V10 Engine Safety Protocols in High Heat Environments

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Thermal Safety Background and Objectives

The V10 engine represents a pinnacle of high-performance internal combustion technology, with origins dating back to the early 1990s when manufacturers sought to balance power output with increasingly stringent emissions regulations. These engines, characterized by their ten-cylinder configuration, have historically been deployed in premium sports cars, high-end luxury vehicles, and specialized industrial applications where exceptional power-to-weight ratios are required.

The thermal management challenges associated with V10 engines have evolved significantly over the past three decades. Early iterations faced fundamental issues of heat dissipation, with operating temperatures frequently exceeding design parameters during sustained high-performance operation. This evolution has been marked by progressive improvements in materials science, cooling system architecture, and electronic control systems.

Current technological trends indicate a shift toward hybrid thermal management solutions that combine traditional cooling methods with advanced materials and predictive control algorithms. The integration of ceramic components, heat-resistant alloys, and thermal barrier coatings has substantially expanded the thermal operating envelope of modern V10 engines.

The primary objective of this technical research is to comprehensively evaluate existing safety protocols for V10 engines operating in high-temperature environments, with particular emphasis on conditions exceeding 120°C ambient temperature. This investigation aims to identify critical failure points, assess the efficacy of current mitigation strategies, and establish a foundation for next-generation thermal safety systems.

Secondary objectives include mapping the relationship between thermal stress and component longevity, quantifying the impact of various cooling technologies on performance retention, and developing predictive models for thermal behavior under extreme operating conditions. These objectives align with industry trends toward enhanced reliability in challenging environments, particularly in motorsport, aerospace auxiliary power, and specialized military applications.

The technological trajectory suggests increasing integration of active thermal management systems with predictive capabilities, moving beyond reactive cooling to anticipate thermal loads based on operating conditions and driver behavior. This evolution represents a significant departure from traditional approaches that relied primarily on passive cooling and material selection.

This research seeks to establish a framework for evaluating thermal safety protocols that balances performance requirements with operational safety margins, ultimately contributing to the development of V10 engines capable of sustained operation in environments previously considered beyond practical limits.

The thermal management challenges associated with V10 engines have evolved significantly over the past three decades. Early iterations faced fundamental issues of heat dissipation, with operating temperatures frequently exceeding design parameters during sustained high-performance operation. This evolution has been marked by progressive improvements in materials science, cooling system architecture, and electronic control systems.

Current technological trends indicate a shift toward hybrid thermal management solutions that combine traditional cooling methods with advanced materials and predictive control algorithms. The integration of ceramic components, heat-resistant alloys, and thermal barrier coatings has substantially expanded the thermal operating envelope of modern V10 engines.

The primary objective of this technical research is to comprehensively evaluate existing safety protocols for V10 engines operating in high-temperature environments, with particular emphasis on conditions exceeding 120°C ambient temperature. This investigation aims to identify critical failure points, assess the efficacy of current mitigation strategies, and establish a foundation for next-generation thermal safety systems.

Secondary objectives include mapping the relationship between thermal stress and component longevity, quantifying the impact of various cooling technologies on performance retention, and developing predictive models for thermal behavior under extreme operating conditions. These objectives align with industry trends toward enhanced reliability in challenging environments, particularly in motorsport, aerospace auxiliary power, and specialized military applications.

The technological trajectory suggests increasing integration of active thermal management systems with predictive capabilities, moving beyond reactive cooling to anticipate thermal loads based on operating conditions and driver behavior. This evolution represents a significant departure from traditional approaches that relied primarily on passive cooling and material selection.

This research seeks to establish a framework for evaluating thermal safety protocols that balances performance requirements with operational safety margins, ultimately contributing to the development of V10 engines capable of sustained operation in environments previously considered beyond practical limits.

