Optimizing V10 Engine for Thermal Energy Management

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Thermal Management Background and Objectives

The V10 engine represents a pinnacle of internal combustion engine design, combining high performance with sophisticated engineering. Historically, V10 engines emerged in the 1980s in Formula One racing before transitioning to production vehicles in the early 1990s. These engines have since evolved from purely performance-focused designs to more balanced systems that must address increasingly stringent efficiency and emissions requirements while maintaining their characteristic power delivery and acoustic signature.

Thermal management has become a critical aspect of V10 engine development as manufacturers seek to optimize performance while meeting regulatory standards. The evolution of thermal management systems in high-performance engines has progressed from basic cooling systems to complex, integrated thermal energy management architectures that address multiple heat sources and utilize waste heat recovery technologies.

The primary objective of optimizing V10 engines for thermal energy management is to achieve an optimal balance between performance, efficiency, and reliability. This involves developing systems that can maintain ideal operating temperatures across all engine components under varying load conditions, from idle to full throttle, and in diverse environmental conditions. Additionally, modern thermal management must address the challenge of heat rejection in increasingly compact engine compartments where aerodynamic considerations limit cooling airflow.

Current thermal management challenges specific to V10 engines include managing the substantial heat generated by ten high-compression cylinders, addressing thermal expansion across the extended block length, and ensuring uniform temperature distribution to prevent localized hotspots that can lead to detonation or component failure. The V-configuration presents unique cooling channel design challenges compared to inline or flat engine layouts.

Technological advancements in materials science, computational fluid dynamics, and electronic control systems have enabled significant improvements in thermal management capabilities. Modern V10 engines increasingly incorporate precision cooling strategies, variable-flow cooling systems, integrated exhaust heat recovery, and advanced thermal barrier coatings to optimize thermal energy utilization.

The target outcomes for enhanced thermal management in V10 engines include reducing warm-up times to minimize cold-start emissions, improving thermal efficiency to extract maximum energy from fuel, extending component longevity through more consistent temperature control, and potentially recovering waste heat for conversion to useful energy through thermoelectric generators or other recovery systems.

As regulatory pressures intensify globally, optimizing thermal energy management represents a critical pathway for preserving the viability of high-performance V10 engines in both motorsport and production vehicle applications, making this research area strategically important for manufacturers committed to this engine configuration.

Thermal management has become a critical aspect of V10 engine development as manufacturers seek to optimize performance while meeting regulatory standards. The evolution of thermal management systems in high-performance engines has progressed from basic cooling systems to complex, integrated thermal energy management architectures that address multiple heat sources and utilize waste heat recovery technologies.

The primary objective of optimizing V10 engines for thermal energy management is to achieve an optimal balance between performance, efficiency, and reliability. This involves developing systems that can maintain ideal operating temperatures across all engine components under varying load conditions, from idle to full throttle, and in diverse environmental conditions. Additionally, modern thermal management must address the challenge of heat rejection in increasingly compact engine compartments where aerodynamic considerations limit cooling airflow.

Current thermal management challenges specific to V10 engines include managing the substantial heat generated by ten high-compression cylinders, addressing thermal expansion across the extended block length, and ensuring uniform temperature distribution to prevent localized hotspots that can lead to detonation or component failure. The V-configuration presents unique cooling channel design challenges compared to inline or flat engine layouts.

Technological advancements in materials science, computational fluid dynamics, and electronic control systems have enabled significant improvements in thermal management capabilities. Modern V10 engines increasingly incorporate precision cooling strategies, variable-flow cooling systems, integrated exhaust heat recovery, and advanced thermal barrier coatings to optimize thermal energy utilization.

The target outcomes for enhanced thermal management in V10 engines include reducing warm-up times to minimize cold-start emissions, improving thermal efficiency to extract maximum energy from fuel, extending component longevity through more consistent temperature control, and potentially recovering waste heat for conversion to useful energy through thermoelectric generators or other recovery systems.

As regulatory pressures intensify globally, optimizing thermal energy management represents a critical pathway for preserving the viability of high-performance V10 engines in both motorsport and production vehicle applications, making this research area strategically important for manufacturers committed to this engine configuration.

