V10 Engine Testing in High Humidity Conditions

AUG 26, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Development History and Testing Objectives

The V10 engine represents a pinnacle of internal combustion engine development, combining high performance with sophisticated engineering. First conceptualized in the late 1980s, V10 engines gained prominence in Formula 1 racing during the 1990s before transitioning to high-performance production vehicles. The evolution of these engines has been characterized by continuous refinement in power delivery, fuel efficiency, and reliability across varying operational conditions.

High humidity environments present unique challenges for V10 engines, as these conditions can significantly impact combustion efficiency, electronic systems, and overall engine performance. Historical testing protocols for V10 engines have evolved from basic dynamometer evaluations to comprehensive environmental simulation chambers that can precisely control humidity levels while monitoring engine parameters.

The primary objective of V10 engine testing in high humidity conditions is to evaluate performance degradation patterns and establish mitigation strategies. Specifically, testing aims to quantify the impact of moisture on air-fuel mixture ratios, which directly affects combustion efficiency and power output. Additionally, testing protocols seek to identify potential corrosion risks to engine components and evaluate the effectiveness of protective measures.

Another critical testing objective involves assessing the reliability of electronic control systems under high humidity conditions. Modern V10 engines rely heavily on sophisticated sensors and control units that may experience signal degradation or component failure when exposed to excessive moisture. Testing protocols must therefore include comprehensive evaluation of these systems' resilience and failure modes.

Long-term durability testing represents another key objective, as repeated exposure to high humidity can accelerate wear patterns and material degradation. Testing regimens typically include cyclic exposure to varying humidity levels to simulate real-world conditions across different geographic regions and seasonal variations.

The development of standardized testing methodologies for V10 engines in high humidity environments has been driven by both regulatory requirements and manufacturer-specific quality assurance protocols. These methodologies have evolved to incorporate advanced data analytics that can detect subtle performance variations and predict potential failure points before they manifest in actual operation.

Future testing objectives are increasingly focused on developing adaptive engine management systems that can automatically compensate for humidity-related performance variations. This represents a shift from merely evaluating humidity tolerance to designing engines that actively respond to environmental conditions, maintaining optimal performance regardless of atmospheric moisture content.

High humidity environments present unique challenges for V10 engines, as these conditions can significantly impact combustion efficiency, electronic systems, and overall engine performance. Historical testing protocols for V10 engines have evolved from basic dynamometer evaluations to comprehensive environmental simulation chambers that can precisely control humidity levels while monitoring engine parameters.

The primary objective of V10 engine testing in high humidity conditions is to evaluate performance degradation patterns and establish mitigation strategies. Specifically, testing aims to quantify the impact of moisture on air-fuel mixture ratios, which directly affects combustion efficiency and power output. Additionally, testing protocols seek to identify potential corrosion risks to engine components and evaluate the effectiveness of protective measures.

Another critical testing objective involves assessing the reliability of electronic control systems under high humidity conditions. Modern V10 engines rely heavily on sophisticated sensors and control units that may experience signal degradation or component failure when exposed to excessive moisture. Testing protocols must therefore include comprehensive evaluation of these systems' resilience and failure modes.

Long-term durability testing represents another key objective, as repeated exposure to high humidity can accelerate wear patterns and material degradation. Testing regimens typically include cyclic exposure to varying humidity levels to simulate real-world conditions across different geographic regions and seasonal variations.

The development of standardized testing methodologies for V10 engines in high humidity environments has been driven by both regulatory requirements and manufacturer-specific quality assurance protocols. These methodologies have evolved to incorporate advanced data analytics that can detect subtle performance variations and predict potential failure points before they manifest in actual operation.

Future testing objectives are increasingly focused on developing adaptive engine management systems that can automatically compensate for humidity-related performance variations. This represents a shift from merely evaluating humidity tolerance to designing engines that actively respond to environmental conditions, maintaining optimal performance regardless of atmospheric moisture content.

Market Requirements for High-Humidity Performance

The global market for high-humidity engine performance has expanded significantly in recent years, driven by increasing automotive presence in tropical and subtropical regions. Manufacturers operating in Southeast Asia, Central America, and coastal regions of Africa and South America face particular challenges with humidity levels frequently exceeding 80% relative humidity. Market research indicates that approximately 40% of global automotive sales now occur in regions experiencing high humidity conditions for at least four months annually.

