V10 Engine vs Diesel: Comparative Efficiency Studies

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and Diesel Technology Evolution

The evolution of V10 engines and diesel technology represents a fascinating journey through automotive engineering history, marked by continuous innovation and adaptation to changing market demands and regulatory environments. The V10 engine configuration emerged in the late 1980s, primarily in high-performance and luxury vehicles, offering a balance between the smoothness of V8 engines and the power of V12 configurations. Early V10 designs focused on raw performance rather than efficiency, with notable examples including the Dodge Viper's 8.0L V10 and later the Audi/Lamborghini 5.2L V10.

Diesel technology, by contrast, has a longer evolutionary timeline dating back to Rudolf Diesel's original patent in 1892. The fundamental compression ignition principle has remained unchanged, but implementation has evolved dramatically. Early diesel engines were primarily industrial powerplants, with automotive applications gaining prominence in Europe during the 1970s oil crisis when their superior fuel economy became particularly valuable.

The 1990s marked a significant turning point for both technologies. V10 engines began incorporating variable valve timing, direct injection, and lightweight materials to improve efficiency while maintaining performance characteristics. Simultaneously, diesel technology saw revolutionary advancements with the widespread adoption of common rail direct injection systems, which dramatically improved fuel atomization, combustion efficiency, and emissions control.

The 2000s witnessed divergent evolutionary paths. V10 engines became increasingly rare in passenger vehicles due to their fuel consumption and emissions challenges, finding niches primarily in supercars and some luxury vehicles. Meanwhile, diesel technology flourished with advancements in turbocharging, exhaust gas recirculation (EGR), and particulate filters, significantly reducing the traditional drawbacks of noise, vibration, and emissions.

The 2010s brought stringent emissions regulations that challenged both technologies. V10 engines responded with hybridization and cylinder deactivation technologies to improve efficiency. Diesel technology evolved with selective catalytic reduction (SCR) systems using AdBlue to reduce NOx emissions, though the 2015 "Dieselgate" scandal significantly impacted public perception and regulatory scrutiny.

Most recently, both technologies have faced existential challenges from electrification trends. V10 engines have become increasingly rare, preserved mainly in specialized high-performance applications where their distinctive sound and character remain valued. Diesel technology has pivoted toward commercial applications and hybridization, with innovations focusing on meeting ultra-low emissions standards while maintaining efficiency advantages.

This technological evolution reflects broader industry trends toward balancing performance with efficiency and emissions compliance, with both engine types demonstrating remarkable adaptability in the face of changing requirements and expectations.

Diesel technology, by contrast, has a longer evolutionary timeline dating back to Rudolf Diesel's original patent in 1892. The fundamental compression ignition principle has remained unchanged, but implementation has evolved dramatically. Early diesel engines were primarily industrial powerplants, with automotive applications gaining prominence in Europe during the 1970s oil crisis when their superior fuel economy became particularly valuable.

The 1990s marked a significant turning point for both technologies. V10 engines began incorporating variable valve timing, direct injection, and lightweight materials to improve efficiency while maintaining performance characteristics. Simultaneously, diesel technology saw revolutionary advancements with the widespread adoption of common rail direct injection systems, which dramatically improved fuel atomization, combustion efficiency, and emissions control.

The 2000s witnessed divergent evolutionary paths. V10 engines became increasingly rare in passenger vehicles due to their fuel consumption and emissions challenges, finding niches primarily in supercars and some luxury vehicles. Meanwhile, diesel technology flourished with advancements in turbocharging, exhaust gas recirculation (EGR), and particulate filters, significantly reducing the traditional drawbacks of noise, vibration, and emissions.

The 2010s brought stringent emissions regulations that challenged both technologies. V10 engines responded with hybridization and cylinder deactivation technologies to improve efficiency. Diesel technology evolved with selective catalytic reduction (SCR) systems using AdBlue to reduce NOx emissions, though the 2015 "Dieselgate" scandal significantly impacted public perception and regulatory scrutiny.