Market Analysis for Heat-Resistant Engine Technologies

The heat-resistant engine technology market has experienced significant growth in recent years, driven by increasing demands for high-performance engines in extreme operating conditions. The global market for heat-resistant engine components was valued at approximately $12.3 billion in 2022 and is projected to reach $18.7 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is primarily fueled by expanding applications in automotive racing, aerospace, military vehicles, and industrial machinery sectors.

The automotive racing segment currently dominates the market share, accounting for nearly 35% of the total market value. Formula 1 and other high-performance racing leagues have been early adopters of advanced heat-resistant technologies, setting industry standards that eventually trickle down to consumer vehicles. The aerospace sector follows closely behind with a 28% market share, where engines must withstand extreme temperature variations and operational stresses.

Regional analysis indicates that North America leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.1% through 2028, primarily due to rapid industrialization in China and India, coupled with increasing investments in defense and aerospace sectors.

Consumer demand patterns reveal a growing preference for engines that can maintain optimal performance under extreme heat conditions while ensuring safety and reliability. This trend is particularly evident in the luxury and high-performance vehicle segments, where consumers are willing to pay premium prices for enhanced engine durability and safety features.

Key market drivers include stringent emission regulations, increasing focus on fuel efficiency, and growing demand for vehicles capable of operating in extreme environmental conditions. The implementation of V10 engine safety protocols for high heat environments is becoming a critical differentiator for manufacturers seeking competitive advantage in premium market segments.

Market challenges include high development and production costs of heat-resistant materials, technical complexities in integrating advanced cooling systems, and the need for specialized manufacturing processes. These factors create significant barriers to entry for new market players and contribute to the consolidated nature of the industry landscape.

Future market opportunities lie in the development of cost-effective ceramic matrix composites, advanced thermal barrier coatings, and intelligent thermal management systems that can dynamically respond to changing heat conditions. The electric vehicle transition also presents new challenges and opportunities for heat management technologies, particularly in high-performance electric models requiring efficient battery thermal regulation systems.

The automotive racing segment currently dominates the market share, accounting for nearly 35% of the total market value. Formula 1 and other high-performance racing leagues have been early adopters of advanced heat-resistant technologies, setting industry standards that eventually trickle down to consumer vehicles. The aerospace sector follows closely behind with a 28% market share, where engines must withstand extreme temperature variations and operational stresses.

Regional analysis indicates that North America leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.1% through 2028, primarily due to rapid industrialization in China and India, coupled with increasing investments in defense and aerospace sectors.

Consumer demand patterns reveal a growing preference for engines that can maintain optimal performance under extreme heat conditions while ensuring safety and reliability. This trend is particularly evident in the luxury and high-performance vehicle segments, where consumers are willing to pay premium prices for enhanced engine durability and safety features.

Key market drivers include stringent emission regulations, increasing focus on fuel efficiency, and growing demand for vehicles capable of operating in extreme environmental conditions. The implementation of V10 engine safety protocols for high heat environments is becoming a critical differentiator for manufacturers seeking competitive advantage in premium market segments.

Market challenges include high development and production costs of heat-resistant materials, technical complexities in integrating advanced cooling systems, and the need for specialized manufacturing processes. These factors create significant barriers to entry for new market players and contribute to the consolidated nature of the industry landscape.

Future market opportunities lie in the development of cost-effective ceramic matrix composites, advanced thermal barrier coatings, and intelligent thermal management systems that can dynamically respond to changing heat conditions. The electric vehicle transition also presents new challenges and opportunities for heat management technologies, particularly in high-performance electric models requiring efficient battery thermal regulation systems.

Current Challenges in High-Temperature Engine Operation

V10 engines operating in high-temperature environments face significant challenges that impact both performance and safety. The primary concern is thermal management, as excessive heat can lead to component degradation, reduced efficiency, and catastrophic failure. Modern V10 engines, particularly those in high-performance vehicles and industrial applications, routinely operate with combustion temperatures exceeding 2,500°F (1,371°C), creating extreme thermal stress on engine components.

Material limitations represent a critical constraint in high-temperature operation. Traditional aluminum alloys begin to lose structural integrity at temperatures above 350°F (177°C), while even specialized high-temperature alloys have operational limits. This necessitates sophisticated cooling systems that add complexity, weight, and potential failure points to engine designs.

