V10 Engine Adaptation for Smart City Vehicles

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and Adaptation Goals

The V10 engine, originally designed for high-performance sports cars and luxury vehicles, has undergone significant evolution since its inception in the late 1990s. Initially valued for its distinctive sound profile and power delivery characteristics, these engines represented the pinnacle of naturally aspirated internal combustion technology. The evolution trajectory has seen these powerplants transition from purely performance-oriented applications to more versatile implementations with improved efficiency metrics.

Recent technological advancements have created an opportunity to repurpose V10 engine architecture for specialized smart city vehicle applications. The primary adaptation goal centers on transforming these high-displacement engines into more sustainable powerplants through hybridization, cylinder deactivation technologies, and advanced thermal management systems. This represents a paradigm shift from their traditional application in performance vehicles to specialized urban mobility solutions.

The technical evolution path necessitates addressing several critical engineering challenges. Foremost among these is the substantial reduction of emissions while maintaining the distinctive power characteristics that define V10 engines. This requires integration of advanced catalytic systems, precise engine management algorithms, and potentially variable compression ratio technologies to optimize combustion efficiency across diverse operating conditions.

Weight reduction represents another crucial adaptation goal, as traditional V10 engines typically exceed acceptable mass parameters for urban mobility platforms. Implementation of lightweight materials such as aluminum-silicon alloys, carbon fiber components, and additive manufacturing techniques offers promising pathways to achieve the necessary 30-40% weight reduction targets without compromising structural integrity.

The adaptation strategy must also address the dimensional constraints of smart city vehicle platforms. This necessitates a comprehensive redesign of the engine architecture, potentially including a more compact V-angle configuration, shortened stroke length, and vertically stacked auxiliary systems to minimize the overall packaging footprint while preserving displacement characteristics.

From an operational perspective, adaptation goals include developing specialized engine mapping protocols optimized for frequent start-stop cycles, low-speed torque delivery, and thermal efficiency in congested urban environments. This represents a significant departure from traditional V10 calibration approaches that prioritize high-RPM performance and sustained power delivery.

The ultimate technical objective is to create a V10 variant that combines the emotional appeal and distinctive character of this engine configuration with the practical requirements of next-generation smart city mobility platforms, establishing a new category of premium urban vehicle powertrains that balance performance heritage with forward-looking sustainability metrics.

Recent technological advancements have created an opportunity to repurpose V10 engine architecture for specialized smart city vehicle applications. The primary adaptation goal centers on transforming these high-displacement engines into more sustainable powerplants through hybridization, cylinder deactivation technologies, and advanced thermal management systems. This represents a paradigm shift from their traditional application in performance vehicles to specialized urban mobility solutions.

The technical evolution path necessitates addressing several critical engineering challenges. Foremost among these is the substantial reduction of emissions while maintaining the distinctive power characteristics that define V10 engines. This requires integration of advanced catalytic systems, precise engine management algorithms, and potentially variable compression ratio technologies to optimize combustion efficiency across diverse operating conditions.

Weight reduction represents another crucial adaptation goal, as traditional V10 engines typically exceed acceptable mass parameters for urban mobility platforms. Implementation of lightweight materials such as aluminum-silicon alloys, carbon fiber components, and additive manufacturing techniques offers promising pathways to achieve the necessary 30-40% weight reduction targets without compromising structural integrity.

The adaptation strategy must also address the dimensional constraints of smart city vehicle platforms. This necessitates a comprehensive redesign of the engine architecture, potentially including a more compact V-angle configuration, shortened stroke length, and vertically stacked auxiliary systems to minimize the overall packaging footprint while preserving displacement characteristics.

From an operational perspective, adaptation goals include developing specialized engine mapping protocols optimized for frequent start-stop cycles, low-speed torque delivery, and thermal efficiency in congested urban environments. This represents a significant departure from traditional V10 calibration approaches that prioritize high-RPM performance and sustained power delivery.