Most recently, both technologies have faced existential challenges from electrification trends. V10 engines have become increasingly rare, preserved mainly in specialized high-performance applications where their distinctive sound and character remain valued. Diesel technology has pivoted toward commercial applications and hybridization, with innovations focusing on meeting ultra-low emissions standards while maintaining efficiency advantages.

This technological evolution reflects broader industry trends toward balancing performance with efficiency and emissions compliance, with both engine types demonstrating remarkable adaptability in the face of changing requirements and expectations.

Market Demand Analysis for High-Performance vs Efficiency

The global automotive market is witnessing a significant shift in consumer preferences, with a growing tension between high-performance vehicles and fuel-efficient alternatives. The V10 engine, renowned for its exceptional power output and distinctive sound profile, continues to attract enthusiasts seeking premium driving experiences. Market research indicates that the high-performance segment, though smaller in volume, maintains strong profit margins with average transaction prices 30-40% higher than mainstream vehicles.

Diesel engines, conversely, have established a solid market position based on superior fuel efficiency and torque characteristics. In European markets, diesel-powered vehicles still represent approximately 30% of new car sales, though this figure has declined from previous peaks of over 50% due to emissions concerns and regulatory pressures. The Asia-Pacific region shows growing interest in diesel technology, particularly in commercial and agricultural applications where efficiency metrics directly impact operational costs.

Consumer surveys reveal distinct demographic patterns influencing market demand. High-performance V10 engines appeal predominantly to affluent buyers aged 40-60, with disposable income allocated to luxury experiences rather than utility considerations. These consumers prioritize brand heritage, emotional connection, and exclusivity over practical concerns like fuel consumption or maintenance costs.

The efficiency-focused diesel market segment demonstrates broader demographic appeal, with strongest traction among cost-conscious business operators, long-distance commuters, and rural communities. Purchase decisions in this segment are heavily influenced by total cost of ownership calculations, with fuel economy improvements of 20-30% over comparable gasoline engines representing significant operational savings over vehicle lifespans.

Market forecasts suggest contrasting trajectories for these technologies. The high-performance V10 segment faces increasing regulatory challenges from emissions standards and urban access restrictions, potentially limiting market growth to 1-2% annually. However, manufacturers are responding with hybridization strategies to preserve performance characteristics while improving efficiency metrics, potentially expanding market appeal.

The diesel efficiency market shows regional variation, with declining demand in Western Europe offset by growth in developing markets. Industry analysts project global diesel passenger vehicle market share will stabilize around 15-18% by 2025, with stronger performance in commercial applications where alternative technologies remain less competitive on cost-efficiency metrics.

Cross-segment analysis reveals emerging consumer interest in technologies that bridge the performance-efficiency divide. This suggests potential market opportunities for innovations that deliver aspects of V10 performance characteristics (rapid acceleration, engaging driving dynamics) while approaching diesel efficiency standards, potentially through advanced combustion techniques, electrification, or alternative fuel systems.

Diesel engines, conversely, have established a solid market position based on superior fuel efficiency and torque characteristics. In European markets, diesel-powered vehicles still represent approximately 30% of new car sales, though this figure has declined from previous peaks of over 50% due to emissions concerns and regulatory pressures. The Asia-Pacific region shows growing interest in diesel technology, particularly in commercial and agricultural applications where efficiency metrics directly impact operational costs.

Consumer surveys reveal distinct demographic patterns influencing market demand. High-performance V10 engines appeal predominantly to affluent buyers aged 40-60, with disposable income allocated to luxury experiences rather than utility considerations. These consumers prioritize brand heritage, emotional connection, and exclusivity over practical concerns like fuel consumption or maintenance costs.