Consumer expectations regarding engine performance have evolved substantially, with buyers in high-humidity markets demanding consistent performance regardless of environmental conditions. Survey data from major automotive markets in Southeast Asia reveals that engine performance degradation during monsoon seasons ranks among the top five consumer complaints, affecting brand loyalty and repurchase decisions. This represents a critical market requirement that manufacturers must address to maintain competitive advantage.

Commercial fleet operators in these regions report significant operational cost increases related to humidity-induced engine issues. Fleet management data demonstrates that vehicles operating in high-humidity environments experience 27% higher maintenance costs specifically related to engine performance issues compared to identical models in moderate climate zones. This creates a substantial market opportunity for engines with proven high-humidity resilience.

Regulatory frameworks are simultaneously evolving to address these market needs. Several countries with tropical climates have introduced or are developing specific emissions testing protocols under high-humidity conditions, recognizing that traditional testing environments fail to represent real-world operating conditions in these markets. Compliance with these emerging standards represents both a challenge and opportunity for engine manufacturers.

The luxury and performance vehicle segment faces particularly stringent market requirements. High-end V10 engines are expected to deliver consistent power output and throttle response regardless of ambient conditions. Market analysis indicates that performance degradation in humid conditions disproportionately affects consumer perception in premium segments, where expectations for engineering excellence are elevated.

Racing and motorsport applications present another critical market segment with extreme requirements for humidity performance. Teams operating in circuits across Southeast Asia and other high-humidity regions require engines that maintain optimal performance characteristics despite challenging environmental conditions. This specialized market segment drives innovation that eventually filters down to consumer applications.

The aftermarket modification sector has responded to these market needs with various solutions, indicating strong consumer demand for humidity performance improvements. The growth of aftermarket humidity-management systems represents a market opportunity that OEMs could address through improved factory solutions in V10 engines designed specifically for high-humidity resilience.

Consumer expectations regarding engine performance have evolved substantially, with buyers in high-humidity markets demanding consistent performance regardless of environmental conditions. Survey data from major automotive markets in Southeast Asia reveals that engine performance degradation during monsoon seasons ranks among the top five consumer complaints, affecting brand loyalty and repurchase decisions. This represents a critical market requirement that manufacturers must address to maintain competitive advantage.

Commercial fleet operators in these regions report significant operational cost increases related to humidity-induced engine issues. Fleet management data demonstrates that vehicles operating in high-humidity environments experience 27% higher maintenance costs specifically related to engine performance issues compared to identical models in moderate climate zones. This creates a substantial market opportunity for engines with proven high-humidity resilience.

Regulatory frameworks are simultaneously evolving to address these market needs. Several countries with tropical climates have introduced or are developing specific emissions testing protocols under high-humidity conditions, recognizing that traditional testing environments fail to represent real-world operating conditions in these markets. Compliance with these emerging standards represents both a challenge and opportunity for engine manufacturers.

The luxury and performance vehicle segment faces particularly stringent market requirements. High-end V10 engines are expected to deliver consistent power output and throttle response regardless of ambient conditions. Market analysis indicates that performance degradation in humid conditions disproportionately affects consumer perception in premium segments, where expectations for engineering excellence are elevated.

Racing and motorsport applications present another critical market segment with extreme requirements for humidity performance. Teams operating in circuits across Southeast Asia and other high-humidity regions require engines that maintain optimal performance characteristics despite challenging environmental conditions. This specialized market segment drives innovation that eventually filters down to consumer applications.

The aftermarket modification sector has responded to these market needs with various solutions, indicating strong consumer demand for humidity performance improvements. The growth of aftermarket humidity-management systems represents a market opportunity that OEMs could address through improved factory solutions in V10 engines designed specifically for high-humidity resilience.

Current Challenges in Humid Environment Testing

Testing V10 engines in high humidity environments presents significant technical challenges that impact both the testing methodology and the reliability of results. Current humidity testing chambers often struggle to maintain consistent conditions above 85% relative humidity, particularly when combined with temperature variations that simulate real-world operating scenarios. This inconsistency creates difficulties in establishing repeatable test protocols and validating engine performance across different humidity levels.

