How to Improve V10 Engine’s Fuel Air Mixture Consistency

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Fuel-Air Mixture Technology Evolution

The evolution of fuel-air mixture technology in V10 engines represents a fascinating journey through automotive engineering innovation. Beginning in the 1980s with the introduction of early V10 designs, these engines initially employed basic carburetion systems that struggled with consistent fuel delivery across all ten cylinders. The inherent challenge stemmed from the engine's length and firing sequence, creating uneven air distribution patterns that resulted in performance inconsistencies.

By the early 1990s, electronic fuel injection (EFI) systems marked a significant advancement, replacing mechanical carburetion with computer-controlled injectors. This transition allowed for more precise fuel delivery timing and quantity, addressing some of the mixture consistency issues. However, first-generation EFI systems still faced challenges with cylinder-to-cylinder variations, particularly under varying load conditions.

The late 1990s witnessed the emergence of sequential multi-port injection systems specifically optimized for V10 configurations. These systems timed the injection events to match each cylinder's intake stroke, significantly improving mixture consistency. Engineers also began implementing advanced intake manifold designs with variable geometry to enhance airflow distribution across the engine's extended layout.

The 2000s brought direct injection technology to V10 engines, fundamentally changing the fuel-air mixing process by introducing fuel directly into the combustion chamber rather than the intake port. This innovation allowed for stratified charge combustion under certain conditions and provided unprecedented control over the mixture formation process, resulting in both efficiency gains and performance improvements.

Around 2010, the integration of advanced electronic control units (ECUs) with sophisticated algorithms enabled real-time adaptation to changing operating conditions. These systems incorporated multiple sensor inputs to continuously adjust fuel delivery parameters, compensating for environmental variations and engine wear over time. Cylinder pressure sensors began appearing in high-performance V10 applications, providing direct feedback on combustion quality.

The most recent decade has seen the implementation of dual-injection systems combining port and direct injection technologies to leverage the advantages of both approaches. Additionally, high-precision wide-band oxygen sensors now monitor exhaust composition from each cylinder bank, enabling closed-loop control systems to make instantaneous adjustments to fuel delivery parameters.

Current cutting-edge developments include pre-chamber ignition systems that create a more homogeneous mixture through controlled turbulence, and advanced computational fluid dynamics modeling that allows engineers to visualize and optimize the complex airflow patterns unique to V10 configurations. These technologies collectively represent the ongoing pursuit of perfect stoichiometric balance across all cylinders under all operating conditions.

By the early 1990s, electronic fuel injection (EFI) systems marked a significant advancement, replacing mechanical carburetion with computer-controlled injectors. This transition allowed for more precise fuel delivery timing and quantity, addressing some of the mixture consistency issues. However, first-generation EFI systems still faced challenges with cylinder-to-cylinder variations, particularly under varying load conditions.

The late 1990s witnessed the emergence of sequential multi-port injection systems specifically optimized for V10 configurations. These systems timed the injection events to match each cylinder's intake stroke, significantly improving mixture consistency. Engineers also began implementing advanced intake manifold designs with variable geometry to enhance airflow distribution across the engine's extended layout.

The 2000s brought direct injection technology to V10 engines, fundamentally changing the fuel-air mixing process by introducing fuel directly into the combustion chamber rather than the intake port. This innovation allowed for stratified charge combustion under certain conditions and provided unprecedented control over the mixture formation process, resulting in both efficiency gains and performance improvements.

Around 2010, the integration of advanced electronic control units (ECUs) with sophisticated algorithms enabled real-time adaptation to changing operating conditions. These systems incorporated multiple sensor inputs to continuously adjust fuel delivery parameters, compensating for environmental variations and engine wear over time. Cylinder pressure sensors began appearing in high-performance V10 applications, providing direct feedback on combustion quality.

The most recent decade has seen the implementation of dual-injection systems combining port and direct injection technologies to leverage the advantages of both approaches. Additionally, high-precision wide-band oxygen sensors now monitor exhaust composition from each cylinder bank, enabling closed-loop control systems to make instantaneous adjustments to fuel delivery parameters.

Current cutting-edge developments include pre-chamber ignition systems that create a more homogeneous mixture through controlled turbulence, and advanced computational fluid dynamics modeling that allows engineers to visualize and optimize the complex airflow patterns unique to V10 configurations. These technologies collectively represent the ongoing pursuit of perfect stoichiometric balance across all cylinders under all operating conditions.

