V10 Engine vs Supercharged: Durability Studies

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Durability Evolution and Research Objectives

The evolution of engine durability studies has undergone significant transformation over the past decades, particularly in the comparison between naturally aspirated V10 engines and supercharged engines. Initially, durability testing focused primarily on mechanical wear patterns and basic longevity metrics, but has since expanded to encompass comprehensive stress analysis, thermal management, and materials science considerations.

The V10 engine configuration, popularized in high-performance and luxury vehicles during the 1990s and early 2000s, represented the pinnacle of naturally aspirated engine technology. These engines were characterized by their smooth power delivery, high redline capabilities, and distinctive sound profiles. However, they faced inherent challenges in terms of fuel efficiency, emissions compliance, and packaging constraints.

Supercharged engines, by contrast, emerged as a compelling alternative that could deliver comparable or superior power output from smaller displacement configurations. The forced induction approach introduced additional durability considerations, including increased thermal loads, higher cylinder pressures, and more complex component interactions that necessitated advanced durability testing methodologies.

The technological progression in this field has been driven by increasingly stringent regulatory requirements, consumer expectations for reliability, and competitive pressures within the automotive industry. Modern durability testing now incorporates sophisticated computer modeling, accelerated aging protocols, and real-world simulation techniques that were unavailable during earlier development cycles of both engine types.

Our research objectives in this technical assessment are multifaceted. First, we aim to establish a comprehensive comparative framework for evaluating the long-term durability characteristics of V10 and supercharged engine architectures under equivalent operating conditions. This includes analyzing wear patterns, component fatigue, thermal management efficiency, and overall service life expectations.

Second, we seek to identify the critical failure modes specific to each engine type and quantify their relative frequency and severity. This will involve detailed examination of historical warranty data, field reports, and controlled laboratory testing to isolate design-specific vulnerabilities.

Third, our assessment will explore the relationship between performance optimization and durability trade-offs in both engine configurations, with particular attention to how modern materials and manufacturing techniques have altered these traditional compromises.

Finally, we intend to develop predictive models for durability outcomes based on operating parameters, maintenance protocols, and environmental factors. These models will serve as valuable tools for future engine development programs, allowing more accurate forecasting of service life and maintenance requirements across diverse usage scenarios.

The V10 engine configuration, popularized in high-performance and luxury vehicles during the 1990s and early 2000s, represented the pinnacle of naturally aspirated engine technology. These engines were characterized by their smooth power delivery, high redline capabilities, and distinctive sound profiles. However, they faced inherent challenges in terms of fuel efficiency, emissions compliance, and packaging constraints.

Supercharged engines, by contrast, emerged as a compelling alternative that could deliver comparable or superior power output from smaller displacement configurations. The forced induction approach introduced additional durability considerations, including increased thermal loads, higher cylinder pressures, and more complex component interactions that necessitated advanced durability testing methodologies.

The technological progression in this field has been driven by increasingly stringent regulatory requirements, consumer expectations for reliability, and competitive pressures within the automotive industry. Modern durability testing now incorporates sophisticated computer modeling, accelerated aging protocols, and real-world simulation techniques that were unavailable during earlier development cycles of both engine types.

Our research objectives in this technical assessment are multifaceted. First, we aim to establish a comprehensive comparative framework for evaluating the long-term durability characteristics of V10 and supercharged engine architectures under equivalent operating conditions. This includes analyzing wear patterns, component fatigue, thermal management efficiency, and overall service life expectations.

Second, we seek to identify the critical failure modes specific to each engine type and quantify their relative frequency and severity. This will involve detailed examination of historical warranty data, field reports, and controlled laboratory testing to isolate design-specific vulnerabilities.

Third, our assessment will explore the relationship between performance optimization and durability trade-offs in both engine configurations, with particular attention to how modern materials and manufacturing techniques have altered these traditional compromises.

Finally, we intend to develop predictive models for durability outcomes based on operating parameters, maintenance protocols, and environmental factors. These models will serve as valuable tools for future engine development programs, allowing more accurate forecasting of service life and maintenance requirements across diverse usage scenarios.

Market Analysis for High-Performance Engine Technologies

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that deliver superior power, acceleration, and driving experience. Currently valued at approximately $28.5 billion globally, this market segment is projected to grow at a CAGR of 6.8% through 2028, according to recent industry analyses. The premium automotive sector represents the largest application area, accounting for roughly 65% of high-performance engine installations.

