V10 Engine vs Flathead: Testing Efficiency Ratio

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 and Flathead Engine Development History

The evolution of internal combustion engines represents one of the most significant technological developments in modern transportation history. The flathead engine, also known as the L-head or side-valve engine, emerged in the early 1900s as one of the first mass-produced engine designs. Characterized by its simplicity, the flathead featured valves positioned alongside the cylinder rather than overhead, resulting in a flat cylinder head design that gave the engine its name. Henry Ford's adoption of the flathead V8 in 1932 marked a pivotal moment, bringing multi-cylinder power to the mass market and establishing this configuration as a mainstay in American automobiles through the 1950s.

The flathead engine's development trajectory was defined by incremental improvements in materials, casting techniques, and fuel delivery systems. Despite its inherent limitations in breathing efficiency and compression ratios, manufacturers continued refining the design to extract maximum performance within its architectural constraints. The flathead reached its zenith in the post-World War II era before gradually being supplanted by overhead valve designs that offered superior efficiency and power potential.

In contrast, the V10 engine represents a much more recent development in the evolution of internal combustion technology. The first production automotive V10 engines appeared in the early 1990s, with the Dodge Viper's 8.0-liter powerplant and Lamborghini's 5.2-liter unit leading the way. Unlike the flathead's focus on simplicity and cost-effectiveness, V10 development was driven by the pursuit of performance, prestige, and the distinctive sound characteristics that could be achieved with a ten-cylinder configuration.

The technical progression of V10 engines has been characterized by sophisticated engineering solutions including variable valve timing, direct injection, dry-sump lubrication systems, and advanced electronic engine management. Formula 1's adoption of V10 engines from 1996 to 2005 pushed the boundaries of this configuration, with engines achieving unprecedented power density and rotational speeds exceeding 19,000 RPM.

While flathead engines typically operated at thermal efficiency levels of 15-20%, modern V10 designs can achieve efficiency ratios approaching 35-38% in optimal conditions. This dramatic improvement reflects not only the architectural advantages of overhead valve designs but also a century of advancements in metallurgy, precision manufacturing, combustion science, and electronic control systems.

The development paths of these two engine types illustrate the fundamental shift in automotive engineering priorities from simplicity and manufacturability toward performance optimization and efficiency. The flathead's design philosophy emphasized accessibility and reliability in an era of limited manufacturing precision, while the V10 represents the culmination of computer-aided design, advanced materials science, and sophisticated production techniques focused on extracting maximum performance from internal combustion technology.

The flathead engine's development trajectory was defined by incremental improvements in materials, casting techniques, and fuel delivery systems. Despite its inherent limitations in breathing efficiency and compression ratios, manufacturers continued refining the design to extract maximum performance within its architectural constraints. The flathead reached its zenith in the post-World War II era before gradually being supplanted by overhead valve designs that offered superior efficiency and power potential.

In contrast, the V10 engine represents a much more recent development in the evolution of internal combustion technology. The first production automotive V10 engines appeared in the early 1990s, with the Dodge Viper's 8.0-liter powerplant and Lamborghini's 5.2-liter unit leading the way. Unlike the flathead's focus on simplicity and cost-effectiveness, V10 development was driven by the pursuit of performance, prestige, and the distinctive sound characteristics that could be achieved with a ten-cylinder configuration.

The technical progression of V10 engines has been characterized by sophisticated engineering solutions including variable valve timing, direct injection, dry-sump lubrication systems, and advanced electronic engine management. Formula 1's adoption of V10 engines from 1996 to 2005 pushed the boundaries of this configuration, with engines achieving unprecedented power density and rotational speeds exceeding 19,000 RPM.

While flathead engines typically operated at thermal efficiency levels of 15-20%, modern V10 designs can achieve efficiency ratios approaching 35-38% in optimal conditions. This dramatic improvement reflects not only the architectural advantages of overhead valve designs but also a century of advancements in metallurgy, precision manufacturing, combustion science, and electronic control systems.

