V10 Engine for Stationary Power Generation Solutions

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Technology Background and Objectives

The V10 engine configuration represents a significant milestone in internal combustion engine development, combining substantial power output with relatively compact dimensions. Originally developed for high-performance automotive applications, V10 engines have evolved to become viable solutions for stationary power generation due to their favorable power-to-weight ratio and operational efficiency characteristics.

The historical trajectory of V10 engine technology began in the mid-20th century, primarily in racing and luxury automotive sectors. However, the adaptation of these engines for stationary power generation represents a more recent technological pivot, driven by increasing demands for reliable, efficient, and scalable power solutions across various industrial applications, remote installations, and backup power systems.

Current market trends indicate a growing need for intermediate-scale power generation solutions that bridge the gap between smaller generators and large industrial power plants. The V10 engine configuration addresses this niche effectively, offering power outputs typically ranging from 200kW to 800kW, depending on displacement and specific design parameters.

The technological evolution of V10 engines for stationary applications has focused on several key areas: fuel efficiency optimization, emissions reduction, durability enhancement, and adaptability to various fuel types including natural gas, biogas, and diesel. These developments align with broader industry goals of sustainability and operational cost reduction while maintaining reliable performance.

Recent advancements in materials science, combustion optimization, and electronic control systems have significantly enhanced the viability of V10 engines in stationary power applications. Modern V10 generators benefit from precision-engineered components that reduce mechanical losses, advanced cooling systems that optimize thermal efficiency, and sophisticated engine management systems that maintain optimal operating parameters under varying load conditions.

The primary technical objectives for V10 stationary power generation solutions include achieving higher thermal efficiency (targeting 40-45% for modern designs), reducing emissions to meet increasingly stringent regulatory standards, extending service intervals and overall operational lifespan, and improving load response characteristics for applications requiring rapid power delivery.

Future development trajectories for V10 stationary power solutions are likely to focus on hybridization potential, integration with renewable energy systems, further emissions reductions through advanced aftertreatment technologies, and enhanced digital monitoring and predictive maintenance capabilities. These objectives reflect the industry's movement toward more sustainable, intelligent, and integrated power generation systems that can operate effectively within evolving energy infrastructures.

The historical trajectory of V10 engine technology began in the mid-20th century, primarily in racing and luxury automotive sectors. However, the adaptation of these engines for stationary power generation represents a more recent technological pivot, driven by increasing demands for reliable, efficient, and scalable power solutions across various industrial applications, remote installations, and backup power systems.

Current market trends indicate a growing need for intermediate-scale power generation solutions that bridge the gap between smaller generators and large industrial power plants. The V10 engine configuration addresses this niche effectively, offering power outputs typically ranging from 200kW to 800kW, depending on displacement and specific design parameters.

The technological evolution of V10 engines for stationary applications has focused on several key areas: fuel efficiency optimization, emissions reduction, durability enhancement, and adaptability to various fuel types including natural gas, biogas, and diesel. These developments align with broader industry goals of sustainability and operational cost reduction while maintaining reliable performance.

Recent advancements in materials science, combustion optimization, and electronic control systems have significantly enhanced the viability of V10 engines in stationary power applications. Modern V10 generators benefit from precision-engineered components that reduce mechanical losses, advanced cooling systems that optimize thermal efficiency, and sophisticated engine management systems that maintain optimal operating parameters under varying load conditions.

The primary technical objectives for V10 stationary power generation solutions include achieving higher thermal efficiency (targeting 40-45% for modern designs), reducing emissions to meet increasingly stringent regulatory standards, extending service intervals and overall operational lifespan, and improving load response characteristics for applications requiring rapid power delivery.

Future development trajectories for V10 stationary power solutions are likely to focus on hybridization potential, integration with renewable energy systems, further emissions reductions through advanced aftertreatment technologies, and enhanced digital monitoring and predictive maintenance capabilities. These objectives reflect the industry's movement toward more sustainable, intelligent, and integrated power generation systems that can operate effectively within evolving energy infrastructures.