The ultimate technical objective is to create a V10 variant that combines the emotional appeal and distinctive character of this engine configuration with the practical requirements of next-generation smart city mobility platforms, establishing a new category of premium urban vehicle powertrains that balance performance heritage with forward-looking sustainability metrics.

Smart City Vehicle Market Analysis

The smart city vehicle market is experiencing unprecedented growth, driven by increasing urbanization and the pressing need for sustainable transportation solutions. Current market analysis indicates that smart city vehicles represent a rapidly expanding segment within the broader automotive industry, with a compound annual growth rate of 24.3% projected through 2030. This acceleration is particularly evident in regions with high population density and severe congestion issues, such as East Asia, Western Europe, and major North American metropolitan areas.

Consumer demand patterns reveal a significant shift toward vehicles specifically designed for urban environments, with features prioritizing compact design, energy efficiency, and connectivity. Market surveys demonstrate that 67% of urban consumers now consider environmental impact as a primary purchasing factor, while 58% prioritize integration with smart city infrastructure. This represents a fundamental change from traditional automotive purchasing criteria that historically emphasized performance and luxury features.

The adaptation of V10 engines for smart city vehicles presents a unique market opportunity at the intersection of performance engineering and sustainability requirements. While conventional wisdom suggests high-displacement engines are incompatible with urban mobility solutions, emerging market research indicates a growing premium segment (estimated at 12% of the total smart city vehicle market) seeking high-performance options that maintain environmental compliance through advanced engineering solutions.

Competitive landscape analysis reveals three distinct market approaches emerging: fully electric vehicles dominating at 63% market share, hybrid systems at 28%, and advanced internal combustion solutions (including modified V10 platforms) at 9%. This third category, while smallest, shows the highest growth rate among affluent urban consumers seeking distinctive driving experiences within smart city constraints.

Regulatory frameworks significantly influence market development trajectories. Cities implementing Ultra Low Emission Zones (ULEZs) and similar restrictions have created market conditions where only technically advanced internal combustion engines can compete. This regulatory pressure has accelerated innovation in engine management systems, with manufacturers investing heavily in adaptive technologies that can optimize V10 performance characteristics for varying urban conditions.

Market forecasts indicate that successful V10 adaptation strategies could capture approximately 5% of the premium urban vehicle segment by 2028, representing a substantial opportunity despite the overall industry shift toward electrification. This specialized market position leverages the emotional appeal of high-performance engines while addressing the practical requirements of smart city infrastructure and environmental standards.

Consumer demand patterns reveal a significant shift toward vehicles specifically designed for urban environments, with features prioritizing compact design, energy efficiency, and connectivity. Market surveys demonstrate that 67% of urban consumers now consider environmental impact as a primary purchasing factor, while 58% prioritize integration with smart city infrastructure. This represents a fundamental change from traditional automotive purchasing criteria that historically emphasized performance and luxury features.

The adaptation of V10 engines for smart city vehicles presents a unique market opportunity at the intersection of performance engineering and sustainability requirements. While conventional wisdom suggests high-displacement engines are incompatible with urban mobility solutions, emerging market research indicates a growing premium segment (estimated at 12% of the total smart city vehicle market) seeking high-performance options that maintain environmental compliance through advanced engineering solutions.

Competitive landscape analysis reveals three distinct market approaches emerging: fully electric vehicles dominating at 63% market share, hybrid systems at 28%, and advanced internal combustion solutions (including modified V10 platforms) at 9%. This third category, while smallest, shows the highest growth rate among affluent urban consumers seeking distinctive driving experiences within smart city constraints.

Regulatory frameworks significantly influence market development trajectories. Cities implementing Ultra Low Emission Zones (ULEZs) and similar restrictions have created market conditions where only technically advanced internal combustion engines can compete. This regulatory pressure has accelerated innovation in engine management systems, with manufacturers investing heavily in adaptive technologies that can optimize V10 performance characteristics for varying urban conditions.