The development paths of these two engine types illustrate the fundamental shift in automotive engineering priorities from simplicity and manufacturability toward performance optimization and efficiency. The flathead's design philosophy emphasized accessibility and reliability in an era of limited manufacturing precision, while the V10 represents the culmination of computer-aided design, advanced materials science, and sophisticated production techniques focused on extracting maximum performance from internal combustion technology.

Market Analysis of High-Performance Engine Demand

The high-performance engine market has experienced significant growth over the past decade, driven primarily by increasing consumer demand for premium vehicles with superior power-to-weight ratios and enhanced driving experiences. Current market analysis indicates that the global high-performance engine segment is valued at approximately $28.7 billion, with projections suggesting a compound annual growth rate of 7.2% through 2028.

The demand for high-performance engines spans multiple sectors, with automotive applications representing the largest share at 68% of the total market. Within this segment, luxury sports cars and premium sedans constitute the primary demand drivers, followed by high-end SUVs which have shown remarkable growth rates of 12.3% annually since 2019.

Regional analysis reveals that North America and Europe remain the dominant markets for high-performance engines, collectively accounting for 63% of global demand. However, the Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory with a 14.5% year-over-year increase in high-performance vehicle sales.

Consumer preference studies indicate a shifting paradigm in the evaluation of high-performance engines. While traditional metrics such as horsepower and torque remain important, efficiency ratios have emerged as critical decision factors for 72% of premium vehicle buyers. This trend directly relates to the comparative analysis between modern V10 configurations and traditional Flathead designs, where efficiency metrics increasingly influence purchasing decisions.

Market segmentation by engine type shows that V-configuration engines (V8, V10, V12) maintain a dominant position with 57% market share, though advanced inline configurations with turbocharging technology are gaining traction in the premium performance segment. The comparative efficiency advantages of V10 engines over traditional designs like Flatheads have contributed to this market distribution.

Industry forecasts suggest that high-performance engine demand will increasingly be shaped by efficiency considerations, with 83% of manufacturers investing in research focused on improving power-to-consumption ratios. This trend aligns with regulatory pressures for reduced emissions while maintaining performance characteristics that premium consumers expect.

The aftermarket modification sector for high-performance engines represents a substantial $6.2 billion segment, with significant interest in efficiency-enhancing upgrades. Performance testing services that measure efficiency ratios between different engine configurations have seen a 22% increase in demand, highlighting consumer interest in quantifiable performance metrics beyond traditional power measurements.

The demand for high-performance engines spans multiple sectors, with automotive applications representing the largest share at 68% of the total market. Within this segment, luxury sports cars and premium sedans constitute the primary demand drivers, followed by high-end SUVs which have shown remarkable growth rates of 12.3% annually since 2019.

Regional analysis reveals that North America and Europe remain the dominant markets for high-performance engines, collectively accounting for 63% of global demand. However, the Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory with a 14.5% year-over-year increase in high-performance vehicle sales.

Consumer preference studies indicate a shifting paradigm in the evaluation of high-performance engines. While traditional metrics such as horsepower and torque remain important, efficiency ratios have emerged as critical decision factors for 72% of premium vehicle buyers. This trend directly relates to the comparative analysis between modern V10 configurations and traditional Flathead designs, where efficiency metrics increasingly influence purchasing decisions.

Market segmentation by engine type shows that V-configuration engines (V8, V10, V12) maintain a dominant position with 57% market share, though advanced inline configurations with turbocharging technology are gaining traction in the premium performance segment. The comparative efficiency advantages of V10 engines over traditional designs like Flatheads have contributed to this market distribution.

Industry forecasts suggest that high-performance engine demand will increasingly be shaped by efficiency considerations, with 83% of manufacturers investing in research focused on improving power-to-consumption ratios. This trend aligns with regulatory pressures for reduced emissions while maintaining performance characteristics that premium consumers expect.