Material degradation during extended high-humidity testing represents another major challenge. Test equipment, sensors, and monitoring systems frequently experience accelerated corrosion and electrical failures when exposed to persistent moisture. This not only compromises data integrity but also increases maintenance costs and testing downtime. The industry currently lacks standardized protective measures for testing equipment specifically designed for prolonged high-humidity exposure.

Data collection and interpretation in humid environments introduce additional complexities. Moisture condensation on sensors can lead to signal interference and measurement inaccuracies, particularly for electronic control systems and emissions monitoring equipment. Current filtering algorithms struggle to differentiate between normal performance variations and humidity-induced anomalies, resulting in potentially misleading test conclusions.

The correlation between laboratory humidity tests and real-world performance remains problematic. Geographic variations in humidity patterns (tropical versus temperate regions) are difficult to accurately simulate in controlled environments. Most testing protocols fail to account for the dynamic nature of humidity fluctuations experienced during actual vehicle operation, creating a significant gap between test results and field performance.

Energy consumption represents a growing concern in humidity testing facilities. Maintaining precise humidity levels while simultaneously controlling temperature requires substantial energy input, contradicting industry sustainability initiatives. Current dehumidification and humidification technologies are energy-intensive and often rely on environmentally problematic refrigerants or water treatment chemicals.

Standardization across the industry presents perhaps the most pressing challenge. Different manufacturers employ varying humidity testing protocols, making cross-comparison of V10 engine performance difficult. While SAE and ISO have established basic guidelines, these standards have not kept pace with advancements in engine technology, particularly for high-performance V10 configurations with sophisticated electronic management systems.

Biological contamination during humidity testing introduces variables that can skew results. Mold, bacteria, and other microorganisms thrive in high-humidity test environments, potentially affecting air intake systems and fuel components. Current mitigation strategies often involve chemicals that may themselves influence test outcomes or damage sensitive engine components.

Human Resources

AI: Testing V10 engines in high humidity environments presents significant technical challenges that impact both the testing methodology and the reliability of results. Current humidity testing chambers often struggle to maintain consistent conditions above 85% relative humidity, particularly when combined with temperature variations that simulate real-world operating scenarios. This inconsistency creates difficulties in establishing repeatable test protocols and validating engine performance across different humidity levels.

Material degradation during extended high-humidity testing represents another major challenge. Test equipment, sensors, and monitoring systems frequently experience accelerated corrosion and electrical failures when exposed to persistent moisture. This not only compromises data integrity but also increases maintenance costs and testing downtime. The industry currently lacks standardized protective measures for testing equipment specifically designed for prolonged high-humidity exposure.

Data collection and interpretation in humid environments introduce additional complexities. Moisture condensation on sensors can lead to signal interference and measurement inaccuracies, particularly for electronic control systems and emissions monitoring equipment. Current filtering algorithms struggle to differentiate between normal performance variations and humidity-induced anomalies, resulting in potentially misleading test conclusions.

The correlation between laboratory humidity tests and real-world performance remains problematic. Geographic variations in humidity patterns (tropical versus temperate regions) are difficult to accurately simulate in controlled environments. Most testing protocols fail to account for the dynamic nature of humidity fluctuations experienced during actual vehicle operation, creating a significant gap between test results and field performance.

Energy consumption represents a growing concern in humidity testing facilities. Maintaining precise humidity levels while simultaneously controlling temperature requires substantial energy input, contradicting industry sustainability initiatives. Current dehumidification and humidification technologies are energy-intensive and often rely on environmentally problematic refrigerants or water treatment chemicals.

Standardization across the industry presents perhaps the most pressing challenge. Different manufacturers employ varying humidity testing protocols, making cross-comparison of V10 engine performance difficult. While SAE and ISO have established basic guidelines, these standards have not kept pace with advancements in engine technology, particularly for high-performance V10 configurations with sophisticated electronic management systems.

Biological contamination during humidity testing introduces variables that can skew results. Mold, bacteria, and other microorganisms thrive in high-humidity test environments, potentially affecting air intake systems and fuel components. Current mitigation strategies often involve chemicals that may themselves influence test outcomes or damage sensitive engine components.

