V10 Engine vs LPG Systems: Comparative Analysis

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and LPG Technology Evolution

The evolution of V10 engines and LPG (Liquefied Petroleum Gas) systems represents two distinct technological trajectories in the automotive industry, each with its own developmental milestones and engineering philosophies. The V10 engine emerged in the 1980s as a high-performance power unit, initially finding application in Formula 1 racing before transitioning to production vehicles. Its development was driven by the pursuit of increased power output while maintaining a reasonable package size compared to V12 configurations.

The technological progression of V10 engines has been marked by significant advancements in materials science, with aluminum alloy blocks replacing cast iron to reduce weight, and the integration of variable valve timing systems to optimize performance across different operating conditions. The introduction of direct fuel injection in the early 2000s further enhanced combustion efficiency and power delivery in these engines.

Concurrently, LPG systems have evolved from rudimentary aftermarket conversions in the 1970s to sophisticated factory-integrated solutions. The initial LPG systems were characterized by simple mechanical mixers that often compromised engine performance. The technological trajectory shifted significantly with the introduction of vapor sequential injection systems in the 1990s, which maintained closer performance parity with gasoline operation.

The most recent generation of liquid-phase direct injection LPG systems represents a convergence point where alternative fuel technology approaches the sophistication of modern gasoline direct injection. These systems maintain the full power and torque characteristics of the base engine while offering reduced emissions and operating costs.

Market forces have shaped these parallel technological paths differently. V10 engine development has been primarily driven by performance benchmarks and brand prestige considerations, while LPG system evolution has responded to economic pressures and emissions regulations. This distinction is evident in their respective development timelines, with V10 technology focusing on incremental performance gains, while LPG systems have undergone more fundamental architectural changes.

The engineering challenges faced by both technologies have also diverged significantly. V10 development has concentrated on managing thermal loads, reducing friction, and optimizing NVH (Noise, Vibration, Harshness) characteristics. In contrast, LPG system evolution has focused on addressing fuel delivery precision, cold-start performance, and seamless fuel switching capabilities.

Recent trends indicate a potential technological convergence, with high-performance engines including V10s being adapted for alternative fuel compatibility, including LPG in some markets. This represents a synthesis of the performance-oriented engineering of V10 engines with the emissions advantages of LPG systems.

The technological progression of V10 engines has been marked by significant advancements in materials science, with aluminum alloy blocks replacing cast iron to reduce weight, and the integration of variable valve timing systems to optimize performance across different operating conditions. The introduction of direct fuel injection in the early 2000s further enhanced combustion efficiency and power delivery in these engines.

Concurrently, LPG systems have evolved from rudimentary aftermarket conversions in the 1970s to sophisticated factory-integrated solutions. The initial LPG systems were characterized by simple mechanical mixers that often compromised engine performance. The technological trajectory shifted significantly with the introduction of vapor sequential injection systems in the 1990s, which maintained closer performance parity with gasoline operation.

The most recent generation of liquid-phase direct injection LPG systems represents a convergence point where alternative fuel technology approaches the sophistication of modern gasoline direct injection. These systems maintain the full power and torque characteristics of the base engine while offering reduced emissions and operating costs.

Market forces have shaped these parallel technological paths differently. V10 engine development has been primarily driven by performance benchmarks and brand prestige considerations, while LPG system evolution has responded to economic pressures and emissions regulations. This distinction is evident in their respective development timelines, with V10 technology focusing on incremental performance gains, while LPG systems have undergone more fundamental architectural changes.

The engineering challenges faced by both technologies have also diverged significantly. V10 development has concentrated on managing thermal loads, reducing friction, and optimizing NVH (Noise, Vibration, Harshness) characteristics. In contrast, LPG system evolution has focused on addressing fuel delivery precision, cold-start performance, and seamless fuel switching capabilities.

Recent trends indicate a potential technological convergence, with high-performance engines including V10s being adapted for alternative fuel compatibility, including LPG in some markets. This represents a synthesis of the performance-oriented engineering of V10 engines with the emissions advantages of LPG systems.

Market Demand Analysis for V10 and LPG Systems

The global automotive market is witnessing a significant shift in consumer preferences and regulatory frameworks, directly impacting the demand dynamics for both V10 engines and Liquefied Petroleum Gas (LPG) systems. Current market analysis indicates that traditional V10 engines, once symbols of automotive power and luxury, are experiencing declining demand in most developed markets, with annual sales decreasing by approximately 15% year-over-year since 2018.

This decline is primarily attributed to stringent emission regulations in Europe and North America, coupled with increasing consumer awareness regarding environmental sustainability. The premium segment, where V10 engines traditionally dominated, now represents less than 2% of the global automotive market, with further contraction projected over the next five years.

Conversely, LPG systems are experiencing robust growth, particularly in emerging economies and regions with established LPG infrastructure. The global LPG automotive market has expanded at a compound annual growth rate of 7.3% over the past five years, with particularly strong adoption in countries like South Korea, Turkey, Poland, and India. This growth is driven by LPG's cost advantage, with fuel expenses typically 30-40% lower than conventional gasoline.