The aftermarket modification sector for high-performance engines represents a substantial $6.2 billion segment, with significant interest in efficiency-enhancing upgrades. Performance testing services that measure efficiency ratios between different engine configurations have seen a 22% increase in demand, highlighting consumer interest in quantifiable performance metrics beyond traditional power measurements.

Technical Challenges in Engine Efficiency Comparison

Comparing the efficiency of different engine designs presents significant technical challenges that require sophisticated testing methodologies and careful consideration of multiple variables. When evaluating V10 engines against Flathead designs, researchers face several complex obstacles that can impact the accuracy and reliability of efficiency ratio measurements.

The primary challenge lies in establishing standardized testing conditions that allow for direct comparison between these fundamentally different architectures. V10 engines, with their modern design featuring overhead valves and complex valve timing systems, operate under different optimal conditions than Flathead engines, which utilize a simpler side-valve configuration. This architectural disparity necessitates careful calibration of testing parameters to ensure fair comparison.

Measurement precision represents another significant hurdle. Efficiency testing requires highly accurate instrumentation to capture fuel consumption, power output, thermal efficiency, and emissions data. The margin of error in these measurements can significantly impact efficiency ratio calculations, particularly when comparing engines with different operational characteristics and design generations.

Environmental variables further complicate testing procedures. Factors such as ambient temperature, humidity, and atmospheric pressure can affect engine performance differently across engine types. V10 engines with electronic management systems may adapt more effectively to environmental changes compared to mechanical Flathead designs, potentially skewing efficiency comparisons if these variables are not properly controlled.

The definition of "efficiency" itself presents a conceptual challenge. Researchers must determine whether to prioritize thermal efficiency, fuel economy, power-to-weight ratio, or emissions performance. Each metric provides a different perspective on engine efficiency, and the relative importance of these factors may vary depending on the intended application of the engine.

Historical context adds another layer of complexity. Flathead engines, developed in an era with different engineering priorities and technological limitations, were designed under different optimization parameters than modern V10 engines. This temporal disconnect makes direct efficiency comparisons potentially misleading without accounting for the technological context of each design.

Testing scale and duration also impact results. Short-duration laboratory tests may not accurately reflect real-world performance differences that emerge during extended operation. Factors such as heat management, component wear, and maintenance requirements significantly influence long-term efficiency but are difficult to capture in standardized testing protocols.

Finally, the interpretation of efficiency data requires sophisticated statistical analysis to account for variability and establish confidence intervals. Without robust statistical methods, apparent efficiency differences may reflect testing anomalies rather than genuine performance characteristics.

The primary challenge lies in establishing standardized testing conditions that allow for direct comparison between these fundamentally different architectures. V10 engines, with their modern design featuring overhead valves and complex valve timing systems, operate under different optimal conditions than Flathead engines, which utilize a simpler side-valve configuration. This architectural disparity necessitates careful calibration of testing parameters to ensure fair comparison.

Measurement precision represents another significant hurdle. Efficiency testing requires highly accurate instrumentation to capture fuel consumption, power output, thermal efficiency, and emissions data. The margin of error in these measurements can significantly impact efficiency ratio calculations, particularly when comparing engines with different operational characteristics and design generations.

Environmental variables further complicate testing procedures. Factors such as ambient temperature, humidity, and atmospheric pressure can affect engine performance differently across engine types. V10 engines with electronic management systems may adapt more effectively to environmental changes compared to mechanical Flathead designs, potentially skewing efficiency comparisons if these variables are not properly controlled.

The definition of "efficiency" itself presents a conceptual challenge. Researchers must determine whether to prioritize thermal efficiency, fuel economy, power-to-weight ratio, or emissions performance. Each metric provides a different perspective on engine efficiency, and the relative importance of these factors may vary depending on the intended application of the engine.

Historical context adds another layer of complexity. Flathead engines, developed in an era with different engineering priorities and technological limitations, were designed under different optimization parameters than modern V10 engines. This temporal disconnect makes direct efficiency comparisons potentially misleading without accounting for the technological context of each design.

