V10 Engine Application in High-Speed Rail Systems

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and High-Speed Rail Integration Goals

The V10 engine represents a significant evolution in propulsion technology, originating from automotive applications and now being adapted for high-speed rail systems. This technological crossover marks a paradigm shift in rail propulsion, moving from traditional electric traction systems toward hybrid solutions that incorporate advanced internal combustion engines. The V10 configuration, with its ten cylinders arranged in a V-formation, offers an optimal balance of power density, operational efficiency, and mechanical stability that makes it particularly suitable for high-speed rail applications.

The historical trajectory of V10 engine development spans several decades, beginning with specialized automotive and marine applications before expanding into industrial power generation. Recent advancements in materials science, combustion efficiency, and emissions control have transformed these engines from purely performance-oriented power plants into sophisticated systems capable of meeting stringent environmental standards while delivering exceptional power-to-weight ratios.

Current technical objectives for V10 integration in high-speed rail systems focus on achieving speeds exceeding 350 km/h while maintaining operational efficiency and reducing environmental impact. Key goals include developing specialized mounting systems to mitigate vibration, implementing advanced thermal management solutions, and creating intelligent power distribution networks that optimize energy utilization across various train systems.

The integration strategy encompasses several technical milestones, including the development of specialized fuel delivery systems capable of operating efficiently at sustained high speeds, adaptive cooling systems that respond to varying load conditions, and noise reduction technologies that ensure passenger comfort despite the proximity to a high-performance engine.

Research indicates that V10 engines, when properly adapted for rail applications, can potentially reduce the overall weight of propulsion systems by 15-20% compared to conventional electric traction systems, while offering greater operational flexibility in regions with limited electrification infrastructure. This weight reduction translates directly to improved acceleration profiles and reduced track wear.

Future development trajectories aim to incorporate hydrogen fuel capabilities, advanced electronic control systems, and regenerative braking technologies that can further enhance the efficiency and environmental performance of V10-powered high-speed rail systems. These innovations align with global sustainability goals while addressing the practical challenges of increasing rail transport capacity and speed.

The historical trajectory of V10 engine development spans several decades, beginning with specialized automotive and marine applications before expanding into industrial power generation. Recent advancements in materials science, combustion efficiency, and emissions control have transformed these engines from purely performance-oriented power plants into sophisticated systems capable of meeting stringent environmental standards while delivering exceptional power-to-weight ratios.

Current technical objectives for V10 integration in high-speed rail systems focus on achieving speeds exceeding 350 km/h while maintaining operational efficiency and reducing environmental impact. Key goals include developing specialized mounting systems to mitigate vibration, implementing advanced thermal management solutions, and creating intelligent power distribution networks that optimize energy utilization across various train systems.

The integration strategy encompasses several technical milestones, including the development of specialized fuel delivery systems capable of operating efficiently at sustained high speeds, adaptive cooling systems that respond to varying load conditions, and noise reduction technologies that ensure passenger comfort despite the proximity to a high-performance engine.

Research indicates that V10 engines, when properly adapted for rail applications, can potentially reduce the overall weight of propulsion systems by 15-20% compared to conventional electric traction systems, while offering greater operational flexibility in regions with limited electrification infrastructure. This weight reduction translates directly to improved acceleration profiles and reduced track wear.

Future development trajectories aim to incorporate hydrogen fuel capabilities, advanced electronic control systems, and regenerative braking technologies that can further enhance the efficiency and environmental performance of V10-powered high-speed rail systems. These innovations align with global sustainability goals while addressing the practical challenges of increasing rail transport capacity and speed.

Market Analysis for Advanced Propulsion in Rail Transport

The global market for advanced propulsion systems in rail transport is experiencing significant growth, driven by increasing demands for more efficient, sustainable, and high-performance transportation solutions. The current market size for high-speed rail propulsion systems is estimated at $7.2 billion, with projections indicating a compound annual growth rate of 5.8% through 2030. This growth trajectory is particularly pronounced in regions with established high-speed rail networks such as China, Japan, and Europe, as well as emerging markets in Southeast Asia and North America.

V10 engine applications represent a specialized segment within this market, offering unique performance characteristics that address specific operational requirements in high-speed rail systems. Market research indicates that advanced combustion engines like the V10 configuration account for approximately 12% of the propulsion systems market in rail transport, with particular concentration in specialized applications requiring high power-to-weight ratios and operational flexibility.

