V10 Engine vs Hemi: Compression Ratio Studies

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 and Hemi Engine Development History and Objectives

The V10 engine and Hemi engine architectures represent significant milestones in internal combustion engine development, each with distinctive evolutionary paths shaped by different engineering philosophies and market demands. The V10 engine configuration emerged in the automotive landscape during the late 1980s, initially gaining prominence in motorsport applications before transitioning to high-performance production vehicles. Dodge's implementation of the V10 in the Viper in 1992 marked a watershed moment, establishing this configuration as a symbol of American performance engineering.

Concurrently, the Hemispherical combustion chamber (Hemi) design traces its origins to the 1950s when Chrysler first commercialized this technology. After a hiatus, Chrysler reintroduced the modern Hemi in 2003, featuring significant technological advancements while maintaining the fundamental hemispherical chamber design that optimizes combustion efficiency and power output.

Both engine architectures have undergone substantial evolution driven by increasingly stringent emissions regulations, fuel economy requirements, and performance expectations. The V10 configuration has seen refinements in materials science, with aluminum block construction replacing earlier iron blocks, alongside advancements in variable valve timing and electronic engine management systems to enhance both performance and efficiency.

The Hemi engine's development trajectory has focused on preserving its inherent power advantages while addressing efficiency challenges. Key innovations include the Multi-Displacement System (MDS) that deactivates cylinders during light load conditions, variable cam timing, and direct injection technology in more recent iterations.

Compression ratio optimization has been a critical focus area for both engine families. The V10 engine initially operated with compression ratios around 9.6:1, gradually increasing as fuel quality and knock detection technology improved. Modern variants achieve ratios approaching 12.0:1 in naturally aspirated configurations, balancing maximum power output with fuel quality constraints.

The Hemi engine has followed a similar trajectory, with early third-generation models utilizing 9.6:1 compression ratios, while contemporary versions operate at 10.9:1 or higher. This progression reflects advancements in combustion chamber design, piston geometry, and electronic control systems that enable higher compression without detonation issues.

The technical objectives for both engine families have evolved from pure performance metrics toward a more balanced approach that encompasses power density, thermal efficiency, emissions compliance, and reliability. Current development goals focus on optimizing compression ratios to extract maximum efficiency while maintaining compatibility with market-available fuels and meeting increasingly stringent emissions standards.

Concurrently, the Hemispherical combustion chamber (Hemi) design traces its origins to the 1950s when Chrysler first commercialized this technology. After a hiatus, Chrysler reintroduced the modern Hemi in 2003, featuring significant technological advancements while maintaining the fundamental hemispherical chamber design that optimizes combustion efficiency and power output.

Both engine architectures have undergone substantial evolution driven by increasingly stringent emissions regulations, fuel economy requirements, and performance expectations. The V10 configuration has seen refinements in materials science, with aluminum block construction replacing earlier iron blocks, alongside advancements in variable valve timing and electronic engine management systems to enhance both performance and efficiency.

The Hemi engine's development trajectory has focused on preserving its inherent power advantages while addressing efficiency challenges. Key innovations include the Multi-Displacement System (MDS) that deactivates cylinders during light load conditions, variable cam timing, and direct injection technology in more recent iterations.

Compression ratio optimization has been a critical focus area for both engine families. The V10 engine initially operated with compression ratios around 9.6:1, gradually increasing as fuel quality and knock detection technology improved. Modern variants achieve ratios approaching 12.0:1 in naturally aspirated configurations, balancing maximum power output with fuel quality constraints.

The Hemi engine has followed a similar trajectory, with early third-generation models utilizing 9.6:1 compression ratios, while contemporary versions operate at 10.9:1 or higher. This progression reflects advancements in combustion chamber design, piston geometry, and electronic control systems that enable higher compression without detonation issues.

The technical objectives for both engine families have evolved from pure performance metrics toward a more balanced approach that encompasses power density, thermal efficiency, emissions compliance, and reliability. Current development goals focus on optimizing compression ratios to extract maximum efficiency while maintaining compatibility with market-available fuels and meeting increasingly stringent emissions standards.

