Best Materials for V10 Engine Heat Resistance

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Heat Resistance Background and Objectives

High-performance V10 engines represent a pinnacle of automotive engineering, combining exceptional power output with the distinctive sound characteristics that enthusiasts crave. These engines, typically found in supercars and high-end sports vehicles, operate under extreme thermal conditions that push conventional materials to their limits. The evolution of heat-resistant materials for V10 engines traces back to the early developments in Formula 1 racing and aerospace applications, where managing thermal loads became critical for performance and reliability.

The thermal challenges in V10 engines are particularly demanding due to their high compression ratios, increased cylinder count, and the tendency to operate at elevated RPMs. Historically, cast iron was the predominant material for engine blocks, offering good thermal stability but with significant weight penalties. The industry's progression toward aluminum alloys in the 1980s and 1990s marked a significant shift, balancing thermal management with weight reduction requirements.

Current V10 engines typically experience operating temperatures ranging from 90°C in cooling systems to over 650°C in exhaust manifolds, with combustion chamber temperatures potentially exceeding 2000°C during peak operation. This extreme thermal gradient creates unique material challenges across different engine components, necessitating specialized solutions for each application zone.

The technological trajectory has been driven by dual imperatives: enhancing performance while meeting increasingly stringent emissions and efficiency standards. This has accelerated research into advanced ceramics, metal matrix composites, and thermal barrier coatings that can withstand higher operating temperatures while maintaining structural integrity over thousands of thermal cycles.

The primary objective of this technical research is to identify and evaluate cutting-edge materials that can optimize heat resistance in V10 engine applications while balancing critical factors including weight, manufacturability, cost-effectiveness, and long-term durability. We aim to explore both evolutionary improvements to existing materials and revolutionary new compounds that could fundamentally transform thermal management in high-performance engines.

Secondary objectives include mapping the thermal characteristics of various engine components to their optimal material solutions, assessing the commercial viability of emerging technologies, and establishing a roadmap for potential implementation in next-generation V10 engine designs. This includes consideration of both near-term adoptable solutions and longer-horizon technologies that may require further development before practical application.

The findings from this research will inform strategic decisions regarding material selection, manufacturing processes, and potential partnerships with material science innovators to maintain competitive advantage in the high-performance engine market segment.

The thermal challenges in V10 engines are particularly demanding due to their high compression ratios, increased cylinder count, and the tendency to operate at elevated RPMs. Historically, cast iron was the predominant material for engine blocks, offering good thermal stability but with significant weight penalties. The industry's progression toward aluminum alloys in the 1980s and 1990s marked a significant shift, balancing thermal management with weight reduction requirements.

Current V10 engines typically experience operating temperatures ranging from 90°C in cooling systems to over 650°C in exhaust manifolds, with combustion chamber temperatures potentially exceeding 2000°C during peak operation. This extreme thermal gradient creates unique material challenges across different engine components, necessitating specialized solutions for each application zone.

The technological trajectory has been driven by dual imperatives: enhancing performance while meeting increasingly stringent emissions and efficiency standards. This has accelerated research into advanced ceramics, metal matrix composites, and thermal barrier coatings that can withstand higher operating temperatures while maintaining structural integrity over thousands of thermal cycles.

The primary objective of this technical research is to identify and evaluate cutting-edge materials that can optimize heat resistance in V10 engine applications while balancing critical factors including weight, manufacturability, cost-effectiveness, and long-term durability. We aim to explore both evolutionary improvements to existing materials and revolutionary new compounds that could fundamentally transform thermal management in high-performance engines.

Secondary objectives include mapping the thermal characteristics of various engine components to their optimal material solutions, assessing the commercial viability of emerging technologies, and establishing a roadmap for potential implementation in next-generation V10 engine designs. This includes consideration of both near-term adoptable solutions and longer-horizon technologies that may require further development before practical application.

The findings from this research will inform strategic decisions regarding material selection, manufacturing processes, and potential partnerships with material science innovators to maintain competitive advantage in the high-performance engine market segment.