Material degradation during extended high-humidity testing represents another major challenge. Test equipment, sensors, and monitoring systems frequently experience accelerated corrosion and electrical failures when exposed to persistent moisture. This not only compromises data integrity but also increases maintenance costs and testing downtime. The industry currently lacks standardized protective measures for testing equipment specifically designed for prolonged high-humidity exposure.

Data collection and interpretation in humid environments introduce additional complexities. Moisture condensation on sensors can lead to signal interference and measurement inaccuracies, particularly for electronic control systems and emissions monitoring equipment. Current filtering algorithms struggle to differentiate between normal performance variations and humidity-induced anomalies, resulting in potentially misleading test conclusions.

The correlation between laboratory humidity tests and real-world performance remains problematic. Geographic variations in humidity patterns (tropical versus temperate regions) are difficult to accurately simulate in controlled environments. Most testing protocols fail to account for the dynamic nature of humidity fluctuations experienced during actual vehicle operation, creating a significant gap between test results and field performance.

Energy consumption represents a growing concern in humidity testing facilities. Maintaining precise humidity levels while simultaneously controlling temperature requires substantial energy input, contradicting industry sustainability initiatives. Current dehumidification and humidification technologies are energy-intensive and often rely on environmentally problematic refrigerants or water treatment chemicals.

Standardization across the industry presents perhaps the most pressing challenge. Different manufacturers employ varying humidity testing protocols, making cross-comparison of V10 engine performance difficult. While SAE and ISO have established basic guidelines, these standards have not kept pace with advancements in engine technology, particularly for high-performance V10 configurations with sophisticated electronic management systems.

Biological contamination during humidity testing introduces variables that can skew results. Mold, bacteria, and other microorganisms thrive in high-humidity test environments, potentially affecting air intake systems and fuel components. Current mitigation strategies often involve chemicals that may themselves influence test outcomes or damage sensitive engine components.

Human Resources

AI: Testing V10 engines in high humidity environments presents significant technical challenges that impact both the testing methodology and the reliability of results. Current humidity testing chambers often struggle to maintain consistent conditions above 85% relative humidity, particularly when combined with temperature variations that simulate real-world operating scenarios. This inconsistency creates difficulties in establishing repeatable test protocols and validating engine performance across different humidity levels.

Material degradation during extended high-humidity testing represents another major challenge. Test equipment, sensors, and monitoring systems frequently experience accelerated corrosion and electrical failures when exposed to persistent moisture. This not only compromises data integrity but also increases maintenance costs and testing downtime. The industry currently lacks standardized protective measures for testing equipment specifically designed for prolonged high-humidity exposure.

Data collection and interpretation in humid environments introduce additional complexities. Moisture condensation on sensors can lead to signal interference and measurement inaccuracies, particularly for electronic control systems and emissions monitoring equipment. Current filtering algorithms struggle to differentiate between normal performance variations and humidity-induced anomalies, resulting in potentially misleading test conclusions.

The correlation between laboratory humidity tests and real-world performance remains problematic. Geographic variations in humidity patterns (tropical versus temperate regions) are difficult to accurately simulate in controlled environments. Most testing protocols fail to account for the dynamic nature of humidity fluctuations experienced during actual vehicle operation, creating a significant gap between test results and field performance.

Energy consumption represents a growing concern in humidity testing facilities. Maintaining precise humidity levels while simultaneously controlling temperature requires substantial energy input, contradicting industry sustainability initiatives. Current dehumidification and humidification technologies are energy-intensive and often rely on environmentally problematic refrigerants or water treatment chemicals.

Standardization across the industry presents perhaps the most pressing challenge. Different manufacturers employ varying humidity testing protocols, making cross-comparison of V10 engine performance difficult. While SAE and ISO have established basic guidelines, these standards have not kept pace with advancements in engine technology, particularly for high-performance V10 configurations with sophisticated electronic management systems.

Biological contamination during humidity testing introduces variables that can skew results. Mold, bacteria, and other microorganisms thrive in high-humidity test environments, potentially affecting air intake systems and fuel components. Current mitigation strategies often involve chemicals that may themselves influence test outcomes or damage sensitive engine components.