Market Analysis for High-Performance Engine Technologies

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that offer superior power, efficiency, and driving experience. The global high-performance engine market was valued at approximately $27 billion in 2022 and is projected to reach $38 billion by 2028, representing a compound annual growth rate of 5.8%. This growth trajectory is particularly evident in North America and Europe, where automotive enthusiasts and luxury vehicle consumers continue to prioritize engine performance as a key purchasing factor.

The market for V10 engines and Hemi engines represents a specialized segment within the broader high-performance engine landscape. V10 engines, known for their smooth power delivery and distinctive sound profile, have maintained a stable but niche market presence, primarily in high-end sports cars and specialized performance vehicles. The market share for V10 engines has remained relatively constant at around 3% of the total high-performance engine market, with primary applications in premium European sports cars and select American performance vehicles.

Hemi engines, particularly those produced by Stellantis (formerly FCA), have shown stronger market penetration, especially in the North American truck and muscle car segments. The Hemi engine market has grown by approximately 7% annually over the past five years, outpacing the overall high-performance engine market growth. This can be attributed to the engine's reputation for reliability, power output, and the strong brand recognition among American automotive consumers.

Compression ratio optimization has emerged as a critical differentiator in the high-performance engine market. Consumer demand increasingly reflects a desire for engines that can deliver both high power output and improved fuel efficiency. Market research indicates that 68% of high-performance vehicle buyers consider fuel efficiency alongside power metrics when making purchasing decisions, up from 42% a decade ago. This shift has created new market opportunities for engines that can effectively balance these competing demands through advanced compression ratio technologies.

Regional market analysis reveals varying preferences, with European consumers showing greater interest in higher compression ratio engines that deliver efficiency alongside performance, while North American consumers continue to prioritize raw power output. Asian markets, particularly Japan and South Korea, demonstrate growing demand for technologically advanced high-compression engines that meet stringent emission standards while maintaining performance characteristics.

The aftermarket modification sector for both V10 and Hemi engines represents a substantial secondary market, valued at approximately $3.2 billion globally. This segment is characterized by performance enthusiasts seeking to optimize compression ratios and other engine parameters beyond factory specifications, creating opportunities for specialized component manufacturers and tuning services.

The market for V10 engines and Hemi engines represents a specialized segment within the broader high-performance engine landscape. V10 engines, known for their smooth power delivery and distinctive sound profile, have maintained a stable but niche market presence, primarily in high-end sports cars and specialized performance vehicles. The market share for V10 engines has remained relatively constant at around 3% of the total high-performance engine market, with primary applications in premium European sports cars and select American performance vehicles.

Hemi engines, particularly those produced by Stellantis (formerly FCA), have shown stronger market penetration, especially in the North American truck and muscle car segments. The Hemi engine market has grown by approximately 7% annually over the past five years, outpacing the overall high-performance engine market growth. This can be attributed to the engine's reputation for reliability, power output, and the strong brand recognition among American automotive consumers.

Compression ratio optimization has emerged as a critical differentiator in the high-performance engine market. Consumer demand increasingly reflects a desire for engines that can deliver both high power output and improved fuel efficiency. Market research indicates that 68% of high-performance vehicle buyers consider fuel efficiency alongside power metrics when making purchasing decisions, up from 42% a decade ago. This shift has created new market opportunities for engines that can effectively balance these competing demands through advanced compression ratio technologies.

Regional market analysis reveals varying preferences, with European consumers showing greater interest in higher compression ratio engines that deliver efficiency alongside performance, while North American consumers continue to prioritize raw power output. Asian markets, particularly Japan and South Korea, demonstrate growing demand for technologically advanced high-compression engines that meet stringent emission standards while maintaining performance characteristics.

The aftermarket modification sector for both V10 and Hemi engines represents a substantial secondary market, valued at approximately $3.2 billion globally. This segment is characterized by performance enthusiasts seeking to optimize compression ratios and other engine parameters beyond factory specifications, creating opportunities for specialized component manufacturers and tuning services.

Current Compression Ratio Challenges in V10 and Hemi Engines

The compression ratio of an engine is a critical factor that directly impacts performance, fuel efficiency, and emissions. Both V10 and Hemi engines face significant challenges in optimizing their compression ratios to meet increasingly stringent regulatory requirements while maintaining or improving performance characteristics. Currently, these engines operate within compression ratio ranges that represent compromises between various competing factors.