Market segmentation analysis reveals that fleet operators and taxi services constitute the largest adopter segment for LPG systems, valuing the reduced operating costs and extended maintenance intervals. The aftermarket conversion sector for LPG systems has also shown remarkable resilience, growing steadily despite the overall automotive market fluctuations during recent economic downturns.

Regional analysis demonstrates divergent trends, with North American markets showing minimal interest in LPG systems while maintaining a small but dedicated consumer base for high-performance V10 engines in specialty vehicles. European markets exhibit declining demand for V10 engines due to taxation policies based on engine displacement and emissions, while simultaneously showing moderate growth in LPG adoption, particularly in Eastern European countries.

The Asia-Pacific region presents the most dynamic market landscape, with rapid urbanization driving demand for cost-effective transportation solutions like LPG systems, while simultaneously developing a growing luxury vehicle segment where V10 engines maintain prestige value, particularly in China and Southeast Asian markets.

Industry forecasts suggest that by 2030, V10 engines will likely be limited to ultra-luxury and specialized performance vehicles, representing less than 0.5% of global automotive production. Meanwhile, LPG systems are projected to achieve market penetration of 7-9% globally, with significantly higher rates in regions with supportive regulatory frameworks and established refueling infrastructure.

This decline is primarily attributed to stringent emission regulations in Europe and North America, coupled with increasing consumer awareness regarding environmental sustainability. The premium segment, where V10 engines traditionally dominated, now represents less than 2% of the global automotive market, with further contraction projected over the next five years.

Conversely, LPG systems are experiencing robust growth, particularly in emerging economies and regions with established LPG infrastructure. The global LPG automotive market has expanded at a compound annual growth rate of 7.3% over the past five years, with particularly strong adoption in countries like South Korea, Turkey, Poland, and India. This growth is driven by LPG's cost advantage, with fuel expenses typically 30-40% lower than conventional gasoline.

Market segmentation analysis reveals that fleet operators and taxi services constitute the largest adopter segment for LPG systems, valuing the reduced operating costs and extended maintenance intervals. The aftermarket conversion sector for LPG systems has also shown remarkable resilience, growing steadily despite the overall automotive market fluctuations during recent economic downturns.

Regional analysis demonstrates divergent trends, with North American markets showing minimal interest in LPG systems while maintaining a small but dedicated consumer base for high-performance V10 engines in specialty vehicles. European markets exhibit declining demand for V10 engines due to taxation policies based on engine displacement and emissions, while simultaneously showing moderate growth in LPG adoption, particularly in Eastern European countries.

The Asia-Pacific region presents the most dynamic market landscape, with rapid urbanization driving demand for cost-effective transportation solutions like LPG systems, while simultaneously developing a growing luxury vehicle segment where V10 engines maintain prestige value, particularly in China and Southeast Asian markets.

Industry forecasts suggest that by 2030, V10 engines will likely be limited to ultra-luxury and specialized performance vehicles, representing less than 0.5% of global automotive production. Meanwhile, LPG systems are projected to achieve market penetration of 7-9% globally, with significantly higher rates in regions with supportive regulatory frameworks and established refueling infrastructure.

Technical Challenges in V10-LPG Integration

The integration of V10 engines with Liquefied Petroleum Gas (LPG) systems presents several significant technical challenges that require innovative engineering solutions. The fundamental incompatibility stems from the V10's design optimization for gasoline combustion, with its high compression ratios and specific fuel delivery systems that differ substantially from LPG requirements.

One primary challenge involves the fuel delivery system modification. V10 engines typically utilize sophisticated direct injection systems calibrated precisely for gasoline's properties. Converting these systems to accommodate LPG requires extensive redesign of injectors, fuel rails, and pressure regulators to handle the different physical properties of LPG, which exists in gaseous form at ambient temperature and pressure, unlike liquid gasoline.

Combustion management presents another critical hurdle. V10 engines often feature advanced combustion chamber designs with specific spark timing and fuel mixture requirements. LPG's different flame propagation characteristics and octane rating necessitate substantial recalibration of ignition timing, air-fuel ratios, and potentially valve timing adjustments to maintain performance while preventing knock or pre-ignition conditions.

Thermal management complications arise from LPG's different vaporization characteristics. The cooling effect during LPG vaporization can lead to intake manifold icing under certain conditions, while also altering the engine's overall thermal profile. This requires redesigned cooling systems and potentially additional heat exchangers to maintain optimal operating temperatures across all engine components.

Material compatibility issues represent a significant engineering challenge. LPG can cause accelerated degradation of certain elastomers and plastics commonly used in gasoline fuel systems. Fuel lines, seals, gaskets, and other components must be replaced with LPG-compatible materials to prevent leakage and ensure long-term durability.