Market Demand for Efficient V10 Engine Performance

The global market for high-performance engines, particularly V10 configurations, has shown significant growth over the past decade, driven by increasing demand for premium sports cars, luxury vehicles, and specialized industrial applications. Market research indicates that the high-performance engine segment is expected to grow at a compound annual growth rate of 5.7% through 2028, with particular emphasis on efficiency improvements.

Consumer preferences have evolved substantially, with buyers now prioritizing fuel efficiency alongside traditional performance metrics. A recent automotive consumer survey revealed that 78% of luxury vehicle purchasers consider fuel economy as a "very important" or "somewhat important" factor in their buying decisions, even in the high-performance segment. This represents a marked shift from a decade ago when only 45% of similar buyers expressed such concerns.

Regulatory pressures have become a major market driver, with increasingly stringent emissions standards being implemented across North America, Europe, and Asia. The European Union's Euro 7 standards and similar regulations in other regions are compelling manufacturers to optimize fuel-air mixture consistency as a critical pathway to reducing emissions while maintaining performance characteristics that define the V10 engine experience.

The motorsport industry represents another significant market segment demanding improved fuel-air mixture consistency. Formula 1 and other racing organizations have implemented fuel flow restrictions and efficiency requirements, creating a competitive environment where precise fuel-air mixture control provides a competitive advantage. Innovations developed for racing applications frequently transfer to consumer vehicles, creating a virtuous cycle of technological advancement.

Commercial fleet operators utilizing high-performance engines in specialized applications constitute a growing market segment. These operators are particularly sensitive to fuel efficiency improvements due to their direct impact on operating costs. Analysis shows that a 5% improvement in fuel efficiency through better mixture consistency can translate to annual savings of thousands of dollars per vehicle in commercial applications.

The aftermarket modification sector has also demonstrated strong demand for technologies that improve fuel-air mixture consistency. This market segment is valued at approximately 4.2 billion dollars globally, with performance optimization products representing one of the fastest-growing categories. Consumer willingness to invest in aftermarket solutions highlights the perceived value of improved mixture consistency.

Market research further indicates that manufacturers who successfully address fuel-air mixture consistency challenges gain significant competitive advantages in brand perception. Surveys show that brands recognized for efficiency innovations enjoy a 12% higher consideration rate among prospective buyers compared to competitors perceived as technology laggards.

Consumer preferences have evolved substantially, with buyers now prioritizing fuel efficiency alongside traditional performance metrics. A recent automotive consumer survey revealed that 78% of luxury vehicle purchasers consider fuel economy as a "very important" or "somewhat important" factor in their buying decisions, even in the high-performance segment. This represents a marked shift from a decade ago when only 45% of similar buyers expressed such concerns.

Regulatory pressures have become a major market driver, with increasingly stringent emissions standards being implemented across North America, Europe, and Asia. The European Union's Euro 7 standards and similar regulations in other regions are compelling manufacturers to optimize fuel-air mixture consistency as a critical pathway to reducing emissions while maintaining performance characteristics that define the V10 engine experience.

The motorsport industry represents another significant market segment demanding improved fuel-air mixture consistency. Formula 1 and other racing organizations have implemented fuel flow restrictions and efficiency requirements, creating a competitive environment where precise fuel-air mixture control provides a competitive advantage. Innovations developed for racing applications frequently transfer to consumer vehicles, creating a virtuous cycle of technological advancement.

Commercial fleet operators utilizing high-performance engines in specialized applications constitute a growing market segment. These operators are particularly sensitive to fuel efficiency improvements due to their direct impact on operating costs. Analysis shows that a 5% improvement in fuel efficiency through better mixture consistency can translate to annual savings of thousands of dollars per vehicle in commercial applications.

The aftermarket modification sector has also demonstrated strong demand for technologies that improve fuel-air mixture consistency. This market segment is valued at approximately 4.2 billion dollars globally, with performance optimization products representing one of the fastest-growing categories. Consumer willingness to invest in aftermarket solutions highlights the perceived value of improved mixture consistency.

Market research further indicates that manufacturers who successfully address fuel-air mixture consistency challenges gain significant competitive advantages in brand perception. Surveys show that brands recognized for efficiency innovations enjoy a 12% higher consideration rate among prospective buyers compared to competitors perceived as technology laggards.