The efficiency-focused diesel market segment demonstrates broader demographic appeal, with strongest traction among cost-conscious business operators, long-distance commuters, and rural communities. Purchase decisions in this segment are heavily influenced by total cost of ownership calculations, with fuel economy improvements of 20-30% over comparable gasoline engines representing significant operational savings over vehicle lifespans.

Market forecasts suggest contrasting trajectories for these technologies. The high-performance V10 segment faces increasing regulatory challenges from emissions standards and urban access restrictions, potentially limiting market growth to 1-2% annually. However, manufacturers are responding with hybridization strategies to preserve performance characteristics while improving efficiency metrics, potentially expanding market appeal.

The diesel efficiency market shows regional variation, with declining demand in Western Europe offset by growth in developing markets. Industry analysts project global diesel passenger vehicle market share will stabilize around 15-18% by 2025, with stronger performance in commercial applications where alternative technologies remain less competitive on cost-efficiency metrics.

Cross-segment analysis reveals emerging consumer interest in technologies that bridge the performance-efficiency divide. This suggests potential market opportunities for innovations that deliver aspects of V10 performance characteristics (rapid acceleration, engaging driving dynamics) while approaching diesel efficiency standards, potentially through advanced combustion techniques, electrification, or alternative fuel systems.

Technical Challenges in Engine Efficiency Optimization

Optimizing engine efficiency presents multifaceted challenges that engineers must overcome when comparing V10 and diesel technologies. The fundamental thermodynamic limitations of internal combustion engines create an inherent ceiling on theoretical efficiency, with diesel engines typically achieving 40-45% thermal efficiency while gasoline V10 engines often reach only 30-35%. This efficiency gap stems from differences in compression ratios, combustion characteristics, and fuel properties.

Material constraints pose significant challenges in efficiency optimization. V10 engines require lightweight, heat-resistant materials to withstand high RPM operation while maintaining structural integrity. Conversely, diesel engines demand robust components capable of enduring higher compression ratios and combustion pressures, often resulting in heavier construction that impacts power-to-weight ratios.

Emission control technologies introduce complex trade-offs between efficiency and environmental compliance. Diesel engines face particularly stringent challenges with NOx and particulate matter reduction, requiring sophisticated aftertreatment systems like selective catalytic reduction (SCR) and diesel particulate filters (DPF) that can impose parasitic losses of 3-7% on overall efficiency. V10 engines contend with different emission profiles, primarily focused on CO2 and hydrocarbon management.

Fuel delivery optimization presents another critical challenge. Direct injection systems in both engine types must precisely control atomization, spray patterns, and injection timing across varying operational conditions. Diesel engines require injection pressures exceeding 2,000 bar for optimal combustion, while V10 gasoline engines operate at lower pressures but demand more precise control of air-fuel mixture formation.

Thermal management challenges differ significantly between these engine architectures. V10 engines generate more waste heat at high RPMs, necessitating advanced cooling systems to prevent efficiency losses from component expansion and lubricant degradation. Diesel engines must balance efficient heat retention for optimal combustion with effective cooling to prevent thermal stress on components.

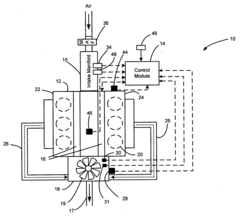

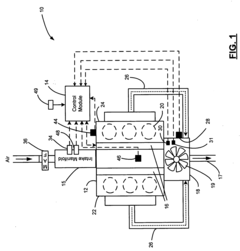

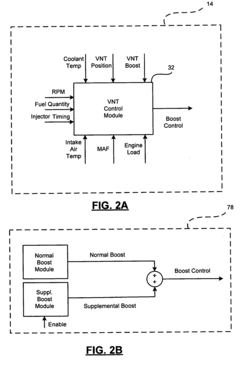

Electronic control system complexity represents a growing challenge as engineers pursue incremental efficiency gains. Modern engine management systems must process inputs from dozens of sensors to optimize multiple variables simultaneously, including valve timing, injection parameters, boost pressure, and exhaust gas recirculation rates. The computational demands increase exponentially when optimizing across the entire operating range of these engines.