Market Demand Analysis for Efficient V10 Engines

The global market for high-performance V10 engines is experiencing significant transformation driven by stringent emission regulations and increasing consumer demand for fuel efficiency without compromising power. Current market analysis indicates that while traditional V10 engines maintain strong appeal in luxury and sports vehicle segments, their market share faces pressure from alternative powertrains and smaller, more efficient engine configurations.

Market research reveals that the premium automotive sector, where V10 engines predominantly operate, is projected to grow at a compound annual rate of 4.2% through 2028. However, within this growth, thermal efficiency has emerged as a critical differentiator. Vehicles equipped with thermally optimized V10 engines command price premiums averaging 15-20% higher than their less efficient counterparts, indicating strong consumer willingness to pay for improved efficiency when performance is maintained.

Regional analysis shows divergent market trends. European markets are increasingly focused on thermal efficiency due to strict CO2 emission standards, with manufacturers facing substantial penalties for non-compliance. North American consumers continue to prioritize performance but show growing interest in fuel economy improvements. Meanwhile, emerging Asian markets, particularly China, demonstrate rapidly increasing demand for high-performance vehicles with advanced thermal management systems that reduce operational costs.

Fleet emission targets worldwide are creating substantial pressure on manufacturers to improve thermal efficiency across all engine types. For V10 engines specifically, OEMs report that each percentage point improvement in thermal efficiency can translate to approximately 3-4% reduction in fleet-wide emissions contribution from these high-output engines, creating significant regulatory value.

Consumer behavior studies indicate evolving priorities among luxury vehicle buyers. While performance metrics remain paramount, efficiency considerations have risen from the eighth most important purchasing factor in 2015 to the third most important in 2023. This shift represents a fundamental change in market expectations for high-performance engines.

Industry forecasts suggest that the market for thermally optimized V10 engines will experience bifurcation. One segment will focus on ultimate performance with efficiency as a secondary benefit, while another will emphasize balanced optimization where thermal efficiency enables sustained performance under varying conditions. The latter segment shows particularly strong growth potential in regions with variable climate conditions and among buyers who use their vehicles for both track and everyday driving.

Competition analysis reveals that manufacturers who have already invested in thermal optimization technologies for their V10 engines have gained market share averaging 2.3% over the past three years, demonstrating tangible commercial benefits from addressing this technical challenge.

Market research reveals that the premium automotive sector, where V10 engines predominantly operate, is projected to grow at a compound annual rate of 4.2% through 2028. However, within this growth, thermal efficiency has emerged as a critical differentiator. Vehicles equipped with thermally optimized V10 engines command price premiums averaging 15-20% higher than their less efficient counterparts, indicating strong consumer willingness to pay for improved efficiency when performance is maintained.

Regional analysis shows divergent market trends. European markets are increasingly focused on thermal efficiency due to strict CO2 emission standards, with manufacturers facing substantial penalties for non-compliance. North American consumers continue to prioritize performance but show growing interest in fuel economy improvements. Meanwhile, emerging Asian markets, particularly China, demonstrate rapidly increasing demand for high-performance vehicles with advanced thermal management systems that reduce operational costs.

Fleet emission targets worldwide are creating substantial pressure on manufacturers to improve thermal efficiency across all engine types. For V10 engines specifically, OEMs report that each percentage point improvement in thermal efficiency can translate to approximately 3-4% reduction in fleet-wide emissions contribution from these high-output engines, creating significant regulatory value.

Consumer behavior studies indicate evolving priorities among luxury vehicle buyers. While performance metrics remain paramount, efficiency considerations have risen from the eighth most important purchasing factor in 2015 to the third most important in 2023. This shift represents a fundamental change in market expectations for high-performance engines.

Industry forecasts suggest that the market for thermally optimized V10 engines will experience bifurcation. One segment will focus on ultimate performance with efficiency as a secondary benefit, while another will emphasize balanced optimization where thermal efficiency enables sustained performance under varying conditions. The latter segment shows particularly strong growth potential in regions with variable climate conditions and among buyers who use their vehicles for both track and everyday driving.

Competition analysis reveals that manufacturers who have already invested in thermal optimization technologies for their V10 engines have gained market share averaging 2.3% over the past three years, demonstrating tangible commercial benefits from addressing this technical challenge.