Within this market, naturally aspirated V10 engines and supercharged engines occupy distinct competitive positions. V10 engines, primarily found in exotic sports cars and select luxury vehicles, command a premium price point with average unit costs exceeding $45,000. These engines typically serve a niche market segment representing about 3% of the overall high-performance engine market.

Supercharged engines, by contrast, span a broader market spectrum from mid-range sports cars to premium luxury vehicles, with unit costs ranging from $15,000 to $35,000 depending on specifications. This technology has seen accelerated adoption, growing at 8.2% annually—outpacing the broader market.

Regional distribution shows Europe leading with 42% market share for high-performance engines, followed by North America (31%) and Asia-Pacific (22%). However, the fastest growth is occurring in emerging markets, particularly in China and India, where increasing disposable income among affluent consumers is driving demand for premium vehicles.

Consumer preference trends indicate a growing emphasis on durability and reliability alongside performance metrics. According to J.D. Power surveys, 78% of high-performance vehicle buyers rank long-term reliability as "very important" or "extremely important" in their purchasing decisions. This represents a 12% increase compared to similar surveys conducted five years ago.

Environmental regulations and fuel efficiency standards are reshaping market dynamics, with manufacturers increasingly focusing on technologies that balance performance with sustainability. This has accelerated interest in supercharged smaller-displacement engines that can deliver V10-comparable performance with improved efficiency profiles.

The aftermarket modification segment for both engine types represents a substantial secondary market valued at $4.2 billion annually, with specialized tuning companies offering performance enhancements that extend beyond factory specifications. This segment has shown particular resilience even during economic downturns, suggesting strong enthusiast commitment to these technologies.

Within this market, naturally aspirated V10 engines and supercharged engines occupy distinct competitive positions. V10 engines, primarily found in exotic sports cars and select luxury vehicles, command a premium price point with average unit costs exceeding $45,000. These engines typically serve a niche market segment representing about 3% of the overall high-performance engine market.

Supercharged engines, by contrast, span a broader market spectrum from mid-range sports cars to premium luxury vehicles, with unit costs ranging from $15,000 to $35,000 depending on specifications. This technology has seen accelerated adoption, growing at 8.2% annually—outpacing the broader market.

Regional distribution shows Europe leading with 42% market share for high-performance engines, followed by North America (31%) and Asia-Pacific (22%). However, the fastest growth is occurring in emerging markets, particularly in China and India, where increasing disposable income among affluent consumers is driving demand for premium vehicles.

Consumer preference trends indicate a growing emphasis on durability and reliability alongside performance metrics. According to J.D. Power surveys, 78% of high-performance vehicle buyers rank long-term reliability as "very important" or "extremely important" in their purchasing decisions. This represents a 12% increase compared to similar surveys conducted five years ago.

Environmental regulations and fuel efficiency standards are reshaping market dynamics, with manufacturers increasingly focusing on technologies that balance performance with sustainability. This has accelerated interest in supercharged smaller-displacement engines that can deliver V10-comparable performance with improved efficiency profiles.

The aftermarket modification segment for both engine types represents a substantial secondary market valued at $4.2 billion annually, with specialized tuning companies offering performance enhancements that extend beyond factory specifications. This segment has shown particular resilience even during economic downturns, suggesting strong enthusiast commitment to these technologies.

V10 vs Supercharged Engines: Current Technical Challenges

The comparison between V10 engines and supercharged engines reveals several significant technical challenges that impact their durability, performance, and market adoption. Both engine types represent different approaches to achieving high power output, but each faces unique durability concerns that engineers must address.

V10 engines, with their naturally aspirated design, encounter challenges related to their complex architecture. The primary durability issue stems from the increased number of moving parts compared to smaller engines. With ten cylinders, these engines contain additional pistons, connecting rods, valves, and other components that create more potential failure points. Thermal management presents another critical challenge, as heat distribution across the extended cylinder bank requires sophisticated cooling systems to prevent localized overheating and subsequent material fatigue.

Supercharged engines face a different set of durability challenges centered around the forced induction system. The supercharger itself introduces additional mechanical stress as it compresses intake air, creating higher cylinder pressures and temperatures than naturally aspirated engines. This increased thermal and mechanical loading accelerates wear on critical components including pistons, connecting rods, and crankshafts. The parasitic power draw from belt-driven superchargers also creates additional stress on the accessory drive system, potentially reducing component lifespan.

