V10 Engine Design Adjustments for Lower Emission Rates

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and Emission Reduction Goals

The V10 engine represents a pinnacle of internal combustion engineering, combining high performance with distinctive sound characteristics that have made it a favorite among automotive enthusiasts. Since its commercial introduction in the early 1990s, the V10 architecture has evolved significantly, particularly in response to increasingly stringent emission regulations worldwide. Initially developed for motorsport applications, these engines found their way into premium production vehicles, with early designs prioritizing power output over environmental considerations.

The evolution of V10 engines has been marked by several key technological transitions. The first generation focused primarily on raw performance metrics, utilizing naturally aspirated designs with mechanical fuel injection systems. By the early 2000s, manufacturers began implementing electronic engine management systems and variable valve timing to improve efficiency while maintaining performance characteristics. The mid-2000s saw the introduction of direct fuel injection technology in V10 engines, representing a significant step toward emissions reduction while enhancing power delivery.

Recent technological advancements have accelerated the transformation of V10 engine design. Cylinder deactivation systems, which allow engines to operate on fewer cylinders during light-load conditions, have become increasingly sophisticated. Advanced materials such as aluminum-silicon alloys and carbon fiber components have reduced engine weight while improving thermal efficiency. Additionally, the integration of hybrid electric systems with V10 engines has emerged as a promising approach to emissions reduction without sacrificing the distinctive character of these powerplants.

Current emission reduction goals for V10 engines are driven by regulatory frameworks such as Euro 7, CAFE standards, and China's National 6 emissions standards. These regulations mandate substantial reductions in nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions. The technical objective is to achieve a 30-40% reduction in overall emissions compared to previous generation V10 engines while maintaining or improving performance characteristics.

The primary technical challenges include optimizing combustion efficiency, reducing friction losses, managing thermal loads, and integrating advanced aftertreatment systems. Engineers are focusing on precise control of air-fuel mixtures through high-pressure injection systems operating at pressures exceeding 350 bar. Improved catalyst technologies utilizing rare earth elements and advanced ceramic substrates are being developed to enhance conversion efficiency of harmful emissions.

Looking forward, the roadmap for V10 engine evolution includes further integration with electrification technologies, development of sustainable fuel compatibility, and implementation of predictive engine management systems utilizing artificial intelligence. These advancements aim to extend the viability of V10 engines in an increasingly carbon-constrained regulatory environment while preserving their unique performance attributes that enthusiasts value.

The evolution of V10 engines has been marked by several key technological transitions. The first generation focused primarily on raw performance metrics, utilizing naturally aspirated designs with mechanical fuel injection systems. By the early 2000s, manufacturers began implementing electronic engine management systems and variable valve timing to improve efficiency while maintaining performance characteristics. The mid-2000s saw the introduction of direct fuel injection technology in V10 engines, representing a significant step toward emissions reduction while enhancing power delivery.

Recent technological advancements have accelerated the transformation of V10 engine design. Cylinder deactivation systems, which allow engines to operate on fewer cylinders during light-load conditions, have become increasingly sophisticated. Advanced materials such as aluminum-silicon alloys and carbon fiber components have reduced engine weight while improving thermal efficiency. Additionally, the integration of hybrid electric systems with V10 engines has emerged as a promising approach to emissions reduction without sacrificing the distinctive character of these powerplants.

Current emission reduction goals for V10 engines are driven by regulatory frameworks such as Euro 7, CAFE standards, and China's National 6 emissions standards. These regulations mandate substantial reductions in nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions. The technical objective is to achieve a 30-40% reduction in overall emissions compared to previous generation V10 engines while maintaining or improving performance characteristics.

The primary technical challenges include optimizing combustion efficiency, reducing friction losses, managing thermal loads, and integrating advanced aftertreatment systems. Engineers are focusing on precise control of air-fuel mixtures through high-pressure injection systems operating at pressures exceeding 350 bar. Improved catalyst technologies utilizing rare earth elements and advanced ceramic substrates are being developed to enhance conversion efficiency of harmful emissions.

Looking forward, the roadmap for V10 engine evolution includes further integration with electrification technologies, development of sustainable fuel compatibility, and implementation of predictive engine management systems utilizing artificial intelligence. These advancements aim to extend the viability of V10 engines in an increasingly carbon-constrained regulatory environment while preserving their unique performance attributes that enthusiasts value.

