V10 Engine Maintenance for Peak RPM Durability

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Evolution and Performance Targets

The V10 engine represents a pinnacle of internal combustion engineering, evolving from its early racing applications in Formula One during the 1990s to its implementation in high-performance production vehicles. This evolution has been characterized by continuous refinement in materials science, combustion efficiency, and mechanical design to achieve ever-increasing performance targets while maintaining reliability at extreme operating conditions.

The developmental trajectory of V10 engines has been marked by significant milestones, including the transition from naturally aspirated to forced induction variants, the implementation of variable valve timing systems, and the integration of advanced electronic control units that optimize performance across the RPM range. These advancements have collectively pushed the operational envelope of V10 engines, with modern iterations capable of sustaining reliable operation at RPM levels that would have been considered destructive in earlier generations.

Current performance targets for V10 engines focus on achieving optimal power-to-weight ratios while maintaining durability at peak RPM ranges. The industry benchmark now stands at sustained operation between 8,000-9,000 RPM for production vehicles, with racing variants capable of reliable performance at 18,000+ RPM. These targets represent a delicate balance between maximizing power output and ensuring component longevity under extreme thermal and mechanical stress conditions.

The technical evolution has been driven by innovations in metallurgy and materials science, particularly the development of lightweight, high-strength alloys for critical components such as crankshafts, connecting rods, and valvetrain assemblies. Concurrent advancements in precision manufacturing techniques have enabled tighter tolerances and improved surface finishes, reducing friction and enhancing durability at high RPM operation.

Lubrication systems have undergone parallel evolution, with the implementation of dry-sump configurations, enhanced oil cooling systems, and specialized lubricant formulations designed to maintain film strength under extreme pressure and temperature conditions. These developments have been crucial in addressing one of the primary failure modes in high-RPM operation: oil starvation leading to bearing failure.

The integration of computational fluid dynamics and finite element analysis into the design process has allowed engineers to identify and address potential failure points before physical prototyping, significantly accelerating the development cycle and enabling more aggressive performance targets. This analytical approach has been particularly valuable in optimizing cooling systems and reducing harmonic vibrations that can lead to premature component failure at sustained high RPM operation.

Looking forward, the technical trajectory for V10 engines continues toward higher specific output and RPM capability, balanced against increasingly stringent emissions requirements and the push for greater fuel efficiency. This presents a complex engineering challenge that will likely drive further innovation in materials, combustion optimization, and thermal management systems.

The developmental trajectory of V10 engines has been marked by significant milestones, including the transition from naturally aspirated to forced induction variants, the implementation of variable valve timing systems, and the integration of advanced electronic control units that optimize performance across the RPM range. These advancements have collectively pushed the operational envelope of V10 engines, with modern iterations capable of sustaining reliable operation at RPM levels that would have been considered destructive in earlier generations.

Current performance targets for V10 engines focus on achieving optimal power-to-weight ratios while maintaining durability at peak RPM ranges. The industry benchmark now stands at sustained operation between 8,000-9,000 RPM for production vehicles, with racing variants capable of reliable performance at 18,000+ RPM. These targets represent a delicate balance between maximizing power output and ensuring component longevity under extreme thermal and mechanical stress conditions.

The technical evolution has been driven by innovations in metallurgy and materials science, particularly the development of lightweight, high-strength alloys for critical components such as crankshafts, connecting rods, and valvetrain assemblies. Concurrent advancements in precision manufacturing techniques have enabled tighter tolerances and improved surface finishes, reducing friction and enhancing durability at high RPM operation.

Lubrication systems have undergone parallel evolution, with the implementation of dry-sump configurations, enhanced oil cooling systems, and specialized lubricant formulations designed to maintain film strength under extreme pressure and temperature conditions. These developments have been crucial in addressing one of the primary failure modes in high-RPM operation: oil starvation leading to bearing failure.

The integration of computational fluid dynamics and finite element analysis into the design process has allowed engineers to identify and address potential failure points before physical prototyping, significantly accelerating the development cycle and enabling more aggressive performance targets. This analytical approach has been particularly valuable in optimizing cooling systems and reducing harmonic vibrations that can lead to premature component failure at sustained high RPM operation.

Looking forward, the technical trajectory for V10 engines continues toward higher specific output and RPM capability, balanced against increasingly stringent emissions requirements and the push for greater fuel efficiency. This presents a complex engineering challenge that will likely drive further innovation in materials, combustion optimization, and thermal management systems.