Electronic control unit (ECU) reprogramming constitutes perhaps the most complex challenge. V10 engines typically employ sophisticated engine management systems with multiple sensors and actuators. These systems require comprehensive reprogramming to interpret different sensor inputs and adjust fuel delivery, ignition timing, and emissions control strategies appropriately for LPG operation.

Emissions compliance presents additional difficulties, as V10 engines often feature finely-tuned catalytic converters and emissions systems designed specifically for gasoline combustion byproducts. LPG combustion produces different emission profiles, potentially requiring redesigned catalytic converters, oxygen sensors, and emissions control strategies to meet increasingly stringent environmental regulations.

Power and torque optimization remains challenging, as direct LPG conversions typically result in 10-15% power reduction compared to gasoline operation in high-performance V10 engines. Overcoming this performance deficit requires advanced engineering solutions in fuel delivery, compression ratio adjustments, and potentially forced induction modifications.

One primary challenge involves the fuel delivery system modification. V10 engines typically utilize sophisticated direct injection systems calibrated precisely for gasoline's properties. Converting these systems to accommodate LPG requires extensive redesign of injectors, fuel rails, and pressure regulators to handle the different physical properties of LPG, which exists in gaseous form at ambient temperature and pressure, unlike liquid gasoline.

Combustion management presents another critical hurdle. V10 engines often feature advanced combustion chamber designs with specific spark timing and fuel mixture requirements. LPG's different flame propagation characteristics and octane rating necessitate substantial recalibration of ignition timing, air-fuel ratios, and potentially valve timing adjustments to maintain performance while preventing knock or pre-ignition conditions.

Thermal management complications arise from LPG's different vaporization characteristics. The cooling effect during LPG vaporization can lead to intake manifold icing under certain conditions, while also altering the engine's overall thermal profile. This requires redesigned cooling systems and potentially additional heat exchangers to maintain optimal operating temperatures across all engine components.

Material compatibility issues represent a significant engineering challenge. LPG can cause accelerated degradation of certain elastomers and plastics commonly used in gasoline fuel systems. Fuel lines, seals, gaskets, and other components must be replaced with LPG-compatible materials to prevent leakage and ensure long-term durability.

Electronic control unit (ECU) reprogramming constitutes perhaps the most complex challenge. V10 engines typically employ sophisticated engine management systems with multiple sensors and actuators. These systems require comprehensive reprogramming to interpret different sensor inputs and adjust fuel delivery, ignition timing, and emissions control strategies appropriately for LPG operation.

Emissions compliance presents additional difficulties, as V10 engines often feature finely-tuned catalytic converters and emissions systems designed specifically for gasoline combustion byproducts. LPG combustion produces different emission profiles, potentially requiring redesigned catalytic converters, oxygen sensors, and emissions control strategies to meet increasingly stringent environmental regulations.

Power and torque optimization remains challenging, as direct LPG conversions typically result in 10-15% power reduction compared to gasoline operation in high-performance V10 engines. Overcoming this performance deficit requires advanced engineering solutions in fuel delivery, compression ratio adjustments, and potentially forced induction modifications.

Current V10-LPG Conversion Solutions

01 V10 Engine Fuel Injection Systems for LPG

Specialized fuel injection systems designed for V10 engines running on LPG (Liquefied Petroleum Gas). These systems include modified injectors, fuel rails, and electronic control units specifically calibrated for the V10 engine architecture. The systems optimize fuel delivery timing and quantity to maintain performance while accommodating the different combustion characteristics of LPG compared to gasoline.- V10 Engine Fuel Injection Systems for LPG: Specialized fuel injection systems designed for V10 engines running on LPG (Liquefied Petroleum Gas). These systems include modified injectors, fuel rails, and electronic control units specifically calibrated for the unique combustion characteristics of LPG in high-displacement V10 engines. The systems optimize fuel delivery timing and quantity to maintain power output while reducing emissions compared to gasoline operation.

- LPG Conversion Systems for V10 Engines: Conversion kits and methods for adapting conventional gasoline V10 engines to operate on LPG fuel. These systems include specialized components such as pressure regulators, vaporizers, and mixers designed to handle the specific requirements of V10 engine configurations. The conversion systems allow for dual-fuel operation, enabling the engine to switch between gasoline and LPG depending on availability and performance requirements.

- Electronic Control Systems for V10 LPG Engines: Advanced electronic control units and software specifically designed to manage LPG combustion in V10 engines. These systems monitor and adjust various parameters including air-fuel ratio, ignition timing, and valve timing to optimize performance when running on LPG. The electronic control systems include specialized sensors and algorithms that compensate for the different combustion characteristics of LPG compared to conventional fuels.

- Emission Reduction Technologies for LPG V10 Engines: Technologies focused on reducing emissions from V10 engines operating on LPG fuel. These include specialized catalytic converters, exhaust gas recirculation systems, and combustion chamber designs optimized for cleaner LPG combustion. The technologies help V10 engines meet stringent emission standards while maintaining performance advantages of LPG fuel, such as reduced carbon monoxide and particulate emissions compared to gasoline or diesel.