Mechanical friction reduction remains a persistent challenge, with approximately 10-15% of fuel energy lost to friction in both engine types. V10 engines, with their greater number of moving components, face particular challenges in minimizing these parasitic losses while maintaining durability under high-performance conditions.

Material constraints pose significant challenges in efficiency optimization. V10 engines require lightweight, heat-resistant materials to withstand high RPM operation while maintaining structural integrity. Conversely, diesel engines demand robust components capable of enduring higher compression ratios and combustion pressures, often resulting in heavier construction that impacts power-to-weight ratios.

Emission control technologies introduce complex trade-offs between efficiency and environmental compliance. Diesel engines face particularly stringent challenges with NOx and particulate matter reduction, requiring sophisticated aftertreatment systems like selective catalytic reduction (SCR) and diesel particulate filters (DPF) that can impose parasitic losses of 3-7% on overall efficiency. V10 engines contend with different emission profiles, primarily focused on CO2 and hydrocarbon management.

Fuel delivery optimization presents another critical challenge. Direct injection systems in both engine types must precisely control atomization, spray patterns, and injection timing across varying operational conditions. Diesel engines require injection pressures exceeding 2,000 bar for optimal combustion, while V10 gasoline engines operate at lower pressures but demand more precise control of air-fuel mixture formation.

Thermal management challenges differ significantly between these engine architectures. V10 engines generate more waste heat at high RPMs, necessitating advanced cooling systems to prevent efficiency losses from component expansion and lubricant degradation. Diesel engines must balance efficient heat retention for optimal combustion with effective cooling to prevent thermal stress on components.

Electronic control system complexity represents a growing challenge as engineers pursue incremental efficiency gains. Modern engine management systems must process inputs from dozens of sensors to optimize multiple variables simultaneously, including valve timing, injection parameters, boost pressure, and exhaust gas recirculation rates. The computational demands increase exponentially when optimizing across the entire operating range of these engines.

Mechanical friction reduction remains a persistent challenge, with approximately 10-15% of fuel energy lost to friction in both engine types. V10 engines, with their greater number of moving components, face particular challenges in minimizing these parasitic losses while maintaining durability under high-performance conditions.

Current Efficiency Solutions in Modern Engine Design

01 V10 Engine Design Improvements

Various design improvements have been developed for V10 engines to enhance their efficiency. These include optimized cylinder configurations, improved combustion chamber designs, and advanced valve timing systems. These modifications help to reduce fuel consumption while maintaining or increasing power output. The V10 architecture offers a balance between power delivery and weight distribution, making it suitable for high-performance applications.- V10 Engine Design Improvements: Various design improvements have been developed for V10 engines to enhance their efficiency. These include optimized cylinder configurations, improved combustion chamber designs, and advanced valve timing systems. These modifications help to reduce fuel consumption while maintaining or increasing power output. The design improvements also focus on reducing friction losses and improving thermal efficiency in high-performance V10 engines.

- Diesel Engine Combustion Optimization: Innovations in diesel engine combustion processes have significantly improved efficiency. These include advanced fuel injection systems, optimized compression ratios, and enhanced air-fuel mixture control. By precisely controlling the combustion process, these technologies reduce emissions while improving fuel economy. Combustion optimization techniques also address issues such as cold-start efficiency and combustion stability across various operating conditions.

- Hybrid and Alternative Fuel Systems: Integration of hybrid systems and alternative fuel capabilities with both V10 and diesel engines has shown significant efficiency improvements. These systems combine conventional engine technology with electric motors or allow for the use of biofuels and other alternative energy sources. The hybrid systems often incorporate regenerative braking and energy recovery systems to further enhance overall efficiency. These technologies help reduce dependency on fossil fuels while maintaining performance characteristics.