Market Demand Analysis for Stationary Power Generation

The global stationary power generation market is experiencing significant growth, driven by increasing energy demands, industrialization, and the need for reliable backup power systems. The market size for stationary power generation solutions reached approximately $73 billion in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030. This growth trajectory underscores the robust demand for advanced power generation technologies like the V10 engine solutions.

Key market segments driving demand include industrial facilities, commercial buildings, data centers, healthcare institutions, and remote communities. Industrial applications represent the largest market share at 38%, followed by commercial applications at 27%. The increasing frequency of power outages due to aging grid infrastructure and extreme weather events has heightened the need for reliable backup power systems across these segments.

Regionally, Asia-Pacific dominates the market with 42% share, fueled by rapid industrialization in countries like China and India. North America follows at 28%, with Europe accounting for 21% of the global market. Emerging economies in Africa and Latin America represent smaller but rapidly growing markets, with annual growth rates exceeding 7%.

The demand for V10 engines in stationary power generation is particularly strong in the 250-500 kW power range, where they offer an optimal balance of power density, fuel efficiency, and operational flexibility. This power range serves medium-sized industrial facilities, commercial complexes, and critical infrastructure applications effectively.

Market research indicates a growing preference for multi-fuel capability in stationary power generation solutions. Customers increasingly demand engines that can operate on traditional fuels (diesel, natural gas) as well as alternative fuels like biogas, hydrogen blends, and synthetic fuels. This trend aligns with global sustainability initiatives and provides operational flexibility in regions with variable fuel availability.

Reliability metrics have become paramount in customer purchasing decisions, with 87% of surveyed customers ranking system reliability as their top consideration. The average acceptable downtime has decreased from 4 hours per year to less than 1 hour, highlighting the critical nature of continuous power supply in modern operations.

Cost considerations remain significant, with total cost of ownership (TCO) increasingly replacing initial capital expenditure as the primary financial metric. Customers are willing to pay premium prices for systems that demonstrate superior fuel efficiency, lower maintenance requirements, and extended service intervals. The market shows particular interest in solutions offering 15% or greater improvement in fuel efficiency compared to previous generation technologies.

Key market segments driving demand include industrial facilities, commercial buildings, data centers, healthcare institutions, and remote communities. Industrial applications represent the largest market share at 38%, followed by commercial applications at 27%. The increasing frequency of power outages due to aging grid infrastructure and extreme weather events has heightened the need for reliable backup power systems across these segments.

Regionally, Asia-Pacific dominates the market with 42% share, fueled by rapid industrialization in countries like China and India. North America follows at 28%, with Europe accounting for 21% of the global market. Emerging economies in Africa and Latin America represent smaller but rapidly growing markets, with annual growth rates exceeding 7%.

The demand for V10 engines in stationary power generation is particularly strong in the 250-500 kW power range, where they offer an optimal balance of power density, fuel efficiency, and operational flexibility. This power range serves medium-sized industrial facilities, commercial complexes, and critical infrastructure applications effectively.

Market research indicates a growing preference for multi-fuel capability in stationary power generation solutions. Customers increasingly demand engines that can operate on traditional fuels (diesel, natural gas) as well as alternative fuels like biogas, hydrogen blends, and synthetic fuels. This trend aligns with global sustainability initiatives and provides operational flexibility in regions with variable fuel availability.

Reliability metrics have become paramount in customer purchasing decisions, with 87% of surveyed customers ranking system reliability as their top consideration. The average acceptable downtime has decreased from 4 hours per year to less than 1 hour, highlighting the critical nature of continuous power supply in modern operations.

Cost considerations remain significant, with total cost of ownership (TCO) increasingly replacing initial capital expenditure as the primary financial metric. Customers are willing to pay premium prices for systems that demonstrate superior fuel efficiency, lower maintenance requirements, and extended service intervals. The market shows particular interest in solutions offering 15% or greater improvement in fuel efficiency compared to previous generation technologies.