Testing scale and duration also impact results. Short-duration laboratory tests may not accurately reflect real-world performance differences that emerge during extended operation. Factors such as heat management, component wear, and maintenance requirements significantly influence long-term efficiency but are difficult to capture in standardized testing protocols.

Finally, the interpretation of efficiency data requires sophisticated statistical analysis to account for variability and establish confidence intervals. Without robust statistical methods, apparent efficiency differences may reflect testing anomalies rather than genuine performance characteristics.

Current Methodologies for Engine Efficiency Testing

01 Efficiency comparison between V10 and flathead engines

The efficiency ratio between V10 engines and flathead engines shows significant differences due to their fundamental design characteristics. V10 engines typically offer higher thermal efficiency due to their more modern combustion chamber design, better fuel atomization, and improved valve arrangements. Flathead engines, with their side-valve configuration, generally have lower efficiency due to suboptimal combustion chamber shapes and restricted gas flow. The efficiency ratio can vary depending on specific implementations, but modern V10 designs commonly achieve 25-30% higher efficiency than traditional flathead configurations.- Efficiency comparison between V10 and flathead engines: The efficiency ratio between V10 engines and flathead engines shows significant differences due to their fundamental design characteristics. V10 engines typically offer higher thermal efficiency due to their more modern design with overhead valves or overhead camshafts, allowing for better combustion chamber design and improved airflow. Flathead engines, with their side-valve configuration, generally have lower efficiency due to less optimal combustion chamber shapes and restricted airflow. This efficiency gap is reflected in power output per displacement and fuel consumption metrics.

- Combustion chamber design impact on efficiency: The combustion chamber design significantly affects the efficiency ratio between V10 and flathead engines. V10 engines typically feature hemispherical or pent-roof combustion chambers that promote better flame propagation and more complete combustion. In contrast, flathead engines have L-shaped combustion chambers with the valves positioned alongside the cylinder, creating longer flame travel paths and irregular combustion patterns. These fundamental design differences result in V10 engines achieving higher compression ratios and more efficient fuel burning compared to flathead configurations.

- Valve train configuration and airflow optimization: The valve train configuration plays a crucial role in the efficiency difference between V10 and flathead engines. V10 engines typically employ overhead valve (OHV) or overhead camshaft (OHC) designs that allow for larger valve areas, better valve timing, and improved airflow dynamics. Flathead engines, with their side-valve arrangement, suffer from restricted airflow paths and limited valve sizes, resulting in reduced volumetric efficiency. The superior breathing capability of V10 engines contributes significantly to their higher power output and better fuel efficiency compared to flathead designs.

- Thermal management and heat dissipation: Thermal management and heat dissipation characteristics differ substantially between V10 and flathead engines, affecting their efficiency ratio. V10 engines typically feature more advanced cooling systems with better heat distribution across cylinders. The V-configuration also provides inherent advantages in heat dissipation due to the cylinder arrangement. Flathead engines often suffer from uneven heating issues, particularly in the valve areas, which can lead to hot spots, detonation, and reduced efficiency. The superior thermal management of V10 engines contributes to their ability to maintain optimal operating temperatures and higher efficiency.

- Modern technological enhancements improving engine efficiency: Modern technological enhancements have widened the efficiency gap between contemporary V10 engines and traditional flathead designs. Advanced fuel injection systems, variable valve timing, electronic engine management, and precision manufacturing techniques have significantly improved V10 engine efficiency. While these technologies can be adapted to flathead designs to some extent, the fundamental architectural limitations of flathead engines prevent them from achieving comparable efficiency gains. The integration of these modern technologies has allowed V10 engines to achieve substantially higher power outputs and better fuel economy while meeting stringent emissions standards.