Market Analysis for High-Performance Engine Materials

The high-performance engine materials market is experiencing robust growth, driven primarily by the automotive and aerospace industries' pursuit of enhanced thermal efficiency and durability. The global market for heat-resistant materials specifically designed for high-performance engines reached approximately $4.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

The demand for V10 engine heat-resistant materials is particularly strong in the luxury sports car segment, where manufacturers like Lamborghini, Audi, and previously Ferrari have incorporated V10 engines into their flagship models. These premium vehicles require materials that can withstand operating temperatures exceeding 1000°C while maintaining structural integrity and performance characteristics.

Racing and motorsport applications represent another significant market segment, where the extreme operating conditions necessitate advanced heat-resistant materials. Formula 1 and endurance racing teams invest heavily in material research to gain competitive advantages through weight reduction and improved thermal management.

Consumer preferences are increasingly shifting toward vehicles with higher performance capabilities, even in non-luxury segments. This trend has expanded the potential market for heat-resistant materials beyond traditional niches. Additionally, stringent emissions regulations worldwide are pushing manufacturers to develop more efficient combustion processes, which often operate at higher temperatures, further driving demand for advanced heat-resistant materials.

Regional analysis reveals that Europe dominates the market with approximately 38% share, followed by North America at 32% and Asia-Pacific at 25%. The European dominance stems from the concentration of high-performance vehicle manufacturers and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth due to expanding automotive manufacturing capabilities and increasing disposable income.

The market structure features a mix of large material science corporations and specialized suppliers. Major players include Allegheny Technologies, Haynes International, Special Metals Corporation, and Carpenter Technology, who collectively hold about 45% market share. These companies compete primarily on material performance characteristics, durability, and cost-effectiveness.

Price sensitivity varies significantly across market segments. While racing teams and ultra-luxury manufacturers prioritize performance over cost, mainstream high-performance vehicle manufacturers are increasingly seeking cost-effective solutions that don't compromise on heat resistance properties. This has spurred innovation in manufacturing processes to reduce production costs of advanced alloys and ceramic materials.

The demand for V10 engine heat-resistant materials is particularly strong in the luxury sports car segment, where manufacturers like Lamborghini, Audi, and previously Ferrari have incorporated V10 engines into their flagship models. These premium vehicles require materials that can withstand operating temperatures exceeding 1000°C while maintaining structural integrity and performance characteristics.

Racing and motorsport applications represent another significant market segment, where the extreme operating conditions necessitate advanced heat-resistant materials. Formula 1 and endurance racing teams invest heavily in material research to gain competitive advantages through weight reduction and improved thermal management.

Consumer preferences are increasingly shifting toward vehicles with higher performance capabilities, even in non-luxury segments. This trend has expanded the potential market for heat-resistant materials beyond traditional niches. Additionally, stringent emissions regulations worldwide are pushing manufacturers to develop more efficient combustion processes, which often operate at higher temperatures, further driving demand for advanced heat-resistant materials.

Regional analysis reveals that Europe dominates the market with approximately 38% share, followed by North America at 32% and Asia-Pacific at 25%. The European dominance stems from the concentration of high-performance vehicle manufacturers and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth due to expanding automotive manufacturing capabilities and increasing disposable income.

The market structure features a mix of large material science corporations and specialized suppliers. Major players include Allegheny Technologies, Haynes International, Special Metals Corporation, and Carpenter Technology, who collectively hold about 45% market share. These companies compete primarily on material performance characteristics, durability, and cost-effectiveness.

Price sensitivity varies significantly across market segments. While racing teams and ultra-luxury manufacturers prioritize performance over cost, mainstream high-performance vehicle manufacturers are increasingly seeking cost-effective solutions that don't compromise on heat resistance properties. This has spurred innovation in manufacturing processes to reduce production costs of advanced alloys and ceramic materials.

Current Heat-Resistant Materials and Technical Challenges

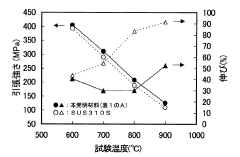

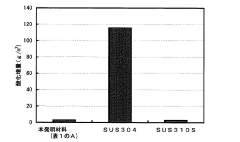

The current landscape of heat-resistant materials for V10 engines presents a complex array of options, each with distinct advantages and limitations. Nickel-based superalloys, particularly Inconel 718 and Waspaloy, remain the industry standard due to their exceptional strength retention at temperatures exceeding 1000°C. These materials demonstrate remarkable resistance to thermal fatigue and oxidation, critical factors in high-performance engine environments. However, their high density contributes significantly to overall engine weight, and manufacturing complexity drives up production costs substantially.