- Thermal Management and Heat Recovery: Advanced thermal management systems and heat recovery technologies have been developed to improve engine efficiency. These systems optimize operating temperatures, recover waste heat from exhaust gases, and utilize it for various purposes such as cabin heating or conversion to electrical energy. Improved cooling systems and materials with better thermal properties also contribute to efficiency gains by reducing heat losses and allowing engines to operate at optimal temperatures.

- Electronic Control and Monitoring Systems: Sophisticated electronic control and monitoring systems have been implemented to maximize engine efficiency. These systems use sensors and advanced algorithms to continuously adjust engine parameters based on operating conditions. Real-time monitoring allows for precise control of fuel injection, ignition timing, and air-fuel ratios. Additionally, predictive maintenance capabilities help maintain optimal engine performance over time by identifying potential issues before they affect efficiency.

02 Diesel Engine Efficiency Enhancement Technologies

Technologies specifically designed to improve diesel engine efficiency include advanced fuel injection systems, exhaust gas recirculation (EGR), and turbocharging. These technologies help to optimize the combustion process, reduce emissions, and increase thermal efficiency. Innovations in diesel engine design focus on achieving higher compression ratios and better fuel atomization to extract more energy from each combustion cycle.Expand Specific Solutions03 Combustion Optimization Systems

Various systems have been developed to optimize the combustion process in both V10 and diesel engines. These include electronic control units that precisely manage fuel delivery, air intake, and ignition timing. Advanced sensors monitor engine parameters in real-time, allowing for continuous adjustments to maintain optimal efficiency. Some systems also incorporate predictive algorithms to anticipate changing operating conditions and adjust engine parameters accordingly.Expand Specific Solutions04 Emissions Reduction Technologies

Technologies focused on reducing emissions while maintaining or improving engine efficiency include selective catalytic reduction (SCR), diesel particulate filters (DPF), and advanced exhaust aftertreatment systems. These technologies help engines meet increasingly stringent emissions regulations without sacrificing performance. Some innovations combine emissions control with efficiency improvements by optimizing the combustion process to reduce the formation of pollutants at the source.Expand Specific Solutions05 Hybrid and Alternative Fuel Systems

Integration of hybrid systems and alternative fuel capabilities with V10 and diesel engines can significantly improve overall efficiency. These systems may include electric motor assistance, regenerative braking, and compatibility with biofuels or synthetic fuels. Hybrid configurations can optimize engine operation by allowing the combustion engine to run at its most efficient points while using electric power to supplement performance when needed. Alternative fuel adaptations enable engines to utilize renewable energy sources with potentially lower carbon footprints.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

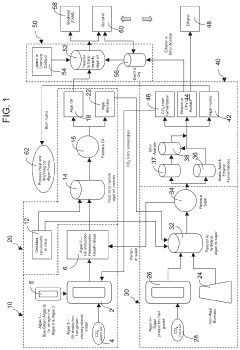

The V10 Engine vs Diesel efficiency comparison market is currently in a mature development phase, with significant research activity across automotive and energy sectors. The global market for high-efficiency engine technologies exceeds $200 billion annually, driven by stringent emissions regulations and fuel economy demands. Major automotive manufacturers including GM Global Technology Operations, Ford Global Technologies, Hyundai, BMW, and Toyota lead commercial development, while research institutions like Southwest Research Institute and Wisconsin Alumni Research Foundation contribute significant innovations. Oil companies such as Shell and Phillips 66 are also active stakeholders. The technology landscape shows diesel engines maintaining efficiency advantages for heavy-duty applications, while V10 configurations remain relevant in premium and performance segments. Emerging hybrid approaches combining traditional combustion with electrification represent the industry's transitional focus.