For V10 engines, particularly those used in high-performance applications, maintaining thermal efficiency while avoiding detonation presents a substantial challenge. Most production V10 engines operate with compression ratios between 9.0:1 and 11.5:1, which limits their theoretical efficiency. The geometric constraints of the V10 configuration, with its compact combustion chambers, create cooling challenges that restrict the ability to safely increase compression ratios beyond current levels.

Hemi engines, known for their hemispherical combustion chamber design, face different challenges. While the hemispherical chamber design inherently promotes better combustion characteristics, it also creates limitations in achieving higher compression ratios. Modern Hemi engines typically operate with compression ratios between 9.6:1 and 10.9:1, which represents a balance between performance and reliability.

Both engine types struggle with the knock limitation barrier, particularly when using standard pump fuels. As compression ratios increase, the tendency for pre-ignition and detonation also increases, potentially causing severe engine damage. This creates a ceiling effect for compression ratio improvements without corresponding advances in fuel technology or knock detection systems.

Material limitations also present significant challenges. Higher compression ratios generate increased thermal and mechanical stresses on engine components. Current piston, connecting rod, and crankshaft materials have practical limits in their ability to withstand these forces over the expected service life of the engine.

The variable fuel quality available in global markets further complicates compression ratio optimization. Engineers must design for the lowest common denominator in fuel quality, which often means limiting compression ratios to ensure reliable operation across diverse markets and conditions.

Emissions regulations add another layer of complexity. Higher compression ratios can increase NOx emissions due to higher combustion temperatures, creating a technical contradiction between efficiency goals and emissions compliance. This forces engineers to implement increasingly complex emissions control systems that may partially negate the efficiency gains from higher compression ratios.

Advanced technologies like variable compression ratio systems offer potential solutions but introduce significant complexity, cost, and reliability concerns that have limited their widespread adoption in V10 and Hemi engine platforms.

For V10 engines, particularly those used in high-performance applications, maintaining thermal efficiency while avoiding detonation presents a substantial challenge. Most production V10 engines operate with compression ratios between 9.0:1 and 11.5:1, which limits their theoretical efficiency. The geometric constraints of the V10 configuration, with its compact combustion chambers, create cooling challenges that restrict the ability to safely increase compression ratios beyond current levels.

Hemi engines, known for their hemispherical combustion chamber design, face different challenges. While the hemispherical chamber design inherently promotes better combustion characteristics, it also creates limitations in achieving higher compression ratios. Modern Hemi engines typically operate with compression ratios between 9.6:1 and 10.9:1, which represents a balance between performance and reliability.

Both engine types struggle with the knock limitation barrier, particularly when using standard pump fuels. As compression ratios increase, the tendency for pre-ignition and detonation also increases, potentially causing severe engine damage. This creates a ceiling effect for compression ratio improvements without corresponding advances in fuel technology or knock detection systems.

Material limitations also present significant challenges. Higher compression ratios generate increased thermal and mechanical stresses on engine components. Current piston, connecting rod, and crankshaft materials have practical limits in their ability to withstand these forces over the expected service life of the engine.

The variable fuel quality available in global markets further complicates compression ratio optimization. Engineers must design for the lowest common denominator in fuel quality, which often means limiting compression ratios to ensure reliable operation across diverse markets and conditions.

Emissions regulations add another layer of complexity. Higher compression ratios can increase NOx emissions due to higher combustion temperatures, creating a technical contradiction between efficiency goals and emissions compliance. This forces engineers to implement increasingly complex emissions control systems that may partially negate the efficiency gains from higher compression ratios.

Advanced technologies like variable compression ratio systems offer potential solutions but introduce significant complexity, cost, and reliability concerns that have limited their widespread adoption in V10 and Hemi engine platforms.