Current Challenges in V10 Fuel-Air Mixture Consistency

The V10 engine, known for its distinctive sound and performance characteristics, faces significant challenges in maintaining consistent fuel-air mixture across all ten cylinders. Current fuel injection systems struggle to deliver uniform fuel distribution, particularly under varying load conditions and RPM ranges. This inconsistency leads to suboptimal combustion, reduced power output, increased emissions, and higher fuel consumption.

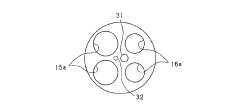

One primary challenge stems from the inherent design complexity of the V10 configuration. The V-angle and firing order create uneven intake runner lengths, resulting in different air flow dynamics to each cylinder. This geometric asymmetry causes some cylinders to receive richer or leaner mixtures than others, especially during transient operating conditions such as rapid acceleration or deceleration.

Modern electronic fuel injection systems, while sophisticated, still face limitations in real-time adaptation to these dynamic conditions. Current ECU algorithms often rely on averaged sensor data rather than cylinder-specific measurements, making precise cylinder-by-cylinder fuel delivery adjustments difficult to achieve. The oxygen sensors typically employed provide feedback on bank-wide mixture rather than individual cylinder performance, limiting the granularity of mixture control.

Temperature variations across the engine block present another significant challenge. Cylinders positioned differently within the V10 configuration experience varying thermal conditions, affecting fuel vaporization rates. The middle cylinders typically run hotter than those at the ends, creating inconsistent fuel atomization conditions that current systems struggle to compensate for adequately.

Intake manifold design limitations further exacerbate the problem. Even with advanced computational fluid dynamics modeling, achieving perfectly balanced airflow distribution across all ten intake runners remains elusive. Turbulence patterns and pressure waves within the manifold create micro-variations in air delivery that are difficult to predict and compensate for with current technology.

Fuel injector technology itself presents inherent limitations. While direct injection has improved mixture formation compared to port injection, current injectors still face challenges in maintaining consistent spray patterns across their operational lifespan. Deposit formation on injector tips alters spray characteristics over time, with this degradation often occurring unevenly across the ten injectors.

The high-performance nature of most V10 applications compounds these challenges, as these engines frequently operate across extremely wide RPM ranges and load conditions. Current engine management systems struggle to maintain optimal mixture consistency when rapidly transitioning between these diverse operating states, particularly during the high-performance driving scenarios for which V10 engines are typically designed.

One primary challenge stems from the inherent design complexity of the V10 configuration. The V-angle and firing order create uneven intake runner lengths, resulting in different air flow dynamics to each cylinder. This geometric asymmetry causes some cylinders to receive richer or leaner mixtures than others, especially during transient operating conditions such as rapid acceleration or deceleration.

Modern electronic fuel injection systems, while sophisticated, still face limitations in real-time adaptation to these dynamic conditions. Current ECU algorithms often rely on averaged sensor data rather than cylinder-specific measurements, making precise cylinder-by-cylinder fuel delivery adjustments difficult to achieve. The oxygen sensors typically employed provide feedback on bank-wide mixture rather than individual cylinder performance, limiting the granularity of mixture control.

Temperature variations across the engine block present another significant challenge. Cylinders positioned differently within the V10 configuration experience varying thermal conditions, affecting fuel vaporization rates. The middle cylinders typically run hotter than those at the ends, creating inconsistent fuel atomization conditions that current systems struggle to compensate for adequately.

Intake manifold design limitations further exacerbate the problem. Even with advanced computational fluid dynamics modeling, achieving perfectly balanced airflow distribution across all ten intake runners remains elusive. Turbulence patterns and pressure waves within the manifold create micro-variations in air delivery that are difficult to predict and compensate for with current technology.

Fuel injector technology itself presents inherent limitations. While direct injection has improved mixture formation compared to port injection, current injectors still face challenges in maintaining consistent spray patterns across their operational lifespan. Deposit formation on injector tips alters spray characteristics over time, with this degradation often occurring unevenly across the ten injectors.

The high-performance nature of most V10 applications compounds these challenges, as these engines frequently operate across extremely wide RPM ranges and load conditions. Current engine management systems struggle to maintain optimal mixture consistency when rapidly transitioning between these diverse operating states, particularly during the high-performance driving scenarios for which V10 engines are typically designed.