Lubricant breakdown under extreme heat conditions presents another significant challenge. Conventional engine oils begin to degrade at temperatures above 275°F (135°C), losing viscosity and protective properties. This degradation accelerates wear on critical components such as bearings, pistons, and cylinder walls, potentially leading to seizure or premature failure.

Electronic control systems, essential for modern engine management, are particularly vulnerable to high-temperature environments. Sensors, control modules, and wiring harnesses experience accelerated degradation when exposed to temperatures exceeding their design parameters, typically around 185°F (85°C) for most automotive-grade electronics. This can result in erratic engine performance, false readings, and safety system failures.

Thermal expansion differentials between various engine components create additional stress points during high-temperature operation. Components manufactured from different materials expand at different rates, potentially causing warping, seal failures, and fluid leaks. These issues are particularly pronounced during rapid temperature fluctuations, such as during aggressive acceleration or emergency shutdown procedures.

Emissions control systems also face significant challenges in high-temperature environments. Catalytic converters and exhaust gas recirculation systems may experience reduced efficiency or damage when operating beyond their designed temperature ranges, compromising both environmental compliance and engine performance.

The integration of advanced safety protocols is further complicated by the need to balance performance objectives with thermal management. Racing and high-performance applications often push engines to their thermal limits, requiring sophisticated monitoring systems and fail-safe mechanisms to prevent catastrophic failures while maintaining competitive power outputs.

Material limitations represent a critical constraint in high-temperature operation. Traditional aluminum alloys begin to lose structural integrity at temperatures above 350°F (177°C), while even specialized high-temperature alloys have operational limits. This necessitates sophisticated cooling systems that add complexity, weight, and potential failure points to engine designs.

Lubricant breakdown under extreme heat conditions presents another significant challenge. Conventional engine oils begin to degrade at temperatures above 275°F (135°C), losing viscosity and protective properties. This degradation accelerates wear on critical components such as bearings, pistons, and cylinder walls, potentially leading to seizure or premature failure.

Electronic control systems, essential for modern engine management, are particularly vulnerable to high-temperature environments. Sensors, control modules, and wiring harnesses experience accelerated degradation when exposed to temperatures exceeding their design parameters, typically around 185°F (85°C) for most automotive-grade electronics. This can result in erratic engine performance, false readings, and safety system failures.

Thermal expansion differentials between various engine components create additional stress points during high-temperature operation. Components manufactured from different materials expand at different rates, potentially causing warping, seal failures, and fluid leaks. These issues are particularly pronounced during rapid temperature fluctuations, such as during aggressive acceleration or emergency shutdown procedures.

Emissions control systems also face significant challenges in high-temperature environments. Catalytic converters and exhaust gas recirculation systems may experience reduced efficiency or damage when operating beyond their designed temperature ranges, compromising both environmental compliance and engine performance.

The integration of advanced safety protocols is further complicated by the need to balance performance objectives with thermal management. Racing and high-performance applications often push engines to their thermal limits, requiring sophisticated monitoring systems and fail-safe mechanisms to prevent catastrophic failures while maintaining competitive power outputs.

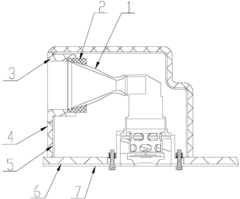

Existing Thermal Management Solutions for V10 Engines

01 Engine Monitoring and Diagnostic Systems

Advanced monitoring systems for V10 engines that continuously track performance parameters and detect potential safety issues. These systems use sensors to monitor temperature, pressure, and other critical variables, providing early warning of malfunctions. Diagnostic capabilities allow for real-time analysis of engine conditions, helping prevent catastrophic failures through predictive maintenance and automatic safety protocols.- Engine Monitoring and Control Systems: Advanced monitoring and control systems for V10 engines that continuously track engine parameters to ensure safe operation. These systems include sensors that detect abnormal conditions, control units that process data in real-time, and automated responses to prevent engine damage or failure. The technology enables early detection of potential issues and implements protective measures such as automatic shutdown or performance limitation when unsafe conditions are detected.