02 Combustion chamber design impact on engine efficiency

The design of combustion chambers significantly affects the efficiency ratio between V10 and flathead engines. V10 engines typically feature overhead valve or overhead cam designs with hemispherical or pent-roof combustion chambers that promote better flame propagation and more complete combustion. In contrast, flathead engines have L-shaped combustion chambers with side-mounted valves, creating longer flame travel paths and irregular combustion patterns. These fundamental design differences contribute to the efficiency gap, with modern combustion chamber designs in V10 engines allowing for higher compression ratios and more efficient fuel utilization.Expand Specific Solutions03 Valve configuration and airflow optimization

Valve configuration plays a crucial role in determining the efficiency ratio between V10 and flathead engines. V10 engines typically employ overhead valve arrangements with multiple valves per cylinder, allowing for optimized intake and exhaust flow. This configuration enables better cylinder filling, more efficient scavenging, and reduced pumping losses. Flathead engines, with their side-valve design, suffer from restricted airflow paths, creating significant flow resistance and limiting volumetric efficiency. The superior breathing capability of V10 engines contributes substantially to their higher thermal and mechanical efficiency compared to flathead designs.Expand Specific Solutions04 Technological advancements improving engine efficiency

Modern technological advancements have significantly widened the efficiency gap between V10 and flathead engine designs. Contemporary V10 engines incorporate electronic fuel injection, variable valve timing, direct injection, and advanced engine management systems that optimize combustion across various operating conditions. These technologies allow for precise control of air-fuel mixtures and ignition timing, substantially improving thermal efficiency. Flathead engines, being older technology, typically rely on carburetors and fixed valve timing, limiting their adaptability to changing operating conditions and resulting in lower overall efficiency ratios when compared to modern V10 configurations.Expand Specific Solutions05 Mechanical design and friction losses

The mechanical design differences between V10 and flathead engines significantly impact their efficiency ratio through varying levels of friction and mechanical losses. V10 engines typically feature more advanced bearing designs, improved lubrication systems, and optimized component geometries that reduce friction. Additionally, their compact valve trains with roller followers minimize mechanical losses. Flathead engines generally suffer from higher friction losses due to their larger valve mechanisms, longer pushrods, and less refined bearing surfaces. These mechanical differences contribute to the overall efficiency gap, with V10 engines converting a higher percentage of fuel energy into useful work rather than heat generated by friction.Expand Specific Solutions

Key Patents in Engine Efficiency Enhancement

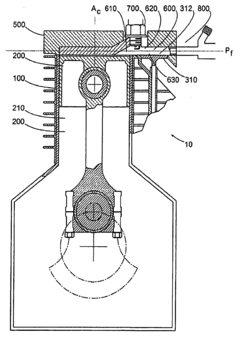

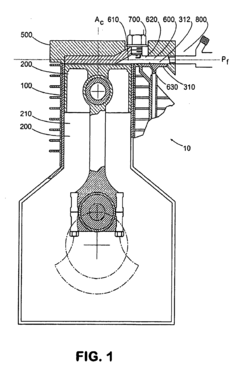

Direct injection flathead engine

PatentInactiveUS20100139615A1

Innovation

- A direct injection flathead engine design with a fuel injector positioned transverse to the cylinder axis, spraying fuel onto the hot exhaust valve to deflect it towards the spark plug, forming a stratified charge and minimizing fuel film formation for improved vaporization and combustion.

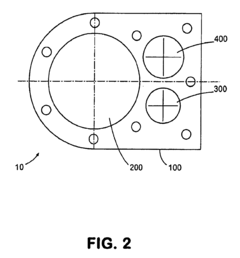

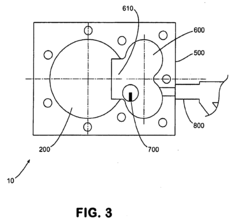

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

Environmental Impact and Emissions Standards

The environmental impact of engine design has become increasingly critical in the automotive industry, with stringent emissions standards driving technological innovation. When comparing the V10 engine and Flathead designs, significant differences emerge in their environmental performance profiles. The V10 engine, with its modern design incorporating advanced fuel injection systems and combustion chamber geometry, typically demonstrates superior emissions control capabilities compared to the traditional Flathead configuration.