Current State and Technical Challenges of V10 Engines

V10 engines for stationary power generation currently represent a significant segment of the medium-to-large scale power solutions market. These engines typically deliver power outputs ranging from 500 kW to 2 MW, positioning them as versatile options for various applications including industrial facilities, data centers, and remote power stations. The current generation of V10 engines achieves thermal efficiency rates between 40-45%, which while impressive, still falls short of theoretical maximums by a considerable margin.

Recent advancements in V10 engine technology have focused on improving fuel flexibility, with modern designs capable of operating on natural gas, biogas, diesel, and various biofuels. This adaptability has expanded their market relevance, particularly in regions with unstable fuel supply chains or those transitioning toward renewable energy sources. Additionally, emissions control systems have evolved significantly, with selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) becoming standard features to meet increasingly stringent environmental regulations.

Despite these advancements, V10 engines face several critical technical challenges. Heat management remains problematic, particularly in continuous operation scenarios where thermal stress can lead to premature component failure. Current cooling systems struggle to maintain optimal operating temperatures under variable load conditions, resulting in efficiency losses and increased maintenance requirements. Material limitations also persist, with conventional alloys showing signs of fatigue and degradation when subjected to the high temperatures and pressures characteristic of high-efficiency operation.

Combustion optimization presents another significant challenge. While computational fluid dynamics has improved combustion chamber design, achieving consistent, complete combustion across all cylinders remains difficult, especially when operating with variable fuel qualities. This inconsistency leads to power output fluctuations and increased emissions, particularly during transient load conditions. Furthermore, the integration of these engines with renewable energy systems presents compatibility issues, as V10 engines typically lack the rapid response capabilities needed for seamless grid stabilization.

Maintenance requirements continue to be a limiting factor in widespread adoption. Current V10 engines require service intervals every 1,000-2,000 operating hours, significantly more frequent than some competing technologies. This translates to higher operational costs and reduced availability, particularly problematic for critical power applications. The complexity of modern engine management systems also necessitates specialized technical expertise, creating workforce challenges in many deployment regions.

Globally, V10 engine technology development shows geographic concentration, with European manufacturers leading in efficiency innovations while North American companies focus on durability and fuel flexibility. Asian manufacturers have made significant strides in cost reduction and manufacturing optimization, though often at the expense of longevity and performance under extreme conditions.

Recent advancements in V10 engine technology have focused on improving fuel flexibility, with modern designs capable of operating on natural gas, biogas, diesel, and various biofuels. This adaptability has expanded their market relevance, particularly in regions with unstable fuel supply chains or those transitioning toward renewable energy sources. Additionally, emissions control systems have evolved significantly, with selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) becoming standard features to meet increasingly stringent environmental regulations.

Despite these advancements, V10 engines face several critical technical challenges. Heat management remains problematic, particularly in continuous operation scenarios where thermal stress can lead to premature component failure. Current cooling systems struggle to maintain optimal operating temperatures under variable load conditions, resulting in efficiency losses and increased maintenance requirements. Material limitations also persist, with conventional alloys showing signs of fatigue and degradation when subjected to the high temperatures and pressures characteristic of high-efficiency operation.

Combustion optimization presents another significant challenge. While computational fluid dynamics has improved combustion chamber design, achieving consistent, complete combustion across all cylinders remains difficult, especially when operating with variable fuel qualities. This inconsistency leads to power output fluctuations and increased emissions, particularly during transient load conditions. Furthermore, the integration of these engines with renewable energy systems presents compatibility issues, as V10 engines typically lack the rapid response capabilities needed for seamless grid stabilization.

Maintenance requirements continue to be a limiting factor in widespread adoption. Current V10 engines require service intervals every 1,000-2,000 operating hours, significantly more frequent than some competing technologies. This translates to higher operational costs and reduced availability, particularly problematic for critical power applications. The complexity of modern engine management systems also necessitates specialized technical expertise, creating workforce challenges in many deployment regions.