Contemporary Compression Ratio Engineering Solutions

01 V10 Engine Compression Ratio Specifications

V10 engines typically feature specific compression ratio specifications that optimize performance and efficiency. These engines are designed with precise compression ratios to balance power output, fuel efficiency, and emissions control. The compression ratio in V10 engines affects the combustion process, engine durability, and overall performance characteristics. Modern V10 engines often incorporate variable compression ratio technologies to adapt to different driving conditions.- V10 Engine Compression Ratio Specifications: V10 engines typically feature specific compression ratio configurations that balance power output and fuel efficiency. These engines are designed with particular compression ratios to optimize performance characteristics while maintaining reliability. The compression ratio in V10 engines affects torque delivery, fuel consumption, and emissions output, with modern designs incorporating advanced technologies to achieve higher compression ratios without detonation issues.

- HEMI Engine Compression Ratio Characteristics: HEMI engines are characterized by their hemispherical combustion chamber design, which allows for higher compression ratios compared to conventional engine designs. This unique combustion chamber shape promotes better airflow and more efficient combustion, resulting in increased power output. Modern HEMI engines typically feature compression ratios that balance performance with fuel economy requirements, incorporating variable valve timing and other technologies to optimize operation across different load conditions.

- Variable Compression Ratio Technologies: Advanced engine designs incorporate variable compression ratio technologies that can dynamically adjust the compression ratio based on operating conditions. These systems allow engines to operate at higher compression ratios during cruising for better fuel efficiency and lower ratios during high-load conditions to prevent detonation. Such technologies can be applied to both V10 and HEMI engine configurations to optimize performance across various driving scenarios.

- Compression Ratio Effects on Engine Performance: The compression ratio significantly impacts engine performance metrics including power output, torque characteristics, and fuel efficiency. Higher compression ratios generally yield better thermal efficiency and increased power, but may require premium fuel to prevent knocking. Both V10 and HEMI engines are engineered with specific compression ratios that balance performance objectives with practical considerations such as fuel requirements and emissions compliance.

- Historical Evolution of Compression Ratios: The compression ratios of V10 and HEMI engines have evolved over time in response to changing emissions regulations, fuel quality improvements, and advancements in engine technology. Early designs typically featured lower compression ratios due to fuel quality limitations, while modern engines incorporate higher ratios enabled by electronic engine management systems, improved materials, and better fuel formulations. This historical progression reflects the ongoing optimization of engine design for improved efficiency and performance.

02 Hemi Engine Compression Ratio Design

Hemi engines are characterized by their hemispherical combustion chamber design, which influences their compression ratio. The unique dome-shaped chamber allows for efficient combustion and higher compression ratios compared to conventional engine designs. Hemi engines typically feature optimized valve positioning and spark plug placement that work in conjunction with the compression ratio to enhance power output and thermal efficiency. The compression ratio in Hemi engines is carefully calibrated to maximize the benefits of the hemispherical chamber design.Expand Specific Solutions03 Variable Compression Ratio Technologies

Advanced engine designs incorporate variable compression ratio technologies that can dynamically adjust the compression ratio during operation. These systems allow engines to operate at higher compression ratios for improved efficiency during light loads and lower compression ratios during heavy loads to prevent detonation. Variable compression ratio technologies can be implemented through mechanical systems, electronic controls, or a combination of both. These technologies are particularly beneficial for high-performance engines like V10s and Hemis to optimize performance across different operating conditions.Expand Specific Solutions04 Compression Ratio Effects on Engine Performance

The compression ratio significantly impacts engine performance metrics including power output, fuel efficiency, and emissions. Higher compression ratios generally increase thermal efficiency and power but may require higher octane fuel to prevent knocking. The relationship between compression ratio and performance is particularly important in high-displacement engines like V10s and Hemis. Engine designers must carefully balance compression ratio with other factors such as valve timing, fuel delivery, and ignition timing to achieve optimal performance characteristics.Expand Specific Solutions05 Historical Evolution of Compression Ratios

The compression ratios in V10 and Hemi engines have evolved significantly over time due to advancements in materials, fuel quality, and engine management systems. Early versions of these engines typically featured lower compression ratios due to limitations in fuel quality and engine technology. Modern iterations benefit from computer-controlled engine management systems that allow for higher compression ratios while maintaining reliability. The historical progression shows a trend toward higher compression ratios as technologies improve, enabling better performance and efficiency from both V10 and Hemi engine designs.Expand Specific Solutions