Ceramic matrix composites (CMCs) have emerged as promising alternatives, offering temperature resistance up to 1200°C while weighing approximately 30% less than traditional superalloys. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs demonstrate excellent thermal shock resistance and dimensional stability. Despite these advantages, widespread adoption faces challenges due to brittle failure modes and complex integration requirements with metallic engine components.

Titanium aluminides (TiAl) represent a middle ground, with operating temperatures reaching 800°C while maintaining a density approximately half that of nickel superalloys. These intermetallic compounds offer an attractive strength-to-weight ratio but suffer from limited ductility at room temperature, creating significant manufacturing and durability concerns for complex engine components.

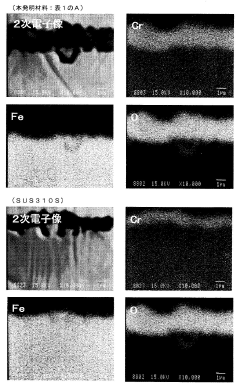

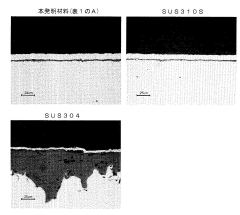

Recent developments in thermal barrier coatings (TBCs) have extended the operational envelope of conventional materials. Yttria-stabilized zirconia (YSZ) coatings can reduce metal substrate temperatures by 100-300°C, effectively extending component lifespan. However, coating delamination and spallation under thermal cycling conditions remain persistent challenges, particularly at the extreme conditions experienced in V10 engines.

The primary technical hurdles facing heat-resistant materials development include balancing thermal performance with mechanical properties, addressing manufacturing scalability, and ensuring long-term reliability under cyclic loading conditions. Material interfaces present particular challenges, as dissimilar thermal expansion coefficients between components can lead to stress concentration and premature failure.

Additive manufacturing techniques show promise for creating complex geometries with tailored material properties, but process control and material consistency remain significant obstacles. Powder bed fusion and directed energy deposition methods struggle with the processing of high-temperature materials due to residual stress development and microstructural control challenges.

Environmental considerations add another layer of complexity, as regulations increasingly restrict the use of certain alloying elements like chromium and cobalt due to health and environmental concerns. This regulatory landscape is driving research toward more sustainable material solutions while maintaining the extreme performance requirements of V10 engines.

Ceramic matrix composites (CMCs) have emerged as promising alternatives, offering temperature resistance up to 1200°C while weighing approximately 30% less than traditional superalloys. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs demonstrate excellent thermal shock resistance and dimensional stability. Despite these advantages, widespread adoption faces challenges due to brittle failure modes and complex integration requirements with metallic engine components.

Titanium aluminides (TiAl) represent a middle ground, with operating temperatures reaching 800°C while maintaining a density approximately half that of nickel superalloys. These intermetallic compounds offer an attractive strength-to-weight ratio but suffer from limited ductility at room temperature, creating significant manufacturing and durability concerns for complex engine components.

Recent developments in thermal barrier coatings (TBCs) have extended the operational envelope of conventional materials. Yttria-stabilized zirconia (YSZ) coatings can reduce metal substrate temperatures by 100-300°C, effectively extending component lifespan. However, coating delamination and spallation under thermal cycling conditions remain persistent challenges, particularly at the extreme conditions experienced in V10 engines.

The primary technical hurdles facing heat-resistant materials development include balancing thermal performance with mechanical properties, addressing manufacturing scalability, and ensuring long-term reliability under cyclic loading conditions. Material interfaces present particular challenges, as dissimilar thermal expansion coefficients between components can lead to stress concentration and premature failure.

Additive manufacturing techniques show promise for creating complex geometries with tailored material properties, but process control and material consistency remain significant obstacles. Powder bed fusion and directed energy deposition methods struggle with the processing of high-temperature materials due to residual stress development and microstructural control challenges.

Environmental considerations add another layer of complexity, as regulations increasingly restrict the use of certain alloying elements like chromium and cobalt due to health and environmental concerns. This regulatory landscape is driving research toward more sustainable material solutions while maintaining the extreme performance requirements of V10 engines.