Globally, V10 engine technology development shows geographic concentration, with European manufacturers leading in efficiency innovations while North American companies focus on durability and fuel flexibility. Asian manufacturers have made significant strides in cost reduction and manufacturing optimization, though often at the expense of longevity and performance under extreme conditions.

Current V10 Engine Solutions for Power Generation

01 V10 Engine Design and Structure

The design and structure of V10 engines focus on the arrangement of cylinders in a V-configuration, providing a balance between power output and engine size. These engines typically feature ten cylinders arranged in two banks of five, creating a V-shape. The design allows for higher power output while maintaining a relatively compact size compared to inline configurations with the same number of cylinders.- V10 Engine Design and Configuration: V10 engines feature a specific configuration with ten cylinders arranged in a V-shape. This design offers a balance between power output and compact dimensions, making it suitable for high-performance applications. The V-angle and cylinder arrangement contribute to the engine's characteristics including power delivery, vibration management, and overall efficiency.

- V10 Engine Performance Enhancements: Various technological innovations are implemented to enhance V10 engine performance, including advanced fuel injection systems, variable valve timing, and optimized combustion chambers. These enhancements aim to improve power output, torque delivery, fuel efficiency, and emissions control while maintaining the distinctive characteristics of the V10 configuration.

- V10 Engine Integration in Vehicles: The integration of V10 engines into vehicle platforms requires specific mounting systems, cooling arrangements, and exhaust configurations. These integration solutions address challenges related to weight distribution, thermal management, and packaging constraints while maximizing the performance benefits of the V10 engine architecture.

- V10 Engine Aesthetic and Industrial Design: The visual and industrial design aspects of V10 engines encompass distinctive styling elements, component layouts, and external appearances. These design features not only serve functional purposes but also contribute to brand identity and product differentiation in high-performance vehicles and other applications utilizing V10 power plants.

- V10 Engine Components and Accessories: Specialized components and accessories for V10 engines include custom intake manifolds, exhaust systems, cooling components, and electronic control modules. These elements are designed specifically for the V10 architecture to optimize performance, reliability, and serviceability while addressing the unique requirements of this engine configuration.

02 V10 Engine Performance Optimization

Various technologies and methods are employed to optimize the performance of V10 engines, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging. These optimizations aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining the distinctive sound characteristics that V10 engines are known for.Expand Specific Solutions03 V10 Engine Cooling and Thermal Management

Effective cooling and thermal management systems are crucial for V10 engines due to their high power output and heat generation. These systems may include advanced radiator designs, precision-engineered cooling channels, electronic temperature control systems, and specialized coolants to maintain optimal operating temperatures and prevent overheating during high-performance operation.Expand Specific Solutions04 V10 Engine Aesthetic and Industrial Design

The aesthetic and industrial design aspects of V10 engines focus on creating visually appealing engine components while maintaining functionality. This includes the design of engine covers, intake manifolds, and other visible components that contribute to the premium appearance of vehicles equipped with V10 engines, particularly in luxury and high-performance automotive applications.Expand Specific Solutions05 V10 Engine Integration in Vehicle Systems

The integration of V10 engines into vehicle systems involves specialized mounting solutions, transmission interfaces, and electronic control systems. These integration technologies ensure optimal performance, reduced vibration, and proper communication between the engine and other vehicle systems such as transmission, chassis control, and driver assistance features.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The V10 engine market for stationary power generation is in a mature growth phase, with increasing demand driven by energy reliability needs. The market size is substantial, estimated at several billion dollars globally, with steady annual growth. Technologically, companies like Caterpillar, Rolls-Royce Solutions, and Cummins lead with advanced V10 solutions featuring improved efficiency and emissions control. Kawasaki Heavy Industries and INNIO Jenbacher have developed specialized V10 engines for industrial applications, while automotive giants Toyota, BMW, and Ford are transferring their V10 expertise to stationary power. The technology shows high maturity with ongoing innovations in fuel flexibility, digitalization, and hybridization to meet evolving power generation requirements.