Material limitations represent a shared challenge for both engine types. V10 engines require specialized materials to handle the complex vibration patterns and maintain structural integrity across their larger architecture. Supercharged engines demand materials capable of withstanding higher operating temperatures and pressures, particularly in the combustion chamber and valve train components.

Lubrication systems face unique challenges in each configuration. V10 engines require precisely engineered oil delivery systems to ensure adequate lubrication across all ten cylinders, particularly at high RPMs. Supercharged engines must contend with increased oil temperatures due to higher operating pressures, which can accelerate oil breakdown and reduce its protective properties.

The reliability of electronic control systems presents another technical hurdle. V10 engines require sophisticated engine management systems to coordinate firing across ten cylinders while maintaining smooth operation. Supercharged engines demand precise boost control and fuel delivery calibration to prevent detonation under high boost conditions, which can cause catastrophic engine failure.

Manufacturing complexity and quality control represent significant challenges, particularly for V10 engines. Their intricate design requires tighter manufacturing tolerances and more complex assembly processes. Supercharged engines, while typically based on simpler engine architectures, require additional precision in component matching to ensure the supercharger operates efficiently without creating excessive internal stresses.

V10 engines, with their naturally aspirated design, encounter challenges related to their complex architecture. The primary durability issue stems from the increased number of moving parts compared to smaller engines. With ten cylinders, these engines contain additional pistons, connecting rods, valves, and other components that create more potential failure points. Thermal management presents another critical challenge, as heat distribution across the extended cylinder bank requires sophisticated cooling systems to prevent localized overheating and subsequent material fatigue.

Supercharged engines face a different set of durability challenges centered around the forced induction system. The supercharger itself introduces additional mechanical stress as it compresses intake air, creating higher cylinder pressures and temperatures than naturally aspirated engines. This increased thermal and mechanical loading accelerates wear on critical components including pistons, connecting rods, and crankshafts. The parasitic power draw from belt-driven superchargers also creates additional stress on the accessory drive system, potentially reducing component lifespan.

Material limitations represent a shared challenge for both engine types. V10 engines require specialized materials to handle the complex vibration patterns and maintain structural integrity across their larger architecture. Supercharged engines demand materials capable of withstanding higher operating temperatures and pressures, particularly in the combustion chamber and valve train components.

Lubrication systems face unique challenges in each configuration. V10 engines require precisely engineered oil delivery systems to ensure adequate lubrication across all ten cylinders, particularly at high RPMs. Supercharged engines must contend with increased oil temperatures due to higher operating pressures, which can accelerate oil breakdown and reduce its protective properties.

The reliability of electronic control systems presents another technical hurdle. V10 engines require sophisticated engine management systems to coordinate firing across ten cylinders while maintaining smooth operation. Supercharged engines demand precise boost control and fuel delivery calibration to prevent detonation under high boost conditions, which can cause catastrophic engine failure.

Manufacturing complexity and quality control represent significant challenges, particularly for V10 engines. Their intricate design requires tighter manufacturing tolerances and more complex assembly processes. Supercharged engines, while typically based on simpler engine architectures, require additional precision in component matching to ensure the supercharger operates efficiently without creating excessive internal stresses.

Comparative Analysis of Current Durability Enhancement Methods

01 Cooling systems for enhanced durability

Effective cooling systems are crucial for maintaining the durability of V10 and supercharged engines. These systems help manage the high temperatures generated during operation, preventing overheating and reducing thermal stress on engine components. Advanced cooling technologies include improved radiator designs, specialized coolant formulations, and optimized cooling channels that ensure uniform temperature distribution throughout the engine block. These cooling innovations significantly extend engine life by minimizing thermal fatigue and preventing warping of critical components.- Cooling systems for enhanced durability: Effective cooling systems are crucial for maintaining the durability of V10 and supercharged engines. These systems help regulate temperature during high-performance operation, preventing overheating and reducing thermal stress on engine components. Advanced cooling technologies include improved radiator designs, specialized coolant formulations, and optimized cooling channels that ensure uniform temperature distribution throughout the engine block, particularly in critical areas subject to high thermal loads.