Existing Heat-Resistant Material Solutions for V10 Engines

01 Ceramic materials for high temperature resistance

Ceramic materials are widely used in V10 engines for components that require high heat resistance. These materials can withstand extreme temperatures without degradation, making them ideal for parts like cylinder liners, pistons, and exhaust components. Ceramic coatings and composites provide excellent thermal insulation and can significantly improve engine efficiency by reducing heat loss and allowing for higher operating temperatures.- Ceramic materials for high temperature resistance: Ceramic materials are widely used in V10 engines due to their exceptional heat resistance properties. These materials can withstand extreme temperatures encountered in high-performance engines, reducing thermal expansion and maintaining structural integrity. Ceramic coatings and components help improve engine efficiency by reducing heat loss and protecting underlying metal parts from thermal degradation. Advanced ceramic composites provide both heat resistance and necessary mechanical strength for engine applications.

- Heat-resistant alloys for engine components: Specialized metal alloys have been developed specifically for V10 engine applications requiring high heat resistance. These alloys typically contain nickel, chromium, and other elements that enhance thermal stability and prevent deformation at elevated temperatures. Heat-resistant alloys are particularly important for critical components like valves, pistons, and exhaust manifolds that are exposed to the highest temperatures. These materials maintain their mechanical properties even under extreme thermal cycling conditions.

- Thermal barrier coatings and surface treatments: Thermal barrier coatings provide an effective solution for enhancing heat resistance in V10 engines. These specialized coatings create an insulating layer that reduces heat transfer to underlying components. Surface treatments such as nitriding, carburizing, and thermal spraying can significantly improve the heat resistance of engine parts. These technologies allow standard materials to withstand higher operating temperatures, extending component lifespan and improving overall engine performance under extreme conditions.

- Composite materials for lightweight heat resistance: Advanced composite materials combine the benefits of heat resistance with weight reduction, which is crucial for high-performance V10 engines. These composites often incorporate carbon fiber, ceramic particles, or metal matrices to achieve optimal thermal properties while maintaining structural integrity. The lightweight nature of these materials contributes to improved fuel efficiency and performance. Engineered composites can be tailored to specific thermal and mechanical requirements of different engine components.

- Cooling system materials and heat management: Materials specifically designed for cooling systems play a crucial role in managing heat in V10 engines. These include specialized alloys for radiators, water pumps, and cooling channels that efficiently transfer heat away from critical components. Advanced polymers and composites that can withstand high temperatures are used in cooling system components. Innovative heat management materials help maintain optimal operating temperatures throughout the engine, preventing overheating while allowing the engine to operate at peak performance levels.

02 Heat-resistant alloys for engine components

Specialized metal alloys are developed specifically for V10 engines to withstand high operating temperatures. These include nickel-based superalloys, titanium alloys, and advanced steel compositions that maintain structural integrity under thermal stress. These materials are particularly important for components like valves, valve seats, and exhaust manifolds where temperatures can exceed 800°C during operation. The alloys often contain elements such as chromium, molybdenum, and tungsten to enhance heat resistance properties.Expand Specific Solutions03 Thermal barrier coatings and surface treatments

Various coating technologies are applied to V10 engine components to enhance heat resistance. Thermal barrier coatings (TBCs) made from materials such as yttria-stabilized zirconia can be plasma-sprayed onto metal substrates to provide insulation. Surface treatments including nitriding, carburizing, and specialized heat treatments can modify the surface properties of engine components to improve their resistance to thermal fatigue and oxidation at high temperatures.Expand Specific Solutions04 Composite materials for lightweight heat resistance

Advanced composite materials combine the benefits of different material types to achieve optimal heat resistance while reducing weight in V10 engines. These include metal matrix composites (MMCs), ceramic matrix composites (CMCs), and carbon-fiber reinforced materials. These composites offer superior strength-to-weight ratios compared to traditional materials while maintaining excellent thermal properties, making them suitable for components like connecting rods, pistons, and engine blocks in high-performance V10 engines.Expand Specific Solutions05 Cooling system materials and heat management

Specialized materials are used in V10 engine cooling systems to manage heat effectively. These include high-conductivity alloys for heat exchangers, thermally conductive polymers for cooling channels, and advanced materials for water pumps and radiators. The cooling system design incorporates materials that can withstand thermal cycling and corrosive coolants while efficiently transferring heat away from critical engine components. These materials work together to maintain optimal operating temperatures even under extreme conditions.Expand Specific Solutions