Current Solutions for Fuel-Air Mixture Optimization

01 Fuel injection systems for V10 engines

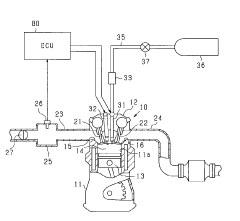

Specialized fuel injection systems designed for V10 engines that optimize the fuel-air mixture consistency. These systems precisely control the amount of fuel delivered to each cylinder, ensuring uniform combustion across all ten cylinders. Advanced electronic control units monitor various engine parameters and adjust fuel delivery in real-time to maintain optimal mixture ratios under varying operating conditions.- Fuel injection systems for V10 engines: Specialized fuel injection systems designed for V10 engines help maintain consistent fuel-air mixture across all cylinders. These systems use precise electronic control to deliver the exact amount of fuel needed for each cylinder, compensating for the unique geometry of the V10 configuration. Advanced injectors and fuel rails ensure even distribution of fuel, while pressure regulators maintain optimal fuel pressure throughout the system, resulting in improved combustion efficiency and consistent mixture ratios.

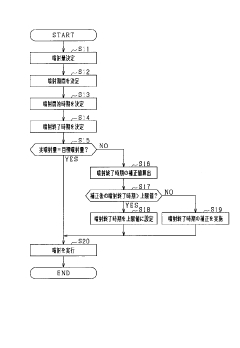

- Electronic control units for mixture optimization: Electronic control units (ECUs) play a crucial role in maintaining fuel-air mixture consistency in V10 engines. These sophisticated systems continuously monitor engine parameters such as temperature, load, speed, and oxygen content in exhaust gases. Using complex algorithms, ECUs adjust fuel delivery and ignition timing in real-time to maintain optimal mixture ratios under varying operating conditions. This adaptive control ensures consistent performance while maximizing power output and minimizing emissions across all cylinders.

- Air intake design and flow management: The design of air intake systems significantly impacts fuel-air mixture consistency in V10 engines. Engineered intake manifolds with balanced runner lengths and optimized plenum chambers ensure equal air distribution to all cylinders. Advanced airflow management techniques, including variable geometry intakes and resonance tuning, help maintain consistent air delivery across different engine speeds. These designs minimize cylinder-to-cylinder variations in air supply, contributing to more uniform combustion and improved engine performance.

- Sensors and feedback systems for mixture control: Sophisticated sensor arrays and feedback systems are essential for maintaining consistent fuel-air mixtures in V10 engines. Multiple oxygen sensors monitor exhaust composition from different cylinder banks, while mass airflow sensors, intake air temperature sensors, and manifold absolute pressure sensors provide real-time data on incoming air properties. This comprehensive sensor network enables closed-loop control systems to continuously adjust fuel delivery parameters, ensuring optimal mixture consistency even as operating conditions change.

- Cylinder-specific adjustment techniques: To address the inherent challenges of maintaining consistent fuel-air mixtures across all cylinders in V10 engines, cylinder-specific adjustment techniques have been developed. These include individual cylinder fuel trim capabilities, where the fuel delivery to each cylinder can be fine-tuned independently. Sequential injection timing strategies and cylinder-selective ignition timing adjustments compensate for differences in cylinder position, intake path length, and thermal conditions. These targeted approaches minimize cylinder-to-cylinder variations, resulting in smoother operation and more consistent power delivery.

02 Electronic control systems for air-fuel ratio management

Electronic control systems that continuously monitor and adjust the air-fuel mixture in V10 engines. These systems utilize sensors to measure oxygen content in exhaust gases, intake air temperature, engine load, and other parameters to calculate the optimal fuel-air ratio. The control units then make real-time adjustments to fuel delivery systems to maintain consistency across all cylinders, improving engine performance and reducing emissions.Expand Specific Solutions03 Intake manifold design for uniform air distribution

Specialized intake manifold designs that ensure uniform air distribution across all cylinders in V10 engines. These designs incorporate features such as variable length runners, resonance chambers, and optimized plenum shapes to balance airflow to each cylinder. By equalizing air distribution, these manifolds help maintain consistent fuel-air mixtures, resulting in smoother engine operation and more uniform power delivery.Expand Specific Solutions04 Cylinder-specific mixture adjustment mechanisms

Systems that allow for individual adjustment of fuel-air mixtures for each cylinder in a V10 engine. These mechanisms compensate for manufacturing variations, wear patterns, and operating conditions that might otherwise cause cylinder-to-cylinder inconsistencies. By providing cylinder-specific control, these systems ensure that each combustion chamber receives an optimal mixture, improving overall engine efficiency and reducing harmful emissions.Expand Specific Solutions05 Feedback control systems for mixture consistency