Market forecasts indicate that successful V10 adaptation strategies could capture approximately 5% of the premium urban vehicle segment by 2028, representing a substantial opportunity despite the overall industry shift toward electrification. This specialized market position leverages the emotional appeal of high-performance engines while addressing the practical requirements of smart city infrastructure and environmental standards.

Technical Challenges in V10 Urban Integration

The integration of V10 engines into smart city vehicles presents significant technical challenges that must be addressed to ensure optimal performance in urban environments. Traditional V10 engines, designed primarily for high-performance sports cars and luxury vehicles, face adaptation hurdles when repurposed for smart city applications. The fundamental issue stems from the engine's architecture, which prioritizes power output and driving dynamics over efficiency and emissions control.

Urban driving patterns characterized by frequent stops, starts, and low-speed operation create suboptimal conditions for V10 engines, which typically reach peak efficiency at higher RPMs. This mismatch results in excessive fuel consumption, increased emissions, and accelerated component wear. The thermal management systems of V10 engines also present challenges, as they were designed for sustained high-speed operation rather than the heat-soak conditions common in congested urban traffic.

Noise, vibration, and harshness (NVH) characteristics of V10 engines pose another significant obstacle. The distinctive sound profile, while desirable in performance applications, conflicts with urban noise regulations and the quieter operation expected of modern city vehicles. Structural modifications to dampen engine noise often compromise the power-to-weight ratio that makes V10 engines attractive in the first place.

The physical dimensions and weight distribution of V10 engines create packaging challenges for smart city vehicle platforms. These engines typically require substantial space and robust supporting structures, limiting design flexibility and potentially compromising passenger and cargo capacity. The additional weight also impacts vehicle dynamics, requiring suspension and braking system modifications to maintain safety and handling characteristics.

Emissions compliance represents perhaps the most formidable challenge. V10 engines were developed before the implementation of today's stringent urban emissions standards. Retrofitting these engines with modern emissions control systems often results in performance penalties and requires complex integration of catalytic converters, particulate filters, and advanced engine management systems.

The electronic control architecture presents compatibility issues with smart city infrastructure. Modern urban mobility solutions require sophisticated vehicle-to-infrastructure communication capabilities, which must be integrated with engine management systems designed for different operational parameters. This integration demands extensive software development and validation to ensure reliable operation.

Manufacturing scalability and cost considerations further complicate V10 adaptation. The precision engineering and specialized materials used in these engines result in high production costs that are difficult to justify in the price-sensitive smart city vehicle segment. Simplifying the manufacturing process without compromising reliability presents a significant engineering challenge that requires innovative approaches to design and production.

Urban driving patterns characterized by frequent stops, starts, and low-speed operation create suboptimal conditions for V10 engines, which typically reach peak efficiency at higher RPMs. This mismatch results in excessive fuel consumption, increased emissions, and accelerated component wear. The thermal management systems of V10 engines also present challenges, as they were designed for sustained high-speed operation rather than the heat-soak conditions common in congested urban traffic.

Noise, vibration, and harshness (NVH) characteristics of V10 engines pose another significant obstacle. The distinctive sound profile, while desirable in performance applications, conflicts with urban noise regulations and the quieter operation expected of modern city vehicles. Structural modifications to dampen engine noise often compromise the power-to-weight ratio that makes V10 engines attractive in the first place.

The physical dimensions and weight distribution of V10 engines create packaging challenges for smart city vehicle platforms. These engines typically require substantial space and robust supporting structures, limiting design flexibility and potentially compromising passenger and cargo capacity. The additional weight also impacts vehicle dynamics, requiring suspension and braking system modifications to maintain safety and handling characteristics.

Emissions compliance represents perhaps the most formidable challenge. V10 engines were developed before the implementation of today's stringent urban emissions standards. Retrofitting these engines with modern emissions control systems often results in performance penalties and requires complex integration of catalytic converters, particulate filters, and advanced engine management systems.