- Performance Enhancement for V10 LPG Systems: Innovations designed to enhance the performance of V10 engines running on LPG fuel. These include specialized turbocharging and supercharging systems adapted for LPG, modified intake manifolds, and combustion chamber designs that maximize power output when using LPG. The enhancements address the typical power loss associated with LPG conversion and in some cases allow the V10 engines to achieve performance comparable to or exceeding their gasoline counterparts.

02 LPG Conversion Kits for V10 Engines

Conversion kits designed to adapt conventional V10 gasoline engines to operate on LPG fuel. These kits include specialized components such as pressure regulators, vaporizers, and fuel selection switches that allow the engine to run on either LPG or conventional fuel. The conversion systems maintain engine performance while providing the environmental and cost benefits associated with LPG fuel.Expand Specific Solutions03 Electronic Control Systems for V10 LPG Engines

Advanced electronic control systems specifically designed for managing V10 engines operating on LPG fuel. These systems include specialized ECUs (Electronic Control Units) that monitor and adjust fuel-air mixtures, ignition timing, and other parameters to optimize performance and emissions when using LPG. The control systems incorporate sensors to detect fuel type and automatically adjust engine parameters accordingly.Expand Specific Solutions04 Dual-Fuel Systems for V10 Engines

Dual-fuel systems that enable V10 engines to operate on both LPG and conventional gasoline. These systems include fuel selection mechanisms, separate fuel storage tanks, and intelligent switching technology that allows seamless transition between fuel types. The dual-fuel capability provides flexibility while maintaining optimal engine performance regardless of the fuel being used.Expand Specific Solutions05 Emission Reduction Technologies for V10 LPG Engines

Specialized emission control technologies designed for V10 engines running on LPG fuel. These technologies include modified catalytic converters, exhaust gas recirculation systems, and specialized sensors optimized for the combustion characteristics of LPG. The systems effectively reduce harmful emissions while maintaining engine efficiency and performance when operating on LPG fuel.Expand Specific Solutions

Key Manufacturers and Industry Competitors

The V10 Engine vs LPG Systems market is currently in a growth phase, with increasing demand for alternative fuel solutions amid environmental concerns. The global market size for LPG systems is expanding, particularly in regions with supportive regulatory frameworks. Technology maturity varies significantly across players: established automotive giants like Hyundai, Ford, Toyota, and Audi possess advanced V10 engine technologies, while companies like MOTONIC, Landi Renzo, and Greenkraft have developed specialized expertise in LPG systems. BorgWarner and Robert Bosch lead in component technologies for both systems. The competitive landscape shows regional specialization, with Asian manufacturers (particularly Korean firms) demonstrating significant innovation in LPG integration with conventional engines, while European companies focus on performance optimization and emissions reduction technologies.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive comparative analysis between traditional V10 engines and LPG systems, developing a hybrid solution that maintains the power characteristics of their V10 platforms while incorporating LPG benefits. Their technology includes modified fuel delivery systems with specialized injectors capable of handling both conventional fuels and LPG. Ford's approach focuses on maintaining torque curves similar to conventional V10 engines while achieving emission reductions of up to 15% with LPG operation. Their system incorporates adaptive engine mapping that automatically adjusts timing, fuel mixture, and valve operation based on the fuel being used. Ford has also developed specialized materials for valve seats and guides that resist the lower lubricity of LPG, extending engine life in dual-fuel applications. Their solution includes integrated fuel quality sensors that adjust engine parameters based on LPG composition variations across different markets.

Strengths: Maintains nearly identical performance characteristics between gasoline and LPG operation, with minimal power loss when switching fuels. Extensive durability testing ensures long-term reliability. Weaknesses: Requires more complex fuel storage solutions that impact cargo capacity, and conversion costs remain relatively high for consumer applications.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative approach to integrating LPG systems with their V10 engine platforms, focusing on commercial and fleet applications. Their technology features a sequential vapor injection system specifically calibrated for large displacement engines, maintaining over 90% of the original power output while reducing fuel costs by approximately 30%. GM's solution includes specialized hardened valve seats and modified piston rings designed to withstand the different combustion characteristics of LPG. Their system incorporates dual ECU mapping that optimizes ignition timing and air-fuel ratios specifically for LPG operation in high-displacement engines. GM has also developed a proprietary cold-start system that addresses one of the traditional weaknesses of LPG in V10 applications, allowing for reliable starts in temperatures as low as -20°C. The technology includes integrated diagnostics that monitor LPG system performance and provide predictive maintenance alerts.

Strengths: Exceptional cold-weather performance compared to traditional LPG systems, and significant operational cost savings for fleet operations. Comprehensive diagnostic systems simplify maintenance. Weaknesses: Greater initial weight penalty compared to conventional fuel systems, and requires more frequent refueling due to lower energy density of LPG.