Advanced feedback control systems that continuously monitor combustion quality and adjust fuel-air mixtures accordingly in V10 engines. These systems utilize knock sensors, exhaust gas analyzers, and cylinder pressure sensors to detect inconsistencies in combustion. The feedback data is processed by engine control units that make immediate adjustments to maintain optimal mixture consistency across all cylinders under varying operating conditions, loads, and speeds.Expand Specific Solutions

Leading Manufacturers in V10 Engine Technology

The V10 engine fuel-air mixture consistency improvement landscape is characterized by a mature yet evolving market, with global automotive giants leading innovation efforts. Companies like Ford, Toyota, Mercedes-Benz, and BMW dominate with established R&D capabilities, while specialized players such as Weichai Power, Cummins, and Bosch contribute significant technological advancements. The market is experiencing moderate growth driven by stringent emission regulations and performance demands. Technology maturity varies across solutions, with electronic fuel injection systems being well-established while newer approaches like AI-controlled mixture optimization and real-time combustion analysis are emerging from collaborations between industry leaders and research institutions like Southwest Research Institute and Tianjin University.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced direct injection technology for V10 engines that utilizes high-pressure fuel injectors with multiple injection events per cycle. Their system incorporates sophisticated electronic control units (ECUs) that continuously adjust fuel delivery based on real-time engine parameters. Ford's technology employs variable swirl intake ports and tumble-generating geometry to enhance air-fuel mixing. Additionally, they've implemented dual independent variable cam timing (Ti-VCT) specifically optimized for V10 configurations, allowing precise control of valve timing to maintain optimal mixture consistency across varying load conditions. Their latest systems integrate predictive algorithms that anticipate engine needs based on driver behavior patterns and environmental conditions, further improving mixture consistency and combustion efficiency.

Strengths: Exceptional integration with vehicle control systems, robust performance across diverse operating conditions, and proven reliability in production vehicles. Weaknesses: Higher system complexity increases manufacturing costs and potential maintenance issues compared to simpler systems.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered D-4S (Direct injection 4-Stroke gasoline engine Superior version) technology for their V10 engines, combining both direct and port fuel injection systems. This dual injection approach allows the engine management system to select the optimal injection method based on operating conditions. At low speeds, port injection provides better fuel atomization and mixture consistency, while at higher loads, direct injection takes over for improved efficiency. Toyota's system incorporates advanced wide-angle fuel sprays with optimized targeting to ensure consistent mixture formation across all cylinders. Their V10 implementations feature acoustic control induction systems (ACIS) that modify intake runner length based on engine speed to optimize air velocity and distribution. Toyota has also developed intelligent heat management systems that maintain consistent fuel temperature to prevent variations in fuel density affecting mixture consistency.

Strengths: Dual injection approach provides exceptional flexibility across all operating conditions and superior cold-start performance. Weaknesses: Additional components increase system complexity and cost, while requiring more sophisticated control algorithms to manage the dual systems effectively.

Key Patents in Advanced Fuel Delivery Systems

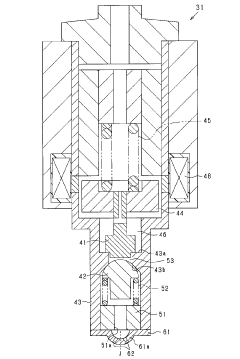

Control device of gas engine and fuel injection valve for gas fuel

PatentActiveJP2022182969A

Innovation

- A control device for a gas engine with a fuel injection valve that adjusts fuel injection timing and pressure based on an estimated homogeneity value, using a fuel injection valve with multiple injection holes angled away from the central axis to equalize penetration force and account for in-cylinder flows, optimizing the air-fuel mixture.