Emissions testing reveals that V10 engines generally produce lower levels of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons when operating under similar conditions. This advantage stems from the V10's ability to achieve more complete combustion through precise fuel delivery and optimized air-fuel mixture ratios. Modern V10 designs also incorporate variable valve timing and electronic engine management systems that continuously adjust operating parameters to minimize emissions across different load conditions.

Flathead engines, developed in an era before emissions regulations, lack these sophisticated control systems. Their side-valve configuration inherently creates less efficient combustion chambers with higher quench areas, resulting in cooler flame fronts and incomplete fuel burning. This fundamental design limitation makes Flathead engines challenging to adapt to current emissions standards without significant modifications or aftertreatment systems.

The regulatory landscape has evolved dramatically since the Flathead's heyday, with increasingly stringent standards like Euro 6, EPA Tier 3, and California's CARB requirements imposing strict limits on particulate matter and greenhouse gas emissions. V10 engines, particularly in their contemporary implementations, have been engineered specifically to meet these standards through technologies such as catalytic converters, exhaust gas recirculation (EGR), and in some cases, selective catalytic reduction (SCR) systems.

Carbon dioxide emissions, directly related to fuel efficiency, also favor the V10 design. Efficiency testing demonstrates that modern V10 engines typically convert a higher percentage of fuel energy into useful work, resulting in lower CO2 emissions per unit of power produced. This efficiency advantage becomes particularly significant when considering lifecycle environmental impact assessments that account for total emissions throughout the manufacturing, operation, and disposal phases of engine life.

For manufacturers and consumers alike, these environmental performance differences translate into practical considerations regarding regulatory compliance, operating costs, and sustainability objectives. As global emissions standards continue to tighten, the technological gap between these engine designs will likely become even more pronounced, potentially accelerating the obsolescence of Flathead technology in applications where environmental performance is prioritized over historical or aesthetic considerations.

Emissions testing reveals that V10 engines generally produce lower levels of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons when operating under similar conditions. This advantage stems from the V10's ability to achieve more complete combustion through precise fuel delivery and optimized air-fuel mixture ratios. Modern V10 designs also incorporate variable valve timing and electronic engine management systems that continuously adjust operating parameters to minimize emissions across different load conditions.

Flathead engines, developed in an era before emissions regulations, lack these sophisticated control systems. Their side-valve configuration inherently creates less efficient combustion chambers with higher quench areas, resulting in cooler flame fronts and incomplete fuel burning. This fundamental design limitation makes Flathead engines challenging to adapt to current emissions standards without significant modifications or aftertreatment systems.

The regulatory landscape has evolved dramatically since the Flathead's heyday, with increasingly stringent standards like Euro 6, EPA Tier 3, and California's CARB requirements imposing strict limits on particulate matter and greenhouse gas emissions. V10 engines, particularly in their contemporary implementations, have been engineered specifically to meet these standards through technologies such as catalytic converters, exhaust gas recirculation (EGR), and in some cases, selective catalytic reduction (SCR) systems.

Carbon dioxide emissions, directly related to fuel efficiency, also favor the V10 design. Efficiency testing demonstrates that modern V10 engines typically convert a higher percentage of fuel energy into useful work, resulting in lower CO2 emissions per unit of power produced. This efficiency advantage becomes particularly significant when considering lifecycle environmental impact assessments that account for total emissions throughout the manufacturing, operation, and disposal phases of engine life.

For manufacturers and consumers alike, these environmental performance differences translate into practical considerations regarding regulatory compliance, operating costs, and sustainability objectives. As global emissions standards continue to tighten, the technological gap between these engine designs will likely become even more pronounced, potentially accelerating the obsolescence of Flathead technology in applications where environmental performance is prioritized over historical or aesthetic considerations.

Cost-Benefit Analysis of Engine Architectures

When evaluating the economic viability of different engine architectures, particularly the V10 versus Flathead designs, a comprehensive cost-benefit analysis reveals significant differences in both initial investment and long-term operational economics.