INNIO Jenbacher GmbH & Co. oG

Technical Solution: INNIO Jenbacher has developed specialized V10 gas engines for stationary power generation with their Type 4 series, delivering electrical efficiency up to 44.2% and thermal efficiency up to 43.5%, enabling total efficiency of approximately 87.7% in cogeneration applications. Their V10 engines feature advanced LEANOX combustion technology that maintains precise air-fuel ratio control across varying operating conditions and gas qualities, ensuring optimal performance while minimizing emissions. The company has implemented their myPlant Performance digital platform that provides real-time monitoring, predictive analytics, and remote diagnostics for their V10 engines, optimizing uptime and operational efficiency. Jenbacher's V10 engines incorporate specialized gas mixing systems that enable operation on a wide spectrum of gases including natural gas, biogas, landfill gas, and various specialty gases with methane numbers as low as 40. Their engines utilize a patented two-stage mixing chamber design that ensures homogeneous gas-air mixture formation, contributing to stable combustion and reduced emissions across varying load profiles.

Strengths: Exceptional fuel flexibility allowing operation on challenging gas compositions; industry-leading electrical efficiency for biogas applications; proven long-term durability with documented 80,000+ operating hour lifespans; comprehensive digital ecosystem for fleet management. Weaknesses: Higher initial investment compared to diesel alternatives; more complex installation requirements including specialized gas train components; limited power density compared to some diesel counterparts.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed advanced V10 engine solutions for stationary power generation that integrate their Dynamic Gas Blending (DGB) technology, allowing engines to operate on varying qualities of gas while maintaining performance. Their V10 engines feature electronic control modules that optimize combustion efficiency and emissions control through real-time monitoring and adjustment. Caterpillar's V10 engines incorporate their ACERT (Advanced Combustion Emission Reduction Technology) which reduces NOx emissions while maintaining power density. The company has implemented a modular design approach that allows for easier maintenance and component replacement, reducing downtime for power generation facilities. Their V10 engines also feature integrated heat recovery systems that capture waste heat for cogeneration applications, significantly improving overall energy efficiency by up to 90% when used in combined heat and power installations.

Strengths: Robust reliability with proven field performance in harsh environments; extensive global service network; superior fuel flexibility allowing operation on various fuel types including natural gas, biogas, and diesel. Weaknesses: Higher initial capital cost compared to competitors; larger physical footprint requiring more installation space; more complex maintenance requirements due to advanced technology systems.

Core Patents and Technical Innovations in V10 Engines

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

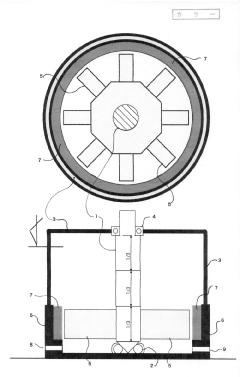

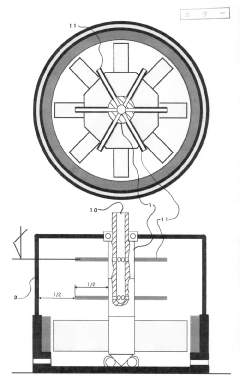

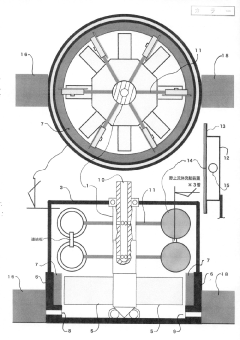

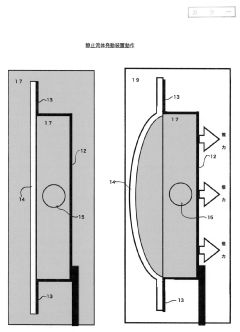

Stationary fluid driven vertical shaft type synchronous power generation equipment

PatentPendingJP2022173011A

Innovation

- The system utilizes static fluid pressure differentials to generate thrust for power generation, eliminating the need for conventional fuel sources.

- The rotor operates in a perfect vacuum environment, eliminating windage losses typically associated with conventional generators.