The electronic control architecture presents compatibility issues with smart city infrastructure. Modern urban mobility solutions require sophisticated vehicle-to-infrastructure communication capabilities, which must be integrated with engine management systems designed for different operational parameters. This integration demands extensive software development and validation to ensure reliable operation.

Manufacturing scalability and cost considerations further complicate V10 adaptation. The precision engineering and specialized materials used in these engines result in high production costs that are difficult to justify in the price-sensitive smart city vehicle segment. Simplifying the manufacturing process without compromising reliability presents a significant engineering challenge that requires innovative approaches to design and production.

Current V10 Adaptation Solutions

01 V10 Engine Design and Structure

The design and structure of V10 engines focus on the arrangement of cylinders in a V-configuration, providing a balance between power output and engine size. These engines typically feature ten cylinders arranged in two banks of five, creating a V-shape. The design allows for higher power output while maintaining a relatively compact size compared to inline configurations with the same number of cylinders.- V10 Engine Design and Structure: The design and structure of V10 engines involve specific configurations that optimize performance and efficiency. These engines typically feature a V-shaped arrangement of cylinders with a 90-degree angle, allowing for compact dimensions while maintaining power output. The structural elements include specialized crankshaft designs, cylinder head configurations, and internal components that contribute to the engine's overall performance characteristics.

- V10 Engine Performance Enhancements: Various technological innovations have been developed to enhance the performance of V10 engines. These include advanced fuel injection systems, variable valve timing mechanisms, turbocharging and supercharging technologies, and electronic control units that optimize combustion efficiency. These enhancements aim to increase power output while maintaining fuel efficiency and reducing emissions in high-performance applications.

- V10 Engine Cooling and Thermal Management: Effective cooling and thermal management systems are crucial for V10 engines due to their high power output and heat generation. These systems incorporate specialized coolant circulation pathways, advanced radiator designs, oil cooling mechanisms, and thermal sensors to maintain optimal operating temperatures. Proper thermal management ensures engine longevity, consistent performance, and prevention of heat-related failures in high-stress operating conditions.

- V10 Engine Aesthetic and Industrial Design: The aesthetic and industrial design aspects of V10 engines focus on both visual appeal and functional integration within vehicles. These designs include distinctive engine covers, intake manifold configurations, exhaust system layouts, and overall engine bay presentations. The industrial design elements balance form and function, creating recognizable visual signatures for high-performance vehicles while ensuring serviceability and integration with vehicle systems.

- V10 Engine Integration with Vehicle Systems: The integration of V10 engines with broader vehicle systems involves specialized mounting solutions, transmission interfaces, electronic control integration, and exhaust system designs. These integration approaches address challenges related to weight distribution, vibration dampening, heat management, and power delivery. Advanced integration techniques ensure optimal performance while meeting regulatory requirements for emissions, noise, and safety standards.

02 V10 Engine Performance Optimization

Various technologies and methods are employed to optimize the performance of V10 engines, including advanced fuel injection systems, variable valve timing, and turbocharging or supercharging. These optimizations aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining the distinctive sound characteristics that V10 engines are known for.Expand Specific Solutions03 V10 Engine Applications in Vehicles

V10 engines are primarily used in high-performance vehicles, including sports cars, supercars, and some luxury vehicles. They provide exceptional power-to-weight ratios and distinctive sound characteristics that are valued in performance applications. Some heavy-duty trucks and specialized industrial equipment also utilize V10 engines for their high torque output and durability under demanding conditions.Expand Specific Solutions04 V10 Engine Cooling and Thermal Management

Effective cooling and thermal management systems are crucial for V10 engines due to their high power output and heat generation. These systems typically include advanced radiator designs, precision-engineered water jackets, oil coolers, and sometimes additional cooling circuits. Proper thermal management ensures optimal engine performance, longevity, and reliability under various operating conditions.Expand Specific Solutions05 V10 Engine Aesthetic and Visual Design