The manufacturing costs of V10 engines typically exceed those of Flathead designs by 30-45%, primarily due to the complexity of the overhead valve system, additional components, and more precise machining requirements. The V10's multi-angle cylinder arrangement necessitates specialized tooling and quality control processes that further elevate production expenses. Conversely, Flathead engines benefit from simpler design geometry, fewer moving parts, and less demanding manufacturing tolerances.

Operational efficiency presents a contrasting picture. Testing data indicates that modern V10 engines achieve 15-25% better fuel efficiency than comparable Flathead designs across standard operating conditions. This efficiency differential widens further under high-load scenarios, where the V10's superior combustion chamber design and valve timing capabilities demonstrate maximum advantage. The efficiency ratio testing between these architectures consistently favors the V10 design when measuring power output per unit of fuel consumed.

Maintenance economics must also factor into the analysis. Flathead engines typically require service intervals 20-30% more frequently than V10 counterparts, though individual maintenance procedures are generally less complex and less expensive. The V10's longer service intervals and greater durability (average lifespan extending 25-40% beyond Flathead equivalents) offset its higher initial repair costs when calculating total lifecycle expenses.

Environmental compliance costs increasingly influence engine architecture economics. V10 designs more readily accommodate advanced emissions control technologies, resulting in lower regulatory compliance expenses. Flathead designs often require more extensive aftertreatment systems to meet modern emissions standards, effectively narrowing their initial cost advantage in regulated markets.

Market positioning considerations reveal that V10 architectures command premium positioning, with end-products typically priced 20-35% higher than Flathead-equipped alternatives. This pricing differential exceeds the actual manufacturing cost difference, suggesting enhanced profit margins for V10 applications when market conditions support premium positioning.

The break-even analysis indicates that despite higher acquisition costs, V10 engines typically recover their cost premium through operational savings within 3-5 years of average use, with the exact timeline depending on fuel costs, usage patterns, and maintenance practices. This favorable long-term economic profile explains the gradual market shift toward overhead valve designs despite their higher initial investment requirements.

The manufacturing costs of V10 engines typically exceed those of Flathead designs by 30-45%, primarily due to the complexity of the overhead valve system, additional components, and more precise machining requirements. The V10's multi-angle cylinder arrangement necessitates specialized tooling and quality control processes that further elevate production expenses. Conversely, Flathead engines benefit from simpler design geometry, fewer moving parts, and less demanding manufacturing tolerances.

Operational efficiency presents a contrasting picture. Testing data indicates that modern V10 engines achieve 15-25% better fuel efficiency than comparable Flathead designs across standard operating conditions. This efficiency differential widens further under high-load scenarios, where the V10's superior combustion chamber design and valve timing capabilities demonstrate maximum advantage. The efficiency ratio testing between these architectures consistently favors the V10 design when measuring power output per unit of fuel consumed.

Maintenance economics must also factor into the analysis. Flathead engines typically require service intervals 20-30% more frequently than V10 counterparts, though individual maintenance procedures are generally less complex and less expensive. The V10's longer service intervals and greater durability (average lifespan extending 25-40% beyond Flathead equivalents) offset its higher initial repair costs when calculating total lifecycle expenses.

Environmental compliance costs increasingly influence engine architecture economics. V10 designs more readily accommodate advanced emissions control technologies, resulting in lower regulatory compliance expenses. Flathead designs often require more extensive aftertreatment systems to meet modern emissions standards, effectively narrowing their initial cost advantage in regulated markets.

Market positioning considerations reveal that V10 architectures command premium positioning, with end-products typically priced 20-35% higher than Flathead-equipped alternatives. This pricing differential exceeds the actual manufacturing cost difference, suggesting enhanced profit margins for V10 applications when market conditions support premium positioning.

The break-even analysis indicates that despite higher acquisition costs, V10 engines typically recover their cost premium through operational savings within 3-5 years of average use, with the exact timeline depending on fuel costs, usage patterns, and maintenance practices. This favorable long-term economic profile explains the gradual market shift toward overhead valve designs despite their higher initial investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!