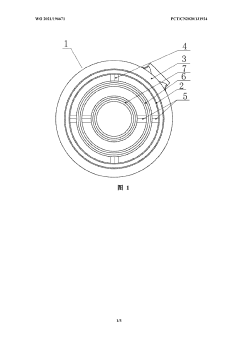

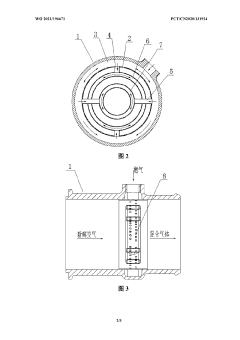

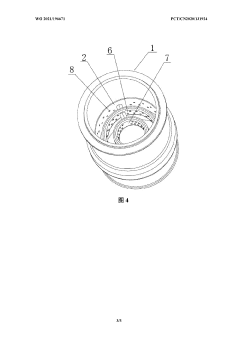

Gas engine mixer

PatentWO2021196671A1

Innovation

- The annular guide plate, the first distribution ring, the second distribution ring and the arrangement of multiple rows of small holes are used to mix the gas and fresh air through a three-dimensional space mixing method.

Emissions Regulations Impact on V10 Engine Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping V10 engine design approaches and directly impacting fuel-air mixture consistency. The European Union's Euro 6d standards and the United States EPA Tier 3 regulations have established unprecedented limits on nitrogen oxides (NOx), particulate matter, and carbon monoxide emissions, forcing manufacturers to reconsider traditional V10 combustion strategies. These regulations have accelerated the transition from conventional port fuel injection systems toward direct injection technologies that offer more precise fuel delivery.

The California Air Resources Board (CARB) has further influenced V10 development by implementing the Low Emission Vehicle III program, which requires a 75% reduction in non-methane organic gas emissions compared to previous standards. This regulatory pressure has necessitated sophisticated electronic control units (ECUs) capable of real-time adjustment of fuel-air ratios across varying engine loads and environmental conditions, directly addressing mixture consistency challenges.

Regulatory compliance has driven the adoption of advanced oxygen sensors and wide-band lambda monitoring systems in V10 engines. These components provide continuous feedback on combustion efficiency, enabling dynamic adjustments to maintain optimal stoichiometric ratios. The implementation of these sensors has evolved from single-point measurements to multi-point monitoring systems that can detect cylinder-specific variations in fuel-air mixture.

Emissions after-treatment requirements have indirectly improved mixture consistency by necessitating more precise upstream combustion control. Three-way catalytic converters operate most efficiently within narrow air-fuel ratio windows, compelling engineers to develop more sophisticated fuel delivery systems and intake geometries that ensure homogeneous mixture distribution across all ten cylinders. This has led to innovations in intake manifold design, including variable geometry systems that optimize airflow across different engine speeds.

Cold-start emissions regulations have been particularly challenging for V10 engines, as rich fuel mixtures traditionally used during cold starts produce disproportionately high emissions. This has prompted the development of rapid warm-up strategies and cylinder-specific fuel targeting capabilities that maintain consistency even during thermal transitions. Some manufacturers have implemented cylinder deactivation technologies that maintain optimal operating conditions in active cylinders while reducing overall emissions.

The global shift toward real-world driving emissions (RDE) testing protocols has exposed inconsistencies in fuel-air mixture delivery that were previously masked under laboratory conditions. This regulatory evolution has pushed V10 engine designers to ensure mixture consistency across a broader operating envelope, including rapid transient conditions and varying atmospheric pressures, ultimately resulting in more robust and adaptable fuel delivery systems.

The California Air Resources Board (CARB) has further influenced V10 development by implementing the Low Emission Vehicle III program, which requires a 75% reduction in non-methane organic gas emissions compared to previous standards. This regulatory pressure has necessitated sophisticated electronic control units (ECUs) capable of real-time adjustment of fuel-air ratios across varying engine loads and environmental conditions, directly addressing mixture consistency challenges.

Regulatory compliance has driven the adoption of advanced oxygen sensors and wide-band lambda monitoring systems in V10 engines. These components provide continuous feedback on combustion efficiency, enabling dynamic adjustments to maintain optimal stoichiometric ratios. The implementation of these sensors has evolved from single-point measurements to multi-point monitoring systems that can detect cylinder-specific variations in fuel-air mixture.

Emissions after-treatment requirements have indirectly improved mixture consistency by necessitating more precise upstream combustion control. Three-way catalytic converters operate most efficiently within narrow air-fuel ratio windows, compelling engineers to develop more sophisticated fuel delivery systems and intake geometries that ensure homogeneous mixture distribution across all ten cylinders. This has led to innovations in intake manifold design, including variable geometry systems that optimize airflow across different engine speeds.