Current Thermal Management Challenges in V10 Engines

V10 engines, known for their high performance and distinctive sound profile, face significant thermal management challenges that impact both efficiency and longevity. The primary challenge stems from the inherent design of these engines, which generate substantial heat during operation due to their high displacement and power output. Internal combustion temperatures can exceed 2,500°C, creating thermal stress points throughout the engine block and cylinder heads.

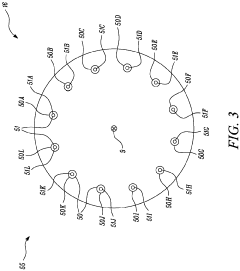

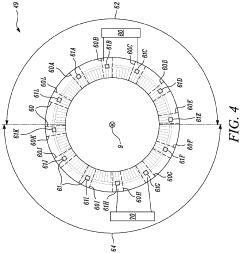

Heat dissipation represents a critical concern, particularly in high-performance applications where V10 engines operate near their maximum capacity for extended periods. Conventional cooling systems often struggle to maintain optimal operating temperatures across all cylinders uniformly. The V-configuration creates uneven heat distribution, with cylinders closer to the center of the engine block typically experiencing higher thermal loads than those positioned at the ends.

Material limitations further complicate thermal management in V10 engines. While lightweight alloys offer weight advantages, they frequently exhibit different thermal expansion characteristics compared to traditional materials, creating potential issues at component interfaces during thermal cycling. This becomes particularly problematic at the junction points between the cylinder head and engine block, where gasket failures can occur due to differential expansion rates.

Oil cooling systems in current V10 designs often reach their capacity limits during sustained high-performance operation. The oil not only serves as a lubricant but also plays a crucial role in heat transfer, carrying thermal energy away from critical components. However, oil degradation accelerates at elevated temperatures, reducing its effectiveness as both a lubricant and coolant over time.

Exhaust heat management presents another significant challenge. The substantial thermal energy carried by exhaust gases contributes to underhood temperature increases, potentially affecting nearby components and electronic systems. Current heat shielding technologies provide limited protection, especially in compact engine bay configurations where space constraints limit the implementation of comprehensive thermal barriers.

Electronic control units governing fuel injection, ignition timing, and other critical functions must operate within specific temperature ranges to maintain accuracy. The proximity of these components to heat sources in modern V10 engines creates reliability concerns, necessitating additional cooling provisions or heat-resistant designs that add complexity and cost to the overall system.

Emissions control systems, particularly catalytic converters, require specific temperature ranges for optimal operation. Too low temperatures prevent proper catalyst activation, while excessive heat can damage these expensive components. Balancing these requirements while managing the overall thermal profile of the engine represents a significant engineering challenge in contemporary V10 designs.

Heat dissipation represents a critical concern, particularly in high-performance applications where V10 engines operate near their maximum capacity for extended periods. Conventional cooling systems often struggle to maintain optimal operating temperatures across all cylinders uniformly. The V-configuration creates uneven heat distribution, with cylinders closer to the center of the engine block typically experiencing higher thermal loads than those positioned at the ends.

Material limitations further complicate thermal management in V10 engines. While lightweight alloys offer weight advantages, they frequently exhibit different thermal expansion characteristics compared to traditional materials, creating potential issues at component interfaces during thermal cycling. This becomes particularly problematic at the junction points between the cylinder head and engine block, where gasket failures can occur due to differential expansion rates.

Oil cooling systems in current V10 designs often reach their capacity limits during sustained high-performance operation. The oil not only serves as a lubricant but also plays a crucial role in heat transfer, carrying thermal energy away from critical components. However, oil degradation accelerates at elevated temperatures, reducing its effectiveness as both a lubricant and coolant over time.

Exhaust heat management presents another significant challenge. The substantial thermal energy carried by exhaust gases contributes to underhood temperature increases, potentially affecting nearby components and electronic systems. Current heat shielding technologies provide limited protection, especially in compact engine bay configurations where space constraints limit the implementation of comprehensive thermal barriers.

Electronic control units governing fuel injection, ignition timing, and other critical functions must operate within specific temperature ranges to maintain accuracy. The proximity of these components to heat sources in modern V10 engines creates reliability concerns, necessitating additional cooling provisions or heat-resistant designs that add complexity and cost to the overall system.