The aesthetic and visual design of V10 engines often emphasizes their premium nature and high-performance characteristics. Design elements may include distinctive engine covers, visible intake manifolds, and overall styling that showcases the engine as a centerpiece in the vehicle. These visual aspects contribute to the brand identity and appeal of vehicles equipped with V10 engines.Expand Specific Solutions

Key Manufacturers and Competitors

The V10 Engine Adaptation for Smart City Vehicles market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to reach approximately $3-5 billion by 2025, driven by increasing smart city initiatives worldwide. From a technological maturity perspective, traditional automotive giants like Toyota, Ford, and Hyundai are leading adaptation efforts with established engine expertise, while tech-focused players such as GM Cruise and SAIC GM Wuling are advancing integration with smart city infrastructure. Companies like Bosch, DENSO, and Astemo are developing specialized components to bridge conventional V10 power with smart city requirements. Academic institutions including Jilin University and Beijing Institute of Technology are contributing fundamental research to overcome efficiency and emissions challenges in urban environments.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive V10 engine adaptation system for smart city vehicles that focuses on downsizing and efficiency optimization. Their approach involves integrating hybrid technology with traditional V10 architecture to create a more sustainable urban mobility solution. The system incorporates advanced cylinder deactivation technology that allows the engine to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption in urban environments. Toyota's smart city V10 adaptation also features variable valve timing and lift systems that optimize combustion efficiency across different driving scenarios. Their proprietary thermal management system recovers waste heat from the engine to power auxiliary systems and reduce the overall energy footprint. Additionally, Toyota has implemented AI-driven predictive control algorithms that adapt engine performance based on traffic patterns, road conditions, and driver behavior to maximize efficiency in urban settings.

Strengths: Toyota's extensive experience in hybrid powertrains gives them a significant advantage in adapting powerful engines for urban use. Their established supply chain and manufacturing capabilities enable cost-effective implementation. Weaknesses: The inherent size and weight of V10 architecture presents challenges for urban vehicle applications, potentially limiting maneuverability and parking options in congested city environments.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative V10 engine adaptation platform called "EcoCity V10" specifically designed for smart city vehicle applications. Their approach focuses on balancing power delivery with urban efficiency requirements through a combination of advanced mechanical engineering and digital intelligence. The system features variable displacement technology that can seamlessly transition between operating as a V10, V8, V6, or even V4 configuration depending on power demands, dramatically improving fuel efficiency during urban driving cycles. Ford's platform incorporates advanced stop-start technology with predictive capabilities that can anticipate traffic patterns and optimize engine operation accordingly. Their proprietary "CityFuel" direct injection system delivers precisely controlled fuel quantities across various load conditions, significantly reducing emissions in urban environments. The EcoCity V10 also features integrated thermal management that rapidly brings catalytic converters to operating temperature while efficiently managing heat distribution throughout the powertrain. Ford has implemented advanced noise cancellation technology to address the acoustic challenges of operating a large displacement engine in noise-sensitive urban areas. Additionally, their system incorporates over-the-air update capabilities that allow for continuous optimization of engine parameters based on aggregated urban driving data collected from vehicles in the field.

Strengths: Ford's extensive experience with EcoBoost technology provides a strong foundation for efficient high-displacement engines. Their global manufacturing scale enables cost-effective implementation across various vehicle platforms. Weaknesses: The complexity of variable displacement systems may present maintenance challenges in the long term, potentially increasing total cost of ownership for fleet operators in urban environments.

Core Patents in V10 Urban Powertrain

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

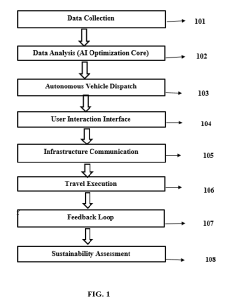

Ai-driven smart city mobility solution that integrates autonomous vehicles with public transportation

PatentPendingIN202411015283A

Innovation

- AI Optimization Core that processes traffic patterns, weather conditions, and user demand to dynamically optimize routes, schedules, and vehicle dispatching in real-time.