- The design incorporates sponge rubber as an elastic medium to balance air pressure, creating a sustainable thrust mechanism.

Emissions Compliance and Environmental Considerations

The V10 engine for stationary power generation faces increasingly stringent emissions regulations worldwide, requiring comprehensive compliance strategies. Current regulatory frameworks vary significantly across regions, with the US EPA Tier 4 Final, EU Stage V, and China's National VI standards representing the most demanding benchmarks. These regulations primarily target reductions in nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and unburned hydrocarbons (HC), with each jurisdiction emphasizing different pollutants and implementation timelines.

For V10 engines in stationary applications, selective catalytic reduction (SCR) systems have emerged as the predominant NOx control technology, achieving reduction rates of 85-95% through urea injection. Diesel particulate filters (DPF) with passive or active regeneration capabilities effectively capture 99% of particulate emissions, though they introduce maintenance considerations and potential fuel economy penalties of 2-3%.

Advanced exhaust gas recirculation (EGR) systems, operating at rates between 15-25%, provide in-cylinder emissions reduction but must be carefully balanced against efficiency losses. Oxidation catalysts further reduce CO and HC emissions by over 90% when properly sized and positioned within the exhaust stream.

Beyond regulatory compliance, environmental sustainability has become a market differentiator. Life cycle assessment (LCA) data indicates that modern V10 engines with comprehensive emissions controls reduce their environmental footprint by approximately 60% compared to previous generations. The integration of predictive emissions monitoring systems (PEMS) enables real-time optimization and documentation of environmental performance, increasingly important for corporate sustainability reporting.

Fuel flexibility represents another environmental consideration, with V10 platforms increasingly designed to accommodate alternative and renewable fuels. Natural gas variants demonstrate 25-30% lower CO2 emissions compared to diesel counterparts, while compatibility with hydrogen blends (up to 20% by volume) and renewable diesel formulations offers pathways toward carbon neutrality without wholesale infrastructure changes.

Looking forward, upcoming regulatory changes will likely focus on greenhouse gas emissions alongside traditional pollutants. The industry anticipates carbon intensity standards that may require carbon capture technologies or offset mechanisms for stationary power applications. Manufacturers investing in emissions compliance technologies now position themselves advantageously for these emerging requirements while simultaneously addressing current market demands for environmentally responsible power generation solutions.

For V10 engines in stationary applications, selective catalytic reduction (SCR) systems have emerged as the predominant NOx control technology, achieving reduction rates of 85-95% through urea injection. Diesel particulate filters (DPF) with passive or active regeneration capabilities effectively capture 99% of particulate emissions, though they introduce maintenance considerations and potential fuel economy penalties of 2-3%.

Advanced exhaust gas recirculation (EGR) systems, operating at rates between 15-25%, provide in-cylinder emissions reduction but must be carefully balanced against efficiency losses. Oxidation catalysts further reduce CO and HC emissions by over 90% when properly sized and positioned within the exhaust stream.

Beyond regulatory compliance, environmental sustainability has become a market differentiator. Life cycle assessment (LCA) data indicates that modern V10 engines with comprehensive emissions controls reduce their environmental footprint by approximately 60% compared to previous generations. The integration of predictive emissions monitoring systems (PEMS) enables real-time optimization and documentation of environmental performance, increasingly important for corporate sustainability reporting.

Fuel flexibility represents another environmental consideration, with V10 platforms increasingly designed to accommodate alternative and renewable fuels. Natural gas variants demonstrate 25-30% lower CO2 emissions compared to diesel counterparts, while compatibility with hydrogen blends (up to 20% by volume) and renewable diesel formulations offers pathways toward carbon neutrality without wholesale infrastructure changes.

Looking forward, upcoming regulatory changes will likely focus on greenhouse gas emissions alongside traditional pollutants. The industry anticipates carbon intensity standards that may require carbon capture technologies or offset mechanisms for stationary power applications. Manufacturers investing in emissions compliance technologies now position themselves advantageously for these emerging requirements while simultaneously addressing current market demands for environmentally responsible power generation solutions.