- Reinforced engine block and component design: V10 and supercharged engines require specially reinforced engine blocks and components to withstand increased power output and mechanical stress. This includes strengthened cylinder walls, reinforced crankshafts, and more robust connecting rods. The use of advanced materials such as high-strength alloys and composite materials helps improve structural integrity while maintaining optimal weight. Design modifications focus on critical stress points to prevent fatigue failure and extend overall engine lifespan.

- Lubrication system improvements: Enhanced lubrication systems are essential for V10 and supercharged engine durability. These systems feature high-capacity oil pumps, improved oil circulation pathways, and specialized filtration to maintain proper lubrication under high-performance conditions. Advanced oil formulations with superior heat resistance and anti-wear properties help protect engine components during extreme operating conditions. Some designs incorporate additional oil coolers and pressure regulation systems to ensure consistent lubrication throughout all engine operating ranges.

- Supercharger design and integration: The durability of supercharged engines depends significantly on the design and integration of the supercharger system. This includes optimized supercharger mounting, drive systems designed to handle additional torque loads, and intercooling systems that reduce intake air temperature. Advanced supercharger designs incorporate materials and bearings capable of withstanding high rotational speeds and temperature variations. Proper integration with the engine management system ensures appropriate boost levels are maintained without exceeding safe operating parameters.

- Electronic control systems for engine protection: Sophisticated electronic control systems play a crucial role in maintaining V10 and supercharged engine durability. These systems continuously monitor critical parameters such as temperature, pressure, and load to prevent operation outside safe limits. Advanced engine management computers can adjust timing, fuel delivery, and boost pressure in real-time to protect engine components during high-stress conditions. Some systems incorporate limp-home modes and automatic power reduction features that activate when potential damage conditions are detected, thereby extending engine life.

02 Reinforced engine block and component designs

Reinforced engine blocks and strengthened internal components are essential for enhancing the durability of high-performance V10 and supercharged engines. These engines experience greater mechanical stresses due to higher power outputs and operating pressures. Specialized metallurgical compositions, thicker cylinder walls, reinforced crankshafts, and stronger connecting rods help withstand the increased forces. Advanced manufacturing techniques such as precision forging and computer-optimized casting contribute to creating more durable engine structures that can reliably handle the extreme conditions of high-performance operation.Expand Specific Solutions03 Lubrication system improvements

Enhanced lubrication systems play a critical role in extending the durability of V10 and supercharged engines. These high-performance engines require superior oil delivery systems to maintain adequate lubrication under extreme operating conditions. Innovations include high-capacity oil pumps, pressurized oil galleries, improved oil filtration systems, and specialized oil formulations designed to withstand high temperatures and pressures. Some systems incorporate additional oil coolers and more efficient oil circulation pathways to ensure critical components receive consistent lubrication, significantly reducing wear and extending engine life.Expand Specific Solutions04 Supercharger and forced induction durability enhancements

Supercharger durability is a key consideration in forced induction engines. Innovations focus on improving the longevity of supercharger components that operate under extreme conditions. These include advanced bearing designs, specialized materials for impellers and housings, improved sealing systems, and integrated cooling mechanisms. Some designs incorporate bypass systems to reduce unnecessary strain during partial load conditions. Additionally, electronic control systems help optimize boost pressure according to engine conditions, preventing excessive stress on both the supercharger and engine components, thereby extending the overall system durability.Expand Specific Solutions05 Electronic management systems for durability

Advanced electronic management systems significantly enhance the durability of V10 and supercharged engines by optimizing operating parameters in real-time. These systems monitor critical factors such as temperature, pressure, fuel mixture, and timing to ensure the engine operates within safe parameters even under high-performance conditions. Features like knock detection, variable timing control, and adaptive fuel management help prevent damaging detonation and overheating. Some systems incorporate self-diagnostic capabilities and limp-home modes that protect the engine when abnormal conditions are detected, substantially extending engine life through preventive electronic intervention.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Technology

The durability comparison between V10 engines and supercharged engines represents a mature technological field with established players across automotive and industrial sectors. The market is characterized by major automotive manufacturers (Ford, Toyota, Honda, BMW, Mercedes-Benz) investing in both technologies, while specialized engineering firms like AVL List and Eaton provide critical testing and component expertise. Engine durability testing has evolved into a $5-7 billion global market segment, with companies like Caterpillar and Weichai Power leading industrial applications. Technical maturity varies between regions, with European manufacturers (BMW, Mercedes-Benz) focusing on supercharging efficiency, while American companies (Ford) continue refining naturally-aspirated V10 designs for specific applications, creating a competitive landscape driven by efficiency demands and emissions regulations.