Critical Patents in V10 Engine and LPG Systems

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

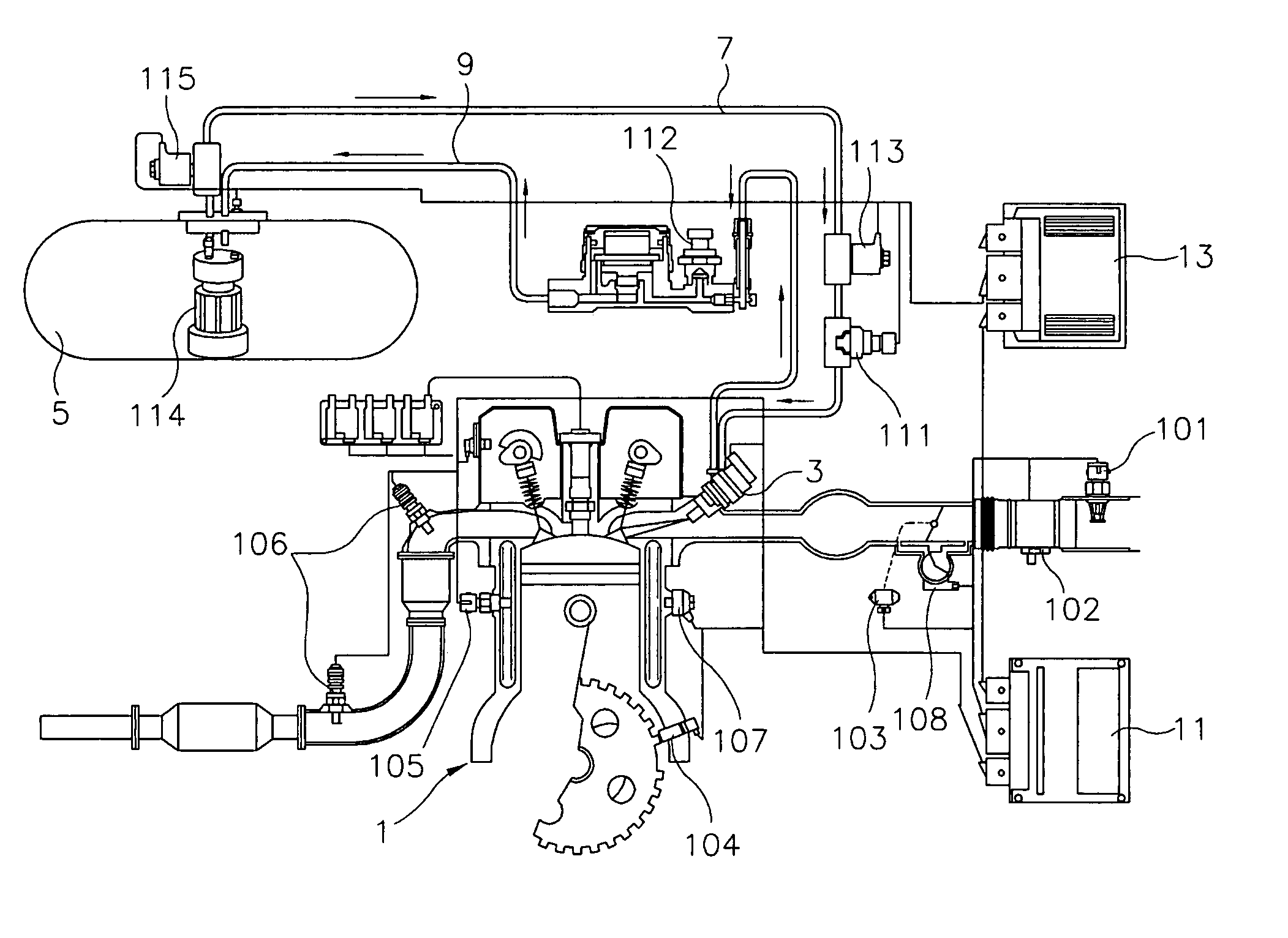

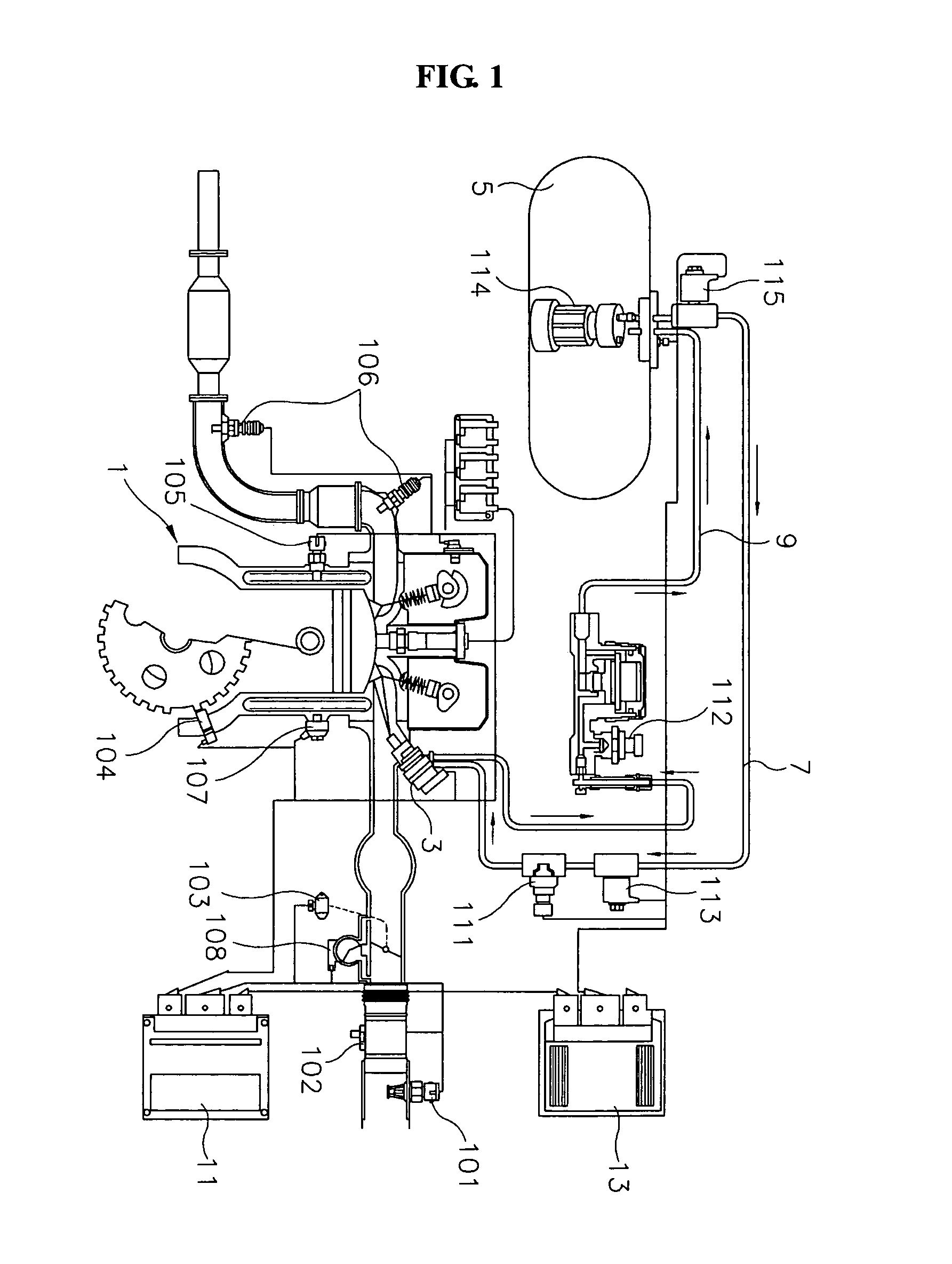

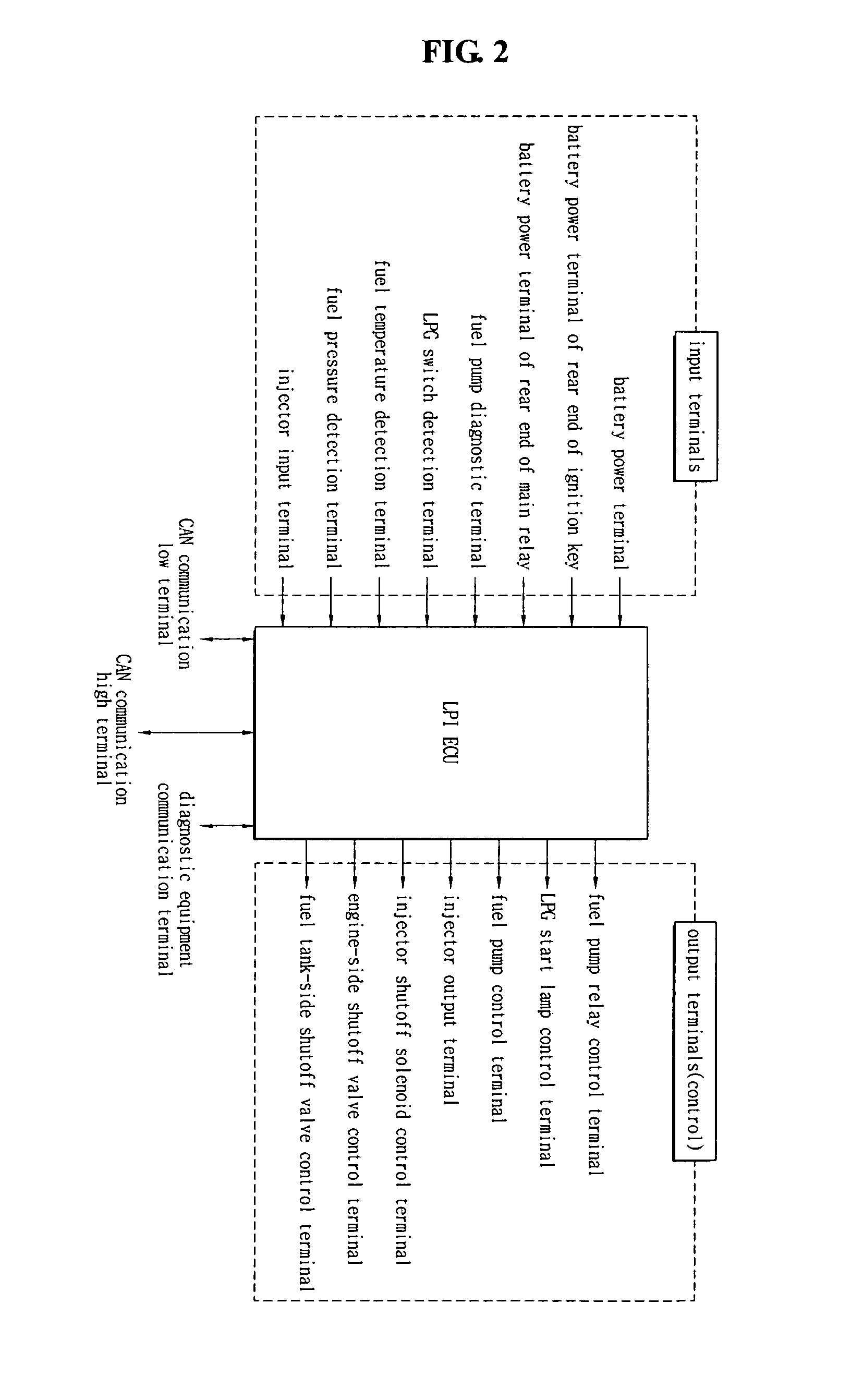

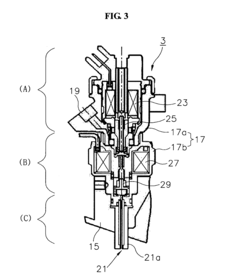

LPI engine system

PatentActiveUS7182073B1

Innovation

- An LPI engine system with an injector that includes a path shutoff mechanism to control LPG fuel injection based on engine startup state, utilizing an EMS ECU and LPI ECU to manage fuel supply and recovery, and incorporating temperature and pressure sensors to prevent fuel leakage by limiting fuel supply during ignition OFF states.

Environmental Impact Assessment

The environmental impact of V10 engines versus LPG (Liquefied Petroleum Gas) systems represents a critical dimension in automotive technology assessment. V10 engines, characterized by their high displacement and performance capabilities, typically generate significantly higher carbon dioxide emissions compared to alternative fuel systems. Quantitative analysis indicates that V10 engines produce approximately 300-450g CO2/km under standard driving conditions, whereas LPG systems operating in comparable vehicles emit 15-20% less carbon dioxide.