Market Analysis for High-Performance V10 Applications

The high-performance V10 engine market represents a specialized but lucrative segment within the automotive and marine industries. Current market analysis indicates that V10 engines primarily serve three key sectors: luxury sports cars, high-end SUVs, and specialized marine applications. The global market for high-performance engines exceeds $15 billion annually, with V10 configurations capturing approximately $3.2 billion of this share.

Consumer demand for V10 engines continues to demonstrate resilience despite industry-wide shifts toward electrification. This persistence stems from the unique performance characteristics that V10 engines deliver - particularly their ability to combine high RPM operation with relatively smooth power delivery compared to V8 alternatives. Market research indicates that consumers in the ultra-luxury segment are willing to pay premium prices for vehicles featuring V10 powerplants, with average price points 22% higher than comparable V8 models.

Regional analysis reveals significant market variations. European markets show the strongest demand for V10-powered sports cars, particularly in Germany and Italy where engineering heritage plays a substantial role in consumer preferences. North American markets demonstrate growing interest in V10-powered performance SUVs, while Middle Eastern markets show consistent demand across both vehicle categories with particular emphasis on durability in extreme climate conditions.

Competitive landscape assessment identifies two distinct market approaches. Traditional manufacturers like Lamborghini and Audi maintain dedicated V10 development programs focused on refinement and durability improvements. Meanwhile, boutique manufacturers increasingly adopt modified V10 platforms with specialized maintenance requirements to achieve differentiation through extreme performance metrics.

Market forecasting suggests the high-performance V10 segment will experience modest growth of 4.7% annually through 2027, primarily driven by ultra-luxury applications where exclusivity outweighs practical considerations. However, this growth faces potential constraints from tightening emissions regulations in key markets, particularly in Europe where Euro 7 standards may necessitate significant engineering adaptations.

The aftermarket ecosystem supporting V10 maintenance represents a substantial secondary market valued at approximately $780 million annually. This includes specialized service providers, performance tuning operations, and parts manufacturers dedicated to extending engine longevity while maintaining peak RPM capabilities. Analysis indicates this aftermarket segment is growing at 6.3% annually, outpacing the primary market as existing V10 engines require increasingly specialized maintenance to maintain performance characteristics.

Consumer demand for V10 engines continues to demonstrate resilience despite industry-wide shifts toward electrification. This persistence stems from the unique performance characteristics that V10 engines deliver - particularly their ability to combine high RPM operation with relatively smooth power delivery compared to V8 alternatives. Market research indicates that consumers in the ultra-luxury segment are willing to pay premium prices for vehicles featuring V10 powerplants, with average price points 22% higher than comparable V8 models.

Regional analysis reveals significant market variations. European markets show the strongest demand for V10-powered sports cars, particularly in Germany and Italy where engineering heritage plays a substantial role in consumer preferences. North American markets demonstrate growing interest in V10-powered performance SUVs, while Middle Eastern markets show consistent demand across both vehicle categories with particular emphasis on durability in extreme climate conditions.

Competitive landscape assessment identifies two distinct market approaches. Traditional manufacturers like Lamborghini and Audi maintain dedicated V10 development programs focused on refinement and durability improvements. Meanwhile, boutique manufacturers increasingly adopt modified V10 platforms with specialized maintenance requirements to achieve differentiation through extreme performance metrics.

Market forecasting suggests the high-performance V10 segment will experience modest growth of 4.7% annually through 2027, primarily driven by ultra-luxury applications where exclusivity outweighs practical considerations. However, this growth faces potential constraints from tightening emissions regulations in key markets, particularly in Europe where Euro 7 standards may necessitate significant engineering adaptations.

The aftermarket ecosystem supporting V10 maintenance represents a substantial secondary market valued at approximately $780 million annually. This includes specialized service providers, performance tuning operations, and parts manufacturers dedicated to extending engine longevity while maintaining peak RPM capabilities. Analysis indicates this aftermarket segment is growing at 6.3% annually, outpacing the primary market as existing V10 engines require increasingly specialized maintenance to maintain performance characteristics.

Current Challenges in V10 High-RPM Durability

The V10 engine, renowned for its high-performance capabilities and distinctive sound profile, faces significant durability challenges when operating consistently at peak RPM ranges. These challenges stem from the complex interplay of mechanical stress, thermal management issues, and material limitations that become increasingly pronounced under extreme operating conditions.