Emissions control systems, particularly catalytic converters, require specific temperature ranges for optimal operation. Too low temperatures prevent proper catalyst activation, while excessive heat can damage these expensive components. Balancing these requirements while managing the overall thermal profile of the engine represents a significant engineering challenge in contemporary V10 designs.

Current V10 Thermal Management Approaches

01 Cooling systems for V10 engines

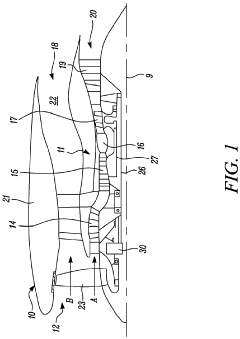

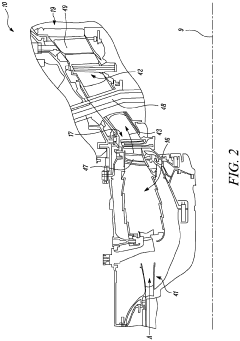

Advanced cooling systems specifically designed for V10 engines help manage thermal energy efficiently. These systems include specialized radiators, coolant circulation pathways, and temperature-controlled components that prevent overheating during high-performance operation. The cooling architecture is optimized to address the unique heat distribution patterns of the V10 configuration, ensuring consistent performance while maintaining optimal operating temperatures across all cylinders.- Cooling systems for V10 engines: Advanced cooling systems are essential for managing thermal energy in V10 engines. These systems typically include specialized coolant circulation pathways, heat exchangers, and temperature-controlled valves that work together to maintain optimal operating temperatures. By efficiently removing excess heat from critical engine components, these cooling systems prevent overheating, reduce thermal stress, and improve overall engine performance and longevity.

- Heat recovery and energy conversion systems: V10 engines generate significant waste heat that can be captured and converted into useful energy. Heat recovery systems utilize thermoelectric generators, Rankine cycle systems, or other technologies to convert thermal energy from exhaust gases and cooling systems into electrical power. These systems improve overall engine efficiency by reclaiming energy that would otherwise be lost, reducing fuel consumption and emissions while providing additional power for vehicle systems.

- Thermal management control strategies: Advanced control strategies are implemented to optimize thermal energy management in V10 engines. These include electronic control units that monitor multiple temperature sensors and adjust cooling system parameters in real-time. Predictive algorithms can anticipate thermal loads based on driving conditions and engine operation, allowing for proactive thermal management. These control strategies balance cooling needs with efficiency goals, managing warm-up periods and maintaining ideal operating temperatures across various engine components.

- Integrated thermal management systems: Integrated thermal management systems take a holistic approach to V10 engine cooling by coordinating multiple subsystems including engine cooling, transmission cooling, and HVAC systems. These integrated systems use shared components such as pumps, valves, and heat exchangers to optimize overall vehicle thermal management. By centralizing thermal control and sharing thermal resources across vehicle systems, these approaches improve efficiency, reduce component count, and enable more precise temperature control throughout the powertrain.

- Advanced materials and design for thermal efficiency: Innovative materials and design approaches enhance thermal efficiency in V10 engines. Ceramic coatings, advanced alloys, and composite materials are used to improve heat retention or dissipation as needed. Strategic component placement and airflow management optimize thermal distribution within the engine bay. Heat shields, insulation, and thermal barriers direct heat flow to protect sensitive components while maintaining efficient operation. These material and design innovations help manage thermal loads while reducing weight and improving durability.

02 Heat recovery systems for V10 engines

Heat recovery systems capture and repurpose thermal energy that would otherwise be wasted in V10 engines. These systems convert exhaust heat into usable energy through technologies such as thermoelectric generators or Rankine cycle systems. By recovering waste heat, these innovations improve overall engine efficiency, reduce fuel consumption, and lower emissions while providing additional power for vehicle systems or battery charging in hybrid applications.Expand Specific Solutions03 Thermal management integration with powertrain systems

Integrated thermal management approaches connect the V10 engine cooling system with other powertrain components such as transmission cooling, battery thermal management, and HVAC systems. This holistic approach optimizes overall vehicle thermal efficiency by sharing cooling resources, prioritizing thermal needs based on operating conditions, and implementing sophisticated control algorithms that balance performance, efficiency, and emissions requirements across the entire vehicle system.Expand Specific Solutions04 Advanced materials and coatings for thermal efficiency