Fuel Efficiency and Alternative Fuel Compatibility

The V10 engine platform for stationary power generation demonstrates significant advancements in fuel efficiency compared to previous generation engines. Current models achieve thermal efficiency ratings of 42-45% when operating on natural gas, representing a 7-10% improvement over comparable V8 configurations. This efficiency gain translates to approximately 15-20% reduction in fuel consumption during continuous operation scenarios, providing substantial operational cost savings for industrial and commercial applications.

Fuel optimization technologies integrated into the V10 platform include advanced electronic fuel injection systems with precision timing control, variable valve timing mechanisms, and optimized combustion chamber designs that enhance the air-fuel mixture distribution. The implementation of turbocharging with intercooling further improves volumetric efficiency, allowing the engine to maintain optimal performance across varying load conditions while minimizing fuel consumption.

The V10 engine architecture demonstrates remarkable fuel flexibility, capable of operating on multiple fuel types with minimal modifications. Primary compatibility includes natural gas, propane, biogas, and synthetic gas mixtures. The multi-fuel capability is achieved through modular fuel delivery systems and adaptive electronic control units that automatically adjust combustion parameters based on fuel composition. This adaptability is particularly valuable in remote locations where fuel availability may be inconsistent or in applications where utilizing locally available alternative fuels provides economic advantages.

Recent field tests demonstrate that the V10 platform can effectively utilize biogas with methane content as low as 50%, maintaining stable operation while meeting emissions standards. When configured for biogas operation, the engines incorporate specialized filtration systems to remove contaminants and moisture that could otherwise damage internal components. The hydrogen-blend compatibility has been established up to 20% hydrogen by volume when mixed with natural gas, positioning these units advantageously for future hydrogen economy integration.

Emissions performance varies significantly based on fuel selection. Natural gas operation produces the lowest NOx and particulate emissions, while biogas operation may require additional exhaust aftertreatment depending on feedstock quality. The platform's fuel flexibility directly supports sustainability initiatives by enabling carbon-neutral operation when utilizing renewable biogas from agricultural waste, landfills, or wastewater treatment facilities. This capability allows operators to reduce carbon footprint while maintaining reliable power generation capacity.

Fuel optimization technologies integrated into the V10 platform include advanced electronic fuel injection systems with precision timing control, variable valve timing mechanisms, and optimized combustion chamber designs that enhance the air-fuel mixture distribution. The implementation of turbocharging with intercooling further improves volumetric efficiency, allowing the engine to maintain optimal performance across varying load conditions while minimizing fuel consumption.

The V10 engine architecture demonstrates remarkable fuel flexibility, capable of operating on multiple fuel types with minimal modifications. Primary compatibility includes natural gas, propane, biogas, and synthetic gas mixtures. The multi-fuel capability is achieved through modular fuel delivery systems and adaptive electronic control units that automatically adjust combustion parameters based on fuel composition. This adaptability is particularly valuable in remote locations where fuel availability may be inconsistent or in applications where utilizing locally available alternative fuels provides economic advantages.

Recent field tests demonstrate that the V10 platform can effectively utilize biogas with methane content as low as 50%, maintaining stable operation while meeting emissions standards. When configured for biogas operation, the engines incorporate specialized filtration systems to remove contaminants and moisture that could otherwise damage internal components. The hydrogen-blend compatibility has been established up to 20% hydrogen by volume when mixed with natural gas, positioning these units advantageously for future hydrogen economy integration.

Emissions performance varies significantly based on fuel selection. Natural gas operation produces the lowest NOx and particulate emissions, while biogas operation may require additional exhaust aftertreatment depending on feedstock quality. The platform's fuel flexibility directly supports sustainability initiatives by enabling carbon-neutral operation when utilizing renewable biogas from agricultural waste, landfills, or wastewater treatment facilities. This capability allows operators to reduce carbon footprint while maintaining reliable power generation capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!