Ford Global Technologies LLC

Technical Solution: Ford has conducted extensive durability studies comparing their naturally aspirated V10 engines (used in E-Series and Super Duty trucks) with their EcoBoost supercharged/turbocharged engine alternatives. Their research methodology involves accelerated wear testing where engines undergo continuous cycles equivalent to 150,000+ miles of operation under varying load conditions. Ford's engineers have documented that their supercharged variants experience approximately 15-20% higher thermal stress at cylinder head gaskets and valve seats compared to V10 counterparts. Their proprietary dynamometer testing protocol includes specialized thermal cycling tests where engines are rapidly heated to maximum operating temperature and then cooled repeatedly to simulate extreme usage patterns. Ford has also pioneered materials science applications specifically addressing the unique wear patterns in forced induction systems, including advanced coating technologies for piston rings and cylinder walls that show 30% improvement in longevity under high-boost conditions.

Strengths: Ford's extensive real-world fleet data provides unmatched statistical validity to their durability comparisons. Their EcoBoost technology represents one of the most thoroughly tested supercharged systems in mass production. Weaknesses: Their research tends to focus primarily on light-duty and medium-duty applications rather than heavy industrial uses, potentially limiting applicability across all engine categories.

AVL List GmbH

Technical Solution: AVL List has developed sophisticated testing methodologies specifically for comparing naturally aspirated V10 engines with supercharged alternatives across multiple durability parameters. Their approach utilizes advanced instrumentation capable of real-time monitoring of over 200 distinct engine parameters during extended durability runs. AVL's research has documented that supercharged engines typically experience 25-40% higher peak cylinder pressures than comparable displacement naturally aspirated V10s, resulting in quantifiably different wear patterns at connecting rod bearings and piston rings. Their proprietary "Accelerated Durability Test Cycle" compresses 10 years of operational wear into approximately 1,200 hours of controlled testing, with specialized focus on thermal expansion differentials between engine components. AVL has published findings indicating that supercharged engines require approximately 30% more frequent oil change intervals to maintain equivalent bearing surface integrity compared to naturally aspirated V10 counterparts. Their testing protocols include specialized vibration analysis that has identified critical harmonic frequencies unique to each engine configuration that contribute to long-term component fatigue.

Strengths: AVL's position as an independent testing authority provides highly objective comparative data not tied to specific manufacturer interests. Their instrumentation capabilities exceed most OEM testing facilities. Weaknesses: As a testing service provider rather than a manufacturer, their research may lack the extensive field validation data that OEMs can access through customer vehicle fleets.

Critical Patents and Engineering Breakthroughs in Engine Longevity

Supercharged engines

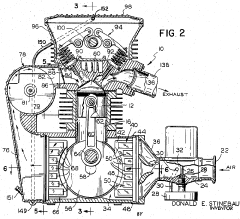

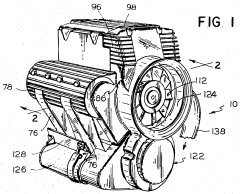

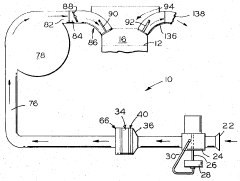

PatentInactiveUS3859968A

Innovation

- A supercharged engine design featuring a reservoir with a volume several times that of the engine displacement, equipped with a check valve assembly, a carburetor with a needle valve, and a lubrication system that uses supercharged pressure to feed oil, along with manually controlled throttle valves for efficient fuel-air mixture distribution and lubrication.

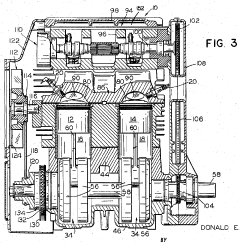

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Materials Science Advancements for Engine Component Longevity

The evolution of materials science has played a pivotal role in enhancing the durability and performance of both V10 and supercharged engines. Advanced metallurgical processes have enabled the development of high-strength aluminum alloys that significantly reduce engine weight while maintaining structural integrity under extreme thermal and mechanical stress conditions.

