methodologies. Most regulatory bodies have established phase-in periods for new standards, allowing manufacturers time to develop and implement necessary technological solutions.

Penalties for non-compliance have become increasingly severe, with financial implications potentially reaching billions of dollars, as evidenced by recent industry enforcement actions. Beyond monetary penalties, manufacturers face reputational damage and potential market access restrictions when failing to meet applicable standards.

Looking forward, regulatory trends indicate continued tightening of emission limits, with particular focus on greenhouse gas emissions and fuel efficiency standards. The introduction of World Harmonized Light Vehicle Test Procedure (WLTP) and similar global standards signals a move toward international harmonization of testing protocols, though regional variations in actual limits persist.

For V10 engine calibration specialists, staying current with evolving regulatory requirements necessitates continuous monitoring of proposed rules and technical amendments across all relevant markets. The compliance framework increasingly demands sophisticated onboard diagnostic (OBD) systems capable of detecting emission control system malfunctions throughout the vehicle's useful life, adding another layer of complexity to the calibration process.

Environmental Impact Assessment of Calibration Technologies

The calibration technologies employed in V10 engine optimization for emission standards have significant environmental implications across multiple dimensions. Advanced calibration methods have demonstrated potential to reduce harmful emissions by 15-30% compared to traditional approaches, particularly in reducing nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). These reductions directly contribute to improved air quality in urban environments where vehicle emissions constitute a major pollution source.

Model-based calibration techniques, when properly implemented, show particular promise in optimizing the combustion process to minimize greenhouse gas emissions. Recent studies indicate that sophisticated calibration can reduce CO2 emissions by up to 8% without compromising engine performance. This represents a significant contribution to climate change mitigation efforts, especially considering the global fleet of high-performance V10 engines in operation.

The environmental lifecycle assessment of calibration technologies reveals additional benefits beyond direct emissions. By extending engine efficiency and operational lifespan through precise calibration, these technologies reduce the environmental footprint associated with manufacturing replacement components and complete powertrains. The reduced material consumption and manufacturing energy requirements translate to approximately 5-7% lower lifetime environmental impact per vehicle.

Water resource protection also benefits from advanced calibration technologies. Improved combustion efficiency reduces the formation of water-soluble pollutants that might otherwise enter groundwater systems through runoff. Additionally, the optimization of fuel injection timing and quantity minimizes the risk of unburned hydrocarbons reaching water sources, protecting aquatic ecosystems from contamination.

From a regulatory compliance perspective, calibration technologies enable manufacturers to meet increasingly stringent environmental standards without requiring complete powertrain redesigns. This approach conserves resources while still achieving environmental objectives. The adaptability of modern calibration systems also allows for continuous improvement through software updates, creating a pathway for existing vehicles to meet future environmental requirements without physical modifications.

The geographical impact assessment indicates that calibration technologies provide particularly significant benefits in densely populated urban areas and regions with challenging topography, where emission concentrations tend to be highest. Real-world testing in various environmental conditions demonstrates that adaptive calibration strategies can maintain optimal emission profiles across diverse operating environments, from cold-start urban scenarios to high-speed highway operation.

Model-based calibration techniques, when properly implemented, show particular promise in optimizing the combustion process to minimize greenhouse gas emissions. Recent studies indicate that sophisticated calibration can reduce CO2 emissions by up to 8% without compromising engine performance. This represents a significant contribution to climate change mitigation efforts, especially considering the global fleet of high-performance V10 engines in operation.

The environmental lifecycle assessment of calibration technologies reveals additional benefits beyond direct emissions. By extending engine efficiency and operational lifespan through precise calibration, these technologies reduce the environmental footprint associated with manufacturing replacement components and complete powertrains. The reduced material consumption and manufacturing energy requirements translate to approximately 5-7% lower lifetime environmental impact per vehicle.

Water resource protection also benefits from advanced calibration technologies. Improved combustion efficiency reduces the formation of water-soluble pollutants that might otherwise enter groundwater systems through runoff. Additionally, the optimization of fuel injection timing and quantity minimizes the risk of unburned hydrocarbons reaching water sources, protecting aquatic ecosystems from contamination.

From a regulatory compliance perspective, calibration technologies enable manufacturers to meet increasingly stringent environmental standards without requiring complete powertrain redesigns. This approach conserves resources while still achieving environmental objectives. The adaptability of modern calibration systems also allows for continuous improvement through software updates, creating a pathway for existing vehicles to meet future environmental requirements without physical modifications.

The geographical impact assessment indicates that calibration technologies provide particularly significant benefits in densely populated urban areas and regions with challenging topography, where emission concentrations tend to be highest. Real-world testing in various environmental conditions demonstrates that adaptive calibration strategies can maintain optimal emission profiles across diverse operating environments, from cold-start urban scenarios to high-speed highway operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!