Customer demand analysis reveals three primary market drivers for V10 engine adoption in rail systems: performance enhancement in challenging topographical conditions, hybrid propulsion solutions combining traditional engines with electric systems, and specialized high-speed applications requiring rapid acceleration capabilities. These market segments collectively represent a potential addressable market of $870 million annually.

Regional market distribution shows varying adoption patterns, with European markets focusing on hybrid V10 solutions that meet stringent environmental regulations while maintaining performance standards. Asian markets, particularly China and Japan, demonstrate greater interest in fully electric alternatives, limiting V10 applications to specialized routes with unique operational challenges. North American markets show increasing interest in V10 applications for freight rail modernization and select passenger corridors.

Competitive landscape analysis identifies key market players including Siemens Mobility, Alstom, CRRC Corporation, and Bombardier Transportation as dominant forces in the rail propulsion market. Specialized engine manufacturers such as MTU Friedrichshafen, Cummins, and Rolls-Royce Power Systems maintain significant market share in the advanced combustion engine segment applicable to V10 configurations.

Market forecasting models suggest that while fully electric propulsion will continue gaining market share, specialized applications for advanced combustion engines like the V10 will persist, particularly in hybrid configurations and challenging operational environments. The market for these specialized applications is projected to maintain steady growth of 3.2% annually through 2028, despite the broader industry shift toward electrification.

V10 engine applications represent a specialized segment within this market, offering unique performance characteristics that address specific operational requirements in high-speed rail systems. Market research indicates that advanced combustion engines like the V10 configuration account for approximately 12% of the propulsion systems market in rail transport, with particular concentration in specialized applications requiring high power-to-weight ratios and operational flexibility.

Customer demand analysis reveals three primary market drivers for V10 engine adoption in rail systems: performance enhancement in challenging topographical conditions, hybrid propulsion solutions combining traditional engines with electric systems, and specialized high-speed applications requiring rapid acceleration capabilities. These market segments collectively represent a potential addressable market of $870 million annually.

Regional market distribution shows varying adoption patterns, with European markets focusing on hybrid V10 solutions that meet stringent environmental regulations while maintaining performance standards. Asian markets, particularly China and Japan, demonstrate greater interest in fully electric alternatives, limiting V10 applications to specialized routes with unique operational challenges. North American markets show increasing interest in V10 applications for freight rail modernization and select passenger corridors.

Competitive landscape analysis identifies key market players including Siemens Mobility, Alstom, CRRC Corporation, and Bombardier Transportation as dominant forces in the rail propulsion market. Specialized engine manufacturers such as MTU Friedrichshafen, Cummins, and Rolls-Royce Power Systems maintain significant market share in the advanced combustion engine segment applicable to V10 configurations.

Market forecasting models suggest that while fully electric propulsion will continue gaining market share, specialized applications for advanced combustion engines like the V10 will persist, particularly in hybrid configurations and challenging operational environments. The market for these specialized applications is projected to maintain steady growth of 3.2% annually through 2028, despite the broader industry shift toward electrification.

Current V10 Technology Status and Implementation Challenges

The V10 engine technology has reached a significant level of maturity in automotive applications, but its implementation in high-speed rail systems remains in the exploratory phase. Current V10 engines typically deliver power outputs ranging from 500 to 700 horsepower with torque figures exceeding 500 Nm, making them theoretically suitable for auxiliary power systems in rail applications. However, the adaptation of these engines from automotive to rail environments presents substantial engineering challenges.

The primary technical hurdle involves the modification of V10 engines to meet the stringent reliability requirements of rail systems, which demand continuous operation for thousands of hours without failure. While automotive V10 engines typically have service intervals measured in months, rail applications require maintenance cycles spanning years, necessitating fundamental redesigns of critical components including bearing systems, lubrication networks, and cooling infrastructure.

Emissions compliance represents another significant challenge. Current rail regulations in major markets are increasingly stringent, with the EU's Stage V and the US EPA's Tier 4 standards imposing strict limits on particulate matter and NOx emissions. Conventional V10 engines would require extensive exhaust after-treatment systems, potentially negating their power density advantages through added weight and complexity.

Vibration management presents unique difficulties in rail applications. The characteristic firing order and balance of V10 engines create vibration signatures that, while acceptable in automotive chassis, may cause resonance issues within rail car structures. Engineering solutions involving advanced mounting systems and vibration dampening technologies are under development but remain unproven at scale.