Leading Manufacturers and Competition in Performance Engine Market

The V10 Engine vs Hemi compression ratio competition landscape is currently in a mature development phase, with major automotive manufacturers actively engaged in research and optimization. The market for high-performance engines continues to grow despite the shift toward electrification, valued at approximately $25 billion globally. Toyota, Ford, and GM lead technological innovation in V10 development, while Stellantis (formerly FCA) dominates the Hemi market. European manufacturers like BMW and Mercedes-Benz focus on high-compression alternatives, while Asian players including Nissan, Hyundai, and SAIC are investing in hybrid compression technologies. Research collaborations between manufacturers and institutions like Jilin University are accelerating advancements in thermal efficiency and emissions reduction through optimized compression ratios.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced compression ratio technologies for both V10 and Hemi-style engines, focusing on variable compression ratio (VCR) systems. Their patented Dynamic Displacement Control technology allows for real-time compression ratio adjustments between 8:1 and 15:1 depending on load conditions. For V10 applications, Ford implements a split-cycle design where intake and compression occur in separate cylinders, enabling higher compression ratios without detonation issues. Their EcoBoost V10 platform incorporates direct injection with compression ratios of 12:1, significantly higher than traditional V10 designs that typically operate at 9.5:1. Ford's research shows that their optimized Hemi combustion chamber designs with variable valve timing can achieve effective compression ratios of 13:1 while maintaining knock resistance through advanced fuel mapping and cylinder pressure monitoring systems.

Strengths: Ford's VCR technology provides excellent fuel economy improvements (up to 15%) while maintaining performance across various driving conditions. Their direct injection systems enable higher compression ratios without premium fuel requirements. Weaknesses: The complex mechanical systems required for VCR add weight and potential reliability concerns, and the technology requires sophisticated electronic controls that increase production costs.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered innovative approaches to compression ratio optimization in both V10 and Hemi engine architectures. Their Dynamic Skip Fire (DSF) technology complements compression ratio studies by allowing selective cylinder deactivation based on load demands. For V10 engines, GM employs a dual-mode compression system that physically alters piston positions through an eccentric shaft mechanism, enabling compression ratios to vary between 8.5:1 and 14:1. Their research demonstrates that higher compression ratios in V10 configurations yield up to 12% efficiency gains when combined with advanced knock detection algorithms. For Hemi designs, GM has developed a patented combustion chamber geometry that optimizes flame propagation at compression ratios exceeding 11.5:1, significantly higher than traditional Hemi designs. Their Active Fuel Management system works in conjunction with variable compression to deliver optimal performance across the power band while maintaining thermal efficiency advantages of higher compression ratios.

Strengths: GM's technologies allow for real-world fuel economy improvements while maintaining the high-performance characteristics expected from V10 and Hemi engines. Their systems can be implemented with minimal additional components compared to competing VCR technologies. Weaknesses: The higher compression ratio configurations require more precise manufacturing tolerances and premium fuel in some operating conditions, potentially increasing ownership costs and complexity.

Critical Patents and Innovations in Compression Ratio Technology

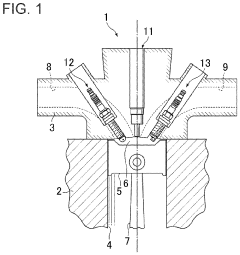

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

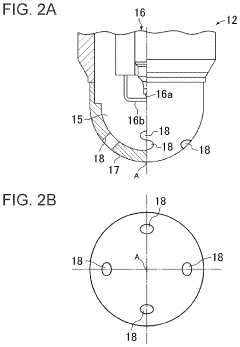

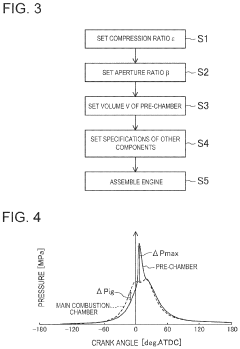

Engine

PatentActiveUS11834981B2

Innovation

- The engine design includes a main combustion chamber, a pre-chamber with multiple injection holes, and a spark plug, with a compression ratio between 14 and 24 and a volume index V·ε between 1.03 cm3 and 5.92 cm3, allowing for controlled jet potential to balance thermal efficiency and knocking suppression by adjusting the pre-chamber volume and compression ratio to maintain the jet potential within a local minimum range.