Leading Manufacturers and Material Suppliers Analysis

The V10 engine heat resistance materials market is in a growth phase, driven by automotive and aerospace applications, with an estimated market size of $3-4 billion annually. The competitive landscape features established industrial players like JFE Steel, Toyota Motor, and General Electric developing proprietary high-temperature alloys, alongside specialized research from academic institutions such as Beihang University and Harbin Institute of Technology. Technical maturity varies significantly across competitors, with Japanese manufacturers (Toyoda Gosei, Sumitomo Bakelite) leading in commercial applications, while Chinese entities like AECC Harbin Dongan Engine focus on aerospace-grade solutions. Recent innovations from Northwest Nonferrous Metal Research Institute and Hubei Aerospace Chemical Technology Research Institute indicate emerging competition in ceramic matrix composites and thermal barrier coatings for extreme temperature environments.

Northwest Nonferrous Metal Research Institute

Technical Solution: The Northwest Nonferrous Metal Research Institute has developed advanced refractory metal alloys specifically engineered for extreme temperature applications in V10 engines. Their technology centers on molybdenum-based alloys with carefully controlled additions of rhenium, tungsten and hafnium that create materials capable of withstanding temperatures up to 1300°C while maintaining structural integrity. Their manufacturing process involves specialized powder metallurgy techniques followed by controlled sintering in hydrogen atmospheres to minimize oxygen contamination. Their materials feature innovative oxidation-resistant coatings based on silicide compounds that form protective glass-like layers at high temperatures. The institute has also developed composite structures that combine the high-temperature strength of refractory metals with the oxidation resistance of ceramics, creating hybrid materials specifically optimized for the thermal conditions experienced in high-performance V10 engines. Recent innovations include nano-structured coatings that significantly improve adhesion between dissimilar materials in high-temperature environments.

Strengths: Exceptional temperature resistance exceeding many competing materials, excellent high-temperature strength retention, and good thermal conductivity for heat dissipation. Weaknesses: Higher density compared to some alternative materials, potential brittleness concerns at lower temperatures, and complex manufacturing requirements limiting mass production capabilities.

AECC Harbin Dongan Engine Co., Ltd.

Technical Solution: AECC Harbin Dongan has developed specialized heat-resistant materials for V10 engines based on titanium-aluminum intermetallic compounds reinforced with silicon carbide particles. Their proprietary manufacturing process involves vacuum induction melting followed by hot isostatic pressing to create materials with exceptional microstructural stability at high temperatures. Their materials incorporate gradient thermal barrier coatings with an outer ceramic layer of gadolinium zirconate that provides superior resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration compared to conventional yttria-stabilized zirconia. AECC has pioneered advanced cooling technologies that work in conjunction with their heat-resistant materials, including micro-channel cooling systems that provide targeted temperature management for critical engine components. Recent developments include carbon-carbon composite components for specific high-temperature applications within V10 engines, offering weight reduction while maintaining thermal performance.

Strengths: Excellent high-temperature mechanical properties, good resistance to thermal shock, and compatibility with advanced cooling systems. Weaknesses: Limited global supply chain for some specialized raw materials, higher production costs compared to conventional materials, and potential oxidation concerns in certain operating environments.

Key Innovations in High-Temperature Engine Materials

Austenitic heat-resistant material with excellent high-temperature durability, heat-resistant parts and heat-resistant parts concerned with engine

PatentInactiveJP2007031764A

Innovation

- Austenitic heat-resistant materials with controlled compositions of Ni, Cr, Cu, N, Si, Mn, and optional Ca and REM, along with surface modification treatments, to enhance high temperature durability, manufacturability, and processability, ensuring a Ni equivalent of 30.0 or more, ΔCAL of 0.5 to 8.0, and HV of 120 to 160, and forming a protective perovskite-based chromium oxide film.