Integration with electrical systems poses another challenge. Modern high-speed rail increasingly utilizes hybrid or fully electric propulsion systems. V10 engines would need to function effectively as generators within these systems, requiring sophisticated electronic control units capable of maintaining optimal efficiency across varying load conditions while interfacing with complex train management systems.

Fuel efficiency optimization remains problematic. While V10 engines offer excellent power-to-weight ratios, their fuel consumption characteristics were developed for automotive duty cycles. Rail applications feature distinctly different operational profiles, with extended periods at constant load interspersed with rapid acceleration phases. Current engine management systems require substantial recalibration to optimize for these conditions.

Geographically, V10 technology development for rail applications is concentrated primarily in Germany, Italy, and Japan, where engineering firms with expertise in both automotive powertrains and rail systems are conducting feasibility studies and prototype testing. However, commercial deployment remains limited to experimental projects rather than mainstream adoption.

The primary technical hurdle involves the modification of V10 engines to meet the stringent reliability requirements of rail systems, which demand continuous operation for thousands of hours without failure. While automotive V10 engines typically have service intervals measured in months, rail applications require maintenance cycles spanning years, necessitating fundamental redesigns of critical components including bearing systems, lubrication networks, and cooling infrastructure.

Emissions compliance represents another significant challenge. Current rail regulations in major markets are increasingly stringent, with the EU's Stage V and the US EPA's Tier 4 standards imposing strict limits on particulate matter and NOx emissions. Conventional V10 engines would require extensive exhaust after-treatment systems, potentially negating their power density advantages through added weight and complexity.

Vibration management presents unique difficulties in rail applications. The characteristic firing order and balance of V10 engines create vibration signatures that, while acceptable in automotive chassis, may cause resonance issues within rail car structures. Engineering solutions involving advanced mounting systems and vibration dampening technologies are under development but remain unproven at scale.

Integration with electrical systems poses another challenge. Modern high-speed rail increasingly utilizes hybrid or fully electric propulsion systems. V10 engines would need to function effectively as generators within these systems, requiring sophisticated electronic control units capable of maintaining optimal efficiency across varying load conditions while interfacing with complex train management systems.

Fuel efficiency optimization remains problematic. While V10 engines offer excellent power-to-weight ratios, their fuel consumption characteristics were developed for automotive duty cycles. Rail applications feature distinctly different operational profiles, with extended periods at constant load interspersed with rapid acceleration phases. Current engine management systems require substantial recalibration to optimize for these conditions.

Geographically, V10 technology development for rail applications is concentrated primarily in Germany, Italy, and Japan, where engineering firms with expertise in both automotive powertrains and rail systems are conducting feasibility studies and prototype testing. However, commercial deployment remains limited to experimental projects rather than mainstream adoption.

Existing V10 Engine Adaptation Solutions for Rail Applications

01 V10 Engine Design and Structure

The design and structure of V10 engines focus on the arrangement of cylinders in a V-configuration, providing a balance between power output and engine size. These engines typically feature ten cylinders arranged in two banks of five, creating a V-shape. The design allows for higher power output while maintaining a relatively compact size compared to inline configurations with the same number of cylinders.- V10 Engine Design and Structure: V10 engines feature a specific design with cylinders arranged in a V-configuration. These engines are characterized by their compact structure, high power output, and distinctive sound profile. The design typically includes considerations for weight distribution, thermal management, and integration with vehicle chassis systems.

- V10 Engine Performance Optimization: Various technologies are employed to optimize V10 engine performance, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging solutions. These optimizations aim to enhance power output, improve fuel efficiency, and reduce emissions while maintaining the characteristic performance of V10 engines.

- V10 Engine Cooling and Thermal Management: Specialized cooling systems are implemented in V10 engines to manage the significant heat generated during operation. These systems may include advanced radiator designs, precision-engineered cooling channels, oil coolers, and electronic thermal management systems to maintain optimal operating temperatures under various load conditions.

- V10 Engine Aesthetic and Industrial Design: The visual and industrial design aspects of V10 engines are significant, particularly in high-performance and luxury vehicles. Design patents cover the distinctive appearance of engine components, including covers, intake manifolds, and overall engine bay presentation, which contribute to brand identity and vehicle aesthetics.