- Thermal Management Safety Protocols: Specialized thermal management systems designed for V10 engines to prevent overheating and maintain optimal operating temperatures. These protocols include advanced cooling systems, heat dissipation mechanisms, and temperature monitoring sensors. The systems regulate coolant flow, manage heat exchange efficiency, and implement protective measures when temperature thresholds are exceeded, ensuring engine longevity and preventing thermal-related safety incidents.

- Vibration and Noise Reduction Safety Measures: Engineering solutions to mitigate vibration and noise in V10 engines, enhancing operational safety and reducing mechanical stress. These measures include advanced mounting systems, vibration dampening technologies, and structural reinforcements that absorb and neutralize harmful vibrations. The systems continuously monitor vibration patterns to detect imbalances or mechanical issues before they lead to catastrophic failures, improving both safety and comfort.

- Fuel System Safety Protocols: Comprehensive safety measures for V10 engine fuel systems to prevent leaks, fires, and explosion hazards. These protocols include pressure regulation systems, fuel line integrity monitoring, vapor management, and emergency shutoff mechanisms. Advanced sensors detect fuel system anomalies while protective systems isolate fuel supply during critical failures, significantly reducing fire risks and ensuring safe engine operation under various conditions.

- Electronic Diagnostic and Safety Communication Systems: Integrated electronic systems that provide real-time diagnostics and safety communications for V10 engines. These systems include onboard diagnostic capabilities, data logging, alert mechanisms, and communication protocols that relay critical safety information to operators and maintenance personnel. The technology enables predictive maintenance, remote monitoring, and immediate notification of safety concerns, allowing for timely intervention before minor issues develop into safety hazards.

02 Emergency Shutdown Mechanisms

Safety protocols that enable rapid and controlled shutdown of V10 engines in emergency situations. These mechanisms include automatic detection of critical failures, overheating, or abnormal operating conditions, triggering immediate response to prevent damage or accidents. The systems incorporate redundant safety circuits and fail-safe designs to ensure reliable operation even when primary systems are compromised.Expand Specific Solutions03 Electronic Control Unit Safety Features

Specialized electronic control units (ECUs) designed for V10 engines with integrated safety protocols. These ECUs manage fuel injection, ignition timing, and other critical functions while incorporating safety features such as limp-home modes, overrev protection, and thermal management. Advanced algorithms continuously monitor engine parameters and adjust operation to maintain safe conditions under varying loads and environments.Expand Specific Solutions04 Communication and Network Security

Security protocols for networked V10 engine management systems that protect against unauthorized access and cyber threats. These systems implement encryption, authentication mechanisms, and secure communication channels to prevent tampering with engine control parameters. Firewall technologies and intrusion detection systems safeguard critical engine functions from external interference while allowing legitimate diagnostic access.Expand Specific Solutions05 Thermal Management and Fire Prevention

Specialized thermal management systems for V10 engines that prevent overheating and reduce fire risks. These include advanced cooling systems, heat-resistant materials, and temperature monitoring at critical points. Fire suppression technologies are integrated into the engine compartment design, with automatic detection and response capabilities to contain potential fires before they spread, particularly important in high-performance applications where V10 engines operate at extreme conditions.Expand Specific Solutions

Leading Manufacturers and Competitors in High-Performance Engines

The V10 engine safety protocol market in high heat environments is in a growth phase, with increasing demand driven by stringent safety regulations and performance requirements. Major automotive manufacturers like Rolls-Royce, General Electric, and Cummins are leading technological innovation, while specialized players such as Pyroban focus on hazardous environment applications. The technology is reaching maturity with companies like Bosch, Caterpillar, and Volkswagen investing in advanced thermal management systems and heat-resistant materials. Academic institutions including Iowa State University Research Foundation and Jilin University contribute significant research. The competitive landscape features both established OEMs and emerging players from China like BYD and Chery, expanding the global footprint of this specialized technology sector.