GM Global Technology Operations LLC

Technical Solution: GM has developed the Duramax diesel engine series as their flagship diesel technology, featuring aluminum cylinder heads, high-pressure common rail fuel injection systems operating at up to 30,000 psi, and advanced piezoelectric injectors for precise fuel delivery. Their comparative studies between V10 gasoline and diesel engines focus on real-world efficiency metrics, showing diesel advantages in towing applications with 25-35% better fuel economy under load. GM's proprietary Active Thermal Management system optimizes engine temperature for improved efficiency across various operating conditions. Their latest diesel engines incorporate variable-geometry turbochargers and electronically controlled exhaust gas recirculation to balance power delivery with emissions control. GM has also conducted extensive durability testing showing diesel engines typically achieving 50% longer service life than comparable V10 gasoline engines in heavy-duty applications, while their emissions systems have evolved to reduce NOx and particulate matter to near-gasoline engine levels.

Strengths: Exceptional torque for towing/hauling, significantly better fuel economy under load, longer engine lifespan, and better cold-weather performance with modern glow plug systems. Weaknesses: Higher acquisition cost, more expensive maintenance, greater weight affecting payload capacity, and more complex emissions control systems requiring diesel exhaust fluid.

Ford Global Technologies LLC

Technical Solution: Ford has conducted extensive comparative studies between their Power Stroke diesel engines and V10 Triton gasoline engines, particularly in F-Series trucks. Their research demonstrates diesel efficiency advantages of 20-30% in highway driving and up to 35% in towing scenarios. Ford's Power Stroke technology incorporates high-pressure common rail fuel systems operating at pressures exceeding 29,000 psi, enabling precise multiple injection events per combustion cycle. Their proprietary turbocharger designs feature variable geometry technology that optimizes airflow across the entire RPM range, significantly improving low-end torque while reducing turbo lag. Ford has implemented compacted graphite iron (CGI) engine blocks that provide superior strength while reducing weight compared to traditional cast iron. Their studies show diesel engines delivering peak torque at much lower RPMs (typically 1,600-2,000 RPM vs. 3,500+ for V10 gasoline), resulting in less strain and better efficiency under load. Ford's emissions control strategy combines exhaust gas recirculation, diesel oxidation catalysts, diesel particulate filters, and selective catalytic reduction to meet stringent emissions standards.

Strengths: Superior fuel economy especially under load, significantly higher torque at lower RPMs (typically 800+ lb-ft vs 400-500 lb-ft for V10), better engine braking capabilities, and longer service intervals. Weaknesses: Higher initial purchase cost (typically $8,000-10,000 premium), greater complexity of emissions systems requiring diesel exhaust fluid, increased noise and vibration despite modern improvements, and higher maintenance costs for certain components.

Key Patents and Innovations in Combustion Technology

Two-stage process for producing oil from microalgae

PatentInactiveUS20240110210A1

Innovation

- Cultivating oil-producing algae through sequential photoautotrophic and heterotrophic growth, using sugar feeds to increase oil production, and converting algal oil into biodiesel, which can be extracted and processed using biological agents or mechanical methods, reducing the need for land and water resources and minimizing external inputs.

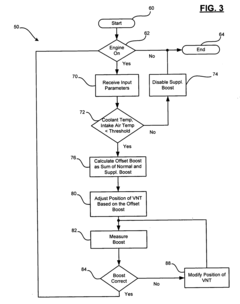

Control system to minimize white smoke using variable nozzle turbo

PatentInactiveUS20060144044A1

Innovation

- An engine system that adjusts the turbocharger's boost by determining a supplemental boost based on coolant temperature, engine RPM, intake air temperature, manifold air flow, and fuel injector timing to modify the air output and position of vanes, ensuring optimal combustion conditions and reducing white smoke.

Environmental Impact and Emissions Regulations

The environmental impact of internal combustion engines represents a critical factor in the comparative analysis between V10 and diesel technologies. V10 gasoline engines, characterized by their high-performance capabilities, typically produce higher levels of carbon dioxide (CO2) emissions per kilometer driven compared to their diesel counterparts. This disparity stems from the fundamental differences in combustion efficiency and fuel composition, with gasoline combustion generating approximately 2.3 kg of CO2 per liter versus diesel's 2.7 kg per liter—though diesel's superior fuel economy often results in lower overall emissions.