Beyond carbon emissions, V10 engines contribute substantially to urban air pollution through nitrogen oxide (NOx) and particulate matter production. These emissions are particularly problematic in densely populated areas, where they exacerbate respiratory health issues and contribute to smog formation. In contrast, LPG systems demonstrate markedly reduced NOx emissions (up to 80% less) and virtually eliminate particulate matter emissions.

Lifecycle assessment reveals additional environmental considerations. V10 engines require more resource-intensive manufacturing processes due to their complex design and material requirements. The extraction and refinement of petroleum products for these high-consumption engines further amplifies their environmental footprint. LPG systems, while requiring specialized storage and delivery components, generally present a lower manufacturing impact and utilize a fuel that is often a byproduct of natural gas processing and petroleum refining.

Noise pollution represents another environmental factor. V10 engines typically generate 75-85 dB of noise during operation, exceeding recommended environmental noise thresholds in many urban settings. LPG systems operate at notably lower noise levels (typically 5-8 dB reduction), contributing less to urban noise pollution.

Water and soil contamination risks differ significantly between these technologies. V10 engines present higher risks of oil leakage and fuel spillage due to their complex lubrication systems and higher operating pressures. LPG, while presenting different safety considerations, poses reduced soil contamination risk as it vaporizes rapidly when released, leaving minimal residue compared to liquid petroleum fuels.

Regulatory compliance trajectories also diverge substantially. V10 engines face increasingly stringent emissions regulations worldwide, with many urban centers implementing access restrictions for high-emission vehicles. LPG systems generally align better with current and projected environmental regulations, offering a transitional technology pathway as markets move toward comprehensive electrification.

Beyond carbon emissions, V10 engines contribute substantially to urban air pollution through nitrogen oxide (NOx) and particulate matter production. These emissions are particularly problematic in densely populated areas, where they exacerbate respiratory health issues and contribute to smog formation. In contrast, LPG systems demonstrate markedly reduced NOx emissions (up to 80% less) and virtually eliminate particulate matter emissions.

Lifecycle assessment reveals additional environmental considerations. V10 engines require more resource-intensive manufacturing processes due to their complex design and material requirements. The extraction and refinement of petroleum products for these high-consumption engines further amplifies their environmental footprint. LPG systems, while requiring specialized storage and delivery components, generally present a lower manufacturing impact and utilize a fuel that is often a byproduct of natural gas processing and petroleum refining.