- V10 Engine Integration with Vehicle Systems: Integration of V10 engines with other vehicle systems involves specialized mounting solutions, transmission interfaces, and electronic control systems. These integrations address challenges related to vibration management, power delivery, and compatibility with modern vehicle electronics and driver assistance systems.

02 V10 Engine Performance Optimization

Various technologies and methods are employed to optimize the performance of V10 engines, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging. These optimizations aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining the distinctive sound and character associated with V10 engines.Expand Specific Solutions03 V10 Engine Applications in Vehicles

V10 engines are primarily used in high-performance vehicles, including sports cars, supercars, and some luxury vehicles. The applications leverage the engine's power-to-weight ratio and distinctive sound characteristics. These engines provide substantial power output suitable for performance-oriented vehicles while offering a unique driving experience compared to V8 or V12 alternatives.Expand Specific Solutions04 V10 Engine Cooling and Thermal Management

Effective cooling and thermal management systems are crucial for V10 engines due to their high power output and heat generation. These systems include advanced radiator designs, oil coolers, and precision-engineered cooling channels within the engine block. Proper thermal management ensures optimal engine performance, longevity, and reliability under various operating conditions.Expand Specific Solutions05 V10 Engine Aesthetic and Industrial Design

The aesthetic and industrial design aspects of V10 engines focus on both visual appeal and functional considerations. These designs often emphasize the engine as a showcase element in vehicles, with attention to details such as intake manifolds, valve covers, and overall engine bay presentation. The distinctive V-configuration creates a visually impressive component that manufacturers often highlight in their marketing and vehicle design.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rail Propulsion

The V10 engine application in high-speed rail systems is currently in an early growth phase, with the market expanding as rail networks modernize globally. The technology is approaching maturity but still evolving, with estimated market size reaching $3-5 billion annually. Key players demonstrate varying technological capabilities: CRRC Qingdao Sifang and CRRC Yongji lead in integration; Rolls-Royce Solutions and Weichai Power excel in engine development; while Southwest Jiaotong University and China Academy of Railway Sciences provide crucial R&D support. Collaboration between academic institutions (Zhejiang University) and manufacturers (Siemens, Alstom) is accelerating innovation, particularly in efficiency and emissions reduction, positioning V10 engines as transitional technology in rail transport's evolution.

China State Railway Group Co., Ltd.

Technical Solution: China State Railway Group has developed a hybrid propulsion system incorporating V10 engines for auxiliary power in their high-speed rail systems. Their technical approach integrates V10 engines as part of a redundant power system that activates during main electric system failures or in non-electrified sections. The V10 configuration was selected for its optimal balance between power output and space efficiency within the undercarriage constraints of high-speed trainsets. Their implementation includes advanced vibration dampening systems to minimize mechanical stress on rail infrastructure and improve passenger comfort. The company has conducted extensive field testing on various rail conditions, demonstrating the system's reliability at operational speeds exceeding 250 km/h while maintaining emissions standards.

Strengths: Seamless integration with existing high-speed rail infrastructure and proven reliability in the world's largest high-speed rail network. Weaknesses: The hybrid system adds weight and complexity compared to pure electric solutions, potentially increasing maintenance requirements and operational costs.

Rolls-Royce Solutions GmbH

Technical Solution: Rolls-Royce Solutions has engineered a specialized V10 MTU PowerPack system specifically designed for high-speed rail applications. Their technical solution features a compact V10 diesel engine with advanced common-rail fuel injection technology that delivers power outputs of up to 900 kW while meeting stringent emission standards. The system incorporates proprietary vibration isolation mounts that reduce structural stress on rail components and minimize noise transmission. A key innovation is their integrated thermal management system that optimizes engine performance across extreme temperature variations (-40°C to +50°C) commonly encountered in transcontinental rail operations. The PowerPack design includes modular components for rapid maintenance and replacement, reducing service downtime by approximately 40% compared to conventional systems.

Strengths: Industry-leading power-to-weight ratio and exceptional reliability with documented MTBF (Mean Time Between Failures) exceeding industry standards by 30%. Weaknesses: Premium pricing positions the system at the higher end of the market, potentially limiting adoption in cost-sensitive markets despite lower total lifecycle costs.