Mechanical stress represents the foremost challenge, with connecting rods, crankshafts, and valve trains experiencing tremendous forces at high RPMs. The reciprocating mass of pistons creates inertial forces that increase exponentially with engine speed, placing enormous strain on connecting rods and bearings. Valve springs struggle to maintain proper valve control at extreme RPMs, leading to valve float phenomena where valves fail to follow their intended timing, potentially resulting in catastrophic piston-valve interference.

Thermal management emerges as another critical hurdle, as friction-generated heat increases dramatically at high RPMs. Cylinder head temperatures can reach critical levels, particularly around exhaust valves, creating thermal expansion differentials that compromise head gasket integrity. Oil temperature management becomes increasingly difficult, with conventional lubrication systems struggling to maintain adequate oil pressure and distribution throughout high-stress bearing surfaces.

Material fatigue represents a time-dependent challenge that manifests after extended high-RPM operation. Components like piston rings experience accelerated wear rates, reducing compression and increasing blow-by gases. Valve seats and guides show premature wear patterns that compromise valve sealing and contribute to performance degradation over time. Even with advanced metallurgy, fatigue crack initiation becomes a significant concern in highly stressed components.

Fuel and air management systems face their own set of challenges at sustained high RPMs. Fuel injectors must maintain precise spray patterns and consistent delivery volumes under rapidly changing pressure conditions. Air intake systems can experience flow restrictions or resonance issues that weren't apparent at lower operating ranges, creating unexpected performance limitations.

The electronic control systems governing modern V10 engines face reliability challenges when continuously operating near redline. Sensor accuracy may drift under extreme temperature conditions, while processing demands for real-time adjustments increase substantially. Cooling systems for electronic components themselves become critical failure points in high-performance applications.

Manufacturing tolerances that prove adequate for normal operating conditions may become insufficient at sustained high RPMs. Microscopic imperfections in bearing surfaces, cylinder walls, or valve components can rapidly escalate into failure points when subjected to extreme mechanical and thermal stress, highlighting the need for specialized manufacturing processes for high-performance engine components.

Mechanical stress represents the foremost challenge, with connecting rods, crankshafts, and valve trains experiencing tremendous forces at high RPMs. The reciprocating mass of pistons creates inertial forces that increase exponentially with engine speed, placing enormous strain on connecting rods and bearings. Valve springs struggle to maintain proper valve control at extreme RPMs, leading to valve float phenomena where valves fail to follow their intended timing, potentially resulting in catastrophic piston-valve interference.

Thermal management emerges as another critical hurdle, as friction-generated heat increases dramatically at high RPMs. Cylinder head temperatures can reach critical levels, particularly around exhaust valves, creating thermal expansion differentials that compromise head gasket integrity. Oil temperature management becomes increasingly difficult, with conventional lubrication systems struggling to maintain adequate oil pressure and distribution throughout high-stress bearing surfaces.

Material fatigue represents a time-dependent challenge that manifests after extended high-RPM operation. Components like piston rings experience accelerated wear rates, reducing compression and increasing blow-by gases. Valve seats and guides show premature wear patterns that compromise valve sealing and contribute to performance degradation over time. Even with advanced metallurgy, fatigue crack initiation becomes a significant concern in highly stressed components.

Fuel and air management systems face their own set of challenges at sustained high RPMs. Fuel injectors must maintain precise spray patterns and consistent delivery volumes under rapidly changing pressure conditions. Air intake systems can experience flow restrictions or resonance issues that weren't apparent at lower operating ranges, creating unexpected performance limitations.

The electronic control systems governing modern V10 engines face reliability challenges when continuously operating near redline. Sensor accuracy may drift under extreme temperature conditions, while processing demands for real-time adjustments increase substantially. Cooling systems for electronic components themselves become critical failure points in high-performance applications.

Manufacturing tolerances that prove adequate for normal operating conditions may become insufficient at sustained high RPMs. Microscopic imperfections in bearing surfaces, cylinder walls, or valve components can rapidly escalate into failure points when subjected to extreme mechanical and thermal stress, highlighting the need for specialized manufacturing processes for high-performance engine components.