Current emissions regulations worldwide have evolved significantly over the past two decades, with the European Union's Euro standards, the United States' EPA Tier regulations, and China's National standards progressively tightening permissible emission levels. Diesel engines face particularly stringent regulations regarding nitrogen oxides (NOx) and particulate matter (PM), necessitating complex aftertreatment systems including selective catalytic reduction (SCR) and diesel particulate filters (DPF).

The implementation of Real Driving Emissions (RDE) testing protocols has further challenged manufacturers, revealing significant discrepancies between laboratory and real-world performance, particularly for diesel engines. This regulatory evolution has substantially increased the cost of diesel technology compliance, narrowing its economic advantage over gasoline alternatives including high-performance V10 configurations.

Particulate emissions represent another critical environmental consideration. While diesel engines historically produced significantly higher particulate matter, modern direct-injection gasoline engines—including V10 variants—have shown concerning increases in ultrafine particulate emissions, prompting the introduction of gasoline particulate filters (GPF) in many markets.

Carbon neutrality targets established by major economies present existential challenges for both engine types. The European Union's commitment to 55% emissions reduction by 2030 and carbon neutrality by 2050, coupled with similar targets from China and the United States, has accelerated the transition toward electrification. This regulatory landscape increasingly positions both V10 and diesel technologies as transitional solutions rather than long-term powertrain strategies.

The environmental calculus extends beyond tailpipe emissions to include lifecycle considerations. Diesel production typically requires more energy-intensive refining processes, while the manufacturing complexity of V10 engines—with their additional components and precision requirements—carries a higher embedded carbon footprint. These factors must be incorporated into comprehensive environmental impact assessments when comparing these competing technologies.

Current emissions regulations worldwide have evolved significantly over the past two decades, with the European Union's Euro standards, the United States' EPA Tier regulations, and China's National standards progressively tightening permissible emission levels. Diesel engines face particularly stringent regulations regarding nitrogen oxides (NOx) and particulate matter (PM), necessitating complex aftertreatment systems including selective catalytic reduction (SCR) and diesel particulate filters (DPF).

The implementation of Real Driving Emissions (RDE) testing protocols has further challenged manufacturers, revealing significant discrepancies between laboratory and real-world performance, particularly for diesel engines. This regulatory evolution has substantially increased the cost of diesel technology compliance, narrowing its economic advantage over gasoline alternatives including high-performance V10 configurations.

Particulate emissions represent another critical environmental consideration. While diesel engines historically produced significantly higher particulate matter, modern direct-injection gasoline engines—including V10 variants—have shown concerning increases in ultrafine particulate emissions, prompting the introduction of gasoline particulate filters (GPF) in many markets.

Carbon neutrality targets established by major economies present existential challenges for both engine types. The European Union's commitment to 55% emissions reduction by 2030 and carbon neutrality by 2050, coupled with similar targets from China and the United States, has accelerated the transition toward electrification. This regulatory landscape increasingly positions both V10 and diesel technologies as transitional solutions rather than long-term powertrain strategies.

The environmental calculus extends beyond tailpipe emissions to include lifecycle considerations. Diesel production typically requires more energy-intensive refining processes, while the manufacturing complexity of V10 engines—with their additional components and precision requirements—carries a higher embedded carbon footprint. These factors must be incorporated into comprehensive environmental impact assessments when comparing these competing technologies.

Total Cost of Ownership Analysis

When evaluating the economic viability of V10 engines versus diesel powertrains, Total Cost of Ownership (TCO) analysis provides critical insights beyond initial purchase price. This comprehensive assessment encompasses acquisition costs, operational expenses, maintenance requirements, and residual value over the vehicle's lifecycle.