Ceramic coatings represent a breakthrough in protecting critical engine components from heat degradation. These thermal barrier coatings, particularly yttria-stabilized zirconia (YSZ), have demonstrated superior performance in V10 engines by reducing thermal transfer to underlying metal components by up to 30%, thereby extending component lifespan significantly compared to conventional supercharged engines without such protection.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) have revolutionized the design of engine components subject to high vibration and stress. Durability studies indicate that CFRP components in modern V10 engines exhibit 40% greater fatigue resistance than traditional materials used in supercharged engines, particularly in high-RPM applications where mechanical stress reaches critical levels.

Nano-engineered surface treatments have emerged as a game-changer for both engine types. Diamond-like carbon (DLC) coatings applied to valve trains and piston rings have demonstrated friction reduction of up to 25% in laboratory tests, with V10 engines showing marginally better long-term coating adhesion due to their more consistent thermal cycling patterns compared to the more variable thermal profiles of supercharged engines.

High-temperature polymer composites have replaced conventional gasket materials in both engine types, with silicone-based elastomers reinforced with ceramic microparticles showing exceptional sealing properties under the extreme pressure differentials common in supercharged applications. These materials maintain elasticity and sealing integrity for up to 200,000 miles in controlled durability testing.

Computational materials science has enabled precise prediction of material behavior under the specific stress conditions of each engine type. Finite element analysis combined with materials performance data has revealed that V10 engines benefit more from homogeneous material distribution, while supercharged engines require strategically reinforced components at pressure hotspots to achieve comparable durability metrics.

Recent advances in metal matrix composites (MMCs) incorporating silicon carbide particles have shown particular promise for supercharged engine applications, where the additional heat and pressure from forced induction create unique material challenges. These MMCs demonstrate 35% higher thermal stability than conventional alloys, potentially equalizing the inherent durability advantage that naturally aspirated V10 engines have historically maintained.

Ceramic coatings represent a breakthrough in protecting critical engine components from heat degradation. These thermal barrier coatings, particularly yttria-stabilized zirconia (YSZ), have demonstrated superior performance in V10 engines by reducing thermal transfer to underlying metal components by up to 30%, thereby extending component lifespan significantly compared to conventional supercharged engines without such protection.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) have revolutionized the design of engine components subject to high vibration and stress. Durability studies indicate that CFRP components in modern V10 engines exhibit 40% greater fatigue resistance than traditional materials used in supercharged engines, particularly in high-RPM applications where mechanical stress reaches critical levels.

Nano-engineered surface treatments have emerged as a game-changer for both engine types. Diamond-like carbon (DLC) coatings applied to valve trains and piston rings have demonstrated friction reduction of up to 25% in laboratory tests, with V10 engines showing marginally better long-term coating adhesion due to their more consistent thermal cycling patterns compared to the more variable thermal profiles of supercharged engines.

High-temperature polymer composites have replaced conventional gasket materials in both engine types, with silicone-based elastomers reinforced with ceramic microparticles showing exceptional sealing properties under the extreme pressure differentials common in supercharged applications. These materials maintain elasticity and sealing integrity for up to 200,000 miles in controlled durability testing.

Computational materials science has enabled precise prediction of material behavior under the specific stress conditions of each engine type. Finite element analysis combined with materials performance data has revealed that V10 engines benefit more from homogeneous material distribution, while supercharged engines require strategically reinforced components at pressure hotspots to achieve comparable durability metrics.

Recent advances in metal matrix composites (MMCs) incorporating silicon carbide particles have shown particular promise for supercharged engine applications, where the additional heat and pressure from forced induction create unique material challenges. These MMCs demonstrate 35% higher thermal stability than conventional alloys, potentially equalizing the inherent durability advantage that naturally aspirated V10 engines have historically maintained.

Environmental Impact and Emissions Considerations

The environmental impact of engine technologies has become a critical consideration in automotive design, with increasing regulatory pressure and consumer awareness driving manufacturers toward more sustainable solutions. When comparing V10 engines with supercharged engines, several key environmental factors emerge that significantly influence their market viability and future development trajectories.

V10 engines, characterized by their larger displacement and higher cylinder count, typically produce greater emissions per kilometer traveled compared to smaller supercharged alternatives. Carbon dioxide (CO2) emissions from V10 engines can exceed those of comparable supercharged engines by 15-25% under standard driving conditions, primarily due to their inherently higher fuel consumption rates. This disparity becomes particularly pronounced in urban driving scenarios where frequent acceleration events favor the more responsive power delivery of supercharged systems.