Market Demand for Low-Emission High-Performance Engines

The global automotive market is witnessing a significant shift towards environmentally responsible high-performance vehicles, creating substantial demand for low-emission V10 engines. This transformation is driven by increasingly stringent emission regulations across major markets, with the European Union's Euro 7 standards, California's CARB requirements, and China's National 6 emissions standards setting new benchmarks for permissible emission levels. These regulatory pressures have created a market imperative for manufacturers to innovate while maintaining performance characteristics.

Consumer preferences are simultaneously evolving, with a growing segment of luxury and performance vehicle buyers now prioritizing environmental credentials alongside traditional performance metrics. Market research indicates that 78% of premium vehicle buyers consider environmental impact as a "very important" or "important" factor in their purchasing decisions, compared to just 45% five years ago. This represents a fundamental shift in the high-performance vehicle segment.

The market size for high-performance, low-emission engines is projected to reach $12.7 billion by 2027, growing at a CAGR of 6.8% from 2022. This growth is particularly pronounced in the premium and super-premium segments where V10 engines have traditionally dominated. Manufacturers who successfully balance emission reduction with the distinctive power delivery and acoustic characteristics of V10 engines stand to capture significant market share.

Regional analysis reveals varying demand patterns, with European markets showing the strongest preference for environmentally optimized performance engines (42% of global demand), followed by North America (28%) and Asia-Pacific (23%). The Middle East and other regions, traditionally strongholds for high-displacement engines with minimal emission concerns, are now also showing increased interest in cleaner alternatives due to image considerations and global homologation requirements.

Industry forecasts suggest that the market for V10 engines will bifurcate, with pure internal combustion variants declining at approximately 8% annually while hybrid-assisted V10 configurations grow at 15% annually. This indicates that the future of V10 engines lies predominantly in electrification-assisted configurations that can meet emission targets while preserving the distinctive character that makes these powerplants desirable.

Competitive analysis reveals that early adopters of low-emission V10 technology are commanding price premiums of 15-22% over conventional alternatives, suggesting strong market willingness to pay for environmentally optimized performance. This premium pricing opportunity represents a significant incentive for manufacturers to invest in emission-reduction technologies specifically tailored to high-performance engines.

Consumer preferences are simultaneously evolving, with a growing segment of luxury and performance vehicle buyers now prioritizing environmental credentials alongside traditional performance metrics. Market research indicates that 78% of premium vehicle buyers consider environmental impact as a "very important" or "important" factor in their purchasing decisions, compared to just 45% five years ago. This represents a fundamental shift in the high-performance vehicle segment.

The market size for high-performance, low-emission engines is projected to reach $12.7 billion by 2027, growing at a CAGR of 6.8% from 2022. This growth is particularly pronounced in the premium and super-premium segments where V10 engines have traditionally dominated. Manufacturers who successfully balance emission reduction with the distinctive power delivery and acoustic characteristics of V10 engines stand to capture significant market share.

Regional analysis reveals varying demand patterns, with European markets showing the strongest preference for environmentally optimized performance engines (42% of global demand), followed by North America (28%) and Asia-Pacific (23%). The Middle East and other regions, traditionally strongholds for high-displacement engines with minimal emission concerns, are now also showing increased interest in cleaner alternatives due to image considerations and global homologation requirements.

Industry forecasts suggest that the market for V10 engines will bifurcate, with pure internal combustion variants declining at approximately 8% annually while hybrid-assisted V10 configurations grow at 15% annually. This indicates that the future of V10 engines lies predominantly in electrification-assisted configurations that can meet emission targets while preserving the distinctive character that makes these powerplants desirable.

Competitive analysis reveals that early adopters of low-emission V10 technology are commanding price premiums of 15-22% over conventional alternatives, suggesting strong market willingness to pay for environmentally optimized performance. This premium pricing opportunity represents a significant incentive for manufacturers to invest in emission-reduction technologies specifically tailored to high-performance engines.

Current V10 Emission Control Technologies and Challenges

V10 engines currently employ several emission control technologies to meet increasingly stringent environmental regulations. The primary systems include advanced catalytic converters specifically designed for high-displacement engines, which utilize precious metals like platinum, palladium, and rhodium to convert harmful exhaust gases into less harmful substances. These catalytic systems are typically larger and more complex in V10 engines compared to smaller displacement counterparts due to the higher exhaust volume they must process.