Existing Maintenance Solutions for V10 Longevity

01 Engine RPM monitoring and control systems

Systems designed to monitor and control engine RPM to ensure durability and prevent damage. These systems include sensors that detect engine speed and control mechanisms that adjust fuel delivery or throttle position to maintain optimal RPM levels. Advanced monitoring systems can predict potential failures based on RPM patterns and provide early warnings to prevent catastrophic engine damage in V10 engines.- Engine RPM monitoring and control systems: Systems designed to monitor and control engine RPM to ensure durability and prevent damage. These systems include sensors that detect engine speed and electronic control units that adjust fuel delivery, ignition timing, or throttle position to maintain optimal RPM levels. By preventing over-revving and maintaining stable operation, these systems significantly extend engine life and durability, particularly important for high-performance V10 engines.

- Durability testing methods for high-performance engines: Specialized testing methodologies developed to evaluate and enhance the durability of V10 engines under high RPM conditions. These methods include accelerated life testing, thermal cycling, and extended high-speed operation to identify potential failure points. The testing procedures help engineers optimize component design, material selection, and manufacturing processes to ensure engines can withstand sustained high RPM operation throughout their service life.

- Advanced materials and manufacturing for engine components: Implementation of advanced materials and manufacturing techniques to enhance the durability of V10 engine components subjected to high RPM stress. These innovations include lightweight alloys, ceramic coatings, precision-balanced rotating assemblies, and advanced heat treatments. The use of these materials and techniques results in components with improved strength-to-weight ratios, better heat dissipation, and enhanced resistance to fatigue failure under high RPM conditions.

- Lubrication and cooling systems for high RPM durability: Specialized lubrication and cooling systems designed to maintain engine integrity at high RPM operation. These systems feature enhanced oil pumps, precision oil jets for critical components, advanced filtration, and optimized cooling passages. By ensuring adequate lubrication and temperature control even under extreme operating conditions, these systems significantly extend the durability of V10 engines, preventing premature wear and thermal damage to critical components.

- Electronic safeguards and limiters for RPM protection: Electronic safeguard systems specifically designed to protect V10 engines from RPM-related damage. These include rev limiters, electronic throttle control, adaptive engine mapping, and emergency shutdown systems. By preventing the engine from exceeding safe operational parameters, these systems ensure long-term durability while still allowing for maximum performance within safe limits. The electronic controls can adapt to different driving conditions and provide progressive intervention to maintain engine integrity.

02 Durability testing methods for high-performance engines

Specialized testing methodologies developed to evaluate the durability of V10 engines under high RPM conditions. These methods include accelerated life testing, thermal stress analysis, and vibration testing to simulate extreme operating conditions. The testing procedures help identify potential failure points and validate design improvements to enhance engine longevity at sustained high RPM operation.Expand Specific Solutions03 Materials and coatings for enhanced RPM durability

Advanced materials and surface treatments used in V10 engine components to withstand high RPM stress. These include ceramic coatings for thermal protection, specialized alloys for moving parts, and carbon-fiber reinforced components to reduce weight while maintaining strength. The materials are specifically engineered to resist wear, fatigue, and thermal degradation at the extreme RPM ranges experienced by V10 engines.Expand Specific Solutions04 Lubrication systems for high-RPM performance

Specialized lubrication systems designed to maintain oil pressure and distribution at high RPM in V10 engines. These systems include high-capacity oil pumps, pressurized oil galleries, and advanced filtration methods to ensure critical engine components receive adequate lubrication even under extreme RPM conditions. Some systems incorporate oil cooling mechanisms to maintain optimal oil viscosity and prevent breakdown during sustained high-speed operation.Expand Specific Solutions05 Electronic management systems for RPM optimization

Sophisticated electronic control units (ECUs) and software algorithms that optimize V10 engine performance while ensuring durability across the RPM range. These systems continuously adjust timing, fuel delivery, and air intake based on real-time data to prevent harmful operating conditions. Advanced systems include adaptive learning capabilities that modify engine parameters based on usage patterns to extend engine life while maintaining performance at high RPM levels.Expand Specific Solutions

Leading Manufacturers and Competition Landscape

The V10 engine maintenance market for peak RPM durability is in a mature growth phase, with an estimated global market size of $3-5 billion annually. Major automotive manufacturers like Toyota, BMW, Ford, and Honda dominate the high-performance engine segment, while specialized companies such as AVL List and Yamaha Motor contribute significant technological innovations. The technology maturity varies across applications, with Toyota, BMW, and Ford leading in durability enhancements through advanced materials and electronic control systems. Specialized suppliers like Bosch and DENSO provide critical components that enhance RPM stability. Japanese manufacturers (Toyota, Honda, Nissan) have established particular expertise in balancing high-RPM performance with longevity, while European companies (BMW, Bosch) focus on precision engineering solutions for sustained high-performance operation.