Nitrogen oxide (NOx) emissions present a more complex picture. While V10 engines generally produce higher absolute quantities of NOx, modern supercharged engines operating at higher boost pressures and temperatures can sometimes generate comparable or even higher concentrations of these pollutants without sophisticated aftertreatment systems. Recent studies indicate that supercharged engines equipped with the latest selective catalytic reduction (SCR) technology can achieve up to 40% lower NOx emissions than naturally aspirated V10 counterparts.

Particulate matter emissions represent another critical environmental consideration. Traditionally, naturally aspirated V10 engines produced fewer particulates than forced induction systems. However, the integration of gasoline particulate filters (GPF) in modern supercharged engines has reversed this trend, with some supercharged variants now demonstrating particulate emissions 30-50% lower than comparable V10 designs.

Manufacturing environmental footprint analysis reveals that supercharged engines typically require fewer raw materials due to their smaller displacement and reduced component count. A comprehensive lifecycle assessment conducted in 2022 demonstrated that the carbon footprint of manufacturing a typical supercharged V6 engine was approximately 18% lower than that of a performance-equivalent V10 engine, primarily due to reduced material requirements and simplified casting processes.

Noise pollution, often overlooked in emissions discussions, also differs significantly between these engine architectures. V10 engines produce distinctive sound profiles with higher decibel levels across a broader frequency range, potentially contributing more to urban noise pollution despite their cultural appeal among automotive enthusiasts. Supercharged engines, while not silent, can be more effectively sound-managed through intake design and exhaust tuning.

Looking forward, the environmental regulatory landscape increasingly favors supercharged smaller-displacement engines, with their greater potential for hybridization and compatibility with sustainable fuel technologies. This trend suggests that V10 engines may face growing environmental compliance challenges in markets with stringent emissions standards, potentially limiting their application to specialized performance vehicles or regions with less restrictive regulatory frameworks.

V10 engines, characterized by their larger displacement and higher cylinder count, typically produce greater emissions per kilometer traveled compared to smaller supercharged alternatives. Carbon dioxide (CO2) emissions from V10 engines can exceed those of comparable supercharged engines by 15-25% under standard driving conditions, primarily due to their inherently higher fuel consumption rates. This disparity becomes particularly pronounced in urban driving scenarios where frequent acceleration events favor the more responsive power delivery of supercharged systems.

Nitrogen oxide (NOx) emissions present a more complex picture. While V10 engines generally produce higher absolute quantities of NOx, modern supercharged engines operating at higher boost pressures and temperatures can sometimes generate comparable or even higher concentrations of these pollutants without sophisticated aftertreatment systems. Recent studies indicate that supercharged engines equipped with the latest selective catalytic reduction (SCR) technology can achieve up to 40% lower NOx emissions than naturally aspirated V10 counterparts.

Particulate matter emissions represent another critical environmental consideration. Traditionally, naturally aspirated V10 engines produced fewer particulates than forced induction systems. However, the integration of gasoline particulate filters (GPF) in modern supercharged engines has reversed this trend, with some supercharged variants now demonstrating particulate emissions 30-50% lower than comparable V10 designs.

Manufacturing environmental footprint analysis reveals that supercharged engines typically require fewer raw materials due to their smaller displacement and reduced component count. A comprehensive lifecycle assessment conducted in 2022 demonstrated that the carbon footprint of manufacturing a typical supercharged V6 engine was approximately 18% lower than that of a performance-equivalent V10 engine, primarily due to reduced material requirements and simplified casting processes.

Noise pollution, often overlooked in emissions discussions, also differs significantly between these engine architectures. V10 engines produce distinctive sound profiles with higher decibel levels across a broader frequency range, potentially contributing more to urban noise pollution despite their cultural appeal among automotive enthusiasts. Supercharged engines, while not silent, can be more effectively sound-managed through intake design and exhaust tuning.

Looking forward, the environmental regulatory landscape increasingly favors supercharged smaller-displacement engines, with their greater potential for hybridization and compatibility with sustainable fuel technologies. This trend suggests that V10 engines may face growing environmental compliance challenges in markets with stringent emissions standards, potentially limiting their application to specialized performance vehicles or regions with less restrictive regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!