Specialized materials and thermal coatings enhance heat management in V10 engines. These include ceramic thermal barriers, advanced alloys with superior heat dissipation properties, and composite materials that can withstand extreme temperature variations. Such materials are strategically applied to critical engine components like cylinder heads, exhaust manifolds, and pistons to control heat flow, reduce thermal stress, and improve durability while maintaining optimal operating temperatures.Expand Specific Solutions05 Electronic thermal management control systems

Sophisticated electronic control systems optimize thermal energy management in V10 engines through real-time monitoring and adjustment. These systems employ multiple temperature sensors, adaptive cooling strategies, and predictive algorithms to anticipate thermal loads. The controllers can adjust coolant flow rates, fan speeds, and other parameters based on driving conditions, engine load, and ambient temperature to maintain ideal operating temperatures while maximizing efficiency and performance.Expand Specific Solutions

Key Players in High-Performance Engine Thermal Solutions

The V10 engine thermal energy management market is in a growth phase, with increasing demand driven by automotive efficiency regulations and sustainability goals. The competitive landscape is characterized by established automotive suppliers like Valeo Thermique Moteur, Hanon Systems, and DENSO Corp leading innovation, alongside major automakers including Hyundai, Kia, BYD, and Mercedes-Benz who are integrating advanced thermal management into their vehicle platforms. Technology maturity varies, with traditional players (Cummins, GE) focusing on incremental improvements while emerging competitors (BYD, Vitesco Technologies) are developing more disruptive electrified solutions. The market is witnessing convergence between conventional thermal management and electrification technologies, with companies like Continental Automotive Technologies and Schaeffler developing hybrid approaches to optimize thermal efficiency across powertrain types.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative thermal energy management system for V10 engines that focuses on maximizing energy recovery and minimizing thermal losses. Their solution incorporates a split cooling system with precision electronic control that maintains optimal operating temperatures across different engine load conditions. The system features Hyundai's proprietary Active Thermal Management (ATM) technology that uses electronically controlled valves to direct coolant flow only to areas requiring cooling, reducing parasitic losses and improving warm-up times by up to 40%. Hyundai's V10 thermal optimization includes an integrated exhaust heat recovery system that captures waste heat from exhaust gases and converts it to useful energy through a compact heat exchanger design. The system also employs advanced thermal barrier coatings on combustion chamber components that reduce heat rejection to the cooling system by approximately 15%, allowing more thermal energy to be converted to mechanical work. Additionally, Hyundai has implemented smart thermostat technology that provides variable temperature control based on engine load and ambient conditions.

Strengths: Excellent cold-start performance with rapid warm-up capabilities; sophisticated electronic control system optimizes temperature across varying operating conditions. Weaknesses: Higher system complexity requires more sophisticated diagnostic equipment; potential reliability concerns with multiple electronically controlled components in harsh underhood environments.

Cummins, Inc.

Technical Solution: Cummins has developed an advanced thermal management system for V10 engines that integrates waste heat recovery (WHR) technology with precision cooling. Their solution employs a split cooling system that separately regulates cylinder head and block temperatures for optimal thermal efficiency. The system incorporates advanced electronic control units that continuously monitor engine temperature across multiple zones and dynamically adjust coolant flow rates. Cummins' V10 thermal optimization includes variable-speed smart pumps that reduce parasitic losses by up to 30% compared to traditional fixed-flow systems. Their proprietary exhaust gas recirculation (EGR) cooling technology precisely manages exhaust gas temperatures to reduce NOx emissions while capturing waste heat for improved fuel efficiency. The system also features advanced materials with enhanced thermal conductivity in critical components, allowing for more efficient heat transfer and reduced thermal stress on engine components.

Strengths: Superior waste heat recovery capabilities that significantly improve overall engine efficiency; advanced electronic control systems provide precise temperature management across varying operating conditions. Weaknesses: Higher initial system complexity and cost compared to conventional cooling systems; requires more sophisticated maintenance procedures and diagnostic equipment.