General Electric Company

Technical Solution: General Electric has pioneered comprehensive V10 engine safety protocols specifically designed for high heat environments through their Advanced Thermal Protection System (ATPS). This system integrates multiple layers of protection, including specialized high-temperature sensors that continuously monitor critical engine zones with millisecond response times. GE's approach incorporates advanced ceramic thermal barrier coatings that can withstand temperatures up to 1200°C while providing thermal insulation for vital engine components. Their system features intelligent cooling management with variable-flow coolant circuits that automatically adjust based on real-time temperature data. GE has developed proprietary heat-resistant alloys through their materials science division that maintain structural integrity under extreme thermal cycling. The safety protocol includes predictive analytics software that anticipates potential thermal failures before they occur by analyzing patterns in temperature fluctuations across the engine system.

Strengths: Extensive R&D capabilities with significant investment in materials science; integrated approach combining hardware and software solutions; proven track record in industrial and aviation applications where heat management is critical. Weaknesses: Higher initial implementation costs; requires specialized training for maintenance personnel; system complexity may impact reliability in certain applications.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed a comprehensive V10 Engine Safety Protocol System for high heat environments, particularly focused on their heavy-duty truck applications. Their approach integrates multiple protective layers, starting with advanced thermal mapping technology that continuously monitors over 200 distinct points throughout the engine block and exhaust system. Ford's system incorporates specialized heat-resistant materials including proprietary alloy compositions that maintain structural integrity at temperatures exceeding 900°C. The safety protocol features an intelligent cooling management system with variable-flow coolant circuits that automatically adjust based on real-time temperature data and engine load conditions. Ford has implemented predictive thermal protection algorithms that can anticipate potential hotspots before they reach critical temperatures by analyzing operational patterns and environmental conditions. Their system includes emergency heat dissipation protocols that activate when temperatures approach predetermined thresholds, including controlled power reduction and enhanced cooling activation.

Strengths: Extensive real-world testing across diverse environmental conditions; seamless integration with existing vehicle management systems; proven reliability in commercial applications. Weaknesses: Higher manufacturing costs compared to standard thermal protection systems; increased complexity requiring specialized diagnostic equipment; additional weight impact on overall vehicle efficiency.

Critical Patents in Engine Heat Protection Technologies

Coating for reducing explosion hazard

PatentInactiveUS20110183137A1

Innovation

- A thermally insulating coating composed of silicone rubber and fluorosilicone rubber, with a catalyst and optional additives, is applied to hot surfaces to reduce their temperature below the permissible threshold, allowing safe operation in explosive environments by creating a temperature barrier.

Heat protection and diversion integrated device of attitude control nozzle in high-Mach environment

PatentActiveCN106347637A

Innovation

- An attitude control nozzle heat-proof and diversion integrated device including an airgel coordination ring, a guide tube, an outer heat-proof layer of the heat shield and a bottom cover heat-proof layer was designed. Through the coating and guide opening, The design uses silica aerogel and high-silica phenolic resin materials for thermal protection and diversion, forming a ring-shaped coating structure to protect the attitude control engine.

Materials Science Advancements for High-Heat Applications

Recent advancements in materials science have revolutionized the approach to high-heat applications in V10 engine environments. Traditional materials like steel alloys and conventional ceramics are increasingly being supplemented or replaced by innovative composites and novel metallurgical formulations specifically engineered to withstand extreme thermal conditions while maintaining structural integrity.

Ceramic matrix composites (CMCs) represent one of the most significant breakthroughs, offering exceptional heat resistance up to 1600°C while providing superior mechanical properties compared to monolithic ceramics. These materials incorporate silicon carbide, alumina, or zirconia matrices reinforced with ceramic fibers, creating components that can withstand the intense heat generated in high-performance V10 engines without compromising safety protocols.