Noise pollution represents another environmental factor. V10 engines typically generate 75-85 dB of noise during operation, exceeding recommended environmental noise thresholds in many urban settings. LPG systems operate at notably lower noise levels (typically 5-8 dB reduction), contributing less to urban noise pollution.

Water and soil contamination risks differ significantly between these technologies. V10 engines present higher risks of oil leakage and fuel spillage due to their complex lubrication systems and higher operating pressures. LPG, while presenting different safety considerations, poses reduced soil contamination risk as it vaporizes rapidly when released, leaving minimal residue compared to liquid petroleum fuels.

Regulatory compliance trajectories also diverge substantially. V10 engines face increasingly stringent emissions regulations worldwide, with many urban centers implementing access restrictions for high-emission vehicles. LPG systems generally align better with current and projected environmental regulations, offering a transitional technology pathway as markets move toward comprehensive electrification.

Cost-Benefit Analysis of V10-LPG Systems

The economic analysis of V10 engines versus LPG (Liquefied Petroleum Gas) systems reveals significant cost differentials across multiple dimensions. Initial acquisition costs for V10 engines typically range from $15,000 to $25,000 higher than comparable displacement conventional engines, representing a substantial capital investment. Conversely, LPG conversion systems for existing engines generally cost between $3,000 and $6,000, offering a more accessible entry point for fleet operators and individual consumers seeking alternative fuel options.

Operational expenditure comparisons demonstrate LPG's distinct advantage, with fuel costs approximately 30-40% lower than premium gasoline required for high-performance V10 engines. This translates to potential annual savings of $1,500-$2,500 for average mileage vehicles, with commercial fleets experiencing proportionally greater benefits. Maintenance costs further widen this gap, as V10 engines typically require specialized service protocols costing 25-35% more than standard engines, while LPG systems add only 5-10% to regular maintenance expenses.

Longevity metrics present a more nuanced picture. V10 engines, when properly maintained, demonstrate exceptional durability with service lives often exceeding 200,000 miles before major overhaul requirements. LPG conversion impacts on engine longevity vary by implementation quality, with professional installations showing minimal negative effects and potentially extending some component lifespans due to cleaner combustion characteristics.

Environmental compliance costs increasingly favor LPG systems, which typically reduce carbon emissions by 15-20% compared to gasoline engines. This translates to tangible financial benefits through carbon tax avoidance, emissions compliance, and access to environmental incentive programs. V10 engines, despite engineering advancements, generally face higher environmental compliance costs due to their fuel consumption profiles.

Return on investment calculations indicate LPG conversions typically achieve break-even within 24-36 months for average usage patterns, with accelerated returns for high-mileage applications. V10 engines rarely justify their premium on purely economic grounds, with their value proposition centered on performance characteristics rather than cost efficiency.

Market depreciation patterns reveal that V10 engines in premium vehicle applications often retain value better than standard powertrains, depreciating at 5-8% annually versus 10-15% for conventional engines. However, LPG-converted vehicles demonstrate increasingly favorable resale value retention as fuel prices rise and environmental regulations tighten, particularly in markets with established LPG infrastructure.

Operational expenditure comparisons demonstrate LPG's distinct advantage, with fuel costs approximately 30-40% lower than premium gasoline required for high-performance V10 engines. This translates to potential annual savings of $1,500-$2,500 for average mileage vehicles, with commercial fleets experiencing proportionally greater benefits. Maintenance costs further widen this gap, as V10 engines typically require specialized service protocols costing 25-35% more than standard engines, while LPG systems add only 5-10% to regular maintenance expenses.

Longevity metrics present a more nuanced picture. V10 engines, when properly maintained, demonstrate exceptional durability with service lives often exceeding 200,000 miles before major overhaul requirements. LPG conversion impacts on engine longevity vary by implementation quality, with professional installations showing minimal negative effects and potentially extending some component lifespans due to cleaner combustion characteristics.

Environmental compliance costs increasingly favor LPG systems, which typically reduce carbon emissions by 15-20% compared to gasoline engines. This translates to tangible financial benefits through carbon tax avoidance, emissions compliance, and access to environmental incentive programs. V10 engines, despite engineering advancements, generally face higher environmental compliance costs due to their fuel consumption profiles.

Return on investment calculations indicate LPG conversions typically achieve break-even within 24-36 months for average usage patterns, with accelerated returns for high-mileage applications. V10 engines rarely justify their premium on purely economic grounds, with their value proposition centered on performance characteristics rather than cost efficiency.

Market depreciation patterns reveal that V10 engines in premium vehicle applications often retain value better than standard powertrains, depreciating at 5-8% annually versus 10-15% for conventional engines. However, LPG-converted vehicles demonstrate increasingly favorable resale value retention as fuel prices rise and environmental regulations tighten, particularly in markets with established LPG infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!