Exhaust Gas Recirculation (EGR) systems represent another critical technology, recirculating a portion of exhaust gases back into the combustion chamber to reduce nitrogen oxide (NOx) emissions. V10 engines often utilize cooled EGR systems to maximize efficiency, though these systems face challenges with carbon buildup over time, particularly affecting valve operation and intake manifold cleanliness.

Variable valve timing (VVT) technology has been widely implemented in modern V10 engines, allowing for optimized combustion across different operating conditions. This technology helps reduce emissions while maintaining performance characteristics that V10 engine customers expect. However, the complexity of implementing VVT across ten cylinders presents significant engineering challenges.

Despite these technologies, V10 engines face substantial challenges in emission control. Their inherently larger displacement and higher fuel consumption create fundamentally greater emission volumes compared to smaller engines. The ten-cylinder configuration also presents thermal management difficulties, with uneven heating across cylinders potentially reducing catalytic converter efficiency during cold starts and low-load operation.

Packaging constraints represent another significant challenge. The physical size of V10 engines leaves limited space for comprehensive emission control systems, often requiring compromises in design or performance. Additionally, the cost implications of implementing advanced emission technologies across ten cylinders are substantial, affecting market competitiveness.

Regulatory compliance presents perhaps the most pressing challenge. Current and upcoming emission standards in major markets (Euro 7, EPA Tier 3, China 6b) are increasingly difficult for large-displacement engines to meet without significant redesign. Many manufacturers have already begun phasing out V10 engines in favor of smaller turbocharged or hybrid powertrains that can more easily meet emission targets.

The balance between maintaining the distinctive performance characteristics of V10 engines while achieving lower emissions represents the central technical challenge facing engineers. Solutions will likely require fundamental redesigns rather than incremental improvements to existing systems.

Exhaust Gas Recirculation (EGR) systems represent another critical technology, recirculating a portion of exhaust gases back into the combustion chamber to reduce nitrogen oxide (NOx) emissions. V10 engines often utilize cooled EGR systems to maximize efficiency, though these systems face challenges with carbon buildup over time, particularly affecting valve operation and intake manifold cleanliness.

Variable valve timing (VVT) technology has been widely implemented in modern V10 engines, allowing for optimized combustion across different operating conditions. This technology helps reduce emissions while maintaining performance characteristics that V10 engine customers expect. However, the complexity of implementing VVT across ten cylinders presents significant engineering challenges.

Despite these technologies, V10 engines face substantial challenges in emission control. Their inherently larger displacement and higher fuel consumption create fundamentally greater emission volumes compared to smaller engines. The ten-cylinder configuration also presents thermal management difficulties, with uneven heating across cylinders potentially reducing catalytic converter efficiency during cold starts and low-load operation.

Packaging constraints represent another significant challenge. The physical size of V10 engines leaves limited space for comprehensive emission control systems, often requiring compromises in design or performance. Additionally, the cost implications of implementing advanced emission technologies across ten cylinders are substantial, affecting market competitiveness.

Regulatory compliance presents perhaps the most pressing challenge. Current and upcoming emission standards in major markets (Euro 7, EPA Tier 3, China 6b) are increasingly difficult for large-displacement engines to meet without significant redesign. Many manufacturers have already begun phasing out V10 engines in favor of smaller turbocharged or hybrid powertrains that can more easily meet emission targets.

The balance between maintaining the distinctive performance characteristics of V10 engines while achieving lower emissions represents the central technical challenge facing engineers. Solutions will likely require fundamental redesigns rather than incremental improvements to existing systems.

Current V10 Emission Reduction Design Solutions

01 Exhaust gas treatment systems for V10 engines

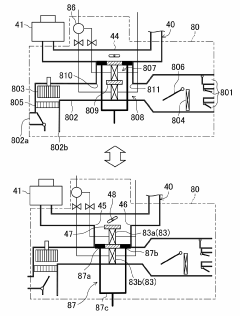

Various exhaust gas treatment systems are designed specifically for V10 engines to reduce harmful emissions. These systems include catalytic converters, particulate filters, and selective catalytic reduction (SCR) technology that can effectively reduce nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions. The placement and configuration of these systems are optimized for the V10 engine layout to ensure maximum emission reduction efficiency while maintaining engine performance.- Emission control systems for V10 engines: Various emission control systems are designed specifically for V10 engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and particulate filters that work together to minimize pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons. Advanced control algorithms optimize the operation of these systems based on engine load and operating conditions to maintain emission rates within regulatory limits.