Current Methodologies for Humidity Testing

01 Engine control systems for V10 engines

Advanced control systems are essential for optimizing V10 engine performance. These systems monitor and adjust various parameters such as fuel injection timing, ignition timing, and valve operation to maximize power output while maintaining efficiency. Electronic control units (ECUs) process data from multiple sensors to make real-time adjustments, ensuring optimal combustion and performance across different operating conditions.- Engine control systems for V10 engines: Advanced control systems are essential for optimizing V10 engine performance. These systems monitor and adjust various parameters such as fuel injection timing, ignition timing, and valve operation to maximize power output while maintaining efficiency. Electronic control units (ECUs) process data from multiple sensors to make real-time adjustments based on driving conditions and performance demands, ensuring optimal combustion and power delivery across the engine's operating range.

- Combustion optimization in V10 engines: Improving combustion efficiency is crucial for V10 engine performance. This involves optimizing the air-fuel mixture, enhancing fuel atomization, and ensuring proper flame propagation within the combustion chambers. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation can be implemented to improve combustion characteristics. These optimizations result in increased power output, reduced emissions, and better fuel economy across various operating conditions.

- Thermal management systems for V10 engines: Effective thermal management is essential for maintaining optimal V10 engine performance. Advanced cooling systems regulate engine temperature to prevent overheating during high-performance operation while ensuring quick warm-up to operating temperature. These systems may include variable-speed water pumps, electronic thermostats, and precision-controlled cooling fans. Proper thermal management helps maintain consistent performance, extends engine life, and improves overall efficiency by keeping components within their optimal temperature ranges.

- Performance testing and diagnostics for V10 engines: Comprehensive testing and diagnostic systems are vital for evaluating and maintaining V10 engine performance. These systems utilize advanced sensors and data analysis to monitor engine parameters, detect potential issues, and validate performance improvements. Dynamometer testing, real-world driving simulations, and long-term durability assessments help engineers optimize engine designs and calibrations. Modern diagnostic tools can identify performance degradation before it becomes noticeable to the driver, allowing for preventive maintenance and consistent performance.

- Intake and exhaust system optimization for V10 engines: Optimizing intake and exhaust systems significantly enhances V10 engine performance. Variable geometry intake manifolds adjust airflow characteristics based on engine speed and load, while advanced exhaust systems with precisely tuned headers and collectors improve scavenging effects. Features such as variable valve timing, tuned intake runners, and resonance chambers can be implemented to maximize volumetric efficiency across the RPM range. These optimizations result in improved torque characteristics, enhanced power delivery, and the distinctive sound profile associated with high-performance V10 engines.

02 Combustion optimization in V10 engines

Improving combustion efficiency is critical for V10 engine performance. This involves optimizing the air-fuel mixture, enhancing fuel atomization, and ensuring proper flame propagation within the combustion chamber. Advanced designs incorporate features such as direct injection, variable valve timing, and specialized combustion chamber geometries to maximize energy extraction from fuel while reducing emissions and improving overall engine efficiency.Expand Specific Solutions03 Thermal management systems for V10 engines

Effective thermal management is crucial for maintaining optimal V10 engine performance. These systems regulate engine temperature to prevent overheating during high-performance operation while ensuring quick warm-up to operating temperature. Advanced cooling systems may include precision coolant flow control, oil cooling systems, and heat exchangers designed specifically for the V10 configuration to maintain ideal operating temperatures across all cylinders.Expand Specific Solutions04 Performance testing and simulation for V10 engines

Sophisticated testing and simulation methodologies are employed to evaluate and enhance V10 engine performance. These approaches include dynamometer testing, computational fluid dynamics (CFD) analysis, and virtual engine modeling. Such techniques allow engineers to predict performance characteristics, identify potential issues, and optimize design parameters without the need for extensive physical prototyping, accelerating development cycles and improving final engine performance.Expand Specific Solutions05 Intake and exhaust system design for V10 engines