Initial acquisition costs typically favor diesel engines, which command a 10-15% premium over comparable V10 gasoline engines. However, this analysis must extend beyond purchase price to capture the complete financial picture. Diesel engines demonstrate 20-30% better fuel efficiency than V10 counterparts, translating to significant savings over time, particularly for high-mileage applications exceeding 15,000 miles annually.

Maintenance expenses reveal contrasting patterns between these powertrain options. V10 engines generally require more frequent service intervals but at lower per-service costs. Diesel engines, while featuring longer service intervals, typically incur higher costs for specialized maintenance procedures and components such as particulate filters and high-pressure injection systems. Data indicates diesel maintenance costs average 15-25% higher per service, though services occur approximately 30% less frequently.

Depreciation rates significantly impact TCO calculations. V10 engines typically experience steeper depreciation curves, losing 50-60% of their value within five years. Diesel powertrains generally retain value better, depreciating 40-50% over the same period, particularly in commercial applications where their durability commands premium resale values.

Insurance costs tend to be 5-10% higher for V10-equipped vehicles due to their performance characteristics and higher replacement parts costs. Conversely, diesel vehicles often benefit from lower insurance premiums reflecting their enhanced durability and safety profiles in certain vehicle categories.

Regulatory factors increasingly influence TCO calculations. Emission compliance costs for diesel engines have risen substantially, with AdBlue/DEF consumption adding approximately $0.01-0.02 per mile to operational costs. Meanwhile, V10 engines face higher carbon taxation in many jurisdictions, offsetting some of diesel's operational advantages.

The breakeven point between these powertrain options typically occurs between 60,000-80,000 miles, depending on usage patterns, fuel prices, and regional factors. For commercial applications with expected lifecycles exceeding 100,000 miles, diesel configurations generally deliver superior TCO despite higher acquisition costs. Conversely, lower-mileage applications often favor V10 gasoline engines from a purely financial perspective.

Initial acquisition costs typically favor diesel engines, which command a 10-15% premium over comparable V10 gasoline engines. However, this analysis must extend beyond purchase price to capture the complete financial picture. Diesel engines demonstrate 20-30% better fuel efficiency than V10 counterparts, translating to significant savings over time, particularly for high-mileage applications exceeding 15,000 miles annually.

Maintenance expenses reveal contrasting patterns between these powertrain options. V10 engines generally require more frequent service intervals but at lower per-service costs. Diesel engines, while featuring longer service intervals, typically incur higher costs for specialized maintenance procedures and components such as particulate filters and high-pressure injection systems. Data indicates diesel maintenance costs average 15-25% higher per service, though services occur approximately 30% less frequently.

Depreciation rates significantly impact TCO calculations. V10 engines typically experience steeper depreciation curves, losing 50-60% of their value within five years. Diesel powertrains generally retain value better, depreciating 40-50% over the same period, particularly in commercial applications where their durability commands premium resale values.

Insurance costs tend to be 5-10% higher for V10-equipped vehicles due to their performance characteristics and higher replacement parts costs. Conversely, diesel vehicles often benefit from lower insurance premiums reflecting their enhanced durability and safety profiles in certain vehicle categories.

Regulatory factors increasingly influence TCO calculations. Emission compliance costs for diesel engines have risen substantially, with AdBlue/DEF consumption adding approximately $0.01-0.02 per mile to operational costs. Meanwhile, V10 engines face higher carbon taxation in many jurisdictions, offsetting some of diesel's operational advantages.

The breakeven point between these powertrain options typically occurs between 60,000-80,000 miles, depending on usage patterns, fuel prices, and regional factors. For commercial applications with expected lifecycles exceeding 100,000 miles, diesel configurations generally deliver superior TCO despite higher acquisition costs. Conversely, lower-mileage applications often favor V10 gasoline engines from a purely financial perspective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!