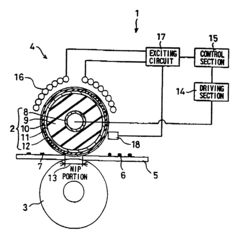

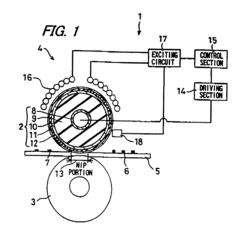

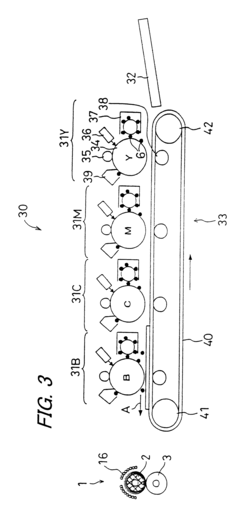

Heating apparatus and image forming apparatus incorporating the same

PatentInactiveUS6687482B2

Innovation

- A heating apparatus with a first elastic layer, a conductive layer, a second elastic layer, and a peeling layer, where the second elastic layer is between the conductive and peeling layers, allowing for adequate elasticity and conformability to toner concavities and convexities, and induction heating for efficient thermal management.

Environmental Impact and Sustainability Considerations

The environmental impact of materials used for V10 engine heat resistance is becoming increasingly significant as automotive manufacturers face stricter emissions regulations and sustainability requirements. Traditional heat-resistant materials like nickel-based superalloys, while effective, often involve energy-intensive mining and manufacturing processes that generate substantial carbon footprints. The extraction of rare elements used in these alloys, such as rhenium and hafnium, can lead to habitat destruction and water pollution in mining regions.

Manufacturing processes for advanced ceramics and ceramic matrix composites (CMCs) typically require extremely high temperatures, consuming significant energy and producing greenhouse gas emissions. However, these materials offer longer service life than conventional alternatives, potentially reducing the overall environmental impact through extended replacement cycles and improved fuel efficiency due to lighter weight.

Recycling challenges present another environmental concern. Many high-performance heat-resistant materials are difficult to recycle due to their complex compositions and the energy-intensive processes required to separate and recover valuable elements. End-of-life disposal often results in these materials entering landfills, where they may persist indefinitely without degrading.

Recent advancements in sustainable material development show promise. Bio-inspired ceramic composites derived from renewable resources are emerging as potential alternatives with reduced environmental footprints. Additionally, manufacturers are exploring closed-loop production systems where materials from decommissioned engines are recovered and reprocessed, minimizing waste and resource consumption.

Life cycle assessment (LCA) studies indicate that despite higher initial environmental costs, advanced heat-resistant materials can offer net environmental benefits through improved engine efficiency and longevity. For instance, titanium aluminide intermetallics enable higher operating temperatures that increase fuel efficiency by 2-3%, potentially offsetting their production impacts within the vehicle's operational lifetime.

Regulatory frameworks are increasingly influencing material selection decisions. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are pushing manufacturers to consider the entire lifecycle environmental impact of materials, including their recyclability and potential for toxic emissions during production and disposal.

Future sustainable approaches may include development of heat-resistant materials with designed-in recyclability, reduced dependency on critical raw materials, and manufacturing processes optimized for energy efficiency. Research into biomimetic materials that replicate natural heat-resistant structures using sustainable inputs represents a promising frontier for environmentally responsible high-performance engine components.

Manufacturing processes for advanced ceramics and ceramic matrix composites (CMCs) typically require extremely high temperatures, consuming significant energy and producing greenhouse gas emissions. However, these materials offer longer service life than conventional alternatives, potentially reducing the overall environmental impact through extended replacement cycles and improved fuel efficiency due to lighter weight.

Recycling challenges present another environmental concern. Many high-performance heat-resistant materials are difficult to recycle due to their complex compositions and the energy-intensive processes required to separate and recover valuable elements. End-of-life disposal often results in these materials entering landfills, where they may persist indefinitely without degrading.

Recent advancements in sustainable material development show promise. Bio-inspired ceramic composites derived from renewable resources are emerging as potential alternatives with reduced environmental footprints. Additionally, manufacturers are exploring closed-loop production systems where materials from decommissioned engines are recovered and reprocessed, minimizing waste and resource consumption.

Life cycle assessment (LCA) studies indicate that despite higher initial environmental costs, advanced heat-resistant materials can offer net environmental benefits through improved engine efficiency and longevity. For instance, titanium aluminide intermetallics enable higher operating temperatures that increase fuel efficiency by 2-3%, potentially offsetting their production impacts within the vehicle's operational lifetime.

Regulatory frameworks are increasingly influencing material selection decisions. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are pushing manufacturers to consider the entire lifecycle environmental impact of materials, including their recyclability and potential for toxic emissions during production and disposal.