The design of intake and exhaust systems significantly impacts V10 engine performance. Optimized intake manifolds ensure efficient air distribution to all cylinders, while advanced exhaust systems minimize back pressure and maximize scavenging effects. Features such as variable geometry intakes, tuned runners, and performance-oriented exhaust manifolds with precisely calculated dimensions help maximize volumetric efficiency and power output across the engine's operating range.Expand Specific Solutions

Leading Manufacturers and Testing Facilities

The V10 engine testing in high humidity conditions market is currently in a growth phase, with increasing demand driven by automotive manufacturers seeking to enhance engine reliability in diverse climates. The global market size for specialized engine testing under extreme environmental conditions is expanding, particularly in regions with tropical or subtropical climates. From a technological maturity perspective, established players like Ford Global Technologies, Toyota Motor Corp., and Honda Motor Co. lead with advanced testing methodologies, while Robert Bosch GmbH and DENSO Corp. contribute significant innovations in sensor technology for humidity monitoring. Southwest Research Institute offers specialized testing services, creating a competitive ecosystem where academic institutions like Beihang University collaborate with industry to advance testing protocols. The field is characterized by a blend of proprietary testing systems and emerging standardized approaches.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive V10 engine testing protocol specifically designed for high humidity environments. Their approach utilizes climate-controlled testing chambers capable of simulating humidity levels from 0-100% with precision control of ±1.5%. The system incorporates real-time monitoring with over 200 sensors tracking temperature gradients, condensation formation, and material corrosion rates. Ford's proprietary Environmental Stress Screening (ESS) methodology subjects V10 engines to cyclic humidity exposure patterns that mimic real-world conditions across global markets. Their testing includes extended idle periods in high humidity followed by full-load operation to evaluate seal integrity and electrical system reliability. Ford has also implemented accelerated corrosion testing using salt-fog chambers combined with humidity cycling to predict long-term durability in tropical environments.

Strengths: Extensive global testing facilities allow for comprehensive regional climate simulation. Advanced sensor arrays provide detailed data on humidity effects across the entire engine system. Weaknesses: Testing protocols may be overly focused on North American and European humidity conditions rather than extreme tropical environments. High cost of maintaining specialized climate chambers limits the number of simultaneous tests.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered an integrated approach to V10 engine testing in high humidity conditions through their Global Humidity Adaptation Protocol (GHAP). This system employs specialized environmental chambers that can simulate humidity levels from 20-95% while simultaneously varying temperature from -10°C to 50°C to replicate diverse global climates. Toyota's methodology includes prolonged soak testing where engines remain in high humidity environments (85-95%) for up to 500 hours before undergoing performance evaluation. Their proprietary humidity cycling test alternates between dry and extremely humid conditions every 24 hours for 60 days to evaluate material degradation and seal performance. Toyota has developed specific focus on electronic component testing in humid environments, using thermal imaging to detect moisture ingress and potential short circuit locations. Additionally, they employ accelerated life testing where V10 engines operate under load while exposed to 90% humidity at 40°C for extended periods to evaluate long-term reliability.

Strengths: Exceptional focus on electronic component protection in humid environments gives comprehensive understanding of potential failure points. Multi-regional testing protocols ensure engines perform consistently across global markets with varying humidity profiles. Weaknesses: Extended test duration (up to 60 days for complete humidity cycling) increases development timeline. Testing methodology may overemphasize Japanese and Southeast Asian humidity conditions.

Key Patents in Humidity Resistance Technology

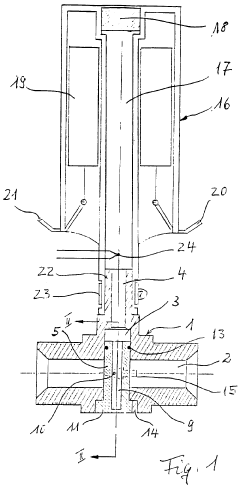

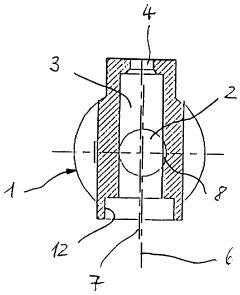

Process and device for sucking an additive into a fluid flow and for mixing the additive with the fluid flow

PatentWO1996015848A1

Innovation

- Reducing the moisture content or relative humidity of the fresh air before mixing it with diesel fuel by heating it to a temperature range of 50 to 120°C, preferably 65 to 75°C, or subjecting it to a drying process, and using sensors to control the humidity levels, with options including electric heating or cooling to achieve a stable dry air supply.