Critical Heat Transfer Technologies for V10 Engines

Increasing the effectiveness of hydrogen-operated internal combustion engines

PatentInactiveEP1664504A1

Innovation

- Supplying steam isochorically at the final phase of compression or after compression has taken place, with water vapor being introduced at temperatures up to 1000°C and pressures between 100 and 300 bar, utilizing heat recovery from exhaust gas streams to reduce working temperatures and enhance material strength.

Method of optimising gas turbine engine, combustion equipment performance

PatentActiveEP4276294A1

Innovation

- Repositioning fuel injectors based on temperature rankings and flow clocking relationships to minimize temperature differences across channels, ensuring optimal operation and preventing TGT cross-check issues.

Environmental Impact and Emissions Regulations

The environmental impact of V10 engines has become a critical concern in the automotive industry, particularly as global emissions regulations continue to tighten. V10 engines, known for their high performance and distinctive sound profile, traditionally consume significant fuel and produce substantial carbon emissions compared to smaller displacement engines. Recent data indicates that unoptimized V10 engines can emit up to 300-350g CO2/km under standard driving conditions, far exceeding the targets set by major regulatory frameworks.

Current emissions regulations present significant challenges for V10 engine development. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose stricter limits on nitrogen oxides (NOx) and particulate matter. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States and China's increasingly stringent emissions policies are reshaping the regulatory landscape for high-performance engines.

Thermal energy management optimization offers a promising pathway to address these regulatory challenges. By improving thermal efficiency, V10 engines can reduce fuel consumption by 8-12% and consequently lower emissions. Advanced thermal management systems that capture and repurpose waste heat can further reduce the environmental footprint of these powerful engines. Technologies such as integrated exhaust heat recovery systems have demonstrated potential to convert up to 10% of otherwise wasted thermal energy into useful power.

The integration of thermal energy management with emissions control systems represents another critical development area. Optimized thermal conditions can significantly enhance the performance of catalytic converters and particulate filters, allowing them to reach operational temperatures more quickly and maintain optimal efficiency across a broader range of driving conditions. Studies indicate that advanced thermal management can reduce cold-start emissions—a major contributor to overall vehicle emissions—by up to 30%.

Manufacturers must also consider the complete lifecycle environmental impact of V10 engines. This includes the carbon footprint of manufacturing processes, the environmental costs of specialized materials required for thermal management systems, and end-of-life recycling considerations. A comprehensive lifecycle assessment conducted by automotive research institutes suggests that optimized thermal management can reduce the overall environmental impact of V10 engines by 15-20% when considering the entire product lifecycle.

Looking forward, compliance with future emissions regulations will likely require a multi-faceted approach combining thermal energy management with complementary technologies such as mild hybridization, advanced materials, and intelligent control systems. This integrated approach will be essential for preserving the V10 engine's place in high-performance applications while meeting increasingly stringent environmental standards.

Current emissions regulations present significant challenges for V10 engine development. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose stricter limits on nitrogen oxides (NOx) and particulate matter. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States and China's increasingly stringent emissions policies are reshaping the regulatory landscape for high-performance engines.

Thermal energy management optimization offers a promising pathway to address these regulatory challenges. By improving thermal efficiency, V10 engines can reduce fuel consumption by 8-12% and consequently lower emissions. Advanced thermal management systems that capture and repurpose waste heat can further reduce the environmental footprint of these powerful engines. Technologies such as integrated exhaust heat recovery systems have demonstrated potential to convert up to 10% of otherwise wasted thermal energy into useful power.

The integration of thermal energy management with emissions control systems represents another critical development area. Optimized thermal conditions can significantly enhance the performance of catalytic converters and particulate filters, allowing them to reach operational temperatures more quickly and maintain optimal efficiency across a broader range of driving conditions. Studies indicate that advanced thermal management can reduce cold-start emissions—a major contributor to overall vehicle emissions—by up to 30%.

Manufacturers must also consider the complete lifecycle environmental impact of V10 engines. This includes the carbon footprint of manufacturing processes, the environmental costs of specialized materials required for thermal management systems, and end-of-life recycling considerations. A comprehensive lifecycle assessment conducted by automotive research institutes suggests that optimized thermal management can reduce the overall environmental impact of V10 engines by 15-20% when considering the entire product lifecycle.