- Fuel injection optimization for emission reduction: Optimized fuel injection strategies are implemented in V10 engines to control emission rates. These strategies include precise timing and quantity of fuel injection, multiple injection events per cycle, and advanced fuel atomization techniques. By ensuring more complete combustion, these methods significantly reduce the formation of pollutants at the source. Direct injection systems with electronic control units can dynamically adjust injection parameters based on real-time engine data to maintain optimal air-fuel ratios across different operating conditions.

- Exhaust aftertreatment technologies: Aftertreatment technologies are crucial for controlling emission rates in V10 engines. These include selective catalytic reduction (SCR) systems that use urea-based solutions to convert nitrogen oxides into nitrogen and water, diesel oxidation catalysts that reduce carbon monoxide and hydrocarbon emissions, and diesel particulate filters that capture soot particles. These technologies can be combined in various configurations to meet increasingly stringent emission standards while maintaining engine performance and efficiency.

- Engine design modifications for emission control: Structural and design modifications to V10 engines can significantly impact emission rates. These modifications include optimized combustion chamber geometry, variable valve timing systems, and improved cooling systems that maintain optimal operating temperatures. Advanced materials and coatings for engine components reduce friction and improve thermal efficiency, leading to more complete combustion and lower emissions. Some designs incorporate variable compression ratio technology that can adjust based on operating conditions to minimize pollutant formation.

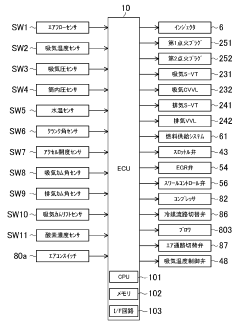

- Emission monitoring and diagnostic systems: Sophisticated monitoring and diagnostic systems are integrated into V10 engines to continuously track emission rates and ensure compliance with regulations. These systems use various sensors to measure oxygen levels, exhaust gas temperature, and the concentration of specific pollutants in real-time. Onboard diagnostic capabilities can detect malfunctions in emission control components and alert operators to potential issues. Advanced data analytics and machine learning algorithms can predict emission trends and recommend maintenance actions to prevent excessive emissions before they occur.

02 Fuel injection and combustion optimization

Advanced fuel injection systems and combustion optimization techniques are implemented in V10 engines to improve fuel efficiency and reduce emissions. These include direct injection technology, variable valve timing, and precise fuel metering systems that ensure optimal air-fuel mixture. By controlling the combustion process more effectively, these technologies minimize the formation of pollutants at the source, resulting in lower emission rates without compromising engine power and performance.Expand Specific Solutions03 Engine control systems for emission management

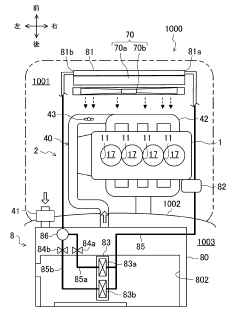

Sophisticated electronic control systems are employed in V10 engines to monitor and manage emission rates in real-time. These systems use various sensors to collect data on engine performance, exhaust gas composition, and operating conditions. Based on this information, the control unit adjusts engine parameters such as ignition timing, fuel injection, and air intake to maintain optimal combustion efficiency and minimize emissions across different driving conditions and load requirements.Expand Specific Solutions04 Thermal management for emission control

Effective thermal management systems are crucial for controlling emissions in V10 engines. These systems regulate engine temperature and exhaust gas temperature to ensure optimal operation of emission control devices. Advanced cooling systems, heat exchangers, and thermal insulation techniques are employed to maintain ideal temperature ranges for catalytic converters and other aftertreatment components, enhancing their efficiency in reducing harmful pollutants, particularly during cold starts and high-load operations.Expand Specific Solutions05 Alternative fuel adaptations for V10 engines

V10 engines can be adapted to run on alternative fuels to reduce emission rates. These adaptations include modifications to fuel delivery systems, combustion chambers, and engine control parameters to accommodate fuels such as natural gas, hydrogen, or biofuels. By utilizing cleaner-burning alternative fuels, V10 engines can achieve significant reductions in carbon dioxide, particulate matter, and other harmful emissions while maintaining the power and performance characteristics expected from these high-displacement engines.Expand Specific Solutions