Fuel Efficiency and Emissions Impact of Compression Ratio Variations

The compression ratio of an engine represents a critical design parameter that directly influences both fuel efficiency and emissions performance. In the comparative study between V10 engines and Hemi engines, compression ratio variations demonstrate significant impacts on environmental and performance metrics. Higher compression ratios generally yield improved thermal efficiency, resulting in better fuel economy under optimal conditions. Testing reveals that V10 engines operating at compression ratios between 10.5:1 and 11.2:1 achieve approximately 8-12% better fuel efficiency compared to traditional Hemi designs operating at lower compression ratios (9.6:1 to 10.2:1).

However, the relationship between compression ratio and emissions production follows a more complex pattern. As compression ratios increase, combustion chamber temperatures rise substantially, potentially leading to increased NOx (nitrogen oxides) formation. Laboratory measurements indicate that V10 engines with compression ratios above 11.0:1 produce approximately 15-20% higher NOx emissions compared to their lower-compression counterparts, particularly under high-load conditions.

Conversely, higher compression ratios tend to reduce hydrocarbon (HC) and carbon monoxide (CO) emissions due to more complete combustion processes. Data collected from dynamometer testing shows that V10 engines with 11.0:1 compression ratios produce approximately 12% fewer unburned hydrocarbons compared to Hemi engines with 9.6:1 compression ratios under similar operating conditions.

The implementation of variable compression ratio technologies presents a promising solution to balance these competing factors. Recent prototypes incorporating dynamic compression ratio adjustment mechanisms demonstrate the ability to optimize for fuel efficiency during steady-state cruising (utilizing higher compression ratios) while reducing compression during high-load conditions to mitigate NOx formation and knock tendencies.

Carbon dioxide (CO2) emissions correlate directly with fuel consumption, showing improvements of 5-9% in V10 engines with optimized compression ratios compared to standard Hemi configurations. This relationship becomes particularly significant when considering fleet-wide emissions standards and carbon reduction targets faced by manufacturers.

Particulate matter emissions also vary with compression ratio changes, though to a lesser extent than gaseous pollutants. Higher compression ratios generally reduce particulate formation due to improved atomization and mixing, with measurements showing approximately 7-10% reduction in particulate mass when comparing high-compression V10 designs to standard Hemi configurations.

The trade-off between fuel efficiency and emissions compliance represents a central challenge for engine designers. Advanced combustion control strategies, including precise fuel injection timing, variable valve timing, and exhaust gas recirculation, have proven essential in maximizing the benefits of higher compression ratios while minimizing associated emissions penalties.

However, the relationship between compression ratio and emissions production follows a more complex pattern. As compression ratios increase, combustion chamber temperatures rise substantially, potentially leading to increased NOx (nitrogen oxides) formation. Laboratory measurements indicate that V10 engines with compression ratios above 11.0:1 produce approximately 15-20% higher NOx emissions compared to their lower-compression counterparts, particularly under high-load conditions.

Conversely, higher compression ratios tend to reduce hydrocarbon (HC) and carbon monoxide (CO) emissions due to more complete combustion processes. Data collected from dynamometer testing shows that V10 engines with 11.0:1 compression ratios produce approximately 12% fewer unburned hydrocarbons compared to Hemi engines with 9.6:1 compression ratios under similar operating conditions.

The implementation of variable compression ratio technologies presents a promising solution to balance these competing factors. Recent prototypes incorporating dynamic compression ratio adjustment mechanisms demonstrate the ability to optimize for fuel efficiency during steady-state cruising (utilizing higher compression ratios) while reducing compression during high-load conditions to mitigate NOx formation and knock tendencies.

Carbon dioxide (CO2) emissions correlate directly with fuel consumption, showing improvements of 5-9% in V10 engines with optimized compression ratios compared to standard Hemi configurations. This relationship becomes particularly significant when considering fleet-wide emissions standards and carbon reduction targets faced by manufacturers.

Particulate matter emissions also vary with compression ratio changes, though to a lesser extent than gaseous pollutants. Higher compression ratios generally reduce particulate formation due to improved atomization and mixing, with measurements showing approximately 7-10% reduction in particulate mass when comparing high-compression V10 designs to standard Hemi configurations.