Looking forward, compliance with future emissions regulations will likely require a multi-faceted approach combining thermal energy management with complementary technologies such as mild hybridization, advanced materials, and intelligent control systems. This integrated approach will be essential for preserving the V10 engine's place in high-performance applications while meeting increasingly stringent environmental standards.

Materials Science Advancements for Thermal Efficiency

Recent advancements in materials science have revolutionized thermal efficiency optimization for V10 engines. High-performance ceramic coatings, particularly yttria-stabilized zirconia (YSZ) and thermal barrier coatings (TBCs), have demonstrated exceptional heat insulation properties when applied to combustion chambers and exhaust manifolds. These coatings can withstand temperatures exceeding 1200°C while reducing heat transfer to surrounding components by up to 30%, significantly improving thermal management.

Nano-engineered aluminum alloys represent another breakthrough, offering 15-20% better thermal conductivity than traditional alloys while maintaining comparable mechanical strength. These materials enable more efficient heat dissipation in critical engine components such as cylinder heads and blocks, preventing localized hotspots that compromise performance and longevity.

Shape memory alloys (SMAs) are emerging as adaptive thermal management solutions, changing their crystalline structure in response to temperature variations. When integrated into cooling systems, these materials can automatically adjust coolant flow paths based on engine temperature, optimizing thermal regulation without requiring additional sensors or control systems.

Carbon-carbon composites, previously limited to aerospace applications due to prohibitive costs, are becoming viable for high-performance V10 engines. These materials offer exceptional thermal stability up to 2000°C in non-oxidizing environments while weighing 60-70% less than traditional metal components. Their application in exhaust components and heat shields has demonstrated fuel efficiency improvements of 2-3%.

Advanced polymer composites reinforced with carbon nanotubes have shown promise for peripheral cooling components. These materials combine lightweight properties with enhanced thermal conductivity, allowing for more efficient radiator designs and cooling channels that optimize airflow dynamics while reducing overall engine weight.

Microencapsulated phase change materials (PCMs) represent an innovative approach to thermal energy storage within engine systems. These materials absorb excess heat during high-load operations and release it during cooler operating conditions, effectively "banking" thermal energy to maintain optimal temperature ranges and reduce thermal cycling stress.

Graphene-enhanced materials are perhaps the most promising frontier, with thermal conductivity values exceeding 5000 W/mK - significantly higher than copper (400 W/mK). Though manufacturing challenges persist, preliminary applications in thermal interface materials have demonstrated temperature reductions of up to 15°C at critical junction points, suggesting transformative potential for comprehensive V10 thermal management systems.

Nano-engineered aluminum alloys represent another breakthrough, offering 15-20% better thermal conductivity than traditional alloys while maintaining comparable mechanical strength. These materials enable more efficient heat dissipation in critical engine components such as cylinder heads and blocks, preventing localized hotspots that compromise performance and longevity.

Shape memory alloys (SMAs) are emerging as adaptive thermal management solutions, changing their crystalline structure in response to temperature variations. When integrated into cooling systems, these materials can automatically adjust coolant flow paths based on engine temperature, optimizing thermal regulation without requiring additional sensors or control systems.

Carbon-carbon composites, previously limited to aerospace applications due to prohibitive costs, are becoming viable for high-performance V10 engines. These materials offer exceptional thermal stability up to 2000°C in non-oxidizing environments while weighing 60-70% less than traditional metal components. Their application in exhaust components and heat shields has demonstrated fuel efficiency improvements of 2-3%.

Advanced polymer composites reinforced with carbon nanotubes have shown promise for peripheral cooling components. These materials combine lightweight properties with enhanced thermal conductivity, allowing for more efficient radiator designs and cooling channels that optimize airflow dynamics while reducing overall engine weight.

Microencapsulated phase change materials (PCMs) represent an innovative approach to thermal energy storage within engine systems. These materials absorb excess heat during high-load operations and release it during cooler operating conditions, effectively "banking" thermal energy to maintain optimal temperature ranges and reduce thermal cycling stress.

Graphene-enhanced materials are perhaps the most promising frontier, with thermal conductivity values exceeding 5000 W/mK - significantly higher than copper (400 W/mK). Though manufacturing challenges persist, preliminary applications in thermal interface materials have demonstrated temperature reductions of up to 15°C at critical junction points, suggesting transformative potential for comprehensive V10 thermal management systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!