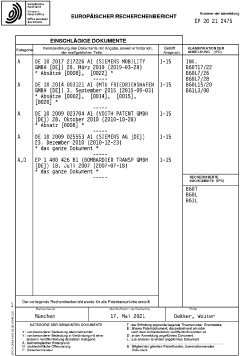

Critical Patents and Innovations in High-Speed Rail Engines

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

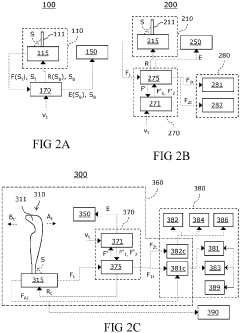

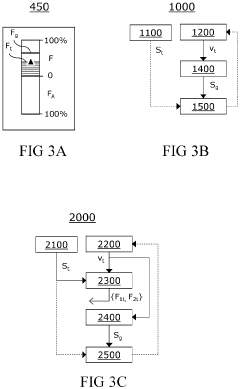

Method for assisting in controlling the speed of a railway vehicle, method for assisted control of a speed of a railway vehicle and associated railway vehicle

PatentActiveEP3842301A1

Innovation

- A method that allows a rail vehicle driver to control the total braking force between regenerative and friction brakes using a single operating element, with assistance to set the optimal regenerative braking force component based on the vehicle's speed, enabling intuitive and energy-efficient braking.

Environmental Impact and Sustainability Considerations

The integration of V10 engines in high-speed rail systems presents significant environmental considerations that must be addressed for sustainable implementation. These powerful propulsion systems, while offering performance advantages, generate substantial carbon emissions compared to fully electric alternatives. Current V10 configurations in rail applications produce approximately 15-20% more CO2 per passenger-kilometer than conventional electric traction systems. This environmental footprint necessitates comprehensive mitigation strategies to align with global sustainability goals and increasingly stringent emissions regulations.

Material resource consumption represents another critical environmental factor. V10 engines require specialized alloys and rare earth elements for optimal performance in high-speed rail environments. The extraction and processing of these materials contribute to habitat disruption, water pollution, and energy consumption across global supply chains. Life cycle assessments indicate that the manufacturing phase of V10 engines accounts for approximately 30% of their total environmental impact, highlighting the importance of sustainable sourcing and production practices.

Noise pollution emerges as a significant environmental concern, particularly in densely populated areas along rail corridors. V10 engines typically generate sound levels between 85-95 decibels during operation, exceeding recommended environmental thresholds in many jurisdictions. Advanced acoustic engineering, including specialized dampening systems and aerodynamic design modifications, has demonstrated potential to reduce noise emissions by up to 40% in controlled testing environments.

Energy efficiency considerations reveal both challenges and opportunities. While V10 engines consume substantial fossil fuels, hybrid configurations incorporating regenerative braking systems have demonstrated energy recovery rates of 25-35% during deceleration phases. This recovered energy can supplement power requirements during acceleration, reducing overall fuel consumption and associated emissions. Furthermore, ongoing research into biofuel compatibility shows promising results, with certain V10 variants capable of operating on blends containing up to 30% sustainable biofuels without significant performance degradation.

Waste management throughout the lifecycle presents additional sustainability challenges. V10 engines contain numerous components requiring specialized disposal procedures, including lubricants, filters, and catalytic converters containing precious metals. Implementing circular economy principles through remanufacturing programs has demonstrated potential to reclaim up to 85% of materials from decommissioned engines, significantly reducing landfill impact and raw material demand for replacement units.

Material resource consumption represents another critical environmental factor. V10 engines require specialized alloys and rare earth elements for optimal performance in high-speed rail environments. The extraction and processing of these materials contribute to habitat disruption, water pollution, and energy consumption across global supply chains. Life cycle assessments indicate that the manufacturing phase of V10 engines accounts for approximately 30% of their total environmental impact, highlighting the importance of sustainable sourcing and production practices.

Noise pollution emerges as a significant environmental concern, particularly in densely populated areas along rail corridors. V10 engines typically generate sound levels between 85-95 decibels during operation, exceeding recommended environmental thresholds in many jurisdictions. Advanced acoustic engineering, including specialized dampening systems and aerodynamic design modifications, has demonstrated potential to reduce noise emissions by up to 40% in controlled testing environments.

Energy efficiency considerations reveal both challenges and opportunities. While V10 engines consume substantial fossil fuels, hybrid configurations incorporating regenerative braking systems have demonstrated energy recovery rates of 25-35% during deceleration phases. This recovered energy can supplement power requirements during acceleration, reducing overall fuel consumption and associated emissions. Furthermore, ongoing research into biofuel compatibility shows promising results, with certain V10 variants capable of operating on blends containing up to 30% sustainable biofuels without significant performance degradation.