Thermal barrier coatings (TBCs) have evolved substantially, with new formulations incorporating rare earth elements that significantly enhance thermal insulation properties. Modern TBCs can reduce the operating temperature of underlying metal components by up to 300°C, extending component lifespan and improving safety margins in critical engine parts exposed to extreme heat conditions.

Nickel-based superalloys with precise additions of rhenium, ruthenium, and other refractory metals have demonstrated remarkable creep resistance at temperatures exceeding 1100°C. These advanced alloys maintain their structural properties under sustained high-temperature operation, making them ideal for turbine components in high-performance V10 engines where thermal management is crucial for safety compliance.

Nano-engineered materials represent the cutting edge of high-heat applications, with carbon nanotube reinforced metals showing promise for components requiring both thermal conductivity and mechanical strength. These materials can be tailored to exhibit anisotropic thermal properties, directing heat flow away from sensitive components while maintaining structural integrity under extreme conditions.

Intermetallic compounds, particularly titanium aluminides and molybdenum silicides, have emerged as viable alternatives to conventional alloys in specific high-temperature applications. Their ordered crystal structures provide inherent resistance to creep and oxidation at elevated temperatures, addressing key safety concerns in V10 engine operation under extreme thermal loads.

Smart materials incorporating phase-change capabilities offer dynamic thermal management solutions, absorbing excess heat during temperature spikes and releasing it gradually during cooling cycles. This property helps maintain more consistent operating temperatures, reducing thermal stress and enhancing the overall safety profile of V10 engines in demanding environments.

Ceramic matrix composites (CMCs) represent one of the most significant breakthroughs, offering exceptional heat resistance up to 1600°C while providing superior mechanical properties compared to monolithic ceramics. These materials incorporate silicon carbide, alumina, or zirconia matrices reinforced with ceramic fibers, creating components that can withstand the intense heat generated in high-performance V10 engines without compromising safety protocols.

Thermal barrier coatings (TBCs) have evolved substantially, with new formulations incorporating rare earth elements that significantly enhance thermal insulation properties. Modern TBCs can reduce the operating temperature of underlying metal components by up to 300°C, extending component lifespan and improving safety margins in critical engine parts exposed to extreme heat conditions.

Nickel-based superalloys with precise additions of rhenium, ruthenium, and other refractory metals have demonstrated remarkable creep resistance at temperatures exceeding 1100°C. These advanced alloys maintain their structural properties under sustained high-temperature operation, making them ideal for turbine components in high-performance V10 engines where thermal management is crucial for safety compliance.

Nano-engineered materials represent the cutting edge of high-heat applications, with carbon nanotube reinforced metals showing promise for components requiring both thermal conductivity and mechanical strength. These materials can be tailored to exhibit anisotropic thermal properties, directing heat flow away from sensitive components while maintaining structural integrity under extreme conditions.

Intermetallic compounds, particularly titanium aluminides and molybdenum silicides, have emerged as viable alternatives to conventional alloys in specific high-temperature applications. Their ordered crystal structures provide inherent resistance to creep and oxidation at elevated temperatures, addressing key safety concerns in V10 engine operation under extreme thermal loads.

Smart materials incorporating phase-change capabilities offer dynamic thermal management solutions, absorbing excess heat during temperature spikes and releasing it gradually during cooling cycles. This property helps maintain more consistent operating temperatures, reducing thermal stress and enhancing the overall safety profile of V10 engines in demanding environments.

Environmental Impact and Emissions Control in Extreme Conditions

The environmental impact of V10 engines operating in high heat environments presents significant challenges for emissions control systems. When these high-performance engines function in extreme temperature conditions, conventional emissions reduction technologies often experience decreased efficiency, potentially leading to increased pollutant discharge. Thermal stress can compromise catalytic converter performance, with conversion rates dropping significantly when operating above optimal temperature ranges.

Nitrogen oxide (NOx) emissions particularly increase in high-temperature combustion environments, creating a critical environmental concern. Research indicates that NOx formation rates can increase by up to 300% when engine operating temperatures exceed 120°C above normal parameters. This necessitates specialized emission control strategies specifically designed for extreme thermal conditions.