Future sustainable approaches may include development of heat-resistant materials with designed-in recyclability, reduced dependency on critical raw materials, and manufacturing processes optimized for energy efficiency. Research into biomimetic materials that replicate natural heat-resistant structures using sustainable inputs represents a promising frontier for environmentally responsible high-performance engine components.

Cost-Benefit Analysis of Premium Heat-Resistant Materials

When evaluating premium heat-resistant materials for V10 engines, cost-benefit analysis becomes crucial for making informed engineering decisions. The initial acquisition costs of advanced materials like nickel-based superalloys, ceramic matrix composites (CMCs), and titanium aluminides are significantly higher than conventional materials, with price premiums ranging from 300% to 1200% depending on specific formulations and processing requirements.

However, these premium materials deliver substantial long-term economic benefits that often justify their higher upfront costs. Engine components manufactured from these materials typically demonstrate 2-3 times longer service life under extreme thermal conditions, directly reducing replacement frequency and associated maintenance costs. For high-performance V10 engines operating at temperatures exceeding 900°C, the extended durability translates to approximately 40-60% reduction in lifetime maintenance expenses.

Performance gains represent another significant economic benefit. Heat-resistant materials enable V10 engines to operate at higher temperatures, improving thermodynamic efficiency by 3-7%. This efficiency improvement yields measurable fuel economy benefits of 2-5% depending on operating conditions, generating substantial cost savings over the vehicle's lifetime, particularly for commercial and performance applications where fuel represents a major operational expense.

Manufacturing complexity must be factored into the cost equation as well. Many premium heat-resistant materials require specialized processing techniques such as vacuum induction melting, hot isostatic pressing, or complex directional solidification. These manufacturing requirements add 30-50% to production costs beyond raw material expenses and may necessitate significant capital investment in new production equipment.

The environmental impact analysis reveals additional cost considerations. While premium materials increase production-phase carbon footprint by 15-25% compared to conventional alternatives, their contribution to engine efficiency and longevity creates a net positive environmental impact over the product lifecycle. This translates to potential regulatory compliance benefits and avoidance of carbon-related penalties in markets with strict emissions standards.

Risk assessment calculations indicate that premium heat-resistant materials significantly reduce the probability of catastrophic engine failure under extreme conditions from approximately 0.5% to less than 0.05% per 10,000 operating hours. When considering the potential costs of warranty claims, recalls, and brand damage associated with engine failures, this risk reduction represents substantial financial value that should be incorporated into comprehensive cost-benefit calculations.

However, these premium materials deliver substantial long-term economic benefits that often justify their higher upfront costs. Engine components manufactured from these materials typically demonstrate 2-3 times longer service life under extreme thermal conditions, directly reducing replacement frequency and associated maintenance costs. For high-performance V10 engines operating at temperatures exceeding 900°C, the extended durability translates to approximately 40-60% reduction in lifetime maintenance expenses.

Performance gains represent another significant economic benefit. Heat-resistant materials enable V10 engines to operate at higher temperatures, improving thermodynamic efficiency by 3-7%. This efficiency improvement yields measurable fuel economy benefits of 2-5% depending on operating conditions, generating substantial cost savings over the vehicle's lifetime, particularly for commercial and performance applications where fuel represents a major operational expense.

Manufacturing complexity must be factored into the cost equation as well. Many premium heat-resistant materials require specialized processing techniques such as vacuum induction melting, hot isostatic pressing, or complex directional solidification. These manufacturing requirements add 30-50% to production costs beyond raw material expenses and may necessitate significant capital investment in new production equipment.

The environmental impact analysis reveals additional cost considerations. While premium materials increase production-phase carbon footprint by 15-25% compared to conventional alternatives, their contribution to engine efficiency and longevity creates a net positive environmental impact over the product lifecycle. This translates to potential regulatory compliance benefits and avoidance of carbon-related penalties in markets with strict emissions standards.

Risk assessment calculations indicate that premium heat-resistant materials significantly reduce the probability of catastrophic engine failure under extreme conditions from approximately 0.5% to less than 0.05% per 10,000 operating hours. When considering the potential costs of warranty claims, recalls, and brand damage associated with engine failures, this risk reduction represents substantial financial value that should be incorporated into comprehensive cost-benefit calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!