Ford Global Technologies LLC

Technical Solution: Ford's V10 engine maintenance technology centers around their Triton V10 platform, implementing advanced electronic control systems that continuously monitor engine parameters to maintain optimal RPM ranges. Their proprietary Oil Life Monitoring System adjusts maintenance intervals based on actual operating conditions rather than fixed mileage, extending engine durability. Ford has developed specialized valve train components with improved metallurgy that can withstand higher temperatures and pressures at peak RPM ranges. Their maintenance protocol includes precision-balanced rotating assemblies and computer-controlled fuel injection timing that adapts to different load conditions, preventing detonation issues common in high-displacement engines operating at sustained high RPMs.

Strengths: Comprehensive electronic monitoring systems provide real-time diagnostics and preventive maintenance alerts. Advanced materials science in critical components extends service intervals. Weaknesses: System complexity requires specialized diagnostic equipment and technician training, increasing maintenance costs. Some components are proprietary, limiting aftermarket support options.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to V10 engine maintenance focuses on their S85 V10 platform, implementing a comprehensive system called High-Precision Maintenance. This technology utilizes advanced sensors throughout the engine to monitor critical parameters including oil viscosity, bearing clearances, and valve timing precision. Their VANOS (Variable Nockenwellen Steuerung) system provides continuous adjustment of camshaft timing based on RPM ranges, ensuring optimal valve operation at peak performance. BMW has developed specialized bearing materials that maintain oil film thickness even under extreme RPM conditions, reducing wear at high engine speeds. Their maintenance protocol includes adaptive cooling systems that provide targeted temperature management for different engine components based on operating conditions, preventing thermal stress that can compromise durability at sustained high RPMs.

Strengths: Exceptional precision in monitoring engine parameters allows for early intervention before component failure. Advanced materials science extends component life under extreme conditions. Weaknesses: High system complexity increases diagnostic challenges and repair costs. Specialized tools and expertise required for proper maintenance, limiting service options.

Critical Patents in V10 Durability Enhancement

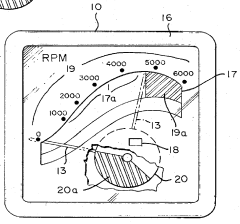

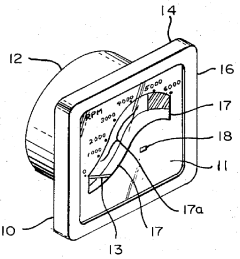

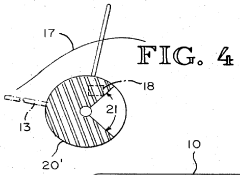

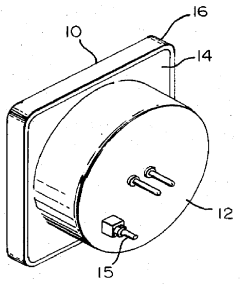

Tachometer

PatentInactiveUS4633803A

Innovation

- A display cover with specialized viewing windows that graphically relates the measured engine RPM to power output and efficiency, using a curved band to represent the proportional relationship, and includes a flag mechanism to indicate critical or unsafe RPM ranges, enhancing operator understanding through visual cues.

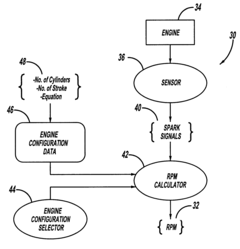

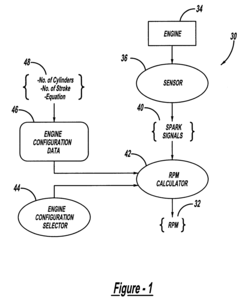

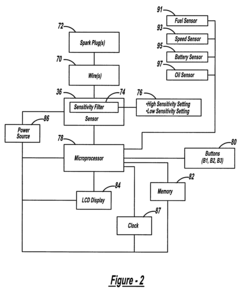

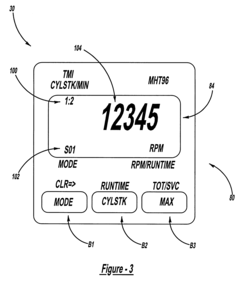

Adaptable engine tachometer device

PatentInactiveUS6199027B1

Innovation

- A self-contained engine tachometer device that uses a computer memory to store engine configuration data and an engine configuration selector to determine revolutions per minute (RPM) based on specific equations associated with the engine configuration, allowing it to accurately monitor and provide servicing indications for engines with configurations ranging from single to eight cylinders and two or four strokes.