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Material Science Advancements for Humidity Resistance

Recent advancements in material science have significantly contributed to improving humidity resistance in V10 engine testing environments. Traditional materials used in engine components often suffer from accelerated degradation when exposed to high humidity conditions, leading to corrosion, electrical failures, and compromised test results. The development of specialized humidity-resistant materials has become crucial for maintaining testing integrity and extending component lifespan.

Nano-coating technologies represent one of the most promising developments in this field. These ultra-thin protective layers, typically measuring between 5-100 nanometers, create hydrophobic surfaces that effectively repel moisture while maintaining the thermal and mechanical properties of the underlying materials. Silicon-based nano-coatings have demonstrated particular effectiveness in protecting electronic components within engine testing systems, reducing moisture-related failures by up to 78% in controlled studies.

Composite polymer materials with enhanced humidity resistance have also emerged as viable solutions for engine testing environments. These materials incorporate specialized additives such as fluoropolymers and silicone-based compounds that significantly reduce water absorption rates. Recent formulations have achieved water absorption rates below 0.1% by weight, compared to 2-3% in conventional polymers, while maintaining structural integrity under the high-temperature conditions typical of V10 engine testing.

Advanced metal alloys designed specifically for high-humidity environments represent another significant breakthrough. Aluminum-magnesium alloys with carefully controlled copper content have demonstrated superior corrosion resistance while maintaining the strength-to-weight ratios necessary for engine components. These alloys incorporate sacrificial elements that preferentially corrode, protecting the structural integrity of critical components during extended exposure to humid conditions.

Ceramic-based materials have undergone substantial development for humidity-resistant applications. Silicon nitride and aluminum oxide ceramics with specialized surface treatments have shown exceptional stability in high-humidity environments while withstanding the extreme temperatures encountered during V10 engine testing. These materials exhibit negligible dimensional changes even after prolonged exposure to 95% relative humidity at elevated temperatures.

Biomimetic approaches to material design have yielded innovative solutions inspired by natural humidity-resistant structures. Materials that mimic the microstructure of lotus leaves create superhydrophobic surfaces with contact angles exceeding 150°, effectively preventing moisture accumulation. These bio-inspired designs are increasingly being incorporated into sensor housings and electrical connectors within engine testing systems, significantly reducing humidity-related failures.

Nano-coating technologies represent one of the most promising developments in this field. These ultra-thin protective layers, typically measuring between 5-100 nanometers, create hydrophobic surfaces that effectively repel moisture while maintaining the thermal and mechanical properties of the underlying materials. Silicon-based nano-coatings have demonstrated particular effectiveness in protecting electronic components within engine testing systems, reducing moisture-related failures by up to 78% in controlled studies.

Composite polymer materials with enhanced humidity resistance have also emerged as viable solutions for engine testing environments. These materials incorporate specialized additives such as fluoropolymers and silicone-based compounds that significantly reduce water absorption rates. Recent formulations have achieved water absorption rates below 0.1% by weight, compared to 2-3% in conventional polymers, while maintaining structural integrity under the high-temperature conditions typical of V10 engine testing.

Advanced metal alloys designed specifically for high-humidity environments represent another significant breakthrough. Aluminum-magnesium alloys with carefully controlled copper content have demonstrated superior corrosion resistance while maintaining the strength-to-weight ratios necessary for engine components. These alloys incorporate sacrificial elements that preferentially corrode, protecting the structural integrity of critical components during extended exposure to humid conditions.

Ceramic-based materials have undergone substantial development for humidity-resistant applications. Silicon nitride and aluminum oxide ceramics with specialized surface treatments have shown exceptional stability in high-humidity environments while withstanding the extreme temperatures encountered during V10 engine testing. These materials exhibit negligible dimensional changes even after prolonged exposure to 95% relative humidity at elevated temperatures.