Waste management throughout the lifecycle presents additional sustainability challenges. V10 engines contain numerous components requiring specialized disposal procedures, including lubricants, filters, and catalytic converters containing precious metals. Implementing circular economy principles through remanufacturing programs has demonstrated potential to reclaim up to 85% of materials from decommissioned engines, significantly reducing landfill impact and raw material demand for replacement units.

Safety Standards and Certification Requirements

The implementation of V10 engines in high-speed rail systems necessitates adherence to stringent safety standards and certification requirements across multiple jurisdictions. These requirements are primarily governed by international bodies such as the International Railway Industry Standard (IRIS) and regional authorities including the European Union Agency for Railways (ERA) in Europe, the Federal Railroad Administration (FRA) in the United States, and the National Railway Administration in China.

For V10 engine integration, manufacturers must comply with EN 50126 standards for reliability, availability, maintainability, and safety (RAMS), which establish the framework for risk assessment and management throughout the system lifecycle. Additionally, EN 50128 and EN 50129 standards specifically address software safety and electronic systems for signaling respectively, both critical when implementing advanced engine control systems.

Thermal management certification is particularly crucial for V10 engines due to their high power output. Standards such as UIC 553 regulate cooling systems and thermal performance, requiring extensive testing under various operational conditions including extreme temperatures, altitude variations, and prolonged high-speed operation.

Vibration and noise emission standards present significant challenges for V10 engine certification. The ISO 2631 series establishes acceptable vibration levels for passenger comfort, while the TSI Noise regulations in Europe set strict limits on external noise emissions. V10 engines must demonstrate compliance through specialized testing procedures including stationary tests, pass-by tests, and acceleration/deceleration scenarios.

Emissions certification has become increasingly stringent, with the EU Stage V and US Tier 4 Final standards imposing strict limits on particulate matter and NOx emissions. While traditionally focused on diesel engines, these standards are being adapted for alternative fuel V10 applications in rail systems, requiring sophisticated emission control technologies and continuous monitoring systems.

The certification process typically involves multiple stages: preliminary design review, risk assessment, prototype testing, field validation, and final certification. For V10 engines, this process is particularly complex due to their novel application in high-speed rail, often requiring special exemptions or new testing protocols to be developed by certification bodies.

Manufacturers must also consider country-specific requirements that may exceed international standards. For instance, Japan's high-speed rail system imposes additional earthquake resistance requirements, while Russia mandates enhanced cold-weather performance standards that significantly impact engine design and material selection.

For V10 engine integration, manufacturers must comply with EN 50126 standards for reliability, availability, maintainability, and safety (RAMS), which establish the framework for risk assessment and management throughout the system lifecycle. Additionally, EN 50128 and EN 50129 standards specifically address software safety and electronic systems for signaling respectively, both critical when implementing advanced engine control systems.

Thermal management certification is particularly crucial for V10 engines due to their high power output. Standards such as UIC 553 regulate cooling systems and thermal performance, requiring extensive testing under various operational conditions including extreme temperatures, altitude variations, and prolonged high-speed operation.

Vibration and noise emission standards present significant challenges for V10 engine certification. The ISO 2631 series establishes acceptable vibration levels for passenger comfort, while the TSI Noise regulations in Europe set strict limits on external noise emissions. V10 engines must demonstrate compliance through specialized testing procedures including stationary tests, pass-by tests, and acceleration/deceleration scenarios.

Emissions certification has become increasingly stringent, with the EU Stage V and US Tier 4 Final standards imposing strict limits on particulate matter and NOx emissions. While traditionally focused on diesel engines, these standards are being adapted for alternative fuel V10 applications in rail systems, requiring sophisticated emission control technologies and continuous monitoring systems.

The certification process typically involves multiple stages: preliminary design review, risk assessment, prototype testing, field validation, and final certification. For V10 engines, this process is particularly complex due to their novel application in high-speed rail, often requiring special exemptions or new testing protocols to be developed by certification bodies.

Manufacturers must also consider country-specific requirements that may exceed international standards. For instance, Japan's high-speed rail system imposes additional earthquake resistance requirements, while Russia mandates enhanced cold-weather performance standards that significantly impact engine design and material selection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!