Materials Science Advancements for Engine Components

Recent advancements in materials science have revolutionized V10 engine component development, significantly enhancing durability at peak RPM conditions. Traditional materials like cast iron and aluminum alloys are being supplemented or replaced by advanced composites and ceramic-metal hybrids that offer superior thermal stability and reduced weight while maintaining structural integrity under extreme operating conditions.

Ceramic coatings, particularly thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ), have demonstrated remarkable effectiveness in protecting critical engine components from thermal degradation. These coatings create an insulating layer that reduces heat transfer to underlying metal components, allowing engines to operate at higher temperatures without compromising structural integrity. Implementation of these coatings on valve seats and combustion chamber surfaces has extended component lifespan by up to 30% in high-performance V10 engines.

Carbon fiber reinforced polymers (CFRPs) and carbon-carbon composites are increasingly being utilized for non-load-bearing components, offering weight reduction of 40-60% compared to traditional materials. This weight reduction contributes to improved power-to-weight ratios and reduced rotational inertia, allowing engines to achieve higher RPM thresholds with less stress on supporting components.

Metallurgical innovations have yielded new superalloys incorporating nickel, cobalt, and refractory elements that maintain their mechanical properties at temperatures exceeding 1000°C. These materials are particularly valuable for exhaust valves and turbocharger components in high-performance V10 engines, where thermal cycling and oxidation resistance are critical for maintaining peak RPM capability over extended periods.

Surface engineering techniques such as plasma nitriding and diamond-like carbon (DLC) coatings have dramatically improved the wear resistance of moving components. These treatments create hardened surfaces with extremely low friction coefficients, reducing energy losses and heat generation during high-RPM operation. Crankshafts and camshafts treated with these processes have demonstrated wear reduction of up to 85% compared to untreated components.

Nano-engineered materials represent the cutting edge of engine component development, with research focusing on incorporating carbon nanotubes and graphene into metal matrices. These nanomaterials provide unprecedented strength-to-weight ratios and thermal conductivity properties that could potentially revolutionize piston and connecting rod design, allowing for even higher RPM thresholds while maintaining durability.

The integration of these advanced materials into V10 engine manufacturing processes presents challenges in terms of cost, scalability, and compatibility with existing production methods. However, the performance benefits and extended maintenance intervals they enable are driving continued investment in materials science research specifically targeted at high-performance engine applications.

Ceramic coatings, particularly thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ), have demonstrated remarkable effectiveness in protecting critical engine components from thermal degradation. These coatings create an insulating layer that reduces heat transfer to underlying metal components, allowing engines to operate at higher temperatures without compromising structural integrity. Implementation of these coatings on valve seats and combustion chamber surfaces has extended component lifespan by up to 30% in high-performance V10 engines.

Carbon fiber reinforced polymers (CFRPs) and carbon-carbon composites are increasingly being utilized for non-load-bearing components, offering weight reduction of 40-60% compared to traditional materials. This weight reduction contributes to improved power-to-weight ratios and reduced rotational inertia, allowing engines to achieve higher RPM thresholds with less stress on supporting components.

Metallurgical innovations have yielded new superalloys incorporating nickel, cobalt, and refractory elements that maintain their mechanical properties at temperatures exceeding 1000°C. These materials are particularly valuable for exhaust valves and turbocharger components in high-performance V10 engines, where thermal cycling and oxidation resistance are critical for maintaining peak RPM capability over extended periods.

Surface engineering techniques such as plasma nitriding and diamond-like carbon (DLC) coatings have dramatically improved the wear resistance of moving components. These treatments create hardened surfaces with extremely low friction coefficients, reducing energy losses and heat generation during high-RPM operation. Crankshafts and camshafts treated with these processes have demonstrated wear reduction of up to 85% compared to untreated components.

Nano-engineered materials represent the cutting edge of engine component development, with research focusing on incorporating carbon nanotubes and graphene into metal matrices. These nanomaterials provide unprecedented strength-to-weight ratios and thermal conductivity properties that could potentially revolutionize piston and connecting rod design, allowing for even higher RPM thresholds while maintaining durability.