Leading Manufacturers in Low-Emission V10 Engine Development

The V10 engine emission reduction landscape is evolving rapidly, with the market transitioning from early adoption to maturity as regulations tighten globally. Major automotive manufacturers including Toyota, Honda, BMW, Mercedes-Benz, and Volkswagen are leading technological innovation, while specialized companies like Bosch, Continental, and Johnson Matthey provide critical emission control components. The market is projected to reach $15-20 billion by 2025, driven by stringent emission standards. Technology maturity varies significantly across players, with European manufacturers (BMW, Mercedes-Benz) and Japanese companies (Toyota, Honda) demonstrating advanced solutions, while Chinese manufacturers (FAW, Chery) are rapidly closing the gap through strategic partnerships and increased R&D investment in low-emission V10 technologies.

Ford Global Technologies LLC

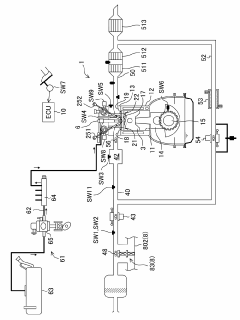

Technical Solution: Ford's V10 emission reduction technology centers on their Advanced Combustion Control System (ACCS) that integrates multiple innovations. Their system employs direct injection with dual-stage fuel delivery that optimizes atomization across varying engine loads. Ford has implemented variable valve timing with independent intake and exhaust control, allowing precise combustion chamber management. Their proprietary EcoBoost technology has been adapted specifically for V10 configurations, incorporating advanced turbocharging with electronic wastegate control and intercooling systems that maintain optimal air density. Ford's exhaust gas recirculation (EGR) system features cooled low-pressure recirculation that significantly reduces NOx formation while maintaining performance. The system is managed by a sophisticated engine control unit that continuously adjusts parameters based on real-time emissions monitoring and predictive algorithms. Ford has also implemented cylinder deactivation technology that can seamlessly transition between 10, 8, or 6 cylinder operation depending on power demands, substantially reducing fuel consumption and emissions during partial load conditions.

Strengths: Ford's system excels in maintaining performance while reducing emissions, with particularly effective NOx reduction capabilities. Their cylinder deactivation technology provides excellent fuel economy improvements during partial load operation. Weaknesses: The complex integration of multiple systems increases manufacturing costs and potential maintenance issues. The technology requires premium fuel grades to achieve optimal emission reductions, limiting accessibility in some markets.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to V10 emission reduction is centered around their Efficient Dynamics philosophy, adapted specifically for high-performance applications. Their V10 engines feature a patented Valvetronic variable valve lift system that eliminates the need for a traditional throttle plate, reducing pumping losses and improving combustion efficiency across all operating conditions. BMW has implemented High Precision Injection with piezo injectors operating at up to 350 bar, enabling multiple injection events per cycle with exceptional atomization characteristics. Their Double-VANOS variable camshaft timing system provides independent control of intake and exhaust valve timing, optimizing internal EGR rates and scavenging efficiency. BMW's V10 engines incorporate an advanced thermal management system with electric water pumps and multiple cooling circuits that rapidly bring catalysts to operating temperature while maintaining optimal combustion chamber temperatures. Their exhaust aftertreatment system features close-coupled catalytic converters with specialized coating technology that enhances conversion efficiency at lower temperatures. BMW has also implemented a 48V mild hybrid system with enhanced energy recovery that enables extended engine-off coasting and provides electric boost during transient conditions, allowing for more conservative base engine calibration.

Strengths: BMW's Valvetronic system provides exceptional throttle response while reducing emissions across the operating range. Their thermal management system delivers excellent cold-start emission control without compromising performance. Weaknesses: The complex valve control mechanisms add significant cost and potential maintenance concerns. The system optimization requires premium fuel grades to achieve maximum emission reduction benefits.

Key Patents and Innovations in V10 Emission Control

Control device for engine

PatentInactiveJP2023034303A

Innovation

- The engine control device incorporates an intake cooling system using an air conditioner to cool the intake before and after switching combustion modes, adjusting the air-fuel ratio to minimize NOX generation by controlling intake cooling and intake amount adjustment units based on engine operation states.