Carbon monoxide and unburned hydrocarbon emissions also present challenges in high heat scenarios. The incomplete combustion resulting from fuel-rich mixtures—often employed as a cooling mechanism in extreme heat—can lead to increased carbon monoxide production. Studies from leading automotive research institutions demonstrate that emissions profiles change dramatically when ambient temperatures exceed 45°C, particularly in high-performance V10 configurations.

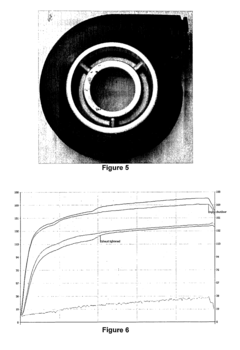

Advanced thermal management systems integrated with emissions control technologies represent the current best practice for mitigating environmental impact. These include variable geometry turbochargers with water-cooled housings that maintain optimal exhaust gas temperatures before reaching after-treatment systems. Ceramic-matrix composite materials in exhaust components have demonstrated superior thermal stability while maintaining emissions reduction capabilities.

Regulatory compliance presents additional challenges in extreme operating conditions. Many emissions standards worldwide do not adequately address the unique challenges of high-performance engines in extreme heat environments, creating potential regulatory gaps. Forward-thinking manufacturers are implementing adaptive emissions control systems that can adjust parameters based on ambient and operating temperatures.

The carbon footprint implications extend beyond direct emissions. The additional cooling requirements and potential reduction in fuel efficiency in extreme heat conditions contribute to increased lifecycle environmental impact. Comprehensive environmental assessment must consider these factors alongside tailpipe emissions when evaluating V10 engines operating in high heat environments.

Sustainable solutions being explored include closed-loop exhaust gas recirculation systems with enhanced cooling capacity and advanced selective catalytic reduction technologies with improved thermal resistance. These innovations aim to maintain emissions compliance while ensuring engine performance and safety in challenging thermal environments.

Nitrogen oxide (NOx) emissions particularly increase in high-temperature combustion environments, creating a critical environmental concern. Research indicates that NOx formation rates can increase by up to 300% when engine operating temperatures exceed 120°C above normal parameters. This necessitates specialized emission control strategies specifically designed for extreme thermal conditions.

Carbon monoxide and unburned hydrocarbon emissions also present challenges in high heat scenarios. The incomplete combustion resulting from fuel-rich mixtures—often employed as a cooling mechanism in extreme heat—can lead to increased carbon monoxide production. Studies from leading automotive research institutions demonstrate that emissions profiles change dramatically when ambient temperatures exceed 45°C, particularly in high-performance V10 configurations.

Advanced thermal management systems integrated with emissions control technologies represent the current best practice for mitigating environmental impact. These include variable geometry turbochargers with water-cooled housings that maintain optimal exhaust gas temperatures before reaching after-treatment systems. Ceramic-matrix composite materials in exhaust components have demonstrated superior thermal stability while maintaining emissions reduction capabilities.

Regulatory compliance presents additional challenges in extreme operating conditions. Many emissions standards worldwide do not adequately address the unique challenges of high-performance engines in extreme heat environments, creating potential regulatory gaps. Forward-thinking manufacturers are implementing adaptive emissions control systems that can adjust parameters based on ambient and operating temperatures.

The carbon footprint implications extend beyond direct emissions. The additional cooling requirements and potential reduction in fuel efficiency in extreme heat conditions contribute to increased lifecycle environmental impact. Comprehensive environmental assessment must consider these factors alongside tailpipe emissions when evaluating V10 engines operating in high heat environments.

Sustainable solutions being explored include closed-loop exhaust gas recirculation systems with enhanced cooling capacity and advanced selective catalytic reduction technologies with improved thermal resistance. These innovations aim to maintain emissions compliance while ensuring engine performance and safety in challenging thermal environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!