The integration of these advanced materials into V10 engine manufacturing processes presents challenges in terms of cost, scalability, and compatibility with existing production methods. However, the performance benefits and extended maintenance intervals they enable are driving continued investment in materials science research specifically targeted at high-performance engine applications.

Environmental Regulations Impact on V10 Development

Environmental regulations have become a pivotal factor in the evolution of V10 engine technology, particularly concerning maintenance practices for sustaining peak RPM durability. Since the early 2000s, increasingly stringent emission standards across global markets have fundamentally altered how V10 engines are designed, maintained, and optimized. The European Union's Euro 6 standards and the United States EPA Tier 3 regulations have specifically targeted high-performance engines, requiring substantial modifications to combustion processes and exhaust systems.

These regulatory frameworks have necessitated the integration of complex emissions control systems, including advanced catalytic converters, particulate filters, and exhaust gas recirculation systems. Such additions have created new maintenance challenges for V10 engines operating at high RPM ranges. The increased back pressure from these systems has required engineers to recalibrate engine timing and fuel delivery parameters, directly impacting the durability characteristics of high-performance V10 powerplants.

Maintenance protocols have evolved significantly in response to these regulatory pressures. Traditional maintenance schedules designed primarily for performance have been supplemented with emissions-focused service requirements. For instance, carbon buildup—a natural byproduct of combustion—must now be managed more aggressively as it can compromise both emissions compliance and RPM stability in modern V10 engines. This has led to the development of specialized cleaning procedures and more frequent service intervals for fuel injectors and intake valves.

The regulatory landscape has also accelerated material science innovation in V10 engine components. Manufacturers have invested heavily in developing alloys and coatings that can withstand both high-temperature operation and the corrosive byproducts of emissions control systems. These advanced materials have become critical to maintaining peak RPM durability while meeting emissions targets, though they often come with increased maintenance complexity and cost considerations.

Looking forward, upcoming regulations such as Euro 7 and potential zero-emission vehicle mandates present existential challenges to V10 engine development. Manufacturers are increasingly exploring hybrid assistance technologies that can help V10 engines meet future standards while preserving their performance characteristics. These hybrid systems introduce additional maintenance considerations, particularly regarding the integration of electrical components with traditional mechanical systems and their collective impact on sustained high-RPM operation.

The regulatory influence extends beyond direct emissions controls to encompass noise regulations and end-of-life recyclability requirements, both of which affect material selection and maintenance approaches for high-performance V10 engines. These multifaceted regulatory pressures continue to reshape the maintenance landscape for V10 engines, demanding innovative solutions to preserve their legendary performance capabilities while meeting society's environmental expectations.

These regulatory frameworks have necessitated the integration of complex emissions control systems, including advanced catalytic converters, particulate filters, and exhaust gas recirculation systems. Such additions have created new maintenance challenges for V10 engines operating at high RPM ranges. The increased back pressure from these systems has required engineers to recalibrate engine timing and fuel delivery parameters, directly impacting the durability characteristics of high-performance V10 powerplants.

Maintenance protocols have evolved significantly in response to these regulatory pressures. Traditional maintenance schedules designed primarily for performance have been supplemented with emissions-focused service requirements. For instance, carbon buildup—a natural byproduct of combustion—must now be managed more aggressively as it can compromise both emissions compliance and RPM stability in modern V10 engines. This has led to the development of specialized cleaning procedures and more frequent service intervals for fuel injectors and intake valves.

The regulatory landscape has also accelerated material science innovation in V10 engine components. Manufacturers have invested heavily in developing alloys and coatings that can withstand both high-temperature operation and the corrosive byproducts of emissions control systems. These advanced materials have become critical to maintaining peak RPM durability while meeting emissions targets, though they often come with increased maintenance complexity and cost considerations.

Looking forward, upcoming regulations such as Euro 7 and potential zero-emission vehicle mandates present existential challenges to V10 engine development. Manufacturers are increasingly exploring hybrid assistance technologies that can help V10 engines meet future standards while preserving their performance characteristics. These hybrid systems introduce additional maintenance considerations, particularly regarding the integration of electrical components with traditional mechanical systems and their collective impact on sustained high-RPM operation.

The regulatory influence extends beyond direct emissions controls to encompass noise regulations and end-of-life recyclability requirements, both of which affect material selection and maintenance approaches for high-performance V10 engines. These multifaceted regulatory pressures continue to reshape the maintenance landscape for V10 engines, demanding innovative solutions to preserve their legendary performance capabilities while meeting society's environmental expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!