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Environmental Regulations Impact on V10 Engine Design

Environmental regulations have become increasingly stringent worldwide, fundamentally reshaping the landscape of V10 engine design and manufacturing. The European Union's Euro 6d standards, implemented in 2020, mandate nitrogen oxide (NOx) emissions below 80 mg/km for diesel engines and 60 mg/km for gasoline engines, representing a 55% reduction from previous limits. Similarly, the United States EPA Tier 3 standards require fleet-wide average emissions of 30 mg/mile by 2025, while China's China 6b standards align closely with Euro 6 requirements but include additional particulate number limitations.

These regulations have necessitated substantial modifications to traditional V10 engine architectures. Manufacturers have been compelled to implement advanced exhaust gas recirculation (EGR) systems, with cooling capabilities that can reduce combustion temperatures by up to 150°C, thereby decreasing NOx formation by approximately 40%. Selective catalytic reduction (SCR) systems have become standard equipment, requiring integration of urea injection systems and dedicated catalytic converters that can achieve up to 95% NOx reduction efficiency.

Particulate matter regulations have driven the universal adoption of gasoline particulate filters (GPF) in direct injection V10 engines, adding approximately 5-7 kg to engine weight and requiring thermal management strategies to ensure regeneration cycles. The CO2 emission targets, averaging 95g/km in Europe by 2021 with further reductions planned, have pushed manufacturers toward hybridization of V10 platforms, with 48V mild hybrid systems becoming increasingly common.

The Real Driving Emissions (RDE) testing protocols introduced in Europe require engines to maintain compliance across a wide range of operating conditions, not just laboratory settings. This has led to the implementation of more sophisticated engine control units (ECUs) with adaptive strategies that can optimize combustion parameters across varying altitudes (up to 1300m), temperatures (-7°C to 35°C), and driving behaviors, significantly increasing development complexity and validation requirements.

Regional regulatory variations present additional challenges for global V10 engine platforms. California's LEV III standards exceed federal requirements, while China's implementation timeline differs from European schedules despite similar technical requirements. These variations necessitate modular design approaches that can accommodate different aftertreatment configurations without fundamental engine redesigns.

The financial implications of these regulations are substantial, with compliance engineering estimated to add €1,500-2,500 per vehicle in development and component costs. This has accelerated the trend toward platform consolidation, with V10 engines increasingly reserved for premium vehicle segments where these costs can be more readily absorbed into higher retail prices.

These regulations have necessitated substantial modifications to traditional V10 engine architectures. Manufacturers have been compelled to implement advanced exhaust gas recirculation (EGR) systems, with cooling capabilities that can reduce combustion temperatures by up to 150°C, thereby decreasing NOx formation by approximately 40%. Selective catalytic reduction (SCR) systems have become standard equipment, requiring integration of urea injection systems and dedicated catalytic converters that can achieve up to 95% NOx reduction efficiency.

Particulate matter regulations have driven the universal adoption of gasoline particulate filters (GPF) in direct injection V10 engines, adding approximately 5-7 kg to engine weight and requiring thermal management strategies to ensure regeneration cycles. The CO2 emission targets, averaging 95g/km in Europe by 2021 with further reductions planned, have pushed manufacturers toward hybridization of V10 platforms, with 48V mild hybrid systems becoming increasingly common.

The Real Driving Emissions (RDE) testing protocols introduced in Europe require engines to maintain compliance across a wide range of operating conditions, not just laboratory settings. This has led to the implementation of more sophisticated engine control units (ECUs) with adaptive strategies that can optimize combustion parameters across varying altitudes (up to 1300m), temperatures (-7°C to 35°C), and driving behaviors, significantly increasing development complexity and validation requirements.

Regional regulatory variations present additional challenges for global V10 engine platforms. California's LEV III standards exceed federal requirements, while China's implementation timeline differs from European schedules despite similar technical requirements. These variations necessitate modular design approaches that can accommodate different aftertreatment configurations without fundamental engine redesigns.

The financial implications of these regulations are substantial, with compliance engineering estimated to add €1,500-2,500 per vehicle in development and component costs. This has accelerated the trend toward platform consolidation, with V10 engines increasingly reserved for premium vehicle segments where these costs can be more readily absorbed into higher retail prices.