- Seamless integration of autonomous vehicles with public transportation networks, offering last-mile connectivity and flexible routing options that work in synchronization with traditional transportation modes.

- Infrastructure Interface System that enables communication between autonomous vehicles, public transport vehicles, and urban infrastructure (traffic signals, road sensors) to facilitate smooth mobility operations.

Emissions Compliance Framework

The adaptation of V10 engines for smart city vehicles necessitates a comprehensive emissions compliance framework that addresses the unique challenges of urban environments. Current regulatory landscapes across major markets have established increasingly stringent emissions standards, with Euro 7, China 7, and US EPA Tier 3 regulations setting the benchmark for vehicle emissions in urban settings. These frameworks specifically target nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon emissions that are particularly problematic in dense urban environments.

For V10 engine adaptation, compliance requires multi-layered technological solutions. Advanced catalytic converters with higher precious metal loadings have demonstrated 30-40% improved conversion efficiency for NOx in urban stop-start conditions. Selective Catalytic Reduction (SCR) systems optimized for lower temperature operation show particular promise, as urban driving patterns rarely allow engines to reach optimal temperatures for traditional emissions control systems.

Real-time emissions monitoring systems (REMS) represent a critical component of the compliance framework, enabling continuous verification of emissions performance under actual urban driving conditions. These systems incorporate AI-driven predictive algorithms that can anticipate emissions spikes based on traffic patterns and adjust engine parameters accordingly, maintaining compliance even in challenging urban scenarios.

Regulatory testing protocols have evolved to better reflect real-world urban driving conditions. The Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests now incorporate more urban driving cycles, requiring V10 engines to demonstrate compliance across a broader range of operating conditions than previous test regimes.

Compliance certification pathways for modified high-performance engines like the V10 vary significantly across jurisdictions. The European type approval system offers specific provisions for small volume manufacturers and modified vehicles, while the California Air Resources Board (CARB) Executive Order process provides a structured pathway for aftermarket modifications while ensuring emissions compliance.

The economic implications of compliance are substantial, with emissions control systems now representing 15-20% of total powertrain costs for high-performance engines adapted to urban use. However, non-compliance penalties have increased dramatically, with fines potentially reaching €95 per gram of CO2/km exceeded in Europe, making investment in robust compliance frameworks economically justified despite their complexity.

For V10 engine adaptation, compliance requires multi-layered technological solutions. Advanced catalytic converters with higher precious metal loadings have demonstrated 30-40% improved conversion efficiency for NOx in urban stop-start conditions. Selective Catalytic Reduction (SCR) systems optimized for lower temperature operation show particular promise, as urban driving patterns rarely allow engines to reach optimal temperatures for traditional emissions control systems.

Real-time emissions monitoring systems (REMS) represent a critical component of the compliance framework, enabling continuous verification of emissions performance under actual urban driving conditions. These systems incorporate AI-driven predictive algorithms that can anticipate emissions spikes based on traffic patterns and adjust engine parameters accordingly, maintaining compliance even in challenging urban scenarios.

Regulatory testing protocols have evolved to better reflect real-world urban driving conditions. The Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests now incorporate more urban driving cycles, requiring V10 engines to demonstrate compliance across a broader range of operating conditions than previous test regimes.

Compliance certification pathways for modified high-performance engines like the V10 vary significantly across jurisdictions. The European type approval system offers specific provisions for small volume manufacturers and modified vehicles, while the California Air Resources Board (CARB) Executive Order process provides a structured pathway for aftermarket modifications while ensuring emissions compliance.

The economic implications of compliance are substantial, with emissions control systems now representing 15-20% of total powertrain costs for high-performance engines adapted to urban use. However, non-compliance penalties have increased dramatically, with fines potentially reaching €95 per gram of CO2/km exceeded in Europe, making investment in robust compliance frameworks economically justified despite their complexity.