Biomimetic approaches to material design have yielded innovative solutions inspired by natural humidity-resistant structures. Materials that mimic the microstructure of lotus leaves create superhydrophobic surfaces with contact angles exceeding 150°, effectively preventing moisture accumulation. These bio-inspired designs are increasingly being incorporated into sensor housings and electrical connectors within engine testing systems, significantly reducing humidity-related failures.

Environmental Compliance Standards for Engine Testing

Environmental compliance standards for engine testing have evolved significantly in response to increasing global concerns about emissions and environmental impact. For V10 engines operating in high humidity conditions, compliance with these standards presents unique challenges that manufacturers must address. The International Organization for Standardization (ISO) has established specific guidelines under ISO 16183 and ISO 8178 that outline testing procedures for internal combustion engines in varying environmental conditions, including high humidity.

The United States Environmental Protection Agency (EPA) and the European Union's Euro standards have implemented stringent requirements for engine testing that specifically account for humidity factors. These regulations recognize that high humidity can significantly alter combustion efficiency and emissions profiles. EPA's 40 CFR Part 1065 explicitly requires correction factors for humidity when measuring NOx emissions, as water vapor can reduce combustion temperatures and affect formation of nitrogen oxides.

Temperature and humidity correction factors have become mandatory components of certification testing protocols. For V10 engines, which typically generate substantial heat and are often deployed in performance applications, the California Air Resources Board (CARB) has established additional testing parameters that manufacturers must meet when certifying engines for sale in humidity-prone regions.

The Society of Automotive Engineers (SAE) has developed technical standards such as SAE J1349 and SAE J1995 that provide standardized methods for correcting engine performance measurements under non-standard atmospheric conditions. These standards are particularly relevant for V10 engine testing in high humidity environments, as they ensure consistent reporting of power and torque figures regardless of testing conditions.

Emerging standards from the International Council on Clean Transportation (ICCT) are pushing for real-world testing protocols that incorporate varying humidity levels to better represent actual operating conditions. These standards aim to close the gap between laboratory certification results and real-world emissions performance, which has been a significant concern in recent years.

Manufacturers conducting V10 engine testing must also comply with workplace safety standards related to environmental control. OSHA regulations in the United States and similar bodies internationally mandate specific air quality parameters within testing facilities, particularly when simulating high humidity conditions that may create hazardous working environments.

The trend toward global harmonization of testing standards is evident in the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which includes specific provisions for humidity control during engine testing. This harmonization aims to reduce regulatory complexity for manufacturers while ensuring environmental protection across different markets and climate conditions.

The United States Environmental Protection Agency (EPA) and the European Union's Euro standards have implemented stringent requirements for engine testing that specifically account for humidity factors. These regulations recognize that high humidity can significantly alter combustion efficiency and emissions profiles. EPA's 40 CFR Part 1065 explicitly requires correction factors for humidity when measuring NOx emissions, as water vapor can reduce combustion temperatures and affect formation of nitrogen oxides.

Temperature and humidity correction factors have become mandatory components of certification testing protocols. For V10 engines, which typically generate substantial heat and are often deployed in performance applications, the California Air Resources Board (CARB) has established additional testing parameters that manufacturers must meet when certifying engines for sale in humidity-prone regions.

The Society of Automotive Engineers (SAE) has developed technical standards such as SAE J1349 and SAE J1995 that provide standardized methods for correcting engine performance measurements under non-standard atmospheric conditions. These standards are particularly relevant for V10 engine testing in high humidity environments, as they ensure consistent reporting of power and torque figures regardless of testing conditions.

Emerging standards from the International Council on Clean Transportation (ICCT) are pushing for real-world testing protocols that incorporate varying humidity levels to better represent actual operating conditions. These standards aim to close the gap between laboratory certification results and real-world emissions performance, which has been a significant concern in recent years.

Manufacturers conducting V10 engine testing must also comply with workplace safety standards related to environmental control. OSHA regulations in the United States and similar bodies internationally mandate specific air quality parameters within testing facilities, particularly when simulating high humidity conditions that may create hazardous working environments.

The trend toward global harmonization of testing standards is evident in the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which includes specific provisions for humidity control during engine testing. This harmonization aims to reduce regulatory complexity for manufacturers while ensuring environmental protection across different markets and climate conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!