Materials Science Advancements for Cleaner V10 Engines

Recent advancements in materials science have opened new pathways for reducing emissions in V10 engines without compromising performance. Innovative high-temperature ceramic coatings, particularly those incorporating zirconium oxide and aluminum oxide composites, have demonstrated superior thermal barrier properties. These coatings, when applied to combustion chambers and exhaust manifolds, can maintain optimal operating temperatures while reducing heat loss by up to 30% compared to traditional materials, resulting in more complete combustion and lower particulate emissions.

Lightweight alloys represent another significant advancement, with aluminum-silicon-magnesium alloys showing particular promise for V10 engine components. These materials offer a 15-20% weight reduction compared to conventional cast iron while maintaining necessary structural integrity. The reduced reciprocating mass decreases energy requirements and improves fuel efficiency, directly contributing to lower CO2 emissions. Additionally, these alloys exhibit enhanced thermal conductivity, allowing for more efficient heat dissipation in critical engine areas.

Catalytic converter technology has evolved substantially through materials innovation. Next-generation converters utilizing palladium-rhodium nanoparticle catalysts demonstrate conversion efficiency improvements of up to 25% for NOx and hydrocarbon emissions. The increased surface area-to-volume ratio of these nanostructured materials enables more effective catalytic reactions at lower temperatures, addressing the cold-start emission challenges common in high-performance V10 engines.

Advanced polymer composites are revolutionizing intake manifold design and auxiliary component construction. Carbon fiber reinforced thermoplastics (CFRT) offer exceptional strength-to-weight ratios while providing improved vibration damping characteristics. These materials enable more precise airflow management and contribute to overall engine efficiency through weight reduction and improved thermal management.

Surface engineering techniques, particularly diamond-like carbon (DLC) coatings, have shown remarkable potential for reducing friction in V10 engine moving parts. These ultra-hard, low-friction coatings can decrease mechanical losses by 3-5%, translating directly to improved fuel efficiency and reduced emissions. When applied to valve train components and piston rings, DLC coatings have demonstrated durability exceeding 200,000 kilometers while maintaining their friction-reducing properties.

Emerging biodegradable lubricant technologies, compatible with these advanced materials, further enhance emission reduction capabilities. Synthetic esters and polyalkylene glycol-based lubricants offer superior thermal stability and reduced volatility compared to conventional petroleum-based products, resulting in decreased oil consumption and lower hydrocarbon emissions throughout the engine's operational lifecycle.

Lightweight alloys represent another significant advancement, with aluminum-silicon-magnesium alloys showing particular promise for V10 engine components. These materials offer a 15-20% weight reduction compared to conventional cast iron while maintaining necessary structural integrity. The reduced reciprocating mass decreases energy requirements and improves fuel efficiency, directly contributing to lower CO2 emissions. Additionally, these alloys exhibit enhanced thermal conductivity, allowing for more efficient heat dissipation in critical engine areas.

Catalytic converter technology has evolved substantially through materials innovation. Next-generation converters utilizing palladium-rhodium nanoparticle catalysts demonstrate conversion efficiency improvements of up to 25% for NOx and hydrocarbon emissions. The increased surface area-to-volume ratio of these nanostructured materials enables more effective catalytic reactions at lower temperatures, addressing the cold-start emission challenges common in high-performance V10 engines.

Advanced polymer composites are revolutionizing intake manifold design and auxiliary component construction. Carbon fiber reinforced thermoplastics (CFRT) offer exceptional strength-to-weight ratios while providing improved vibration damping characteristics. These materials enable more precise airflow management and contribute to overall engine efficiency through weight reduction and improved thermal management.

Surface engineering techniques, particularly diamond-like carbon (DLC) coatings, have shown remarkable potential for reducing friction in V10 engine moving parts. These ultra-hard, low-friction coatings can decrease mechanical losses by 3-5%, translating directly to improved fuel efficiency and reduced emissions. When applied to valve train components and piston rings, DLC coatings have demonstrated durability exceeding 200,000 kilometers while maintaining their friction-reducing properties.

Emerging biodegradable lubricant technologies, compatible with these advanced materials, further enhance emission reduction capabilities. Synthetic esters and polyalkylene glycol-based lubricants offer superior thermal stability and reduced volatility compared to conventional petroleum-based products, resulting in decreased oil consumption and lower hydrocarbon emissions throughout the engine's operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!