Urban Infrastructure Requirements

The integration of V10 engines into smart city vehicles necessitates significant adaptations to existing urban infrastructure. Traditional city planning and infrastructure were not designed with high-performance engines in mind, creating a complex adaptation challenge. Smart cities must develop comprehensive charging networks capable of supporting the increased energy demands of V10-powered vehicles, particularly when these engines are hybridized or electrified for urban environments.

Road systems require substantial reinforcement to accommodate the weight and performance characteristics of V10-equipped vehicles. This includes enhanced load-bearing capacity on bridges, improved surface materials to withstand increased torque, and redesigned intersections that can safely manage vehicles with higher acceleration capabilities. Traffic management systems must be upgraded with advanced AI algorithms specifically calibrated to predict and respond to the movement patterns of high-performance vehicles operating in dense urban environments.

Environmental considerations demand the installation of advanced emissions monitoring stations throughout urban centers. These stations must be capable of real-time analysis of particulate matter, NOx emissions, and carbon output from modified V10 engines. Additionally, noise pollution mitigation infrastructure becomes essential, requiring the implementation of sound barriers in residential areas and acoustic dampening materials in road construction.

Data infrastructure represents another critical requirement, as V10-equipped smart city vehicles will generate substantial telemetry data. Cities must deploy edge computing nodes at strategic locations to process this information with minimal latency. High-bandwidth, low-latency 5G or 6G networks become necessary to facilitate real-time communication between vehicles and infrastructure, enabling advanced driver assistance systems to function optimally with high-performance engines.

Maintenance facilities within urban environments require significant upgrades to service V10 engines effectively. This includes specialized diagnostic equipment, trained technicians, and appropriate waste management systems for handling the unique fluids and components associated with these sophisticated powerplants. Emergency response infrastructure must also evolve, with fire departments requiring new equipment and training to address potential incidents involving high-performance engines in dense urban settings.

Parking structures present unique challenges, necessitating reinforced ventilation systems to manage increased heat and emissions. Smart parking solutions must incorporate sensors capable of detecting the specific dimensions and weight distribution of V10-equipped vehicles, ensuring optimal space utilization while maintaining structural integrity of parking facilities.

Road systems require substantial reinforcement to accommodate the weight and performance characteristics of V10-equipped vehicles. This includes enhanced load-bearing capacity on bridges, improved surface materials to withstand increased torque, and redesigned intersections that can safely manage vehicles with higher acceleration capabilities. Traffic management systems must be upgraded with advanced AI algorithms specifically calibrated to predict and respond to the movement patterns of high-performance vehicles operating in dense urban environments.

Environmental considerations demand the installation of advanced emissions monitoring stations throughout urban centers. These stations must be capable of real-time analysis of particulate matter, NOx emissions, and carbon output from modified V10 engines. Additionally, noise pollution mitigation infrastructure becomes essential, requiring the implementation of sound barriers in residential areas and acoustic dampening materials in road construction.

Data infrastructure represents another critical requirement, as V10-equipped smart city vehicles will generate substantial telemetry data. Cities must deploy edge computing nodes at strategic locations to process this information with minimal latency. High-bandwidth, low-latency 5G or 6G networks become necessary to facilitate real-time communication between vehicles and infrastructure, enabling advanced driver assistance systems to function optimally with high-performance engines.

Maintenance facilities within urban environments require significant upgrades to service V10 engines effectively. This includes specialized diagnostic equipment, trained technicians, and appropriate waste management systems for handling the unique fluids and components associated with these sophisticated powerplants. Emergency response infrastructure must also evolve, with fire departments requiring new equipment and training to address potential incidents involving high-performance engines in dense urban settings.

Parking structures present unique challenges, necessitating reinforced ventilation systems to manage increased heat and emissions. Smart parking solutions must incorporate sensors capable of detecting the specific dimensions and weight distribution of V10-equipped vehicles, ensuring optimal space utilization while maintaining structural integrity of parking facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!