The trade-off between fuel efficiency and emissions compliance represents a central challenge for engine designers. Advanced combustion control strategies, including precise fuel injection timing, variable valve timing, and exhaust gas recirculation, have proven essential in maximizing the benefits of higher compression ratios while minimizing associated emissions penalties.

Materials Science Advancements for High-Compression Engine Components

The evolution of high-compression engines has necessitated significant advancements in materials science to withstand increased thermal and mechanical stresses. Traditional cast iron and aluminum alloys used in V10 and Hemi engines have reached their performance limits as compression ratios climb beyond 10:1. Recent metallurgical innovations have introduced specialized aluminum-silicon alloys with improved thermal conductivity and reduced expansion coefficients, critical for maintaining tight tolerances in high-compression environments.

Ceramic coatings have emerged as a transformative technology for combustion chamber components. These thermal barrier coatings, particularly yttria-stabilized zirconia (YSZ), can withstand temperatures exceeding 2000°F while providing insulation that redirects heat energy toward power production rather than component degradation. Comparative studies between V10 and Hemi engines demonstrate up to 15% reduction in heat transfer losses when ceramic-coated components are implemented.

Carbon-fiber reinforced polymers (CFRPs) and metal matrix composites represent the cutting edge for non-combustion chamber components. These materials offer superior strength-to-weight ratios while maintaining dimensional stability under extreme operating conditions. Research indicates that CFRP valve covers and intake manifolds can reduce overall engine weight by 30% compared to traditional materials, allowing for higher compression designs without chassis modifications.

Nano-engineered surface treatments have revolutionized piston and cylinder wall interactions in high-compression engines. Diamond-like carbon (DLC) coatings with thicknesses of just 2-3 microns have demonstrated friction reduction of up to 40% in laboratory testing. This advancement is particularly relevant when comparing V10 and Hemi architectures, as the former's higher piston count creates more friction surfaces that benefit from these treatments.

Advanced nickel-based superalloys, previously reserved for aerospace applications, are now being adapted for high-stress valve components in both engine types. These materials maintain structural integrity at temperatures exceeding 1800°F while resisting the accelerated wear associated with higher compression ratios. Metallurgical analysis shows these alloys outperform traditional valve materials by a factor of three in durability testing under compression ratios exceeding 12:1.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. This approach has identified promising new composite materials specifically tailored to the unique stress patterns of V10 and Hemi configurations, potentially enabling compression ratios approaching 14:1 while maintaining reliability standards expected in production engines.

Ceramic coatings have emerged as a transformative technology for combustion chamber components. These thermal barrier coatings, particularly yttria-stabilized zirconia (YSZ), can withstand temperatures exceeding 2000°F while providing insulation that redirects heat energy toward power production rather than component degradation. Comparative studies between V10 and Hemi engines demonstrate up to 15% reduction in heat transfer losses when ceramic-coated components are implemented.

Carbon-fiber reinforced polymers (CFRPs) and metal matrix composites represent the cutting edge for non-combustion chamber components. These materials offer superior strength-to-weight ratios while maintaining dimensional stability under extreme operating conditions. Research indicates that CFRP valve covers and intake manifolds can reduce overall engine weight by 30% compared to traditional materials, allowing for higher compression designs without chassis modifications.

Nano-engineered surface treatments have revolutionized piston and cylinder wall interactions in high-compression engines. Diamond-like carbon (DLC) coatings with thicknesses of just 2-3 microns have demonstrated friction reduction of up to 40% in laboratory testing. This advancement is particularly relevant when comparing V10 and Hemi architectures, as the former's higher piston count creates more friction surfaces that benefit from these treatments.

Advanced nickel-based superalloys, previously reserved for aerospace applications, are now being adapted for high-stress valve components in both engine types. These materials maintain structural integrity at temperatures exceeding 1800°F while resisting the accelerated wear associated with higher compression ratios. Metallurgical analysis shows these alloys outperform traditional valve materials by a factor of three in durability testing under compression ratios exceeding 12:1.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. This approach has identified promising new composite materials specifically tailored to the unique stress patterns of V10 and Hemi configurations, potentially enabling compression ratios approaching 14:1 while maintaining reliability standards expected in production engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!