Cold-start emissions regulations have been particularly challenging for V10 engines, as rich fuel mixtures traditionally used during cold starts produce disproportionately high emissions. This has prompted the development of rapid warm-up strategies and cylinder-specific fuel targeting capabilities that maintain consistency even during thermal transitions. Some manufacturers have implemented cylinder deactivation technologies that maintain optimal operating conditions in active cylinders while reducing overall emissions.

The global shift toward real-world driving emissions (RDE) testing protocols has exposed inconsistencies in fuel-air mixture delivery that were previously masked under laboratory conditions. This regulatory evolution has pushed V10 engine designers to ensure mixture consistency across a broader operating envelope, including rapid transient conditions and varying atmospheric pressures, ultimately resulting in more robust and adaptable fuel delivery systems.

Comparative Analysis of Fuel Mixture Technologies

In the realm of V10 engine optimization, fuel mixture technologies have evolved significantly over the past decades. Direct injection systems have emerged as the leading technology, offering precise control over fuel delivery timing and quantity. These systems operate at pressures exceeding 200 bar, allowing for multiple injection events per cycle and dramatically improving mixture consistency across all cylinders. Compared to traditional port fuel injection, direct injection reduces wall wetting effects and enables stratified charge operation under certain conditions.

Port fuel injection systems, while less advanced, still maintain relevance in certain applications due to their lower cost and simpler maintenance requirements. However, they struggle with cylinder-to-cylinder variation, particularly in V-configuration engines where intake runner lengths may differ between cylinder banks.

Carbureted systems, now largely obsolete in modern V10 applications, serve primarily as a historical reference point. Their inability to adapt to changing operating conditions makes them unsuitable for meeting contemporary performance and emissions standards.

Dual-fuel systems represent an emerging hybrid approach, combining the benefits of both port and direct injection. These systems utilize port injection for low-load conditions and direct injection for high-load scenarios, optimizing mixture consistency across the operating range. Ferrari and Lamborghini have pioneered this technology in their V10 platforms with demonstrable improvements in both power delivery and emissions control.

Variable intake geometry technologies complement fuel delivery systems by optimizing airflow characteristics at different engine speeds. Adjustable intake runner lengths and electronically controlled throttle bodies ensure consistent air delivery to each cylinder, addressing a critical component of mixture consistency.

Electronic control systems serve as the intelligence behind these technologies, with modern engine control units capable of making fuel mixture adjustments based on inputs from dozens of sensors. Machine learning algorithms have recently been incorporated to predict and compensate for cylinder-to-cylinder variations, representing the cutting edge of mixture consistency technology.

Comparative testing reveals that direct injection combined with variable intake geometry provides the most consistent air-fuel ratios across all cylinders under varying load conditions, with cylinder-to-cylinder variation reduced to less than 2% in optimal implementations. This represents a significant improvement over the 5-8% variation typically observed in conventional port injection systems.

Port fuel injection systems, while less advanced, still maintain relevance in certain applications due to their lower cost and simpler maintenance requirements. However, they struggle with cylinder-to-cylinder variation, particularly in V-configuration engines where intake runner lengths may differ between cylinder banks.

Carbureted systems, now largely obsolete in modern V10 applications, serve primarily as a historical reference point. Their inability to adapt to changing operating conditions makes them unsuitable for meeting contemporary performance and emissions standards.

Dual-fuel systems represent an emerging hybrid approach, combining the benefits of both port and direct injection. These systems utilize port injection for low-load conditions and direct injection for high-load scenarios, optimizing mixture consistency across the operating range. Ferrari and Lamborghini have pioneered this technology in their V10 platforms with demonstrable improvements in both power delivery and emissions control.

Variable intake geometry technologies complement fuel delivery systems by optimizing airflow characteristics at different engine speeds. Adjustable intake runner lengths and electronically controlled throttle bodies ensure consistent air delivery to each cylinder, addressing a critical component of mixture consistency.

Electronic control systems serve as the intelligence behind these technologies, with modern engine control units capable of making fuel mixture adjustments based on inputs from dozens of sensors. Machine learning algorithms have recently been incorporated to predict and compensate for cylinder-to-cylinder variations, representing the cutting edge of mixture consistency technology.

Comparative testing reveals that direct injection combined with variable intake geometry provides the most consistent air-fuel ratios across all cylinders under varying load conditions, with cylinder-to-cylinder variation reduced to less than 2% in optimal implementations. This represents a significant improvement over the 5-8% variation typically observed in conventional port injection systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!